HIGHLIGHTS

•

Ionic liquids formulated into polyalkylene glycol (PAG)-based hydraulic fluids outperformed ZDDP based hydraulic fluids by exhibiting 20%-30% additional friction reduction and 80%-90% additional wear reduction.

•

Toxicity testing conducted on

Ceriodaphnia found survival rates of greater than 70% after seven days for ionic liquids having less than or equal to four carbons in the alkyl chain.

•

The best ionic liquid combining lubricity performance with aquatic toxicity produces a tribofilm that is smoother and more uniformly distributed compared to that of ZDDP.

Ionic liquids have been under evaluation for many applications over the past 30 years. The reason is that many different types of substances can be classified as ionic liquids, which are salts that are liquids below a melting point of 100°C.

One application where ionic liquids continue to be studied is how to use them as additives in lubricants. A past TLT article

1 highlights the use of ionic liquids based on phosphonium cation derivatives and either phosphate or phosphinate anions as additives in rear axle lubricants used in pinion gears. Comparable friction and wear test results were obtained with these ionic liquids when added to fully formulated axle lubricants compared to commercial offerings. Significantly reduced surface cracking was observed with the lubricants formulated with these ionic liquids.

2 Use of one of the ionic liquids and a secondary zinc dialkyldithiophosphate (ZDDP) in a SAE 0W-12 engine oil led to reduced wear, a lower boundary coefficient of friction and a nearly 10% improvement in fuel economy compared to a commercial SAE 5W-30 engine oil.

3

STLE Fellow Dr. Jun Qu, group leader of Surface Engineering and Tribology at Oak Ridge National Laboratory in Oak Ridge, Tenn., says, “In the 20 years that we have evaluated ionic lubricants, past studies indicated that these substances may be environmentally friendly, but no work has been carried out to assess the toxicity of these specific compounds used in lubrication.”

Qu points out that most of the ionic liquids that have been evaluated for toxicity were for other applications besides in lubricants. He indicates that one of the most common uses was as solvents.

With the ability of ionic liquids to function as antiwear additives, an opportunity has emerged for using them in lubricants with a high chance of exposure to the environment. Qu says, “The most common antiwear additive is ZDDP, which are very effective but unfortunately are toxic because of its zinc content and long-chain thiophosphate. Other sulfur, phosphorus-based additives such as ashless triaryl phosphorothionates display lower toxicity due to being metal-free but do not demonstrate the needed wear protection and thermal stability required.”

The opportunity presented to Qu and his colleagues was to identify and evaluate ionic liquids that will function as effective antiwear additives and yet not be hazardous to the environment. To accomplish this effort, the researchers evaluated a series of ionic liquids based on ammonium phosphates and phosphonium phosphates to assess their properties from the lubricity, toxicity and physicochemical standpoints.

Carbon chain length

Four groups of 10 ionic liquids were prepared with carbon chain lengths ranging from two (C2) to seventeen (C17). They were evaluated in water miscible and oil soluble polyalkylene glycols (PAGs) and their lubricity performance compared to a commercially available ZDDP. The objective was to determine antiwear performance in a formulation similar to a hydraulic fluid.

Qu says, “Our approach for analyzing the ionic liquids was to add them at a 0.5% treat rate by weight to simulate a hydraulic fluid. In a hydraulic fluid, the main surface-interacting component is ZDDP plus the formulation does not usually contain additives such as friction modifiers, dispersants and detergents that may influence the performance of the antiwear additive.”

A ball-on-flat reciprocating sliding configuration on a tribometer was used to evaluate the ionic liquids using a modified version of procedure B of ASTM G-133

(see Figure 1). The ammonium phosphate ionic liquids outperformed ZDDP by exhibiting 20%-30% additional friction reduction, and 80%-90% additional wear reduction regardless of carbon chain length or solubility in mineral oil or water. The C4 and C8 phosphonium phosphates displayed comparably or better performance than ZDDP.

