BASF Corporation

New Viscosity Index Improver & Biomass Balance Additives Moving the Lubricant Industry Forward

By Daniel Niedzwiecki, Technical Service Manager, BASF Corporation and René Koschabek, Senior Manager Technical Marketing, BASF SE | TLT CMF Plus November 2024

When performance matters – BASF Lubricant Components make the difference. Modern lubricants for automotive and industrial equipment are constantly being pushed to their limits, in both their performance and their regulatory scrutiny. BASF is committed to building a more sustainable future while upholding our customer promise of performance continuity and reduced complexity. It is with these reasons in mind that we have expanded our IRGAFLO® line of polymethacrylates (PMAs) and introduced our new BMBcert™ product series.

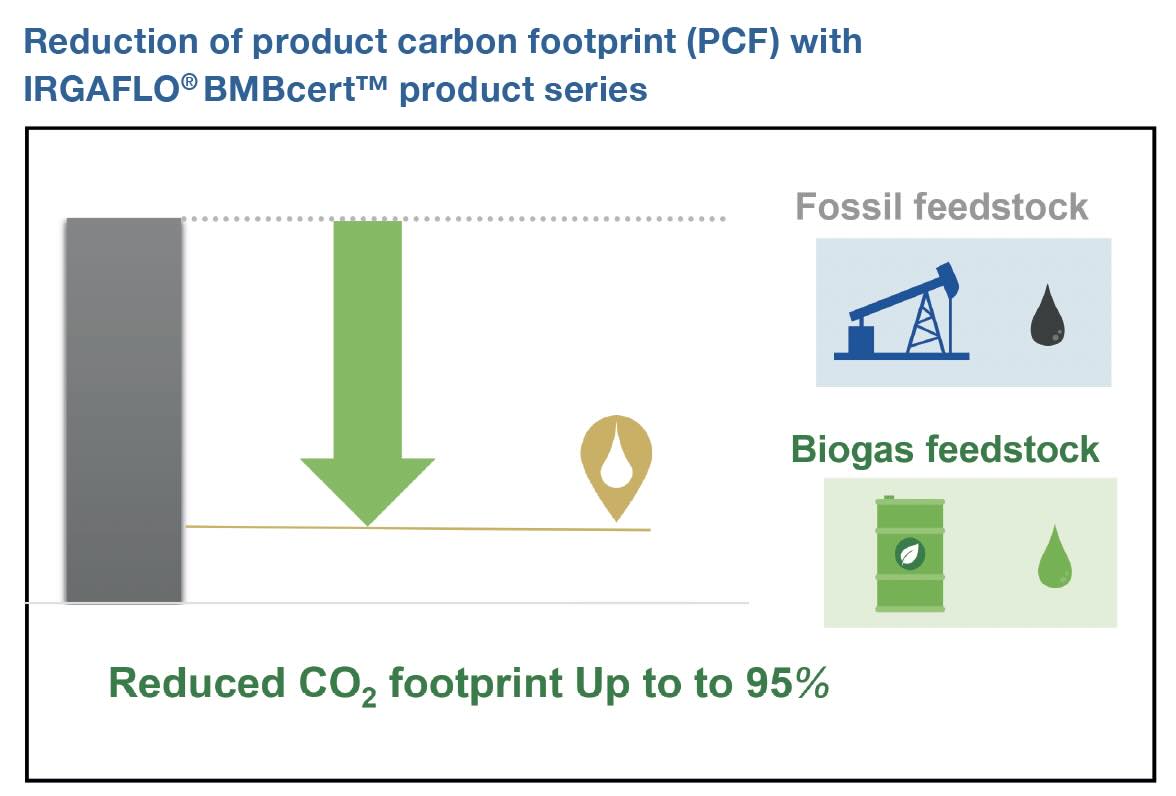

Our IRGAFLO® Viscosity Index (VI) improvers leverage the viscosity - temperature performance of lubricants to deliver high energy efficiency at all operating conditions. In turn, this technology enables lower energy consumption and cost-effective solutions for our customers. To further deliver on sustainability and better utilize our resources, BASF offers the first polymethacrylates based 100% on sustainably sourced renewable feedstocks, IRGAFLO® BMBcert™ series. These products can reduce CO2 emissions up to 95% compared to conventional viscosity index improvers and pour point depressants. Together, with the performance of IRGAFLO® and the sustainability of BMBcertTM, this makes a winning combination for our customers and the lubricant industry.

