Hanna Instruments, Inc.

Quality Matters. Exploring the Advantages of Testing at Critical Process Stages to Deliver a Top-Notch Final Product

By Conor McAnespie, East Regional Sales Manager, Hanna Instruments, Inc. | TLT CMF Plus November 2024

When producing petroleum and developing other products such as lubricant oils, effective management is paramount. Petrochemical companies and lubricant producers must follow strict procedures to ensure a high quality, consistent final product and to guarantee that customer expectations are met. Testing plays a crucial role in these manufacturers’ daily operations and measuring key parameters at various checkpoints of the production process is necessary. Reliable data helps quality assurance departments make sound business decisions, adhere to stringent standards, and create the best product.

Which Parameters are Tested and Why?

Petrochemical companies and lubricant producers need to validate oil quality and effectiveness. This prevents issues like corrosion and moisture defects from occurring. Manufacturers rely on wet chemistry instrumentation to test three important parameters including: Moisture, Acid Number (AN), and Base Number (BN).

The Importance of Moisture Analysis

Testing moisture is crucial to achieve optimal performance. When moisture levels are too high, this can significantly reduce the effectiveness of a lubricant. The presence of moisture in petroleum products can catalyze oxidation in the oil, alter the viscosity, corrode and rust metal surfaces that it comes into contact with, and reduce the combustion efficiency which poses potential safety hazards.

Measuring Acid Base Number (AN) and Base Number (BN)

Testing these parameters gives insights into a lubricant’s chemical stability and performance. With this knowledge and intel, manufacturers can adjust formulations and improve quality.

Measuring Acid Number (AN) determines the acidic substances that are present in a petroleum product or lubricant. It is expressed as the amount of potassium hydroxide (KOH) in milligrams required to neutralize the acids in one gram of sample (mg KOH/g). Acid Number (AN) is used to assess the acidity and overall condition of petroleum products, helping to maintain equipment and avoid any operation failures. Too much acidity in lubricants can lead to chemical degradation and reduce its effectiveness.

Base Number (BN) measures the amount of alkaline or basic substances present in a product or lubricant. It is expressed as the amount of KOH in milligrams equivalent to the amount of acid neutralized by one gram of sample (mg KOH/g). A high base number helps to neutralize acids and maintain the lubricant’s effectiveness over time. This enables the oil to protect against any acidic related damages.

Common Methods for Analyzing Moisture Content

Loss on Drying Method

There are many ways to conduct moisture analysis, with one of the most popular methods being loss on drying. This process involves heating a sample in a drying oven and then calculating the difference in weight before and after the sample is heated. This option is typically more economic because it only requires an analytical balance, a drying oven, and a desiccator for cooling the sample. Additionally, since no solvents or reagents are needed it eliminates the handling and disposing of these chemicals. However, this type of test is not suitable for analyzing petrochemicals and lubricant oils. These substances consist of volatile components that cause interferences in the test that can lead to inaccurate results.

Distillation Method

Another procedure for moisture analysis is through a distillation process. This is a practical method that only requires a distillation flask, solvents, and a condenser and burner. Nonetheless, distillation does involve mixing solvents with a sample and using a burner. This procedure requires manually handling and disposing solvents as well. This raises safety concerns and increases the likelihood of accidents occurring.