Figure 1. Performance testing of ionic liquids formulated into hydraulic fluids was conducted using a ball-on-flat reciprocating sliding configuration on a tribometer. Figure courtesy of Oak Ridge National Laboratory.

Figure 1. Performance testing of ionic liquids formulated into hydraulic fluids was conducted using a ball-on-flat reciprocating sliding configuration on a tribometer. Figure courtesy of Oak Ridge National Laboratory.

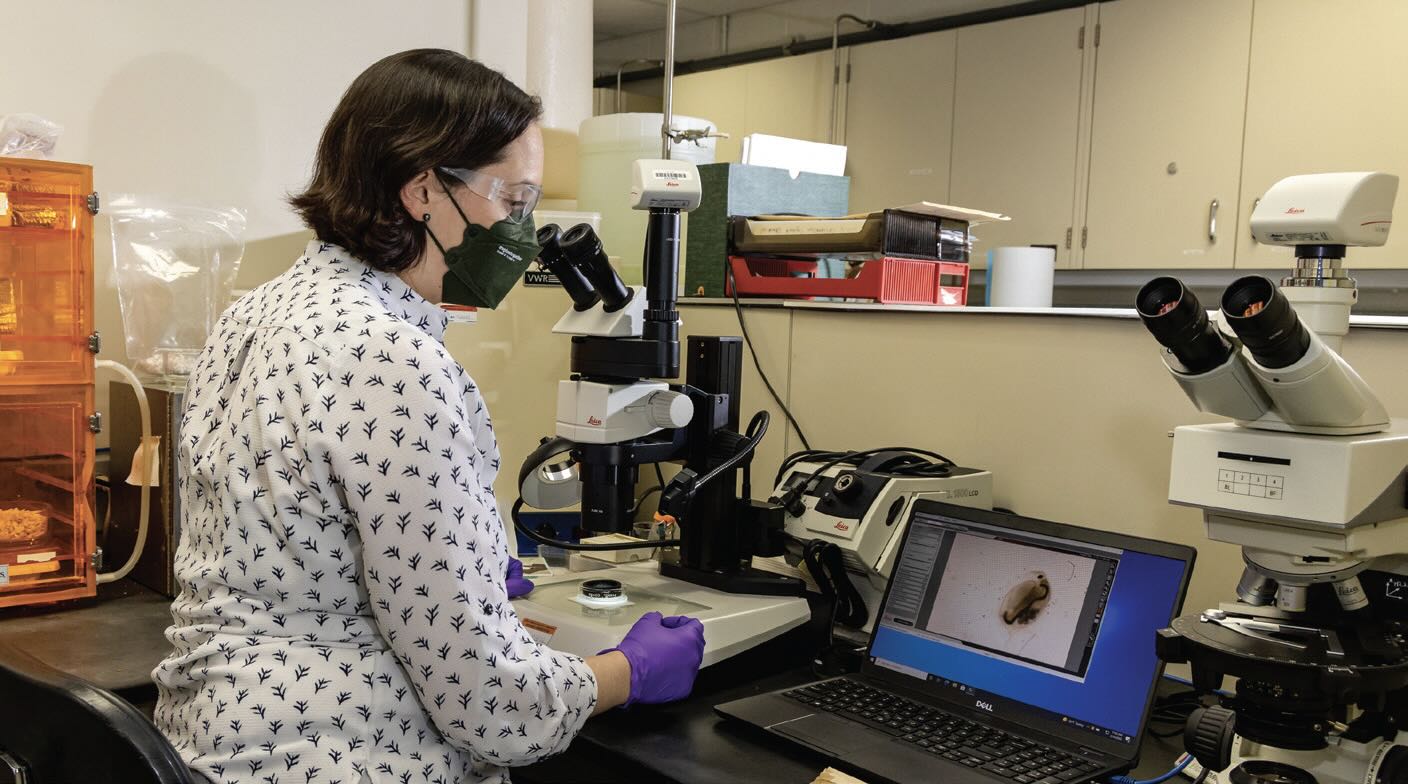

A seven-day chronic toxicity test was conducted on

Ceriodaphnia with the lubricants

(see Figure 2). Qu says, “A

Ceriodaphnia survival rate of greater than 70% after seven days was found with ionic liquids having less than or equal to four carbons in the alkyl chain. In contrast, all Ceriodaphnia were killed when exposed to the ZDDP or ionic liquids with the alkyl chains containing six or more carbons.”

