VBASE Oils

Secondary Polyol Ester™ Technology. Novel, High Performance & Sustainable Base Oils

By Martin Greaves, Jeff DiMaio, Michelle DiMaio, Zach Hunt & Ben Bergmann VBASE® Oil Company, Pendleton, South Carolina, USA | TLT CMF Plus November 2024

A New Enterprise with Novel Technology

VBASE

® Oil company was founded in 2021 and has brought to market a novel class of API Group V base oil known as Secondary Polyol Ester™ (SPE

®) base oils. This family of unique high performance base oils was designed for sustainability. Our Innovation Center, located in Pendleton, South Carolina, USA developed a first-generation family of base oils (ISOVG 32 to 100) and in 2024, has extended this range with the commercialization of a second generation (ISOVG 100 to 460). The background to these developments and the unique functionalities of SPE base oils is presented.

Market & Technology Changes Influencing New Base Oil Developments

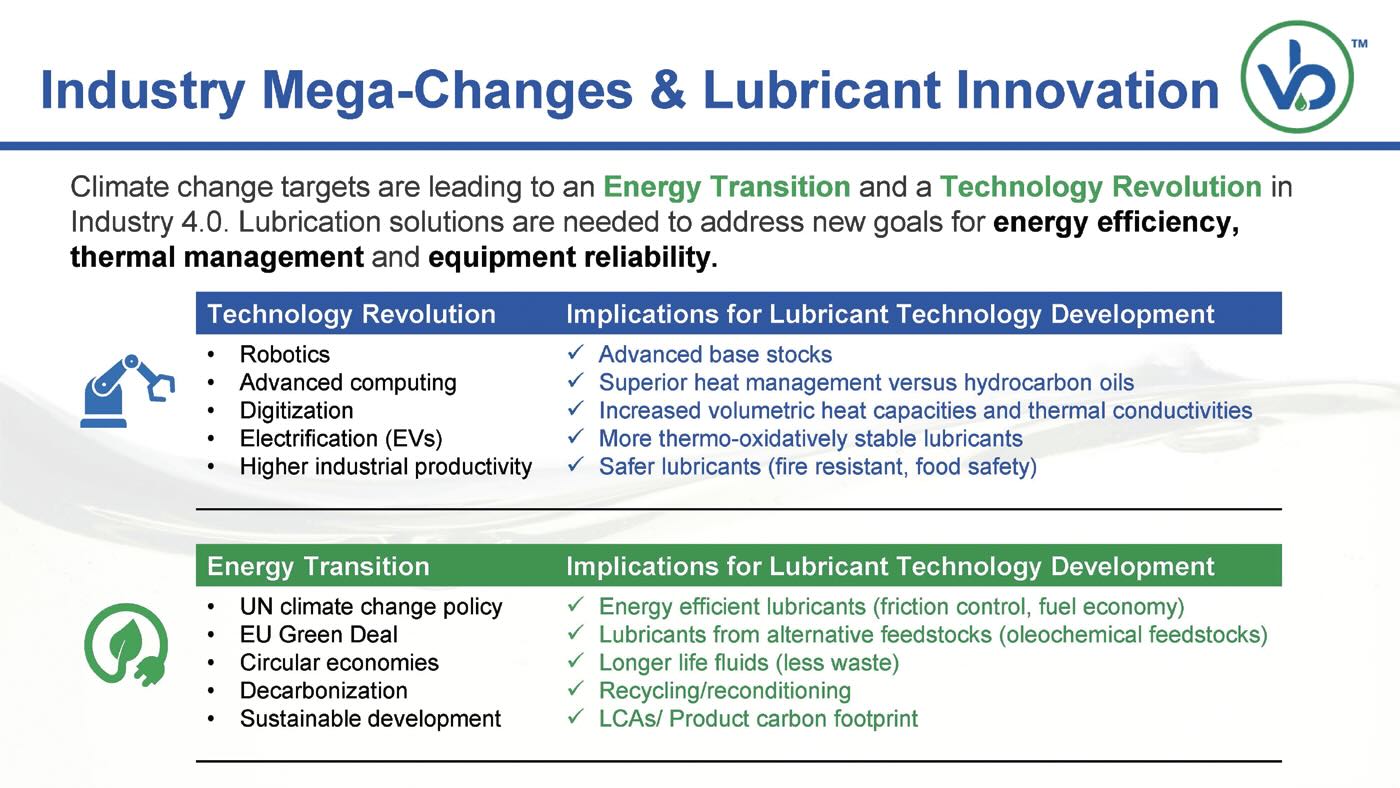

A major challenge in advancing sustainable human progress is the political drive to address climate change. This effort has sparked an energy transition and the adoption of innovative technologies aimed at mitigating and reversing global warming. In the manufacturing sector, which is experiencing a significant shift known as ‘Industry 4.0’ or the Fourth Industrial Revolution, we are witnessing advancements in robotics, artificial intelligence, human-machine interaction, additive manufacturing like 3D printing, and advanced analytics. These developments are opening-up new opportunities for creating innovative lubricants (see Figure 1).