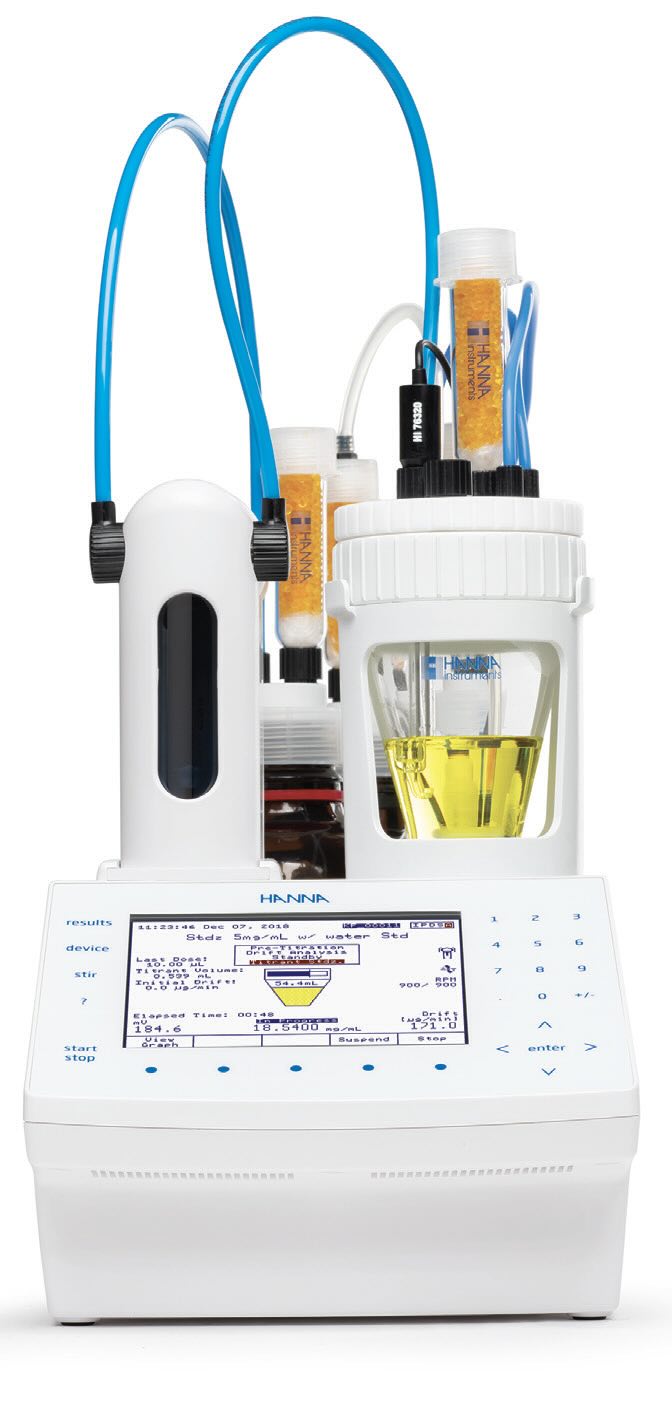

ASTM Method

Petrochemical companies and lubricant producers use ASTM methods for moisture analysis. The ASTM D6304 standard method is frequently used and designed for measuring low levels of moisture in petroleum products and lubricating oils. A Karl Fischer Titrator is required and will automatically determine the exact water content of a sample. This precise testing equipment addresses many of the common challenges that are associated with moisture analysis. One of the biggest advantages of using a Karl Fischer Titrator is that it analyzes and calculates the water content of a sample automatically, unlike with the Loss on Drying or Distillation methods. This greatly minimizes the risk of human error and eliminates concerns regarding volatile components interfering with results. Karl Fischer Titrators are safe and efficient. Built with an air pump that manages substances automatically, this significantly reduces a user’s exposure to harsh chemicals.

Acid Number (AN) and Base Number (BN) Testing

When it comes to Acid Number (AN) and Base Number (BN) analysis, tests are performed via potentiometric titrations. There are four ASTM methods commonly used depending on the makeup of the petrochemicals and lubricant oils being tested. The ASTM D664 method is a standard method for acid number. The ASTM D2896 standard method is for a base number using a non-aqueous pH electrode and is typically for testing new oils with a higher alkalinity. Another method frequently used for testing new oils is the ASTM D7439 standard method, which is for a base number utilizing a non-aqueous pH electrode. Lastly, the ASTM D974 standard method is for a base number using a photometric indicator electrode and measures very low alkalinities.

There are two ways to complete potentiometric titrations.

Manual Titrations

Manual titration is typically used in educational chemistry laboratories and in manufacturing environments. Lab technicians are familiar with this method, which requires basic equipment: a manual burette, a beaker, a titrant, and a color change reagent. Manual titrations are straightforward. Users simply add the color change reagent to the sample, slowly titrate with the manual burette, stop when the expected color change occurs, and then use the volume of titrant to calculate the concentration of the analyte. The simplicity and cost effectiveness of manual titrations makes it a popular choice.

There are several factors that can impact the accuracy of results with manual titrations. One major issue is that the endpoint is determined based on a visual color change. Results are subjective and can vary between individuals, making it challenging to achieve repeatable data. This subjectivity becomes more pronounced with darker samples, where color changes can be harder to discern. Additionally, if different technicians are conducting these tests, the interpretations of the color change can vary for each individual.

Inconsistent endpoint determination has a domino effect and can lead to incorrect titrant measurements, which in turn affects the calculations and subsequent adjustments made based on that result. Over time, these inaccuracies can change the quality of the final product, leading to manufacturing issues.

Accurate data is required for effective management in petrochemical and lubricant oil manufacturing. Without accurate results, manufacturers will struggle to make informed decisions and oversee production processes effectively. Repeated adherence to procedures is essential for ensuring product quality. Inconsistent data can lead to deviations from established procedures, compromising the manufacturing process.

Manual titrations may not provide a robust foundation, and manufacturers will have trouble keeping up with higher testing demands and new business as a result. Without proper processes in place or a lack thereof, the final product will be prone to inconsistencies. Therefore, ensuring that testing methods are accurate is vital to maintaining product integrity and meeting industry demands.

