For more than 40 years, Nouryon’s Armolube® lubricant and Armofuel® fuel solutions have played an essential role in powering people around the world, one molecule at a time. We design innovative solutions for automotive, industrial, metalworking, and electric vehicle fluids as well as gasoline, diesel, and alcohol fuels. Formulators trust our broad range of surfactant and polymer solutions to improve efficiency, productivity, and reliability across multiple applications to keep the world moving.

Nouryon has been a leading supplier of amines and functionalized amines to the lubricants and fuel additive markets for over 25 years. Our additives are widely used in automotive and industrial applications and are regarded as industry benchmarks.

As the industry evolves towards more efficient and sustainable solutions due to changing specifications and regulations, Nouryon is continuously developing new friction modifier concepts. Our R&D team is currently focusing on a range of polymeric organic friction modifiers designed to meet the most stringent customer requirements.

Our strong amine derivative design capabilities allow us to tailor friction properties to diverse application and performance demands, offering sustainable options.

Recent research on polymeric friction modifiers confirms that Nouryon’s components deliver competitive performance at comparatively low treat rates across all friction regimes, with more favorable labeling compared to current mainstream products.

After extensive screening of a broad variety of available chemistries, we have carefully selected three (3) components that will allow our customers to meet or surpass their formulation objectives.

Armolube FM 605, FM 701 and

FM 703 (Figure 1) besides showcasing outstanding performance, bring additional benefits giving our customers the flexibility to incorporate those in their current or future formulation matrices in different applications.

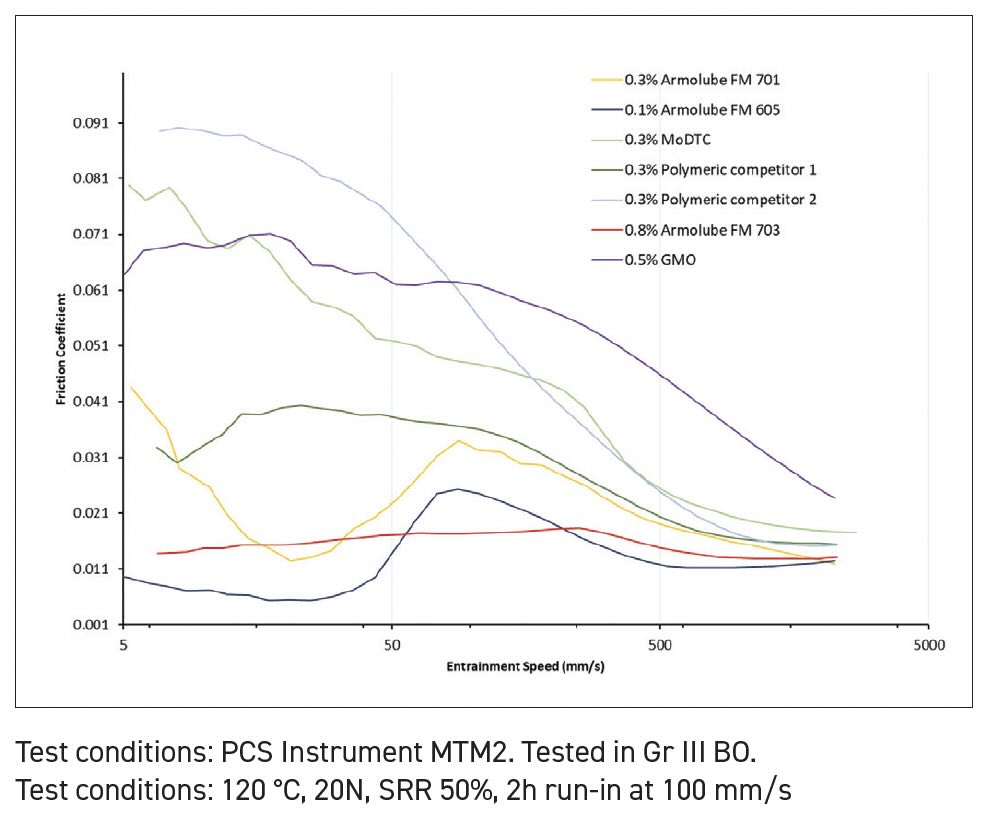

Figure 1. Comparison of Stribeck curves of Nouryon’s new polymeric friction modifiers vs conventional friction modifiers and other polymeric compounds from competitors

Figure 1. Comparison of Stribeck curves of Nouryon’s new polymeric friction modifiers vs conventional friction modifiers and other polymeric compounds from competitors

Nouryon’s new friction modifiers outperform competitor’s polymeric products and standard industrial benchmarks – GMO and Conventional MoDTC.