Figure 1

Figure 1

Moreover, there is a strong emphasis on selecting lubricants that are safer, comply with stricter environmental regulations, and are preferably derived from oleochemical rather than petrochemical feedstocks. While hydrocarbon base oils will remain important for many applications, there is an increasing demand for advanced synthetic lubricants that provide enhanced heat management, greater energy efficiency, and a more favorable environmental impact.

Secondary Polyol Ester™ (SPE®) Technology

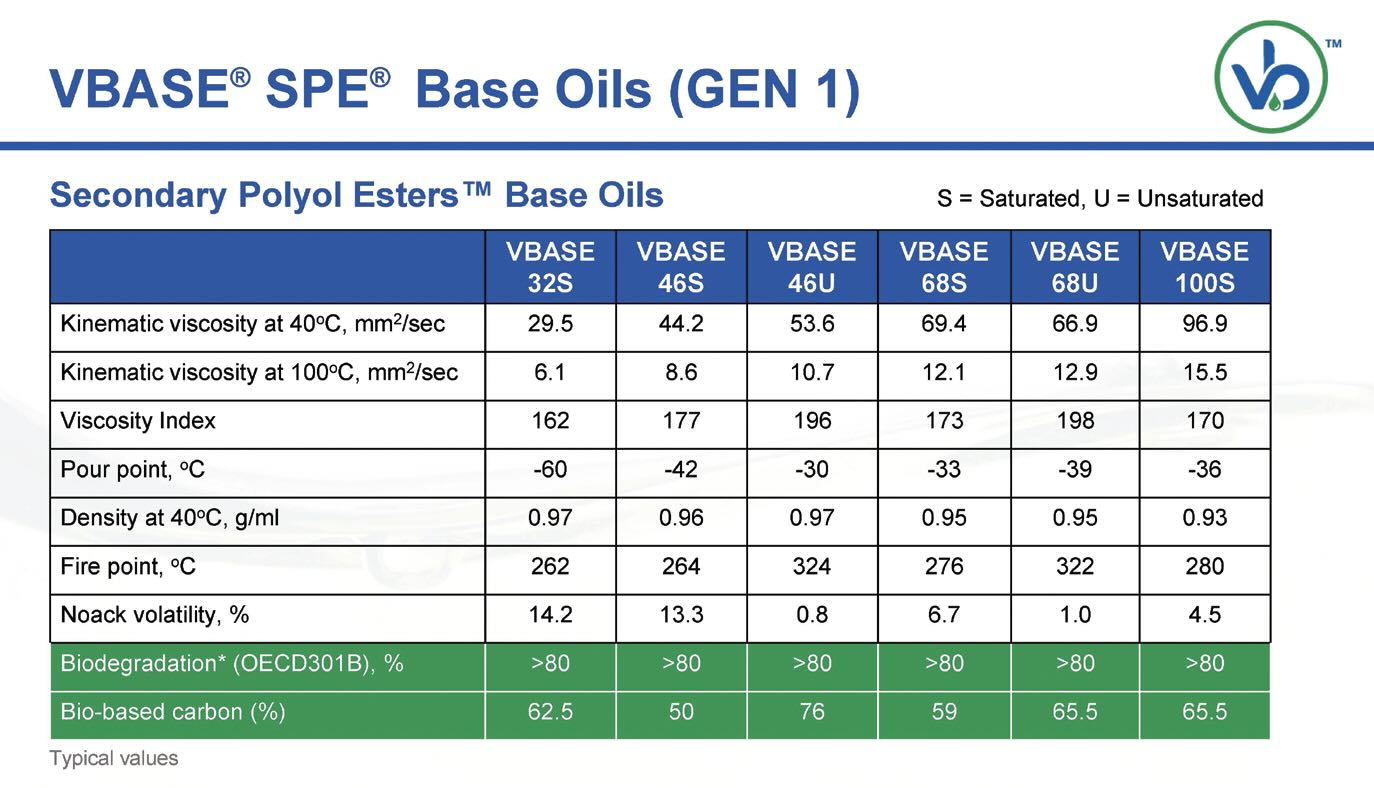

