Unveiling the future: Insights from the STLE e-mobility conference

By Dr. Hyeok Hahn, Chair, 2024 STLE E-Mobility Conference Planning Committee | TLT E-mobility January 2025

This conference explored the intersection of electrification and tribology.

KEY CONCEPTS

• Technical sessions explored innovations, insights and solutions to challenges in the constantly evolving EV field.

• Keynotes from OEMs explored the electrification journeys of three industry giants.

• Expert panels discussed critical topics including regulatory concerns, sustainability and lubricant formulation.

On the crisp morning of Oct. 23, 2024, the Mackinac Room at Detroit Renaissance Center was buzzing with anticipation. Attendees from around the globe gathered to delve into the intricate interplay of electrification and tribology, a field that promises to propel the electric vehicle (EV) industry into new realms of innovation and efficiency.

Day 1: Setting the stage for innovation

The conference opened with a warm welcome from Hyeok Hahn (chair of the 2024 STLE E-Mobility Conference Planning Committee, Chevron Lubricants). Hahn highlighted the extraordinary efforts of this year’s committee in curating a dynamic conference, featuring keynote speakers from industry giants such as John Deere, The Scania Group and Toyota Motor Corp., alongside over 40 technical sessions on EV testing, thermal management, lubricant formulation, efficiency and sustainability.

The first keynote speaker, Kent Wanner with John Deere, opened the conference with “John Deere’s Electrification Journey.”

Keynote 1 insights: Electrification at John Deere

The first keynote speaker, Kent Wanner, opened the conference with “John Deere’s Electrification Journey.” As a principal electrification engineer with 27 years of experience, Wanner shared historical perspectives on John Deere’s innovative approaches to electrification. “Our history is one of continuous innovation to meet and exceed customer expectations,” Wanner asserted. He showcased various examples of electrification architectures that have added significant value across different applications, emphasizing the increasing convergence of electrification and tribology (see Figure 1).

Figure 1. John Deere electrification journey. Figure courtesy of John Deere.

Technical deep dives: Magnet wire compatibility

Following Wanner’s engaging presentation, Dr. Yungwan Kwak introduced his study on “Magnet Wire Compatibility with Electric Transmission Fluids.” Kwak, an expert in polymer science and a key player at Afton Chemical, delved into the critical compatibility of magnet wires (MW) with electric transmission fluids (ETF). “Poor compatibility can result in decreased performance, electrical shorts or even catastrophic e-motor failure,” Kwak warned. His detailed analysis covered copper, iron and water content measurements in EVs and plug-in hybrid electric vehicles (PHEVs), MW testing procedures and the impact of water concentration on MW performance. His findings underscored the significant role of additive components in lubricant formulations.

Cooling innovations: Direct cooling of end windings

Felipe Da Cunha Nunez presented his simulation study on the benefits of direct cooling of the end windings in permanent magnet synchronous machines. Da Cunha Nunez, an automotive engineering specialist at TotalEnergies OneTech, highlighted the challenges posed by heat dissipation in electric machines. “Improper heat dissipation can cause durability problems and even electric machine failures,” Da Cunha Nunez noted. His research demonstrated how direct oil cooling could optimize heat extraction, thus enhancing torque and power density while reducing costs and improving durability.

Exploring wear mechanisms in EVs

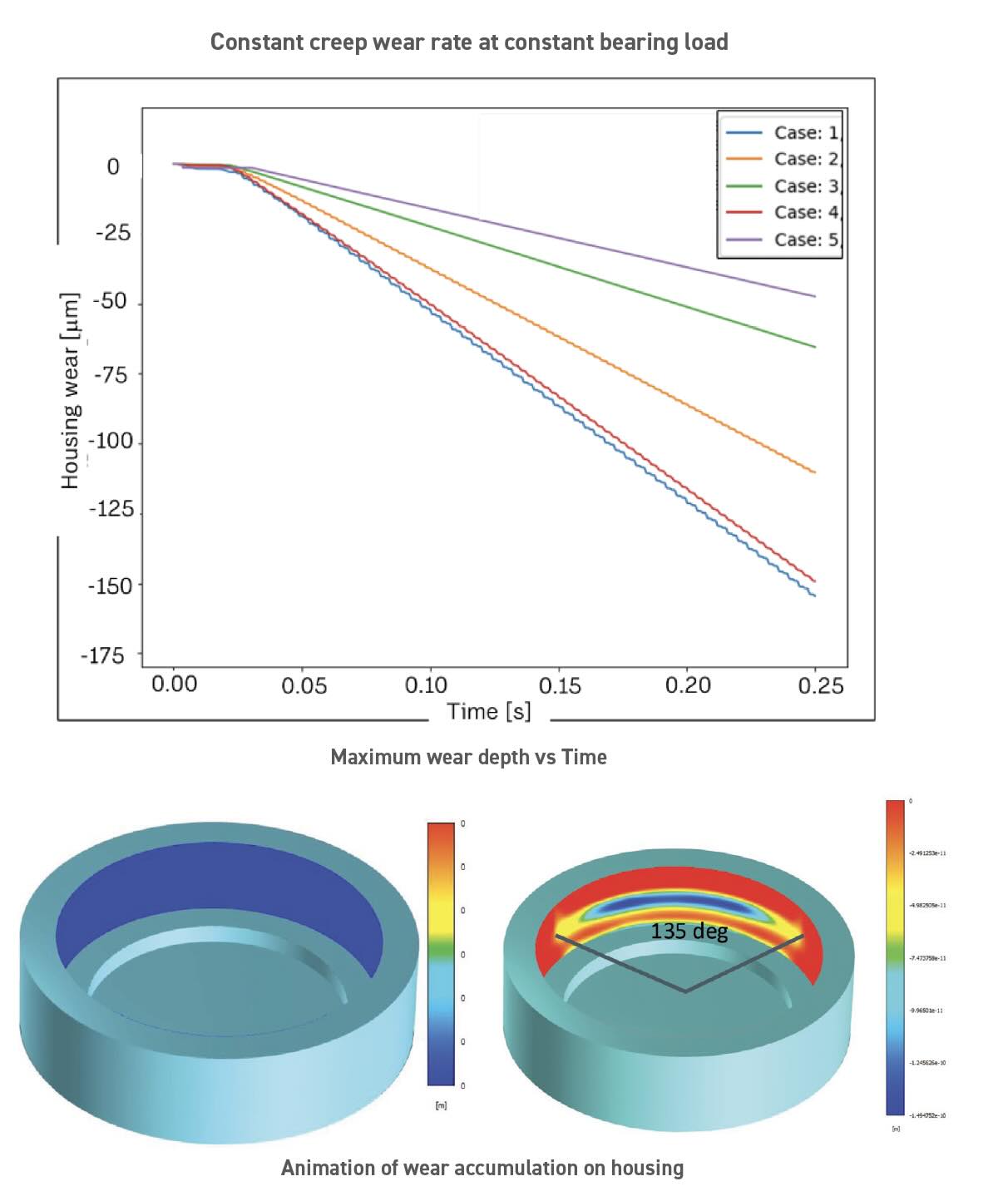

The session continued with Dr. Xiaobo Zhou’s talk on “Wear in Bearing Ring Creep, Prediction, and Solutions in EV Power Transmission.” Zhou, a program manager at SKF RTD, Netherlands, identified three ring creeping mechanisms (creep by strain, drag and run-out) and discussed two wear mechanisms: adhesive and abrasive wear. His insights into predictive modeling and mitigation solutions offered valuable strategies for minimizing ring creep wear damage in EVs (see Figure 2).