The lubricants market is evolving at a fast pace. New OEM requirements, specifications and regulations are bringing new challenges:

• Increased pressure on fuel economy and durability standards requires engine oils with low or no ashes that deliver better performance.

• Cost-efficiency and new specification standards initiatives will require treat rates of metal-containing FMs (MoDTC) to be reduced.

• Hybrid engines and EV transmission fluids require protection at low temperatures that current FMs can’t deliver.

• And new regulations will require components with better labeling.

These market conditions are making formulators, look outside their current toolbox for product that can help them achieve their objectives.

At Nouryon, we strive to be ahead of the game, and anticipate future customers’ requirements. That is why we started about 2 years ago with the objective of developing a platform of components that allow our customers to develop better and more sustainable formulations across different segments.

After screening more than 100 components across different chemistries and finetuning the most promissory ones, we selected 3 products which we believe cover all performance and sustainable needs across different base oils and applications.

This article covers a summary of the performance results obtained across different base oils, conditions, and applications.

Armolube® FM 605

Armolube 605 is a film forming polymeric friction modifier containing multiple functional groups within a single oligomeric molecule that adsorbs onto the metal surface at various points, forming a specific film that significantly reduces the coefficient of friction across all lubrication regimes, even at very low treat rates, without negatively impacting traction properties.

Armolube® FM 605 is a

label free polymeric friction modifier that performs better than GMO and MoDTC in all lubrication regimes (Figure 2).

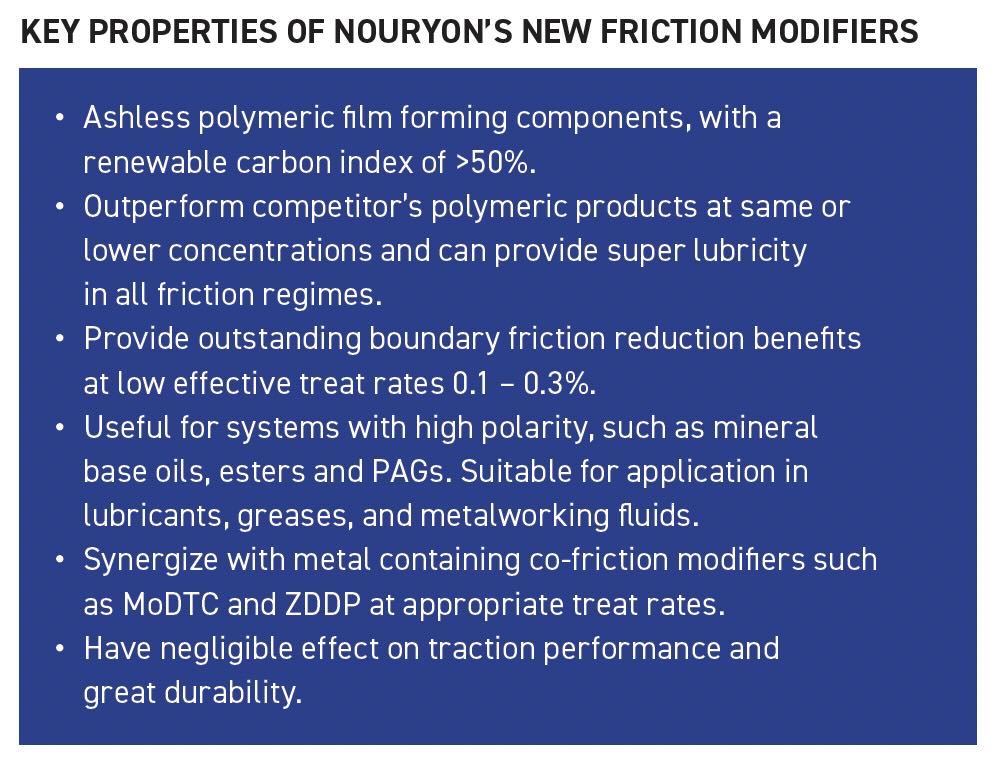

Figure 2. Comparison of Stribeck curves of Nouryon’s Armolube FM 605 and MoDTC and the synergistic effect obtained when combined. Test conditions: PCS Instrument MTM2. Tested in Gr III BO. Test conditions: T=120 C, 20N, SRR50%

Figure 2. Comparison of Stribeck curves of Nouryon’s Armolube FM 605 and MoDTC and the synergistic effect obtained when combined. Test conditions: PCS Instrument MTM2. Tested in Gr III BO. Test conditions: T=120 C, 20N, SRR50%

Also, the combination of Armolube® FM 605 and MoDTC exhibits strong friction modification synergistic benefits.

