Evonik Oil Additives USA, Inc.

VISCOPLEX® Technology for Emulsion Retention in Automotive Engine Oils

By Dr. Rhishikesh Gokhale, Global Technology Manager Automotive, Evonik Operations GmbH | TLT CMF Plus November 2024

Evonik is a leading specialty chemicals company headquartered in Essen, Germany, with a focus on producing high performance materials for various industries. Key markets include automotive and construction, among others. Evonik is committed to create sustainable and value-added solutions for customers. Evonik generates 43% of its sales with products and solutions that have a strongly positive sustainability profile. It aims to increase the share of sales generated with ‘Next Generation Solutions’ to over 50% by 2030. Evonik supports the objectives of the Paris Agreement on Climate Change, which is underscored by its commitment to the Science Based Targets Initiative (SBTi). Evonik aims to reduce scope 1 and scope 2 emissions by 25% and scope emissions by 11% until 2030.

Evonik Oil Additives specializes in the development and production of high-performance lubricant additives and synthetic base oils for automotive and industrial lubricants. The additives are designed to enhance the performance, efficiency and durability of lubricants. Evonik Oil Additives plays a crucial role in the lubricant value chain by providing essential components, helping OEMs to meet evolving performance standards, sustainability goals and environmental regulations.

Automotive Market Trends and Challenges

The global automotive industry is undergoing a significant transformation influenced by technology advancements, changing consumer preferences, environmental regulations and geopolitical dynamics. The industry has witnessed a rapid growth in electric vehicles (EVs), thanks to government incentives and increasing environmental awareness. However, improvements in battery technology, including increased range and reduced costs, as well as advancements in infrastructure are critical for BEV market growth. While governments continue to tighten emission regulations, the automotive industry is seeking alternatives to BEVs that can replace internal combustion engines (ICE) through hybridization, leading to strong growth of hybrid vehicle (HEV) and plug-in hybrid vehicle (PHEV) sales. In addition, hydrogen-fueled internal combustion engines (HICEV) captivate the interest of the commercial vehicle sector as a viable technology to decarbonize cargo transportation.

Hybrid engines offer numerous advantages, such as improved fuel efficiency, reduced emissions, better performance, as well as benefits for end-users in the form of lower operating costs. However, hybrid engines are conducive to certain challenges. Hybrid engines experience frequent stop-start cycles compared to ICE that lead to a lower engine oil temperature, which makes it more difficult for the water to evaporate from the oil sump. Likewise, in HICEV, where water is the main combustion product, water ingression into the engine oil presents a challenge.

The industry is investigating multiple ways to tackle this problem: engine hardware modification can facilitate water evaporation through engine temperature management and improved ventilation, while the use of suitable engine oil additives provides a simple and cost-effective solution.

It is important to ensure the right balance of emulsion performance. A weak emulsion may lead to lubrication loss and harm engine durability, while a strong emulsion can lead to an increased risk of corrosion, foaming and premature engine wear. Evonik Oil Additives’ VISCOPLEX® technology has been carefully designed to provide optimum emulsion retention performance and is described in the following article.