Figure 2. SKF BEAST ring creep model simulated results. Figure courtesy of SKF.

Efficiency comparisons: Bearing power loss

Chris Marks followed with a comparative study on “Optimized Tapered Roller Bearing Power Loss Equal to Deep Groove Ball Bearings in Real-World EV Intermediate Shaft Tests.” Marks, a chief engineer at The Timken Co., tackled the issue of driving range in EVs, emphasizing the need for more realistic comparisons of bearing efficiency during gearbox design stages. His research aimed to bridge the gap between laboratory spin-loss tests and real-world driving conditions.

Addressing electrical currents in tribological contacts

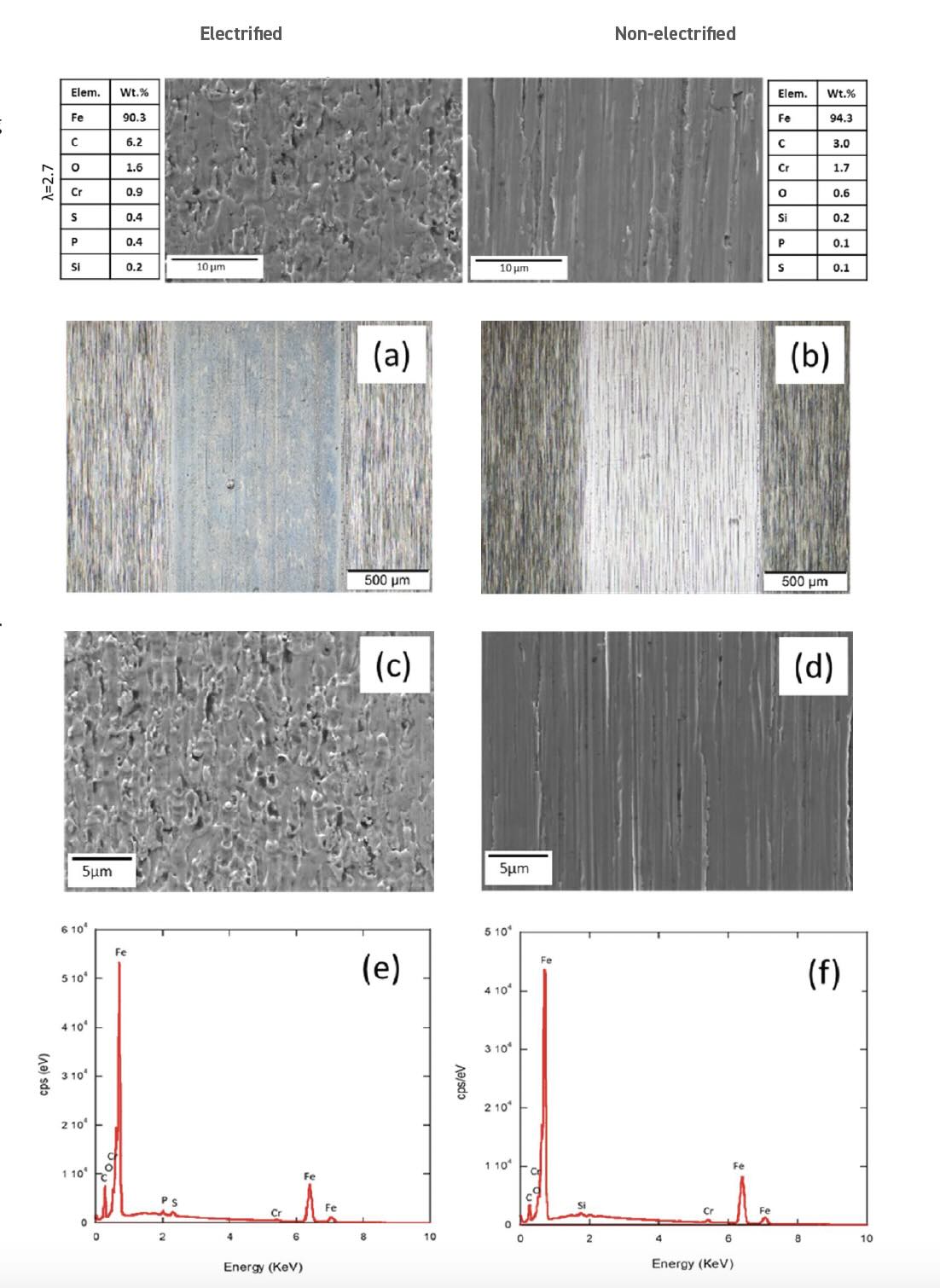

Dr. Aaron Greco took the stage next to discuss “Testing in the Presence of Applied Electrical Current in Rolling/Sliding Contact.” As a principal materials scientist at Argonne National Laboratory, Greco highlighted the reliability issues caused by stray electrical currents in EV bearings and gears. His experiments demonstrated the material degradation that occurs under these conditions, offering insights into the lubrication challenges faced in electric drive units (see Figure 3).

Figure 3. Electrical current impact on tribofilm. Figure courtesy of Argonne National Laboratory.

Enhancing thermal efficiency with engineered lubricants

Concluding the morning session of Day 1, Dr. Babak Lotfi introduced his research on “Enhancing Thermal Efficiency in EVs using Engineered Lubricants.” Lotfi, a tribology expert at ExxonMobil, explored how specially engineered EV lubricants could outperform market general formulations. “Testing suggests superior performance of the engineered lubricants, which could ultimately lower operating temperatures and increase power efficiency,” Lotfi stated, highlighting the potential for optimized designs in integrated electric drive units.

Day 1 afternoon highlights: Focus on drivetrain operation and efficiency

The afternoon session, helmed by Greg Hunt (The Lubrizol Corp.), resumed with Dr. Hannes Grillenberger’s presentation on “Efficient and Reliable Drive Train Systems in EVs.” Grillenberger, a product manager at Schaeffler, emphasized the importance of system simulation in optimizing drivetrain efficiency. His insights into electric currents, friction and component constraints provided a comprehensive understanding of the challenges and opportunities in EV drivetrain design.