So, what’s new?

BASF recently introduced IRGAFLO® 1050 V. This product is a shear stable VI improver for automotive- and heavy-duty gear oil, as well as transmission and electric drivetrain fluids. In these applications, there is a shift towards lower viscosities and higher quality base fluids to address the demands for lower emissions and better fuel economy. Important properties of such formulations include better frictional performance and higher viscosity indices. One way to achieve this is via fully synthetic hydrocarbon base stocks. However, this approach typically comes at a hefty price which can heavily impact overall formulation costs. Additionally, the low polarity of fully synthetic hydrocarbons can pose its own challenge. Often compatibilizers need to be added to keep polar additives in solution under varying operating conditions. BASF offers another solution. Formulating with a highly refined Group II or Group III base oil and using a modern shear stable PMA VI improver like IRGAFLO® 1050 V can achieve the desired performance requirements in a cost-effective manner.

Diving into the details

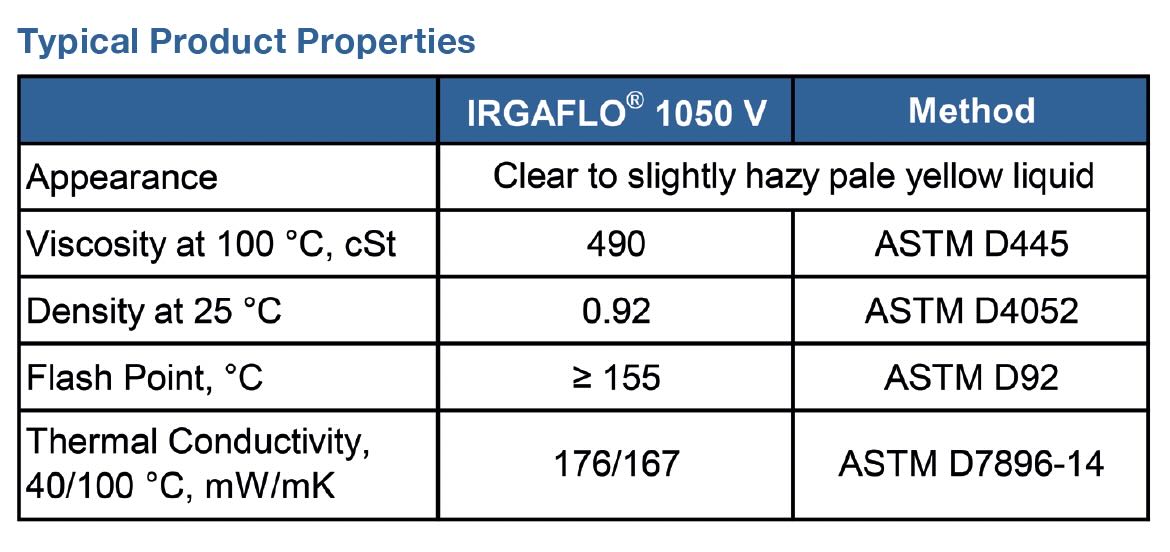

IRGAFLO® 1050 V is our new polyalkyl methacrylate made from innovative synthetic raw materials to achieve excellent low temperature flow properties and superior shear stability, which are crucial for modern powertrain fluids. Like many of our BASF lubricant components, this product benefits from backward integration into key raw materials of our BASF processing Verbund to reduce sourcing complexity and enhance supply reliability. Additionally, this product maintains a high flash point, is oxidatively stable, and provides good thermal conductivity. For economical formulating, the polymer is highly concentrated in a refined hydrotreated paraffinic oil. It can be used in mineral-, hydrocracked-, and fully synthetic base oils, as well as esters (including our own low-viscosity SYNATIVE® ester base stock technology). IRGAFLO® 1050 V is available globally.