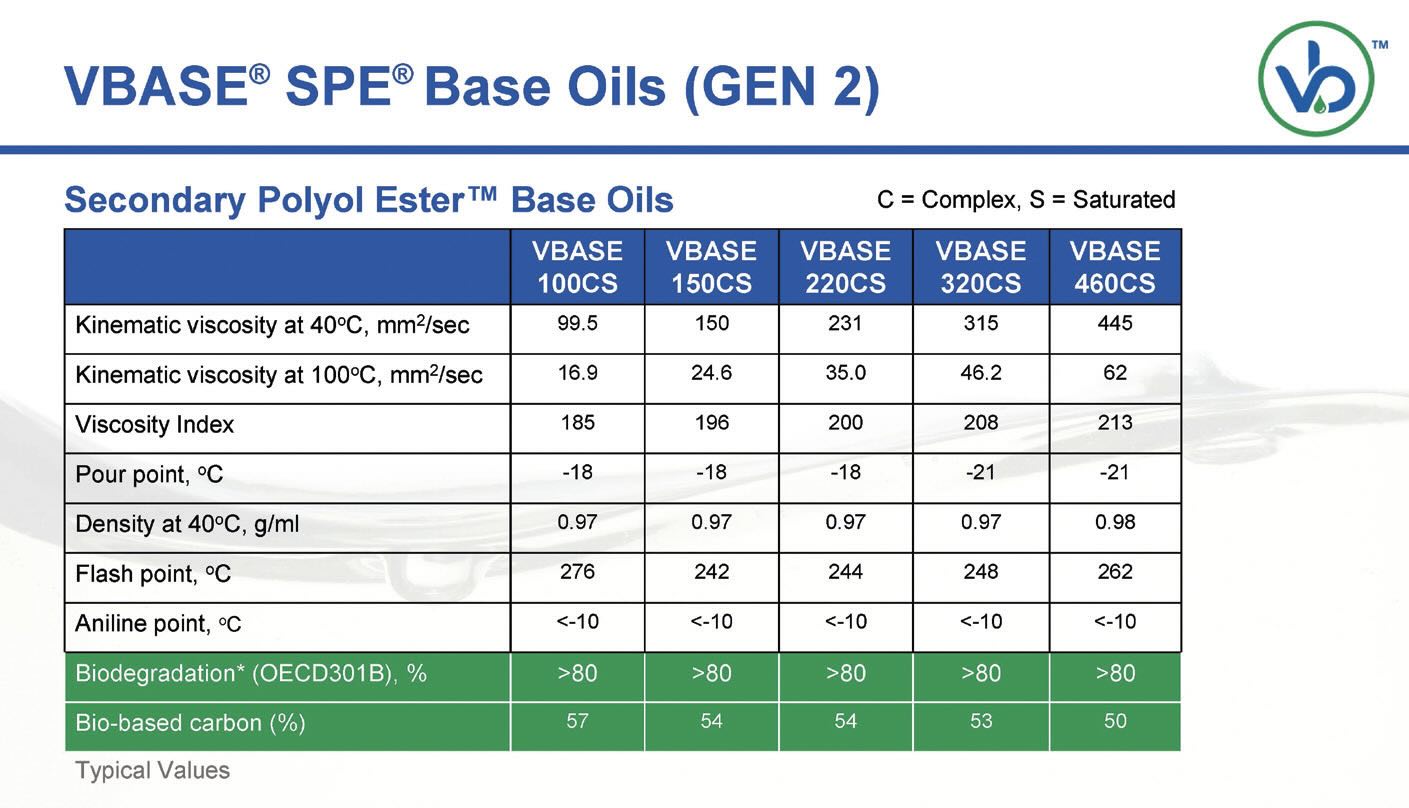

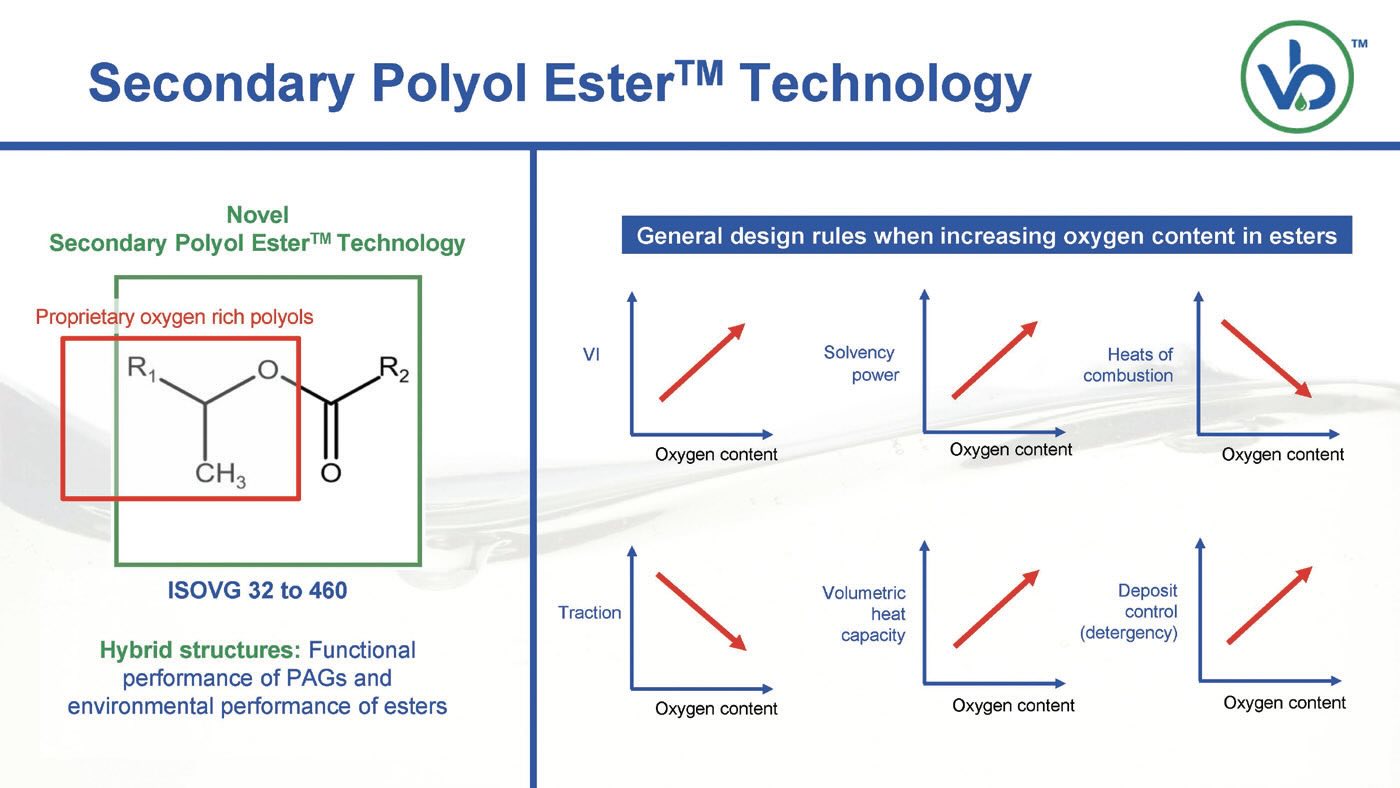

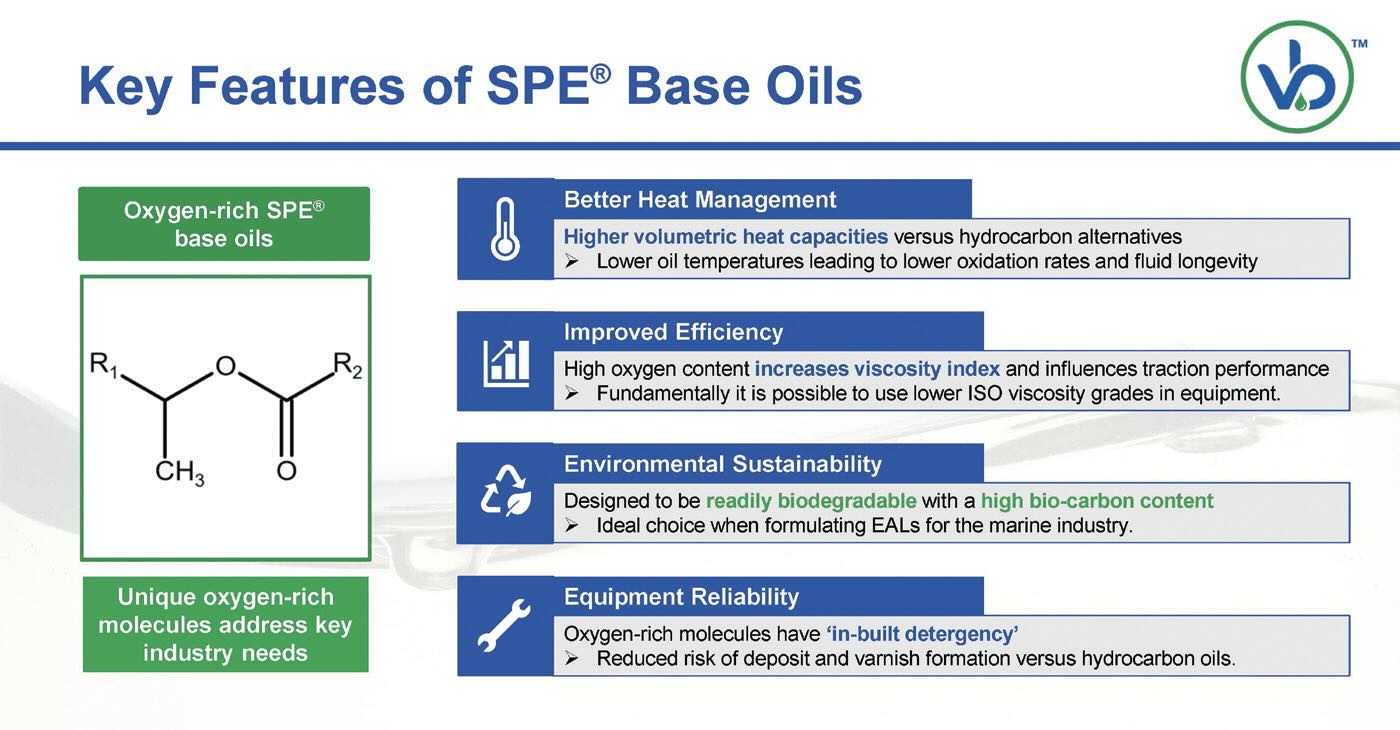

In our industry, there are several classes of synthetic esters which are used in a diverse range of applications. The novel SPE® base oils are unique and provide additional functionalities. Figure 2 illustrates the physical properties of the Generation 1 base oils. Figure 3 provides data on the new Generation 2 Complex SPE

® base oils. One aspect of their novelty is they are designed from proprietary polyols. Chemical reaction of these with saturated or unsaturated fatty acids, in which the esterification occurs on a secondary hydroxyl, leads to novel, ‘oxygen-rich’ SPE

® base oils. The inclusion of high levels of oxygen as ether bondsin the ester molecule significantly influences both their physical and functional performance (Figures 4 and 5). For instance, compared to other synthetic esters with similar viscosity grades, these oils can achieve higher viscosity indices.

Figure 2

Figure 2

Figure 3

Figure 4

Figure 4

Figure 5

Moreover, SPE

® base oils have lower aniline points, indicating high polarity, which contributes to their excellent film-forming behavior. This results in superior anti-wear properties and reduced friction coefficients on ferrous surfaces. Additionally, favorable thermo-physical properties such as higher volumetric heat capacities and low heats of combustion are unique features. There is a vast array of molecular structures that can be designed around the fundamental SPE® structure allowing this science to be adapted to solve modern and future tribology challenges.