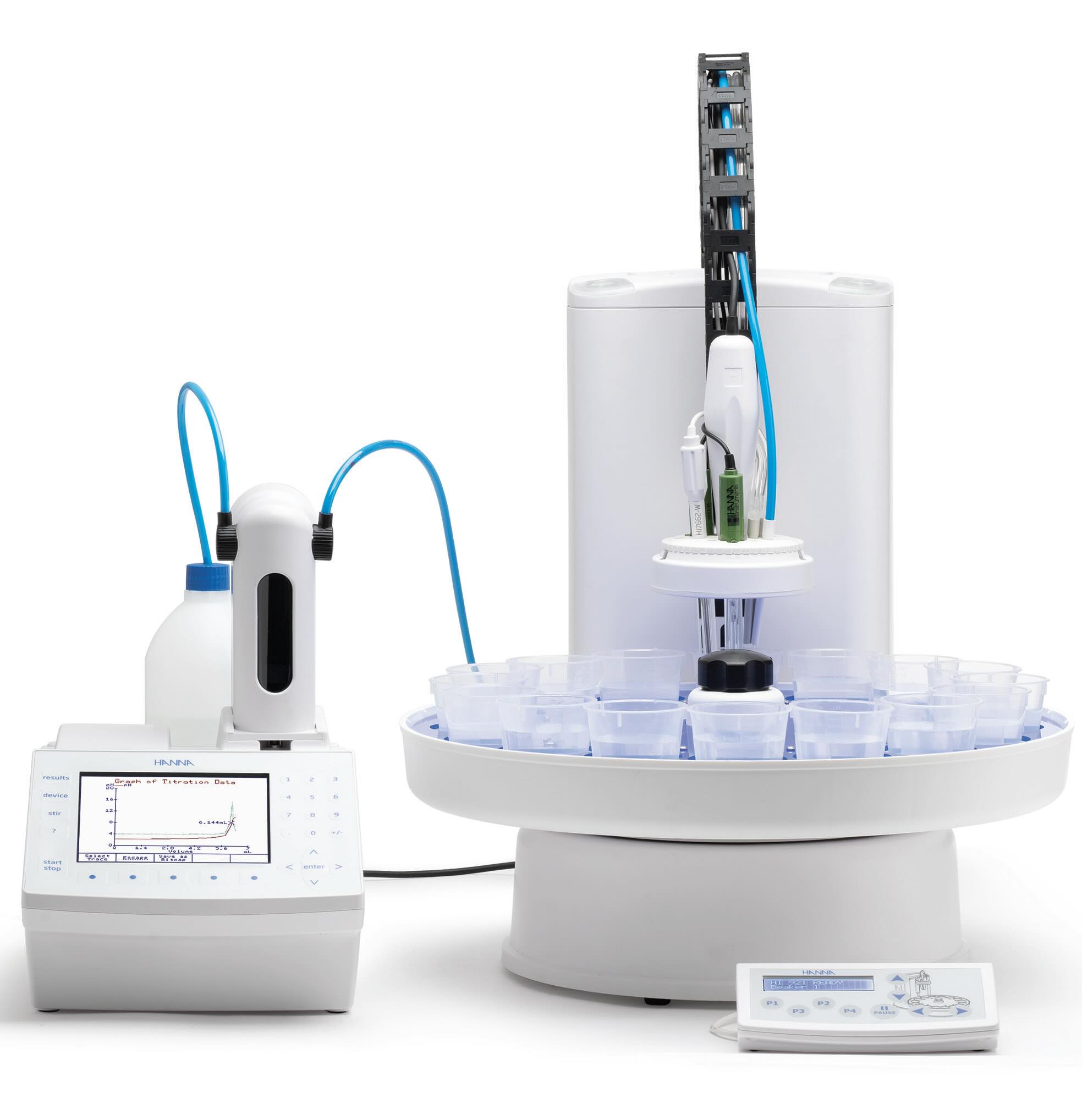

Automatic Potentiometric Titrations

Automatic Potentiometric Titrators, while an initial investment, offer a robust solution for overcoming the challenges associated with manual titrations. Automatic Titrators are compact systems designed to address issues related to color change endpoints and improve consistency.

These systems utilize preprogrammed methods to guide the titration process. Instead of relying on subjective color changes to collect results, titrators use a potentiometric probe—such as a pH or ORP probe—to determine the endpoint. This automated approach eliminates various challenges associated with manual color change detection. This helps reduce any inconsistencies in procedures and product quality.

In addition to automatic endpoint detection, these titrators manage the dosing of titrants with high precision and perform calculations automatically. Lab personnel can focus on other tasks while the titrator does the work, increasing efficiency. As the demand for testing increases, a titrator’s ability to deliver accurate and repeatable results gives manufacturers peace of mind. This also ensures that procedures are strictly followed, which is crucial for petrochemical and lubricant manufacturers who require consistent product quality.

Hanna Instruments as a Testing Solution

Hanna Instruments (Hanna) offers both Automatic Potentiometric Titrators and Karl Fischer Volumetric and Coulometric Titrators for laboratories and businesses alike. For over 45 years, Hanna Instruments has been a leading manufacturer of scientific testing equipment. From portable testers and meters to benchtops and titrators, Hanna makes a wide array of testing equipment for various industries and applications. Hanna caters to many different markets and is commonly used by chemists, researchers, educators, metal finishers, petrochemical companies, lubricant oil producers, and more. No matter the testing needs or requirements, Hanna works with businesses every step of the way to ensure their testing success. To learn more about Hanna Instruments testing equipment, please visit hannainst.com. Also, by using coupon code STLE10, you will receive 10% off any website purchase. Thank you!