Figure 2. The survival rate of Ceriodaphnia when exposed to lubricants was assessed through the use of a seven-day chronic toxicity test. Figure courtesy of Oak Ridge National Laboratory.

Figure 2. The survival rate of Ceriodaphnia when exposed to lubricants was assessed through the use of a seven-day chronic toxicity test. Figure courtesy of Oak Ridge National Laboratory.

Qu points out that ionic liquids with carbon chains greater than four provide good lubricity performance but are toxic toward

Ceriodaphnia. Those with carbon chains less than four often have relatively low thermal stability and poor oil solubility.

Among the selected compounds, the best ionic liquid that combines lubricity performance with aquatic toxicity is triethylammonium di(butyl) phosphate. The tribofilm of this ionic liquid is smoother and more uniformly distributed compared to that of ZDDP as determined by scanning transmission electron microscopy. Qu says, “The smoother tribofilm may be correlated with the superior friction reduction and antiwear performance demonstrated by the ionic liquids as compared to ZDDP.”

Additional information on this phase of work on ionic liquid lubricant additives can be found in a recent paper.

4

In a follow-up study,

5 the researchers evaluated four of the ionic liquids versus five commercial antiwear additives including one conventional ashless and four bio-derived products in an ester base stock. A commercial hydraulic oil was used as the baseline fluid. The additives evaluated at a 0.5% treat rate demonstrated improved friction and wear reductions for the ionic liquids compared to the commercial additives. Chronic aquatic toxicity studies also run with

Ceriodaphnia clearly distinguished the ionic liquids from the commercial products. All ionic liquids were found to be non-toxic while the

Ceriodaphnia exhibited 0% survival when exposed to the commercial bio-derived additives.

Future work will focus on developing fully formulated hydroelectric gear oils with the ionic liquids. Qu says, “We know that preparing a gear oil with additional surface-interacting components may lead to incompatibilities with the ionic liquids. Identifying a fully formulated gear oil for use in environmentally sensitive applications is the next step in preparing lubricants that can provide the needed performance but also display no aquatic toxicity.”

If there are any questions regarding this research, please contact Qu at

qujn@ornl.gov.

REFERENCES

1.

Canter, N. (2020), “Ionic liquid-based additives for automotive lubricants,” TLT,

76 (3), pp. 14-15. Available at

www.stle.org/files/TLTArchives/2020/03_March/Tech_Beat_II.aspx.

2.

Roy, S., Speed, L., Viola, M, Luo, H., Leonard, D. and Qu, J. (2021), “Oil miscible phosphonium-phosphate ionic liquid as novel antiwear and antipitting additive for low-viscosity rear axle lubricants,”

Wear, 466-467, 203588.

3.

Kumara, C., Speed, L., Viola, M., Luo, H. and Qu, J. (2021), “Using ionic liquid additive to enhance lubricating performance for low-viscosity engine oil,”

ACS Sustainable Chemistry & Engineering, 9 (21), pp. 7198-7205.

4.

He, X. Luo, H., Mathews, T., Stevenson, L, Geeza. T., Kumara, C., Meyer, H. and Qu, J. (2024), “Minimizing toxicity and optimizing lubricity of ionic liquids for eco-friendly lubrication,”

ACS Sustainable Chemistry & Engineering, 12 (11), pp. 4344-4355.

5.

He, X., Stevenson, L, Kumara, C., Mathews, T., Luo, H. and Qu, J. (2024), “Comparison of eco-friendly ionic liquids and commercial bio-derived lubricant additives in terms of tribological performance and aquatic toxicity,”

Molecules, 29 (16), 3851.