Exploring conductivity limits and foam creation

Next, Cole Engle (The Lubrizol Corp.) discussed “Exploring Conductivity Limits for e-Fluids,” followed by Greg Miiller’s (Tannas Co. and King Refrigeration) examination of “Evaluating the Propensity for EV Fluids to Create Foam and Aerate Utilizing Simulation Equipment.” Both presentations underscored the critical role of fluid properties in ensuring the reliability and efficiency of EV components under various operational conditions (see Figure 4).

Figure 4. Increasing electrical insulation. Figure courtesy of The Lubrizol Corp.

Innovative coatings for wear resistance

Pranjal Nautiyal’s talk on “In-situ Manufactured Coatings with Exceptional Wear Resistance” introduced an innovative, cost-efficient coating technology for EV drivetrains. Nautiyal, an assistant professor at Oklahoma State University, showcased how tribosintering of TiO2 nanoparticles could enhance wear resistance, offering a promising solution for extending the lifespan of EV components.

Tribological properties of ionic liquids

Wenbo Wang’s presentation on “Tribological Study of Ionic Liquids as Grease Oil Additives for Electric Vehicles” concluded the technical sessions. Wang, a postdoctoral research associate at Oak Ridge National Laboratory, highlighted the potential of ionic liquids as antiwear additives, providing valuable insights into the design of high-performance greases for EVs.

Panel discussion: Efficiency

The Day 1 ended with a panel discussion on efficiency, featuring experts Michael Berhan (Ford Motor Co.), Matthew Hauschild (Evonik Oil Additives), Keiichi Narita (Idemitsu Kosan Co., Ltd.) and Kun Liu (Afton Chemical Co.). Moderated by Dr. Peter Lee (Southwest Research Institute), panelists explored the impact of lubricant composition on the overall efficiency of electric drive units, offering guidelines for formulators and insights into the future of EV technology. In the panel discussion, panelists and attendees converged to address the pressing issues surrounding vehicle efficiency and regulatory requirements. The dialogue was marked by a keen focus on innovative technologies aimed at enhancing fuel and energy economy and reducing emissions, underscoring the automotive sector’s commitment to sustainability.

One of the key takeaways was the emphasis on stringent regulatory frameworks that are shaping the future of vehicle design and manufacturing. Experts highlighted how advancements in hybrid and EV technologies are also pivotal in meeting these rigorous standards. The panelists elaborated on the need for collaborative efforts between policymakers, manufacturers and consumers to achieve a significant reduction in the carbon footprint of the transportation sector.

The session concluded with a Q&A segment where participants engaged actively, reflecting the widespread interest and urgency of the topic. The discussions were not just technical but also imbued with a sense of shared responsibility toward creating a more sustainable future. This panel has set a positive precedent, encouraging ongoing conversations and developments in vehicle efficiency and environmental stewardship.

Day 2: Exploring the frontiers of EV tribology and novel approaches in formulation

Day 2 began with Matthias Hof (Emery Oleochemicals GmbH) serving as the master of ceremonies, setting the tone for an immersive and intellectually stimulating experience.

Pär Nyman, the technical manager at Scania R&D (he recently joined Nynas as a technical manager), took the stage as the second keynote speaker and presented “Tribology Frontiers for Electric Heavy-Duty Vehicles.”

Keynote 2 insights: Impact of tribology on the efficiency and sustainability of heavy-duty EVs

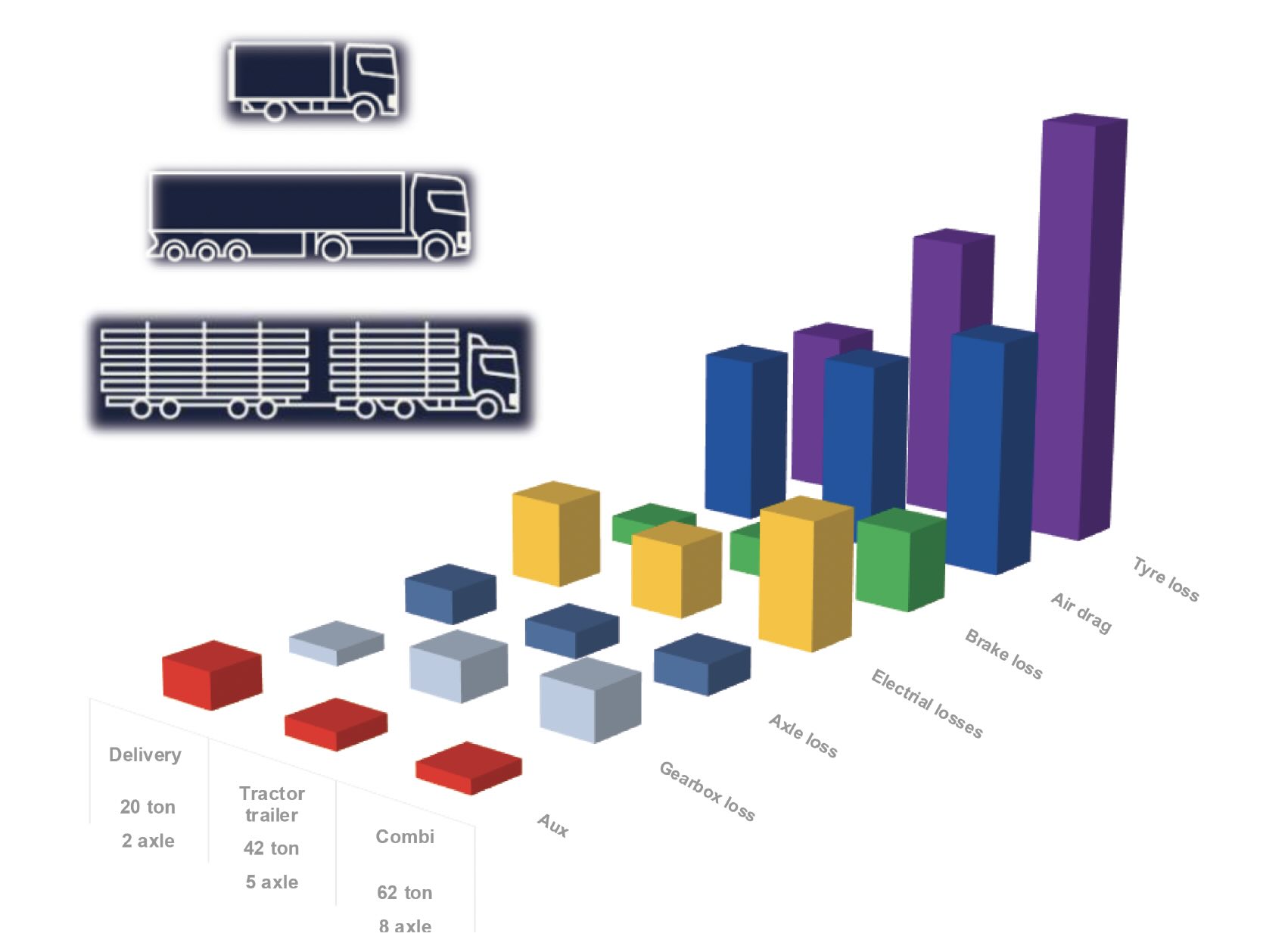

Pär Nyman, the technical manager at Scania R&D (he recently joined Nynas as a technical manager), took the stage as the second keynote speaker. During his presentation on “Tribology Frontiers for Electric Heavy-Duty Vehicles,” Nyman emphasized the significant contributions of heavy-duty vehicles to CO2 emissions and the potential of electrification to mitigate these impacts. “While battery electric and fuel cell EVs have lower CO2 emissions than their combustion engine counterparts, the energy consumption during use remains a primary contributor to life cycle emissions,” Nyman explained. He highlighted the role of tribology in reducing mechanical friction and viscous losses, pointing out that tires and brakes are the largest contributors to these losses, especially in high gross train weights (see Figure 5).