Armolube® FM 701

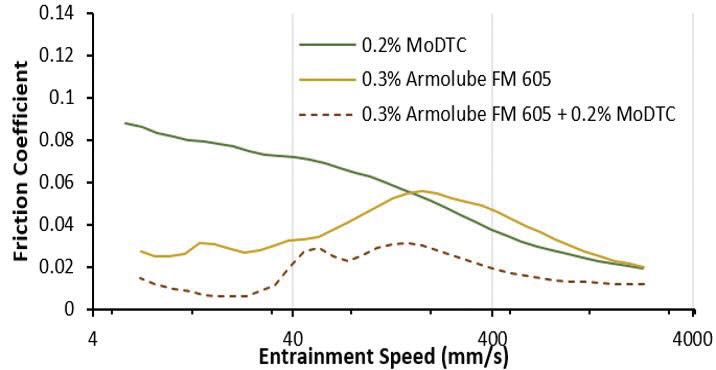

Armolube FM 701 is a high-performance polymeric ester amine that serves as an effective ashless multifunctional friction modifier at different temperature conditions (Figure 3) in engine oils, driveline fluids, EV (Electric Vehicles) fluids and metalworking fluids (MWFs).

Figure 3. Nouryon’s Armolube FM 701 Stribeck curves at different temperatures. Test conditions: PCS Instrument MTM2. Tested in Gr III BO. Test conditions: 20N, SRR 50%, 2h run-in at 100 mm/s. at different temperatures (40°C , 80°C , 120 °C and 150°C

Figure 3. Nouryon’s Armolube FM 701 Stribeck curves at different temperatures. Test conditions: PCS Instrument MTM2. Tested in Gr III BO. Test conditions: 20N, SRR 50%, 2h run-in at 100 mm/s. at different temperatures (40°C , 80°C , 120 °C and 150°C

Along with Armolube 605®, It provides outstanding friction performance during extended periods of time, exhibiting great durability at harsh ICE conditions (Figure 4).

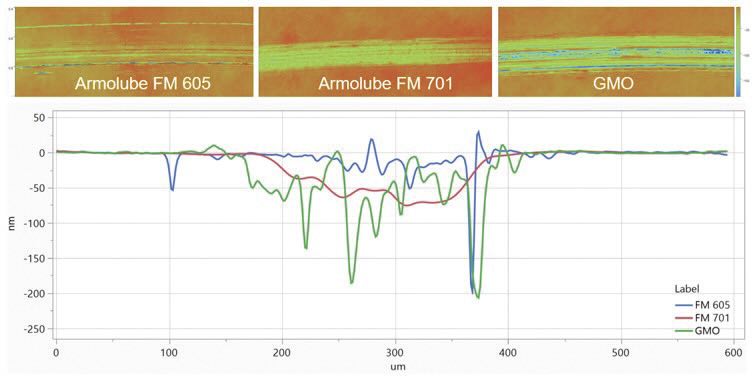

Figure 4. After a 24h MTM test the wear tracks on the disks were analyzed using 3D optical profilometer based on white light interferometry. These results revealed that Armolube® FM605 and FM701, represented by the blue and red lines respectively, exhibited less material loss compared to GMO.

Figure 4. After a 24h MTM test the wear tracks on the disks were analyzed using 3D optical profilometer based on white light interferometry. These results revealed that Armolube® FM605 and FM701, represented by the blue and red lines respectively, exhibited less material loss compared to GMO.

Armolube® FM 703

Armolube® FM 703 is an ethoxylated copolymer designed for application in low polar base oils, and especially useful for application in PAO based formulations of automotive lubricants, including EV application.

Armolube FM 703 has excellent solubility in all types of base stocks including PAO that makes it suitable for high performance formulations, especially in EV transmission fluids.

