SEQENS

SEQENS program for more sustainability in the lubricant industry

By Guillaume Notheaux, Lubricant Additives R&D Manager, SEQENS | TLT CMF Plus November 2024

By Marie LEGATTE, Advanced Specialties BU Marketing Manager, SEQENS

Introduction

Sustainable chemistry is a scientific concept that aims to improve the efficiency with which natural resources are used to meet human needs for chemicals and services. Sustainable chemistry encompasses the design, manufacture and use of chemicals that are efficient, effective, safe, and more environmentally friendly. (source OECD)

Regarding the industrial lubricants market, the EALs (Environmental Acceptable Lubricants, a term created in 1990) represented 3% of the overall market in 2023 with growth of 5% per year. Most traditional industrial lubricants sold are based on petroleum derivatives, non-permanent resources, poorly biodegradable, highly persistent in the environment and toxic to aquatic environments. Thus, the industrial lubricants of tomorrow will have to meet the requirements both in terms of increasing performance and increasingly strict environmental regulations.

What to do when 50% of these industrial lubricants do not follow appropriate treatment channels and risk ending up in our environment?

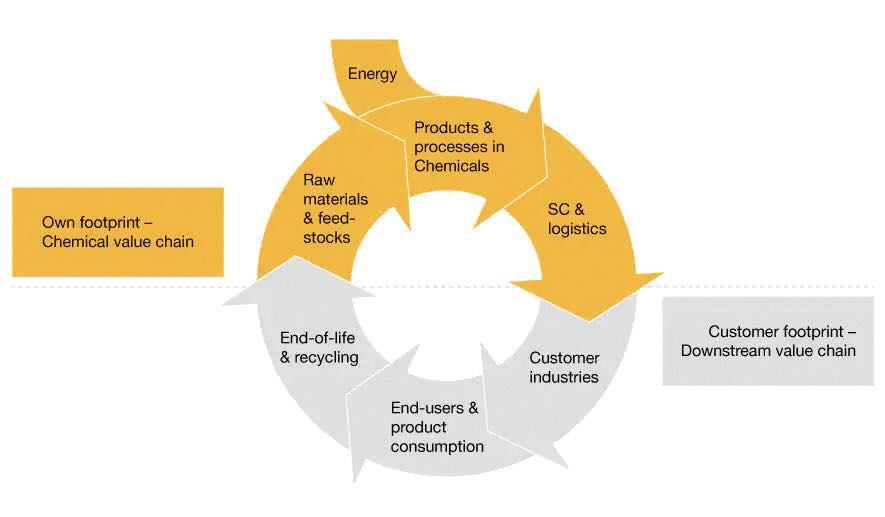

A global approach must therefore be considered because the reduction of the environmental impact of lubricants occurs throughout the life cycle of the product (cradle-to-grave, refer to figure 1).

From raw material suppliers to EALs lubricant formulators, all players now offer targeted offers to help end users of industrial lubricants in their objective of reducing their carbon footprint.

Being Platinum ECOVADIS certified, our French plant is fully involved in the sustainable development of SEQENS activities (figure 2-SEQENS’ CSR objectives).

To face the challenges of sustainability, SEQENS is supporting its customers in the development of lubricants with reduced environmental impact, biodegradable or biobased as well as safer substitutes than conventional additives.

Figure 1-Sutainability along the value chain (PwC)

Figure 1-Sutainability along the value chain (PwC)

Figure 2-SEQENS’ CSR objectives

Biodegradable Overbased calcium sulfonate Greases

A push for alternative technologies to Lithium is rising due to several challenges in term of supply chain, price and toxicological threats and considering the need of more sustainable solutions, SEQENS is the only one to propose overbased calcium sulfonate (OBCaS) biodegradable greases with good anticorrosion resistance, good water resistance, high thermal stability, high Extreme Pressure performance and very good mechanical stability.

Grease producers must consider these new customers’ requirements to focus on the development of special ranges of eco-friendly greases. They can rely on national and international labelling programs based on voluntary initiative (European Ecolabel, German Blau Engel, Japanese Eco mark, Nordic Swan, USDA biopreferred program, Korean ecolabel).

By using 100% of esters carrier, OBCaS greases,

KELICO® V, from SEQENS fit in the category of highly renewable and biodegradable. They complete the wide range of biodegradable greases mostly represented by products based on lithium soaps, calcium soaps or lithium-calcium soaps, addressing the demand in Europe and in the USA for biodegradable greases performing in sensitive applications for the environment.