Figure 5. Energy loss distribution for BEV trucks. Figure courtesy of Nynas.

Optimizing EV drivetrain efficiency through tribology

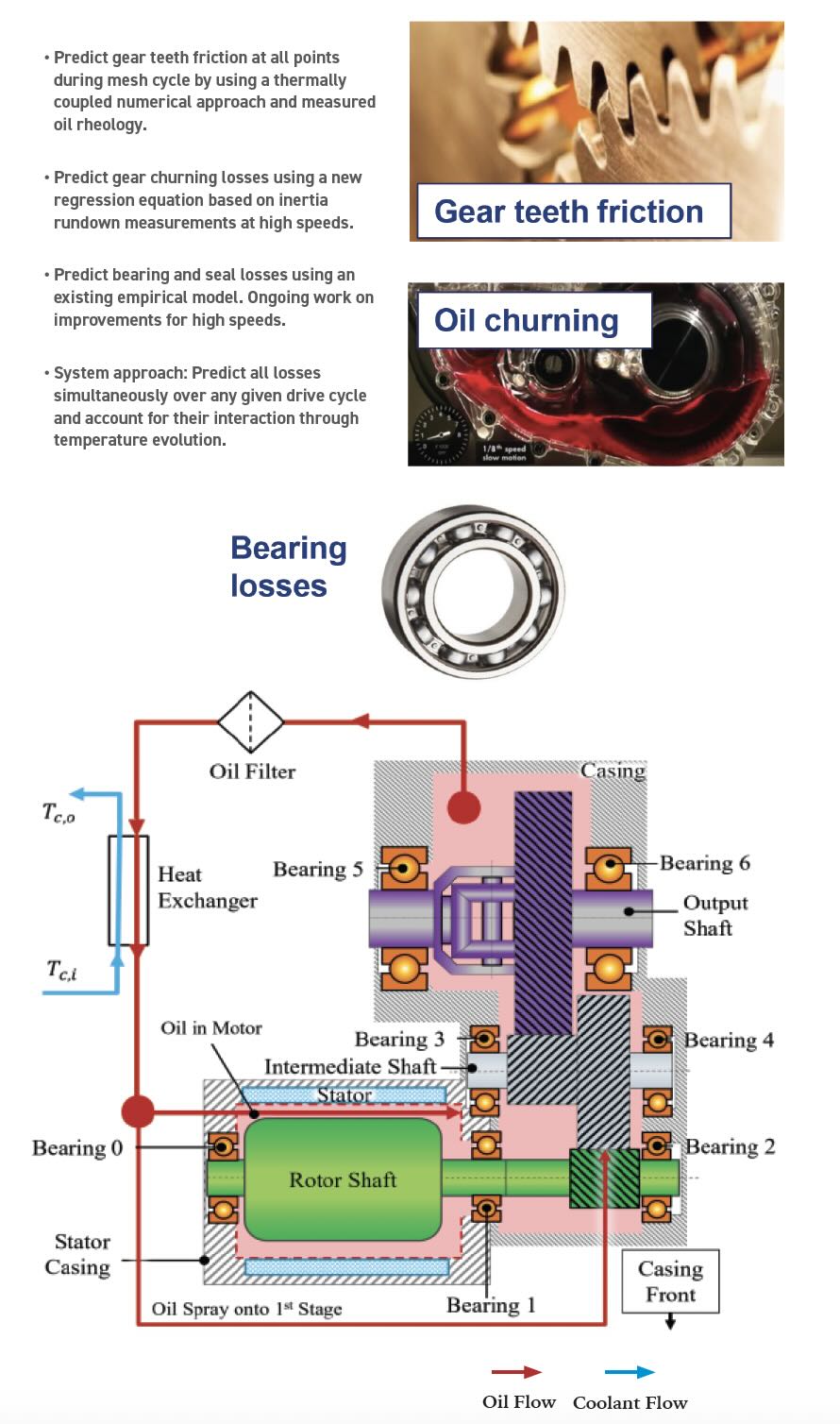

Following Nyman’s keynote, Dr. Amir Kadiric from Imperial College London presented his research on using tribology to optimize EV drivetrain efficiency. Kadiric’s work focuses on the power losses in the transmission system of passenger EVs, which can be up to five times larger than in internal combustion engine (ICE) vehicles. His presentation shed light on the interdependency of power losses from gear friction, bearing friction and oil churning, all influenced by the gearbox’s temperature evolution.

“Optimizing an EV powertrain requires an integrated, thermally coupled approach,” Kadiric noted. He introduced a thermally coupled tribological model developed to predict EV gearbox efficiency. This model considers various factors, including gear teeth friction, bearing and seal losses and churning losses, over a given vehicle drive cycle. Kadiric’s insights underscored the importance of lubricant selection and gearbox design in enhancing EV efficiency (see Figure 6).

Figure 6. System-level tribology model to predict EV transmission losses. Figure courtesy of Imperial College London.

Fluid durability in electrified drivetrains

Cole Hudson from Southwest Research Institute followed with a presentation on fluid durability in electrified drivetrains. Hudson’s research involves long-term projects to understand how different operational parameters affect EV lubricants. He highlighted the rigorous testing methods employed, including instrumenting EV transmissions, electric motors and fluid conditioning systems with 300-500 CAN channels and operating them on a chassis dynamometer for over 100,000 miles.

Hudson’s findings revealed that fluid aging significantly impacts vehicle efficiency. “By analyzing data from standardized efficiency tests and fluid aging metrics, we can quantify the portion of efficiency loss attributable to lubricant aging,” Hudson explained. His research emphasized the need for tailored lubricants that can withstand the demanding conditions of electrified drivetrains.