Functional Attributes

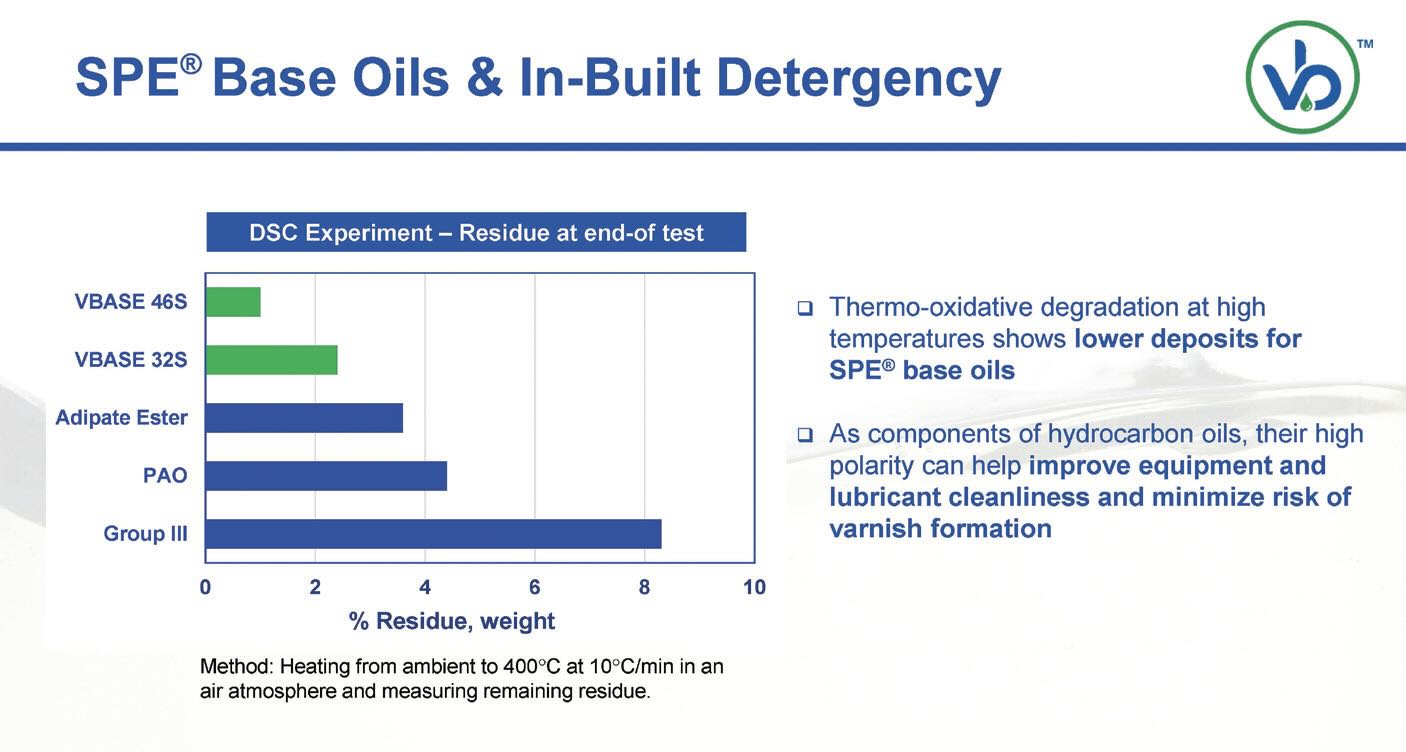

In-built detergency: The inclusion of high levels of oxygen within the ester structure provides ‘in-built’ detergency. Equipment that uses synthetic lubricants designed from SPE

® base oils as the primary base oil can benefit from excellent cleanliness and equipment reliability. SPE® base oils can also be used as performance additives in formulations. Their high polarity and solubility in hydrocarbon base oils enhance the solvency of API Group II-IV hydrocarbon base oils, which have higher aniline points and low polarity. Even in small amounts, SPE base oils can help control deposit formation during the aging of hydrocarbon base oils, reducing the risk of dangerous varnish buildup and improving both equipment reliability and lubricant longevity.

To illustrate their cleanliness functionality, a Differential Scanning Calorimetry (DSC) experiment was conducted. In this test, an API Group III base oil, a polyalphaolefin (Group IV), a synthetic ester (Group V), and two SPE base oils (VBASE 32S and 46S) were heated at a rate of 10°C/minute to 400°C in an air atmosphere. Figure 6 displays the residue formation after the experiment, showing that SPE base oils significantly reduce residue compared to other base oils.