Evaluating performance in SAE J306 formulations

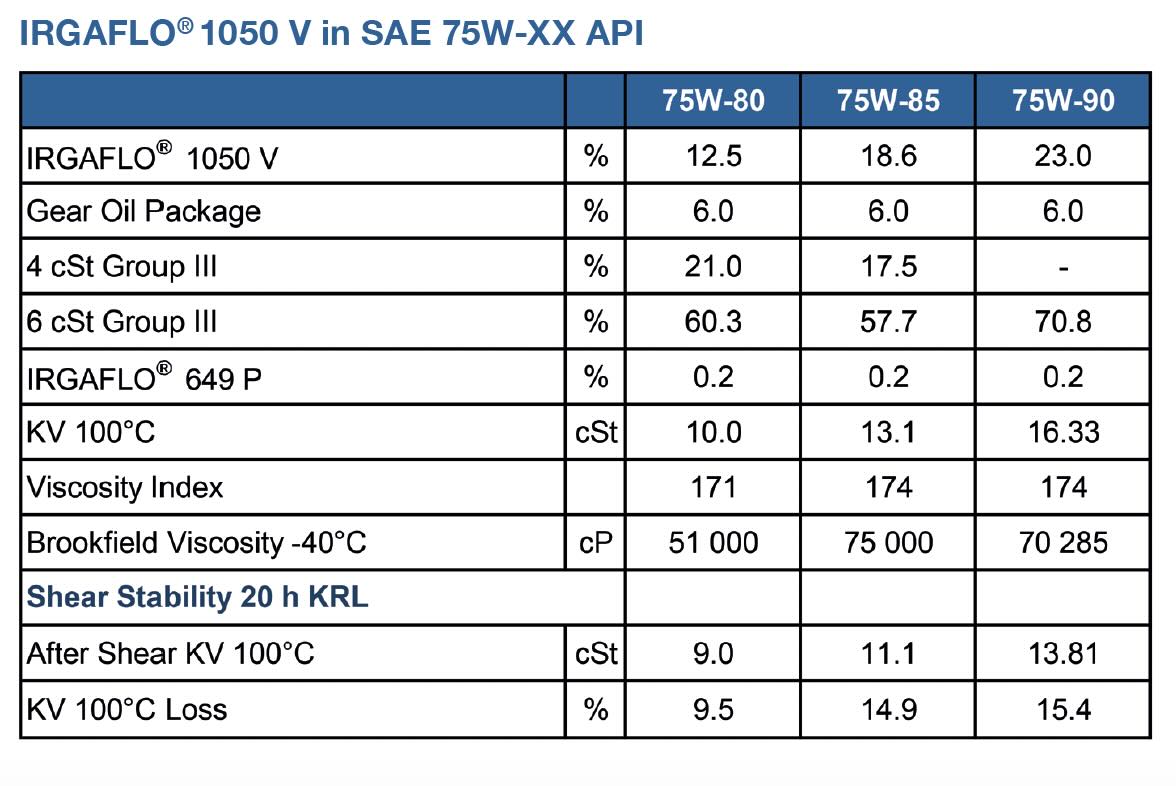

Two key performance parameters of VI improvers for today’s transmission fluids are good shear stability to fulfill stay-in-grade requirements (e.g., SAE J306) and excellent low temperature performance (i.e., Brookfield viscosities at -40°C). IRGAFLO® 1050 V is designed to meet these demands head-on. With IRGAFLO® 1050 V, a wide range of automotive gear lubricants such as SAE J306 75W-grades (-80, -85, and -90) can be achieved using common additive packages, Group III base oil, and IRGAFLO® 649 P without the need for additional solubilizer additives. Across each example SAE formulation, the low-temperature Brookfield viscosity and the KV 100°C post- 20-hour KRL-shear met or exceeded the requirement.