Testing EV lubricants for optimal performance

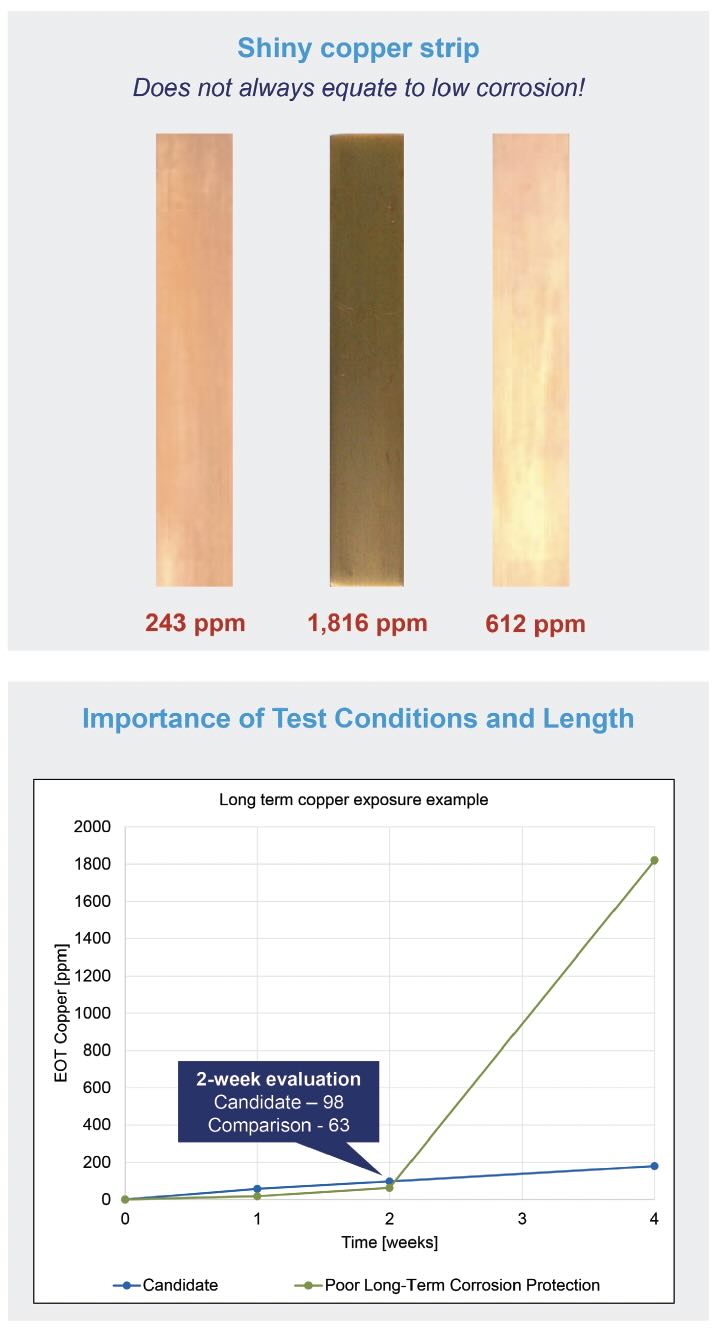

Rebecca Warden from Chevron Oronite presented on the advancements and challenges in testing EV lubricants for optimal field performance. With over 15 years of experience in the lubricants industry, Warden shared her expertise on standardized test methods used to evaluate lubricant performance. She discussed the unique requirements of EV lubricants and the importance of correlation between test conditions/results and field performance.

“Developing lubricants for EVs requires a balance between protection and performance,” Warden stated. Her talk highlighted the ongoing advancements in test methods and the opportunities for further improvement. The insights provided by Warden underscored the critical role of lubricants in ensuring the durability and efficiency of EV powertrains (see Figure 7).

Figure 7. ASTM D130 copper corrosion. Figure courtesy of Chevron Oronite.

Investigating insulating materials and corrosion in EVs

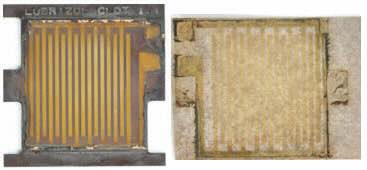

The conference also featured presentations on the impact of insulating materials and corrosion in EVs. Jason Bares from BorgWarner and Christopher Prengaman from The Lubrizol Corp. discussed the potential for corrosive attack on copper windings in electric motors due to fluid exposure. Their research aimed to investigate the formation of conductive deposits and the influence of different fluid chemistries on corrosion (see Figure 8).

Figure 8. Board and slot liner paper. Figure courtesy of The Lubrizol Corp.

Lucy Armstrong from The Lubrizol Corp. followed with a presentation on comparing corrosion under dynamic and static conditions. Her research focused on the impact of diffusion rates on lubricant additives and the corrosion processes between copper and lubricant components. “Understanding the real-world conditions that influence corrosion is crucial for developing effective lubrication technology for EVs,” Armstrong explained.