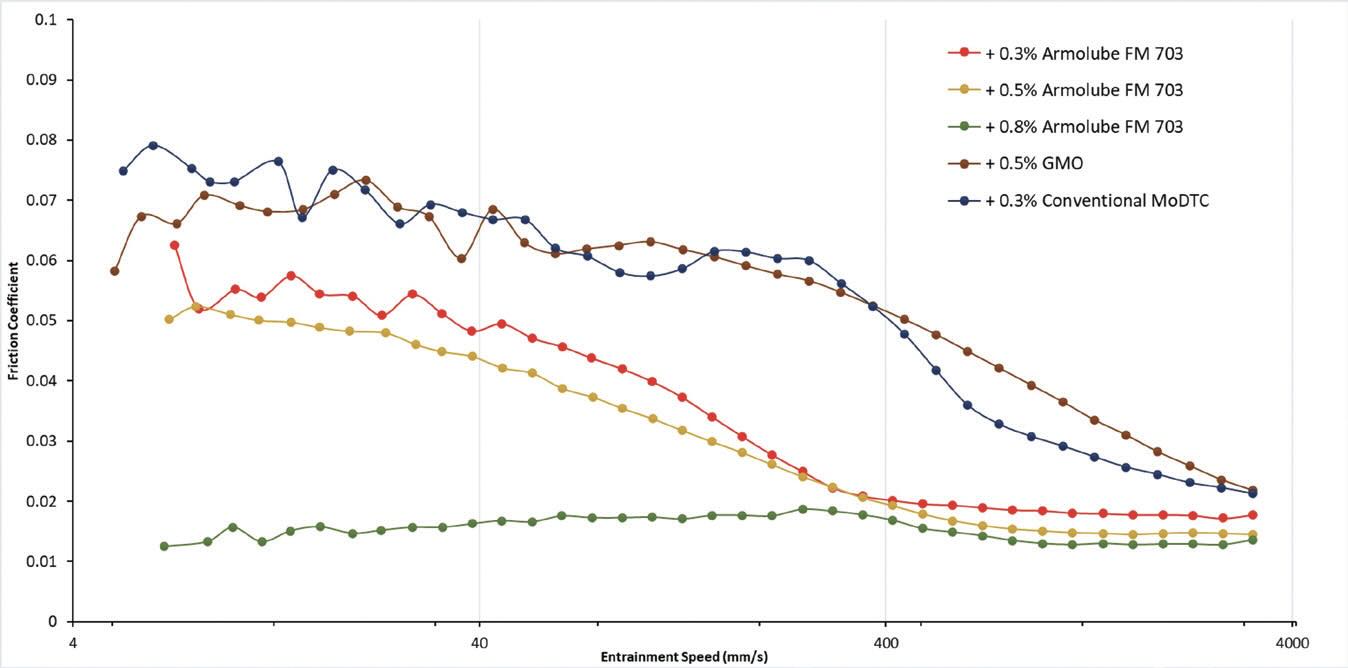

It provides a very low and stable friction coefficient across all the entrainment speeds, surpassing friction performance when compared with conventional friction modifiers like GMO and MoDTC (Figure 5).

Figure 5. Stribeck curves of GrIII base oil blends containing Armolube FM 703 vs conventional friction modifiers. Test conditions: PCS Instrument MTM2. Tested in Gr III BO. Test conditions: 20N, SRR 50%, 2h run-in at 100 mm/s

Figure 5. Stribeck curves of GrIII base oil blends containing Armolube FM 703 vs conventional friction modifiers. Test conditions: PCS Instrument MTM2. Tested in Gr III BO. Test conditions: 20N, SRR 50%, 2h run-in at 100 mm/s