Evonik Oil Additives’ VISCOPLEX® 6-Series for optimum emulsion retention

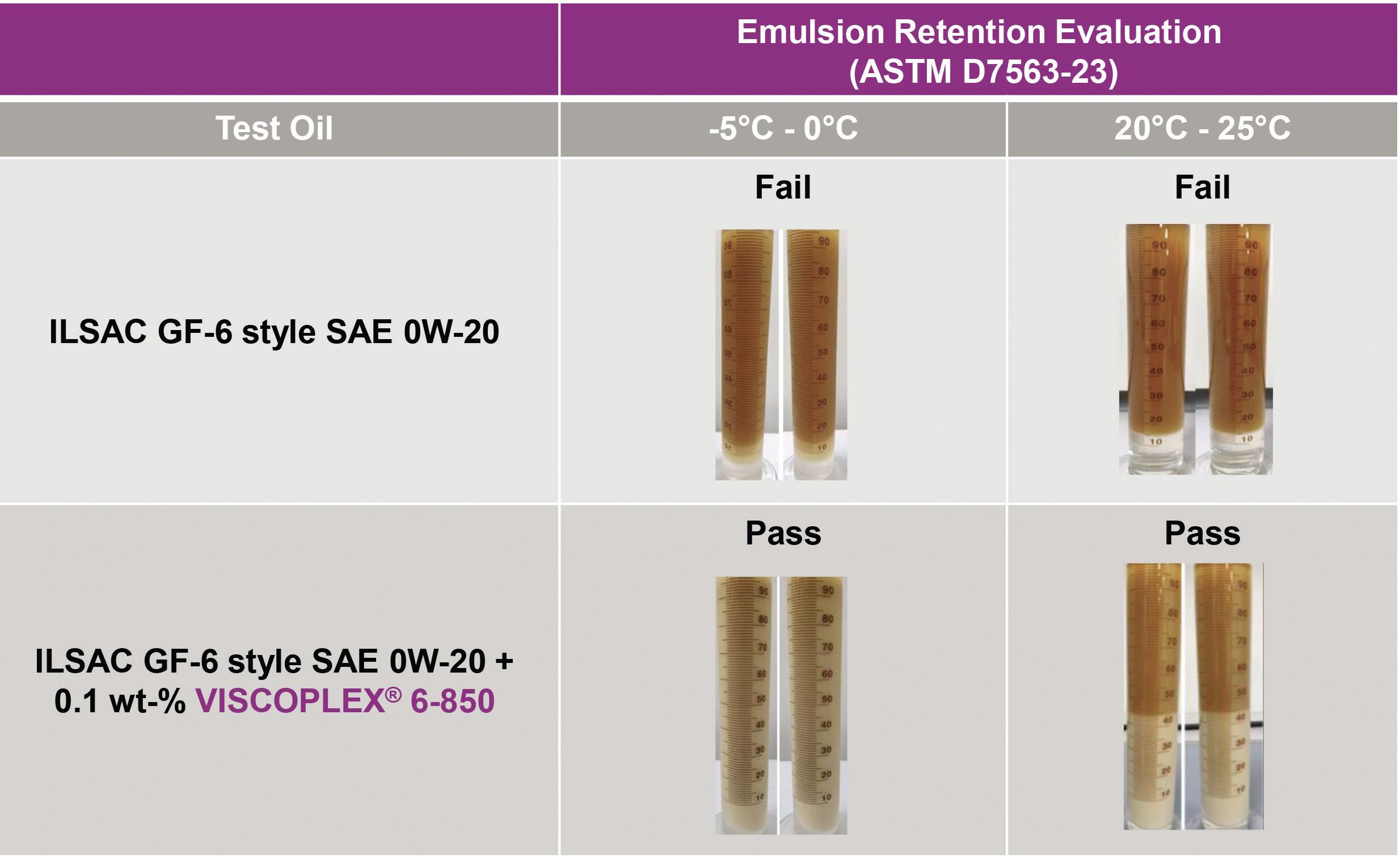

The VISCOPLEX® 6-series additive portfolio comprises of multifunctional dispersant additives combining the effects of viscosity modification, pour point depression, soot dispersancy and emulsion retention. ASTM D7563-23 is the standard test method for the evaluation of the capability of engine oils to retain emulsions. In ASTM D7563-23, an emulsified oil and water mixture is maintained at temperatures of 20°C to 25°C and -5°C to 0°C for at least 24 hours and the sample appearance is observed. A qualified engine oil should have no observable aqueous layer at both temperatures. ASTM D7563-23 is part of the passenger vehicle engine oil requirements for API SP/SN PLUS/SN and ILSAC GF-5/GF-6A/GF-6B categories. OEMs may look at extended emulsion retention performance to ensure robustness. VISCOPLEX® 6-850, besides other VISCOPLEX® 6-series additives in the product portfolio, has been carefully designed to meet current emulsion retention requirements for engine oils.

In a laboratory study, an SAE 0W-20 engine oil comprising of an ILSAC GF-6 additive package and a viscosity modifier in an API Group III 4 cSt base oil system was subjected to ASTM D7563-23. The oil failed to meet the requirements of ASTM D7563-23 with an observable aqueous layer at the bottom of the test flask as shown in picture 1 (top). The oil was then top-treated with 0.1 wt-% VISCOPLEX® 6-850 and comfortably passed the ASTM D7563-23 as shown in picture 1 (bottom). The additive treat-rate of VISCOPLEX® 6-850 may vary between 0.1 wt-% to 0.4 wt-% depending upon the formulation composition and severity of the demulsification.

Picture 1: Emulsion retention evaluation of an SAE 0W-20 oil without (top) and with (bottom) VISCOPLEX® 6-850.