Achieving material compatibility in EV coolants

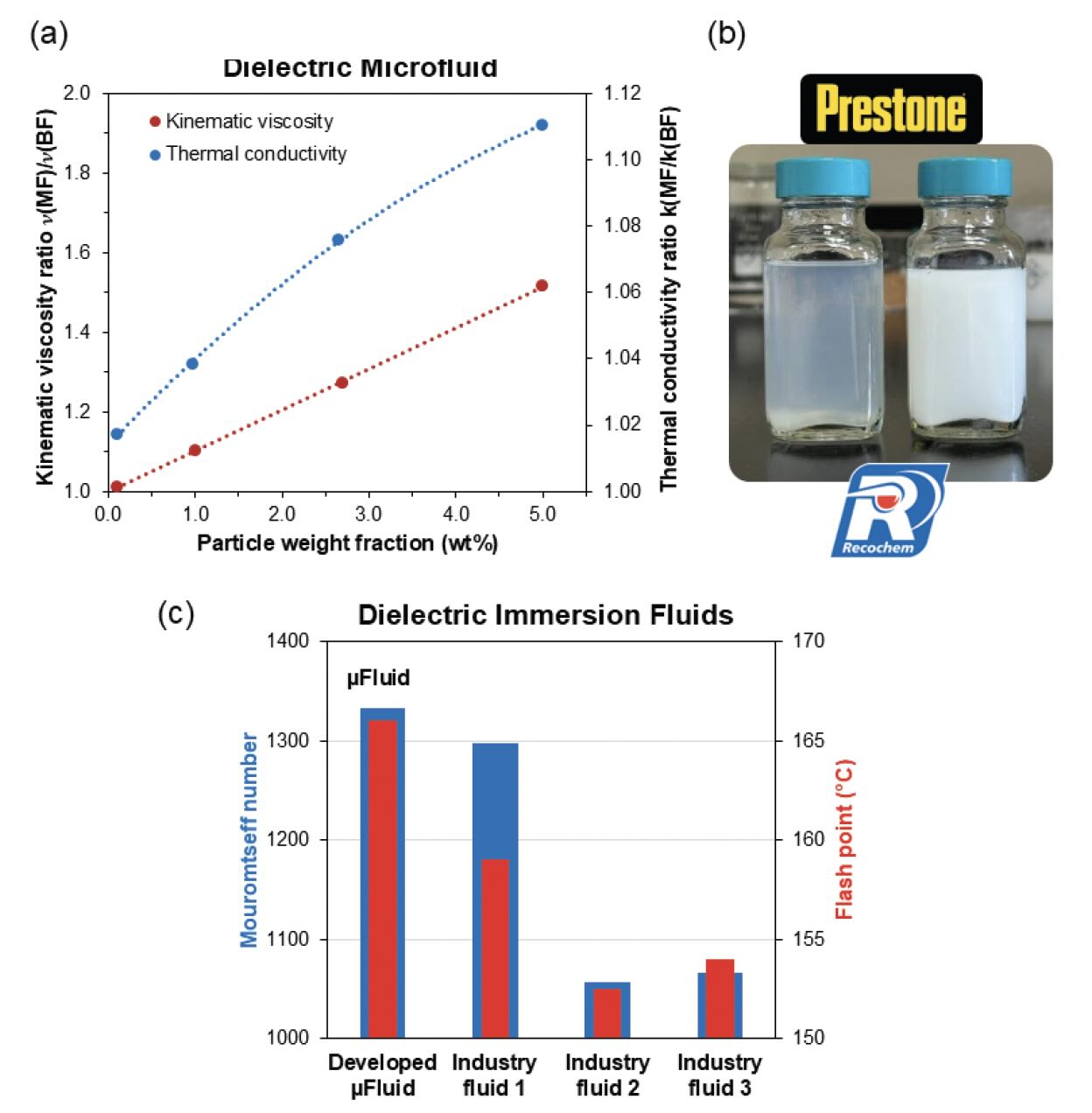

Kevin Sterling from Prestone Products presented on achieving EV material compatibility through a coolant-inspired dielectric corrosion test method. Sterling’s research involved developing a new corrosion test to observe the effects of different metal specimens relevant to EVs under moderate stress conditions. His findings provided valuable insights into the requirements for dielectric thermal management fluids in EV applications (see Figure 9).

Figure 9. Dielectric microfluid and dielectric immersion fluids. Figure courtesy of Prestone Products.

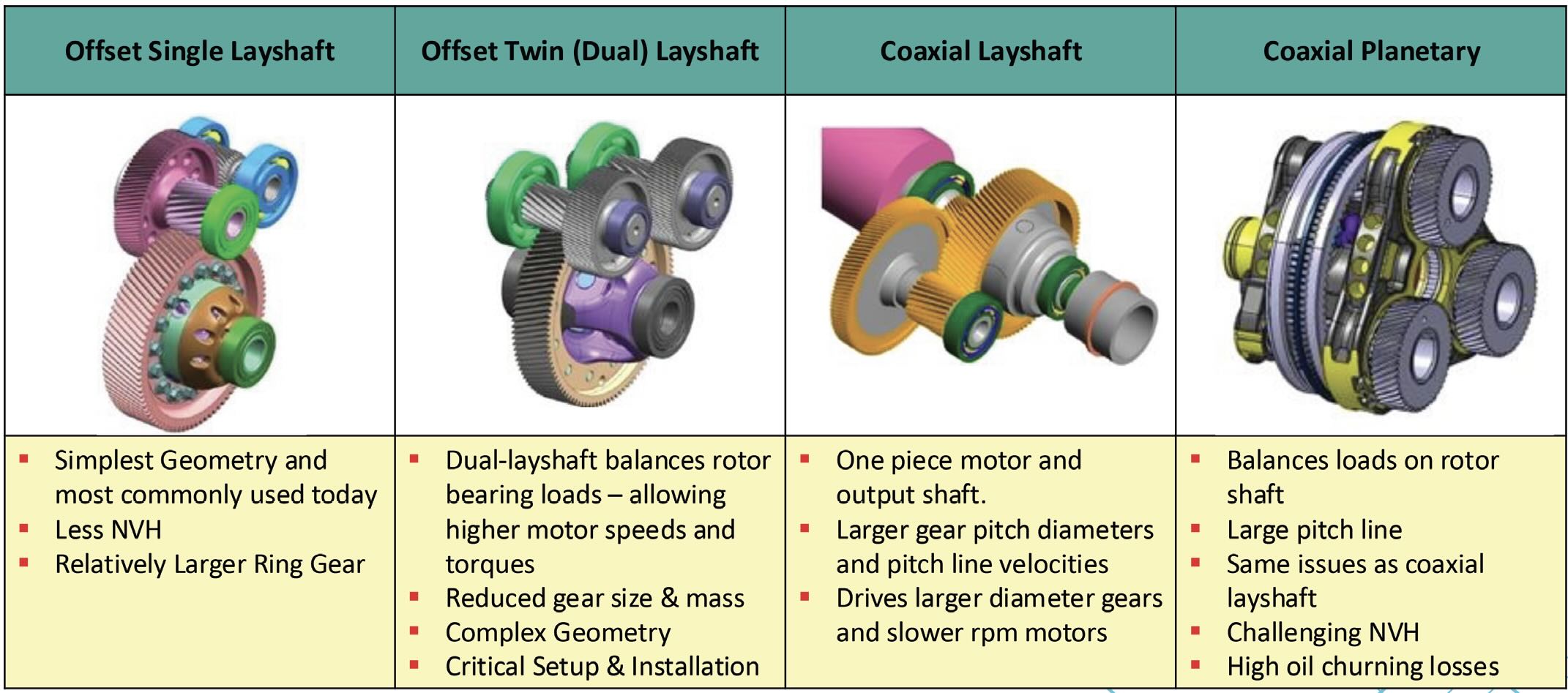

EV hardware design challenges

The post-lunch session kicked off by Dr. Neil Canter (Chemical Solutions) introducing Troy Muransky (American Axle & Manufacturing), an industry veteran with over 18 years in automotive engineering. Muransky’s extensive background in materials science, lubrication and environmental engineering set the stage for a deep dive into the hardware design challenges faced by EV manufacturers.

Muransky highlighted the urgent need to tackle CO2 emissions from the transportation sector, which constituted over 20% of global emissions in 2022. As the industry pivots toward electrification, the design of high-efficiency drivetrains becomes paramount. Muransky explained that modern EVs often integrate the transmission, electric motor and inverter into a compact “3-in-1” unit, posing unique challenges for system lubrication and durability.

To address these challenges, Muransky emphasized the critical role of electric drive fluids (EDFs). These advanced lubricants must meet stringent requirements to ensure the longevity and efficiency of EV components. His presentation underscored the ongoing efforts to refine these fluids to accommodate the sophisticated demands of new drivetrain designs (see Figure 10).

Figure 10. Examples of electric drive units (EDUs) gearbox architectures. Figure courtesy of American Axle & Manufacturing.

Innovations in EV charging

Next, Dr. Shubhamita (Shubha) Basu with Perstorp Polyols captivated the audience with her discussion on the cooling challenges associated with EV charging. Basu, a seasoned expert in organic chemistry and business development, shared her insights on the impact of “range anxiety” and the limitations of current charging infrastructure.