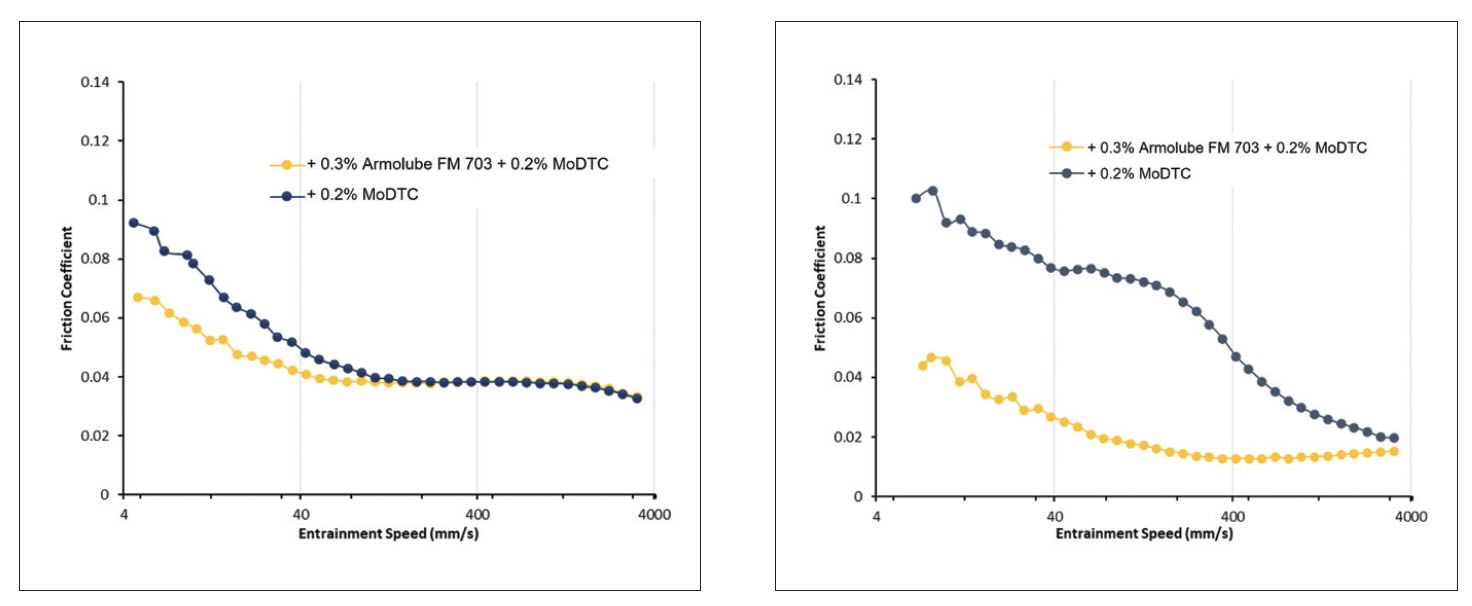

Armolube® FM 703 also improves MoDTC, friction performance at both low and high temperature conditions (Figure 6).

Figure 6 and 7. Stribeck curves of GrIII base oil blends containing Armolube FM 703 and conventional MoDTC under different temperature conditions: 40°C (left) and 120°C (right). Test conditions: PCS Instrument MTM2. Tested in Gr III BO. 20N, SRR 50%, 2h run-in at 100 mm/s

Takeaways

Figure 6 and 7. Stribeck curves of GrIII base oil blends containing Armolube FM 703 and conventional MoDTC under different temperature conditions: 40°C (left) and 120°C (right). Test conditions: PCS Instrument MTM2. Tested in Gr III BO. 20N, SRR 50%, 2h run-in at 100 mm/s

Takeaways

New regulations, specifications and more rigorous OEM requirements are making formulators explore alternative chemistries outside their current “toolbox” that allows them to achieve future performance and sustainability objectives.

After extensive research, Nouryon identified and developed 3 new components that is bringing to the market. Armolube® FM 605, 701and 703 are ash free multifunctional friction modifiers with a renewable carbon index of >50%.

These polymeric friction modifiers exhibit very good performance at very low treat rates (0.1 – 0.5%). Armolube® FM 605, 701

and 703 outperform competitive metal and non-metal containing FMs and provide synergistic effects with MoDTC and ZDDP across all friction regimes and despite their polymeric nature, they have proven no negative impact on traction performance. All of three products bring additional corrosion, antiwear and TBN boosting benefits.

•

Armolube® FM 605 is a label free product that outperforms other polymeric friction modifiers. It also has outstanding durability properties when compared with other conventional friction modifiers. Suitable for industrial and automotive formulations that use GII or GIII base stocks.

•

Armolube® FM 701 brings superior performance at both, low and high temperatures making it suitable for hybrid applications. It also provides traction benefits to different lubricants at all SRRs.

•

Armolube® FM 703 was designed for application in low polar base oils, having excellent solubility in all types of base stocks including PAO making it suitable for high performance formulations, especially in EV transmission fluids.