Figure 6

Figure 6

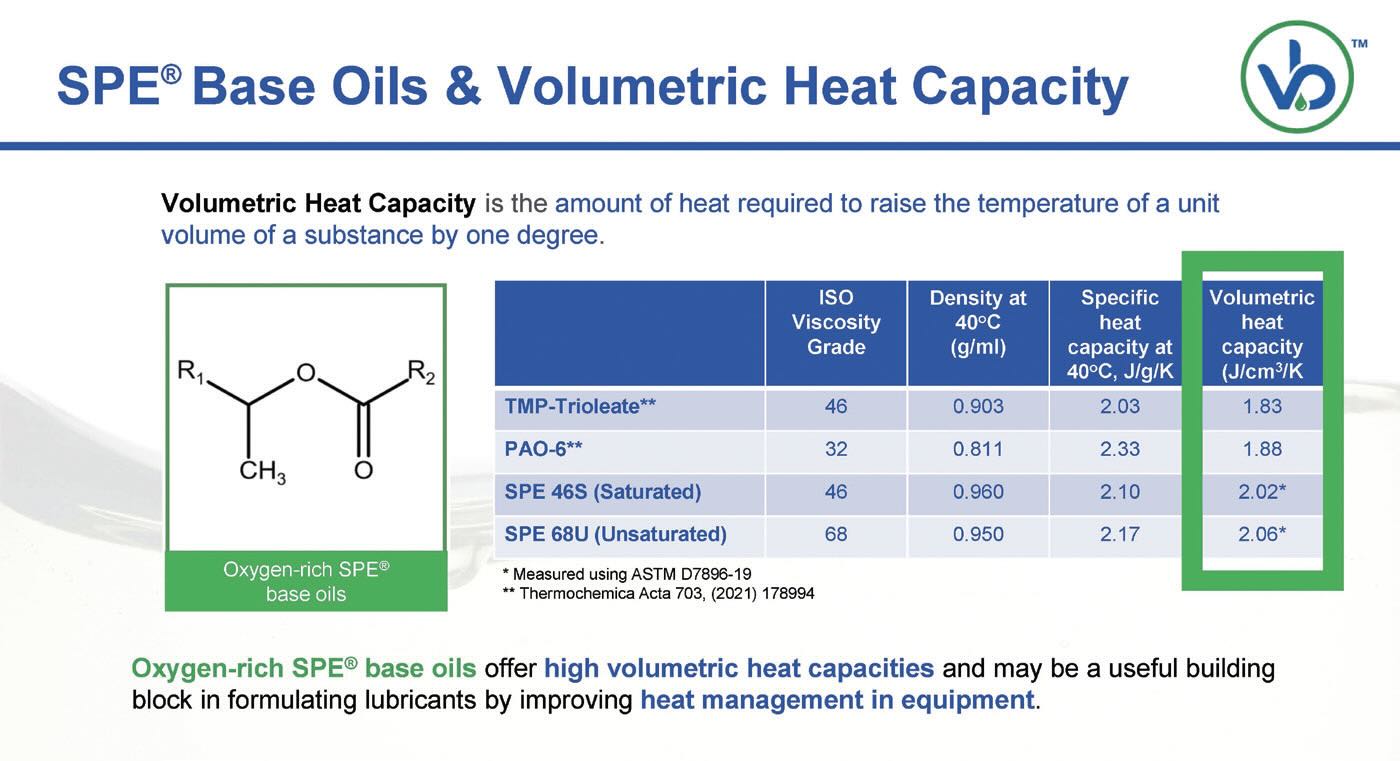

Volumetric heat capacities: Effective thermal management is becoming increasingly crucial for modern automotive and industrial equipment due to the rising thermal stresses on lubricants. The high oxygen content in SPE molecules can enhance thermo-physical properties compared to traditional base oil technologies. Figure 7 demonstrates the superior volumetric heat capacity of two SPE base oils (VBASE 46S and 68U) compared to a polyalphaolefin base oil and a conventional synthetic ester. Volumetric heat capacity measures the amount of heat needed to raise the temperature of a unit volume of substance by one degree. The SPE® base oils show values up to 12% higher. The ability of SPE™ base oils to improve heat management could lead to lower oxidation rates of lubricants, and equipment operating at cooler temperatures.