With the rise of EV adoption, the demand for faster charging solutions has intensified. Basu shed light on the potential of direct current fast charging (DCFC) and extreme fast charging (XFC) to alleviate range anxiety for travelers. However, she noted that these technologies generate significant heat, which can impede charging efficiency and safety.

Her presentation explored innovative cooling solutions designed to dissipate heat more effectively during the charging process. By integrating advanced cooling systems into charging stations, the industry can reduce charging times and enhance the overall EV user experience. Basu’s forward-thinking approach provided a glimpse into the future of EV infrastructure.

Advanced thermal management

Dr. Gerald Singer’s presentation on next-generation high-performance immersion coolants took the stage next. As an R&D chemist with Prestone Products, Singer has been instrumental in developing thermal management fluids for EVs and fast chargers. He drew upon his rich academic and research background to discuss the critical role of immersion cooling in battery safety and performance.

Dr. Singer highlighted the superiority of immersion cooling over traditional indirect cooling methods. He explained that immersion cooling can enhance heat transfer by up to 100 times, enabling faster charging and more uniform temperature distribution within battery packs. This technology, already proven in motorsports and high-end vehicles, is poised for broader adoption in the automotive industry.

He also addressed the challenges of developing dielectric coolants that are both efficient and environmentally friendly. By combining synthetic base oils with naturally derived esters and enhancing them with performance-boosting nanoparticles, Singer’s team has created a new class of dielectric nanofluids. These fluids offer exceptional thermal conductivity and stability, positioning them as key enablers for future EV cooling solutions.

Tribological advances

The final presentation before the break featured Dr. Peter Lee from Southwest Research Institute. Lee, a renowned tribologist, shed light on the unique lubrication challenges within electric drive units (EDUs). His talk focused on the impact of electrical stimuli on lubricant performance and the durability of EV components.

Lee presented findings from tests conducted with the PCS mini traction machine (MTM), which measured the wear and traction of lubricants under various electrical conditions. The results revealed that applying alternating current (AC) and direct current (DC) increased wear scars and traction values, underscoring the need for specialized lubricants in EV applications.

His research emphasized the importance of developing lubricants that can withstand the unique demands of EDUs, thereby improving the overall efficiency and lifespan of EVs. Lee’s insights provided a critical perspective on the intersection of electrical engineering and tribology in the quest for sustainable mobility.

Panel discussion: Lubricant formulation, chemistry and sustainability

The afternoon session of Day 2 featured a panel discussion on lubricant formulation, moderated by Greg Hunt (The Lubrizol Corp.). The panel included industry experts Ian Stewart (Afton Chemical Corp.), Jared Nelson (Emery Oleochemicals), Suzanne Patterson (The Lubrizol Corp.) and Yemi Oyerinde (INEOS Oligomers USA), who shared their perspectives on the role of polyalphaolefins (PAOs) and other lubricant chemistries in enhancing EV drivetrain efficiency and thermal management.

The panelists and experts delved into the intricate interplay between chemistry, formulation and sustainability—a triad crucial to the future of materials science. The conversation, which spanned various facets of the industry, captured the audience’s attention with its depth and practicality. Central to the discourse was the theme of materials compatibility, a foundational element that underpins the efficiency and sustainability of modern formulations.

An engaging point was made about the role of green chemistry in reducing environmental footprints while maintaining high efficiency. The experts argued that sustainable practices must be integrated into every stage of material development, from initial formulation to end-of-life disposal.

In closing, the discussion touched on the collaborative efforts necessary to drive these advancements. The call to action was clear: industry leaders must commit to sustainable practices and embrace innovative chemistry to pave the way for a greener future.

Day 3: Embracing broader definition of sustainable mobilities

The 3rd day began with Peter Lee (Southwest Research Institute) introducing STLE President Jack McKenna (Sea-Land Chemical Company) who opened the final day of the conference with a professional yet enthusiastic tone for the proceedings.

Keynote speaker Masashi Ogawa, a project manager at Toyota Motor Corp., presented “The History of Evolution in Toyota’s HEV and BEV Systems and Lubricants for Electric Vehicles.”

Keynote 3 insights: The captivating journey of Toyota’s hybrid electric vehicle (HEV) lubricants

McKenna’s speech was followed by the introduction of the third and final keynote speaker, Masashi Ogawa, a project manager at Toyota Motor Corp. Ogawa’s presentation, titled “The History of Evolution in Toyota’s HEV and BEV Systems and Lubricants for Electric Vehicles,” captivated the audience with its detailed exploration of Toyota’s journey in hybrid and EV technology. Ogawa, who has been instrumental in the development of lubricants for both traditional and electrified transmissions and axles, shared insights from his 20 years of experience in automotive design and adaptation.

Ogawa delved into the specifics of Toyota’s HEV systems, tracing their evolution from the first-generation Prius in 1997 to the latest fifth-generation models. He highlighted the critical role of lubricants in enhancing the efficiency and performance of these systems. “Reducing the viscosity of lubricants while maintaining durability and reliability is a highly effective means of improving system efficiency,” Ogawa explained. He emphasized the importance of developing dedicated ultra-low viscosity lubricants to achieve maximum performance in electrified powertrains, a necessity driven by the unique demands of these advanced systems.

The operating conditions of HEV and the evolving requirements on lubricants

Kenneth Garelick of Afton Chemical shared his extensive expertise on the hybrid operation characteristics and their influence on engine oil requirements. Garelick, with over two decades at Afton Chemical, highlighted the evolving automotive landscape driven by stringent emission regulations and the quest for efficiency. He emphasized the critical need for innovative engine oils tailored to the unique demands of hybrid vehicles. Garelick presented findings from a hybrid vehicle test study, offering a detailed understanding of how various operating parameters affect fuel and water dilution, thereby shaping the performance requirements for engine oils in hybrid applications.

Following Garelick, Joe Tomaro from BP Lubricants USA, Inc. took the stage to delve into the operating conditions of engine lubricants and their impact on fuel economy. With his rich background in collaborating with OEMs on lubricant solutions, Tomaro provided a comparative analysis of ICE and HEV. He underscored the challenges and opportunities in developing lubricants that enhance fuel economy for hybrid engines. Tomaro shared data from field observations and a novel test rig designed to measure gasoline direct injection (GDI) high-pressure (HP) fuel pump friction, illuminating the complexities and innovations required for lubricant differentiation in hybrid vehicles. The session was a testament to the ongoing advancements in the field of automotive lubricants, driven by dedicated experts like Garelick and Tomaro.

Probing enhanced battery electric vehicle (BEV) performance and reliability

Dr. Prashant Kumar from Indian Oil Corp. Ltd. discussed the optimization of low electrical conductivity coolant formulations for BEVs, emphasizing the importance of maintaining battery packs within optimal temperature ranges for enhanced performance and longevity. His experimental studies showcased significant improvements in thermal profiling and performance trials. Following this, Dr. Mahdi Mohammadpour from Loughborough University introduced a high-speed bearing test method to address electric discharge failure, highlighting the necessity of advanced experimental methods to replicate realistic working conditions and validate efficient electrified systems. Both presentations underscored the critical advancements needed to support the evolving landscape of vehicle electrification.