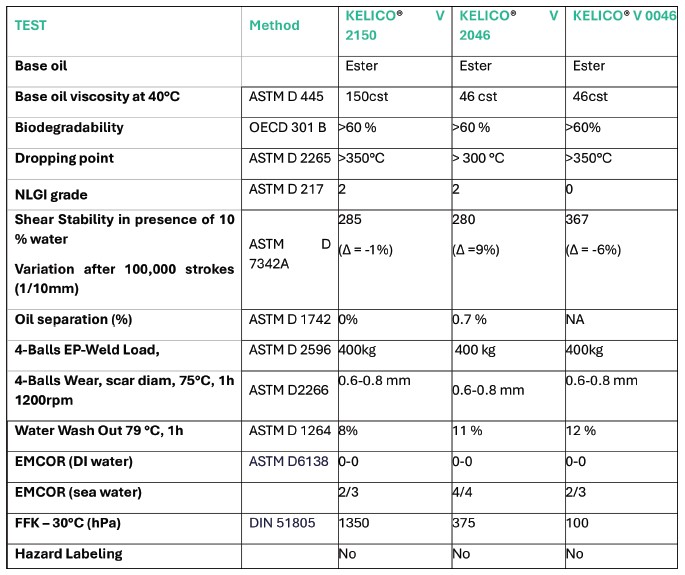

KELICO® V greases from SEQENS enable the lubricants’ manufacturers to formulate environmentally acceptable lubricants with exceptional performances (Table 1).

According to numerous industry standards,

KELICO® V ester-based overbased calcium sulfonate greases are defined as biodegradable, non-bioaccumulative and non-toxic to aquatic species which makes them suitable candidates for applications where EALs are required (figure 3).

KELICO® V overbased calcium sulfonate greases are premium greases for high load and high temperature applications, suitable for extreme environment and particularly adapted for marine applications thanks to their resistance to water and their intrinsic anticorrosion performances.

Figure 3- KELICO® V 2046 in SEQENS R&D lab

Figure 3- KELICO® V 2046 in SEQENS R&D lab

Biobased Extreme Pressure additives

SEQENS has developed Sulfurized Extreme Pressure additives,

SULFAD® 1523E, SULFAD® 1710E and

SULFAD® 1711E, that are registered on the LuSC list (Lubricant Substance Classification List) facilitating the formulation of EAL.

SULFAD

® extreme pressure additives (figure 4) are sulfurized molecules that provide resistance to high loads and at times combined good anti-wear performances. They react with metal surface under heavy loads and form a physical barrier that persists under extreme conditions, preventing metal to metal contact. Containing respectively 15 and 17% of Sulfur, they can be used for metalworking formulations and grease additivation.

Also,

SULFAD® 1710E and

SULFAD® 1711E additives have optimum solubility in Group I, II, III paraffinic base stocks and as well in Naphthenic base stocks (depending on base oil origin). It is recommended to check it in the finished product.

SULFAD® 1711E and

SULFAD® 1523E are also compatible with non-ferrous metals.

Figure 4 - SULFAD® extreme pressure additives used in metalworking fluids formulations.

Figure 4 - SULFAD® extreme pressure additives used in metalworking fluids formulations.

Safer substitutes

Over the years SEQENS acquired a strong expertise in carbonatation process and propose a wide range of calcium sulfonates protection additives with customized features enabling formulation fine-tuning of corrosion protection products.

Specially, overbased calcium sulfonates have a core/shell structure of calcium carbonate surrounded by calcium sulfonates. Dispersed in an oil, a solvent, or a waterborne carrier, they act as a very good antirust component, and they are water resistant. It makes them the perfect candidate for long term protection during storage, transportation, handling, and use (figure 5-ARCOT corrosion protection additives).

Relying on its expertise, SEQENS is supporting customers by expanding its Protection additives range with a new non-labeled long-term protection additive,

ARCOT® CS 401 and a new nonflammable medium-term protection additive,

ARCOT® CS 203.

Solvent-based corrosion protection additives may have a flash point below 60°C and may be considered as flammable with the GHS02 associated labeling. Thus, SEQENS decided to work on a non-flammable alternative.

By using a higher flash point solvent, SEQENS can propose a safer alternative with similar performances to its customers,

ARCOT® CS 203. With a flash point above 70°C,

ARCOT® CS 203 is a solvent based polar overbased calcium sulfonate additive for the formulation of a wide range of film forming anticorrosion protection. It is compatible with most hydrocarbons, solvents, mineral oils, waxes, petrolatums and resins.

ARCOT® CS 203 is used for rust preventive applications such as protection products for ballast tank, industrial gears, and other devices as well as automotive undercoating and cavity protection.

Also, today, calcium-based protection additives are labeled H317, that may cause an allergic skin reaction. Thanks to its one-step process industrialized 20 years ago, SEQENS can propose,

ARCOT® CS 401, a unique additive to answer customers need of low labeling additives.

ARCOT® CS 401 is a non-labeled solvent based polar overbased calcium sulfonate anticorrosion additive.

ARCOT® CS 401 is used for formulation of a wide range of film forming rust preventive applications such as automotive undercoating and cavity protection as well as anticorrosion wax formulations.

ARCOT® CS 401 has good performances in oil and solvent based formulations, it shows more than 1000 hours when diluted at 30% in oil, 400 hours when diluted at 30% in solvent and up to 1600 hours when diluted at 50% in solvent.

Figure 5 - ARCOT® corrosion protection additives

Figure 5 - ARCOT® corrosion protection additives

As detailed with the solutions developed for the lubricant industry, such as biobased, biodegradable, and safer additives, SEQENS has put in place a structured and pragmatic CSR strategy, with shared objectives and a clear roadmap that commit the entire Group. This CSR approach, which is an integral part of the Group's strategy, is designed to ensure the long-term future of both our business and the customers we work with.