Tackling the EV powertrain with IRGAFLO® 1050 V

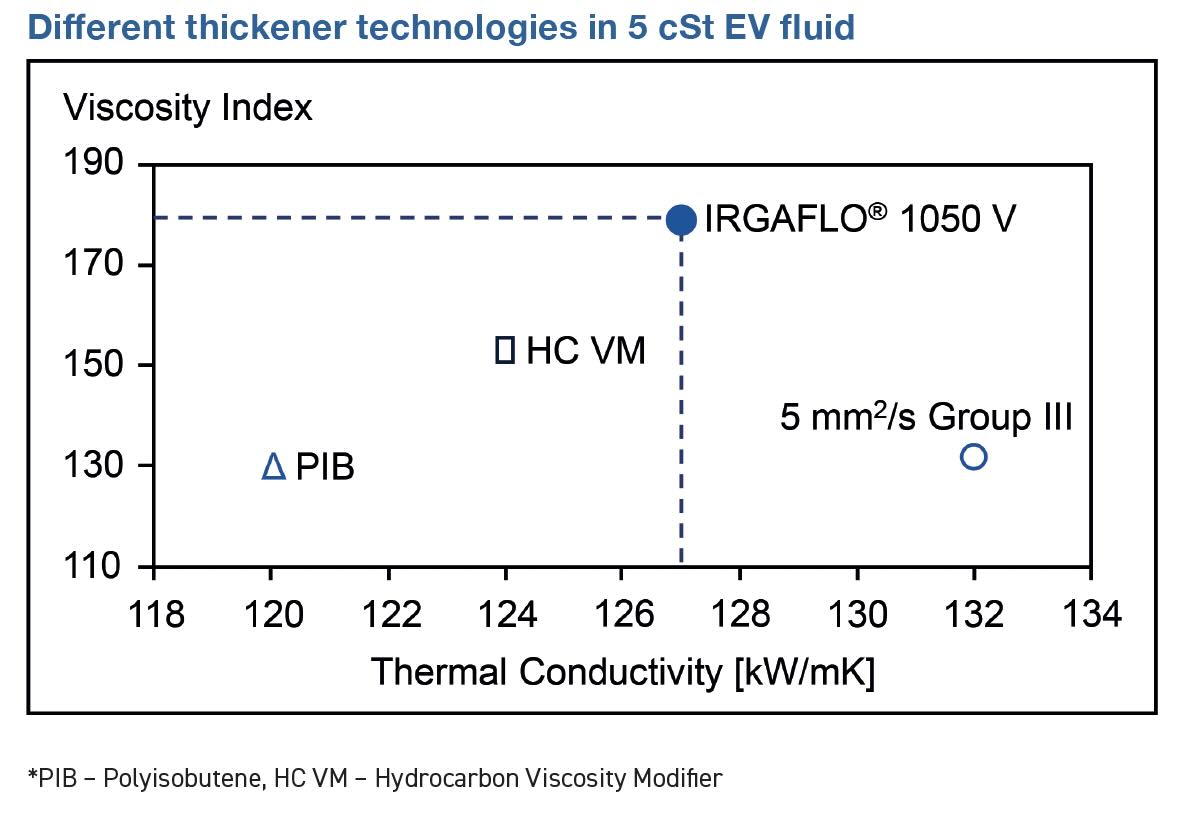

The worldwide need to reduce greenhouse gases such as CO2 is pushing the transportation sector to electrification of drivetrains. Hybrid and fully electric drivetrains still require proper lubrication as their conventional counterparts. Two additional e-features have crystallized in recent years, lower viscosities, 5 cSt or lower at 100°C, and an excellent ability to remove heat. Besides the obvious advantage of higher mechanical efficiency which translates into higher driving ranges of electrified vehicles, ultra-low viscosity plays a crucial role for heat removal. The second critical factor in heat removal is the thermal conductivity of the fluid. Here, IRGAFLO® 1050 V shows the most balanced performance when formulating low viscosity e-driveline fluids. When formulated in a 3 cSt Group III base oil, IRGAFLO® 1050 V delivers the highest VI and highest thermal conductivity among all polymeric thickeners. It also shows exceptional low temperature properties with a measured pour point of -57 °C. Lastly, the use of VI improvers with intrinsic polarity like IRGAFLO® 1050 V can lead to benefits in frictional properties. In this case, IRGAFLO® 1050 V shows lower coefficients of friction than a respective PIB-formulation and similar friction as the respective PAO and HC VM formulations. This makes IRGAFLO® 1050 V an ideal choice for EVs.