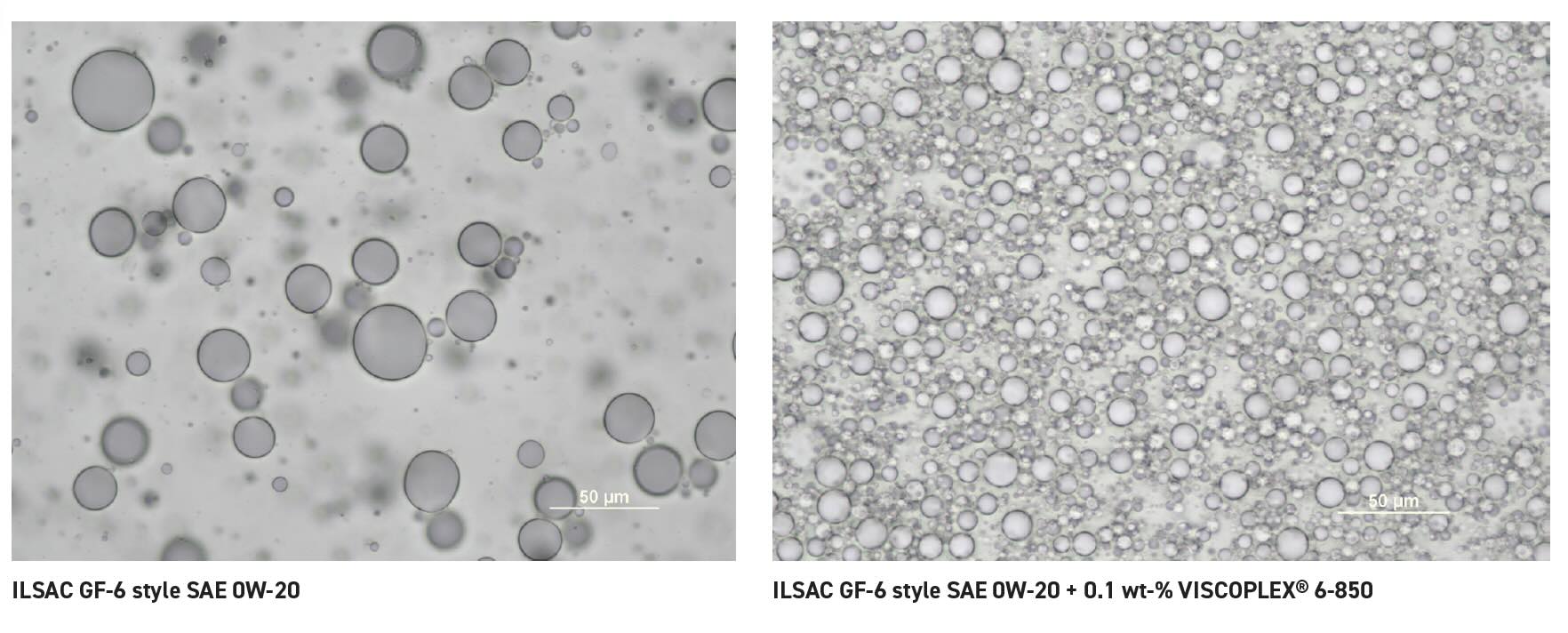

To better understand the effect of emulsion retention, Evonik took microscope images of these 0W-20 engine oil formulations, with and without 0.1 wt-% VISCOPLEX® 6-850. The formulations were stored at 40°C for 24 hours and images were captured at room temperature. The image obtained on the oil failing the emulsion retention test shows large oil droplets (Picture 2, left). The image obtained on the oil containing 0.1 wt-% of VISCOPLEX® 6-850 shows a significantly reduced droplet size (Picture 2, right), which leads to a stable emulsion and a subsequent pass in the emulsion retention test.

ILSAC GF-6 style SAE 0W-20 ILSAC GF-6 style SAE 0W-20 + 0.1 wt-% VISCOPLEX® 6-850

Picture 2: Particle size measurement by Nikon Eclipse Ni microscope on SAE 0W-20 oil without (left) and with (right) addition of VISCOPLEX® 6-850.

The multi-functional nature of VISCOPLEX® 6-series products extends its applicability beyond emulsion retention, making them an attractive solution to improve engine oil components, which can lead to a potential cost advantage for lubricant formulators and blenders.

Visit www.evonik.com/oil-additives to discover more or contact Dr. Rhishikesh Gokhale, Global Technology Manager Automotive directly at rhishikesh.gokhale@evonik.com