Figure 7

Figure 7

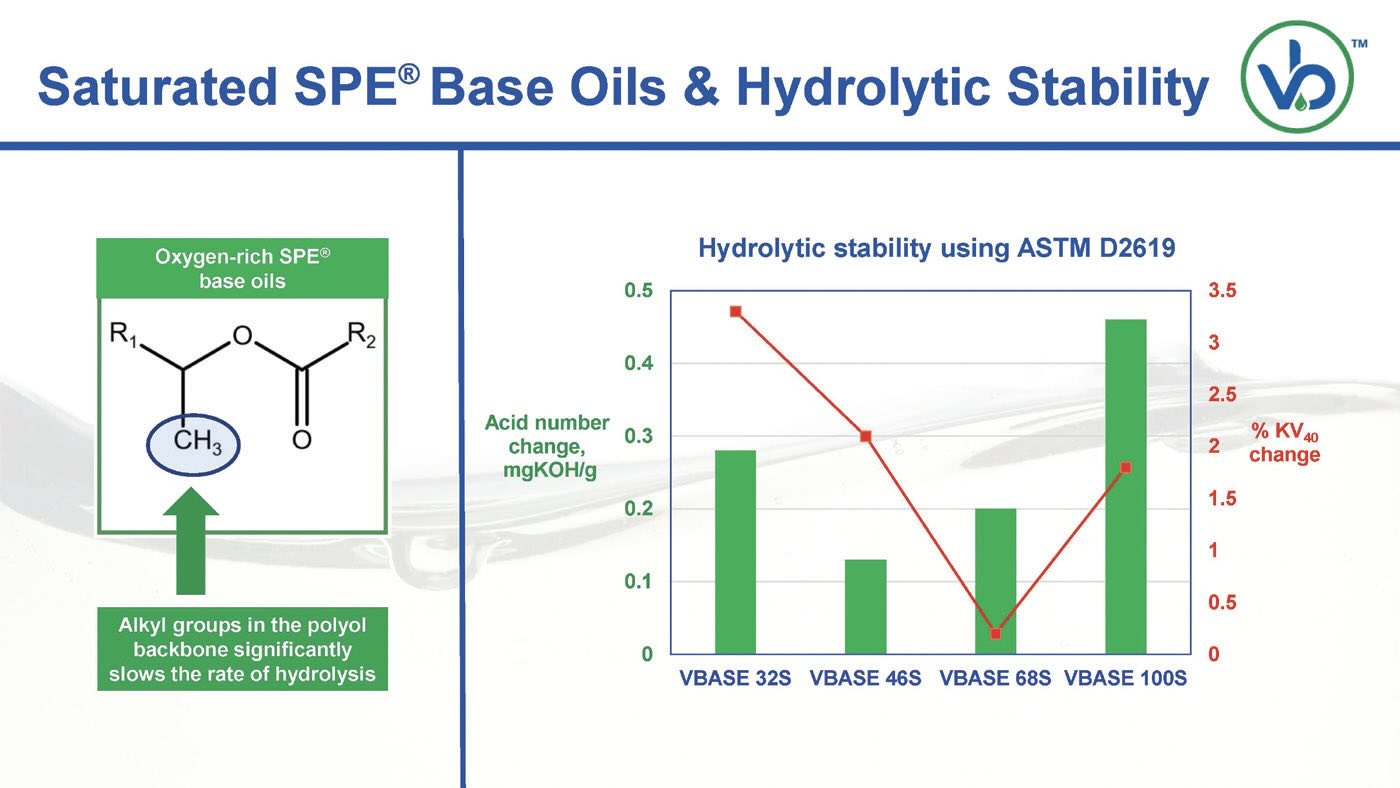

Hydrolytic stability: A key practical consideration when using esters in new lubricant formulations is their hydrolytic stability. SPE

® base oils are designed from a highly branched proprietary polyol and this creates steric hindrance around the ester moieties leading to significantly improved stability versus many other esters. Figure 8 presents data in the ASTM D2619 (Beverage Bottle) test where four saturated SPE

® base oils were evaluated. In this test the esters were exposed to 25% water and a copper catalyst then aged for 48 hours at 93°C. Small acid number changes of less than 0.5 mgKOH/g were observed indicating their good stability under these test conditions.

Figure 8

Figure 8

Fire resistance: Unsaturated SPE base oils (VBASE 46U and 68U) show impressively high fire points (Figure 2) and low heats of combustion. Coupled with their high viscosity indices and good low temperature properties, they are an excellent choice for formulating fire resistant fluids such as HFDU fire resistant hydraulic fluids used in industries like steel and aluminum processing, as well as mining.

Environmental accreditations: SPE base oils are readily biodegradable, feature a high bio-carbon content (Figures 2 and 3), and are non-toxic and non-bio-accumulative. All base oils are EU Eco-label LuSC listed and are USDA Certified BioPreferred (high biobased content) products making them ideal for formulating environmentally acceptable lubricants for the marine industry. Moreover, each base oil has NSF HX-1 accreditation thereby facilitating their use as components of food grade lubricants for incidental food contact.

Summary

Secondary Polyol Ester™ technology is a new platform technology allowing a diverse range of novel base oils or performance additives to be developed to solve some of today’s tribology challenges. A key feature is the inclusion of high levels of oxygen built into their molecular architecture yielding many functional benefits over alternative base oils. Designed for superior performance, SPE

® technology offers formulators a solution for developing cutting-edge, sustainable lubricants suited for the 21st century.