Building a sustainable future

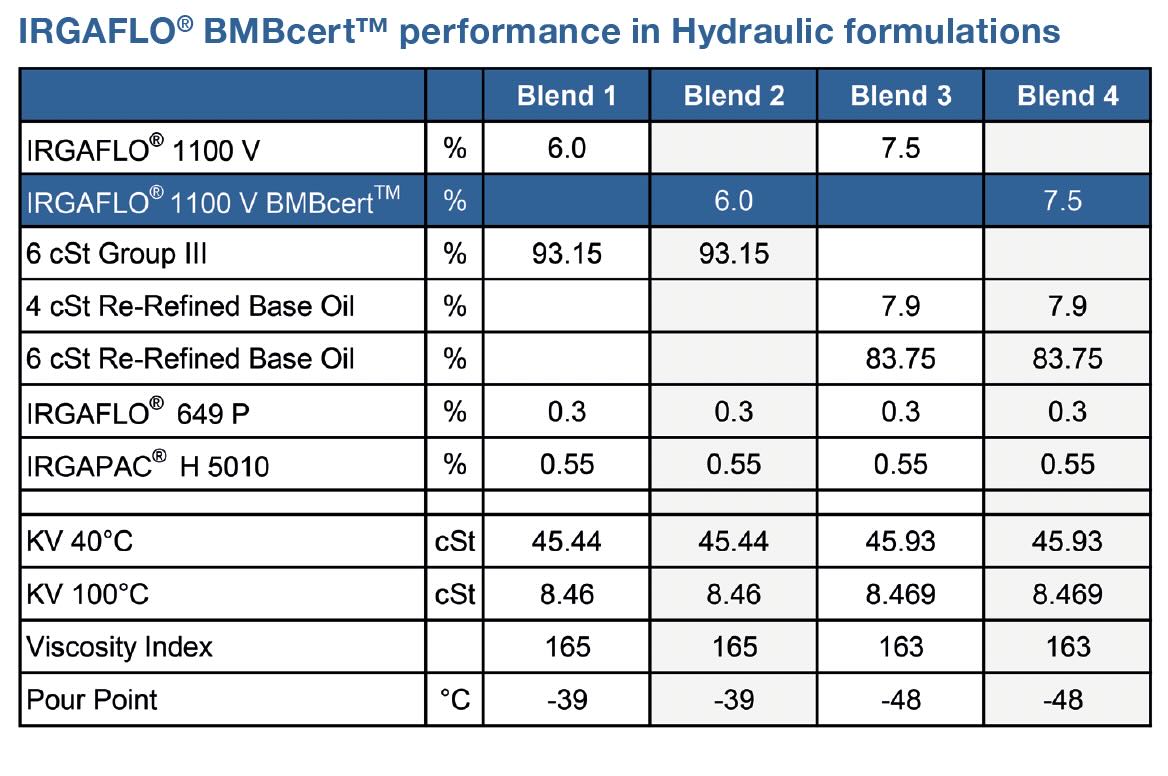

The advanced performance of today’s lubricants is now only one part of the sustainability equation. Thinking beyond fuel efficiency and taking it one step further, BASF offers IRGAFLO® BMBcertTM series as another pivotal tool in moving the lubricants industry forward. These products offer the same high performance as their non-BMBcertTM counterpart, with the added benefit of a lower carbon footprint. In the case of IRGAFLO® 1100 V BMBcertTM, it offers the equivalent thickening efficiency and high VI boosting behavior compared to IRGAFLO® 1100 V across hydraulic formulations. All of which translates to more efficient fluid performance, but with the BMBcertTM products, a significant reduction in the product carbon footprint (PCF) is achieved. This can be applied to both traditionally refined base oil and re-refined base oil. With this approach, customers are given formulation flexibility, (no need to re-qualify if using the existing IRGAFLO® product) to reach their sustainability goals and differentiate themselves from competition. BMBcertTM is available globally in multiple product groups, and it can be expanded to others within our lubricant components portfolio to meet a customer request.

Conclusions

IRGAFLO® 1050 V is a new shear stable VI improver designed to meet the demands of automotive and heavy-duty gear oil and EV transmission. BASF continues to expand its BMBcert™ products to offer low PCF solutions and support the industry’s move towards carbon neutrality.