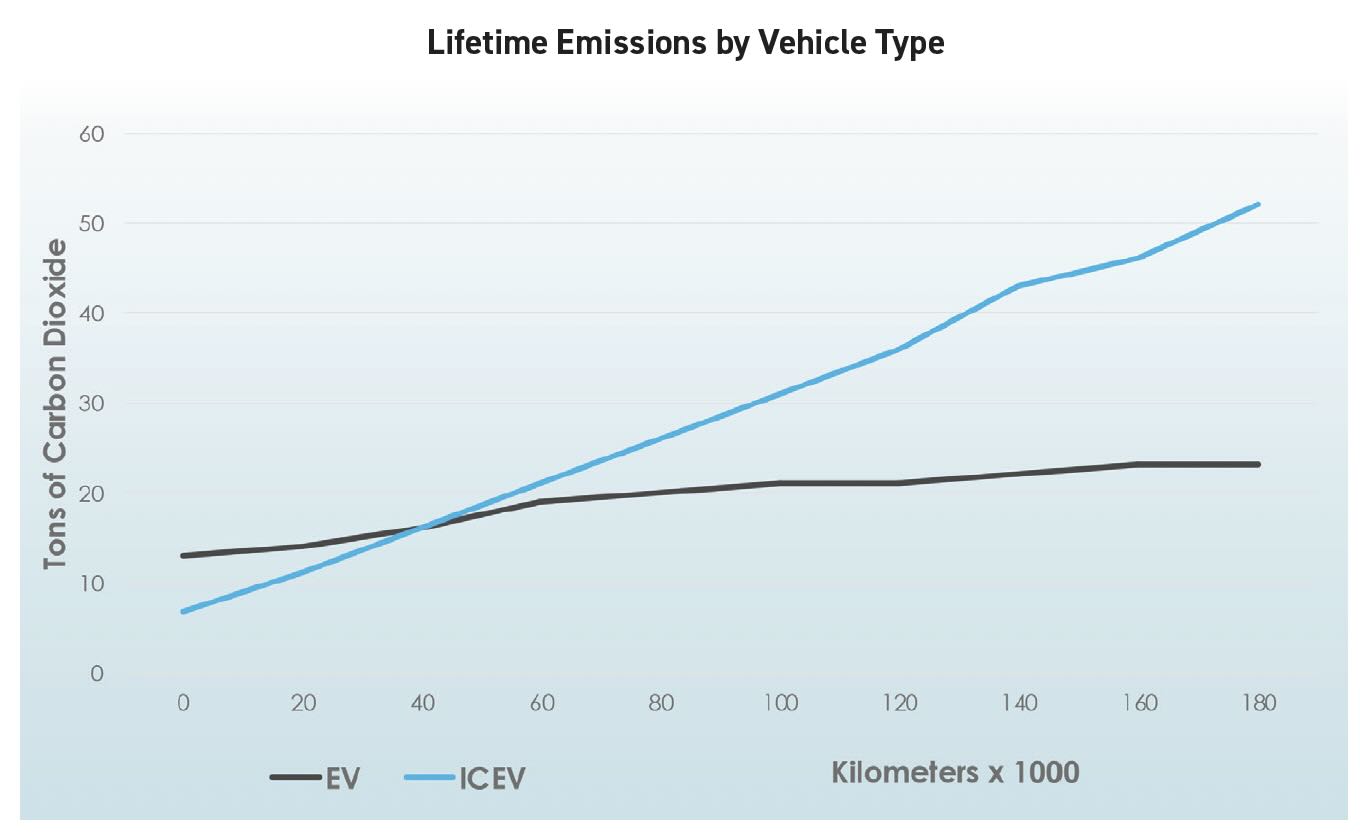

Sustainability and the EV

Dr. Neil Canter (Chemical Solutions) delivered an in-depth analysis of the sustainability and emissions of BEVs compared to internal combustion engine vehicles (ICEVs). He highlighted that while BEVs have higher emissions during manufacturing due to the sourcing of battery components, they have significantly lower emissions during operation. Canter emphasized the importance of considering the entire life cycle of vehicles, including the supply chain and end-of-life recycling, to fully understand their environmental impact. He also discussed the potential for BEVs to reduce global CO2 emissions, especially when powered by renewable energy sources.

Furthermore, Canter underscored the need for improvements in battery energy density, raw material sourcing and the use of renewable energy in both manufacturing and recharging to enhance the sustainability of BEVs. He also mentioned the role of global standards like SAE J3327 in promoting recycling and sustainability and concluded by highlighting the efforts of the STLE Sustainability Committee and other global groups in advancing sustainability activities within the tribology community (see Figure 11).

Figure 11. An Australian study determined the lifetime emissions for two SUVs. One of the vehicles was powered by an ICE while the second was a BEV. At the beginning of the life of each vehicle, greater emissions were generated in producing the BEV than the ICE-powered vehicle primarily due to the need for sourcing and processing minerals that are needed for the battery. Once the vehicles were operated, emissions for the ICE (blue line) automobile steadily climbed over the 14+ years (180,000 kilometers) of driving so that the BEV (black line) generated 30 fewer mt of carbon dioxide by the end of the study. The break even point for both vehicles occurred after three years or 38,000 kilometers of driving. Figure courtesy of Chemical Solutions.

Sensing and scanning: Sustainable mobility

The final presentation by Dr. Graham Conway (Southwest Research Institute) offered an insightful overview of the global light-duty EV market, focusing on key areas such as energy consumption, sales trends, regulatory developments, OEM hurdles and shifting consumer preferences. Conway’s analysis also highlighted challenges in hydrogen-based sustainable mobility in the U.S. market. His enthusiasm for the industry’s advancements was palpable, painting an optimistic picture of the potential for innovation and growth in the light-duty sector.

Conclusion

The STLE Tribology & Lubrication for E-Mobility Conference brought together leading experts to explore the latest research and innovations addressing the tribological challenges in EVs. From enhancing drivetrain efficiency to developing resilient lubricants, the event underscored the essential role of tribology in advancing electric mobility. The presentations highlighted the significant strides being made and the collaborative efforts driving the industry toward a more sustainable and efficient future.

As the conference concluded, participants left with a wealth of new knowledge and ideas poised to contribute to the ongoing evolution of EV technology. The event fostered a vibrant environment for industry professionals to exchange insights and solutions, reinforcing the importance of collaboration and innovation. The discussions and innovations from the conference will undoubtedly influence and shape the future of electric mobility, underscoring the industry’s commitment to progress and sustainability.

Dr. Hyeok Hahn is a research and development scientist with Chevron Lubricants and is chair of the STLE E-Mobility Conference Planning Committee. You can reach him at hyeok.hahn@chevron.com.