Afton Chemical Corporation

Re-think, Re-define, Re-refine: Formulating Solutions for the Future

Introduction by by Alyson Wilson, Marketing Manager-Industrial, Afton Chemical Corporation | TLT CMF Plus November 2024

Article by Dr. Joel Garett, Senior Vice President, and Mr. Leslie Quirós, Marketing Director, Saftey-Kleen

Introduction

The increasing demand for sustainable solutions has the industry looking for choices. The right choice for producers, blenders, and organizations starts with rethinking reliability, redefining quality, and taking a closer look at the sustainability benefits of re-refined base oils. In this article, Afton Chemical’s 2024 Key Driver Seminar partner, Safety-Kleen, provides a closer look at re-refined base oils. Mr. Quirós and Dr. Garrett will also discuss the role re-refined base oils play in corporate ESG goals and how thoughtfully chosen formulations can deliver better quality, reliability, and sustainability.

For decades, Safety-Kleen has helped realize oil’s remarkable capacity to be collected, re-refined, and reused infinitely. The results are base oils and finished lubricants of equal to or better quality than lubricants made from virgin crude oil. Using a proprietary, state-of-the-art closed-loop process, Safety-Kleen provides sustainable solutions through the formulation, manufacturing, and packaging of high-quality lubricants to meet the oil and lubricant needs of customers across North America.

As the largest collector of used motor oil and producer of re-refined base oils in the world, Safety-Kleen is educating, disrupting, and cementing its place in the industry.

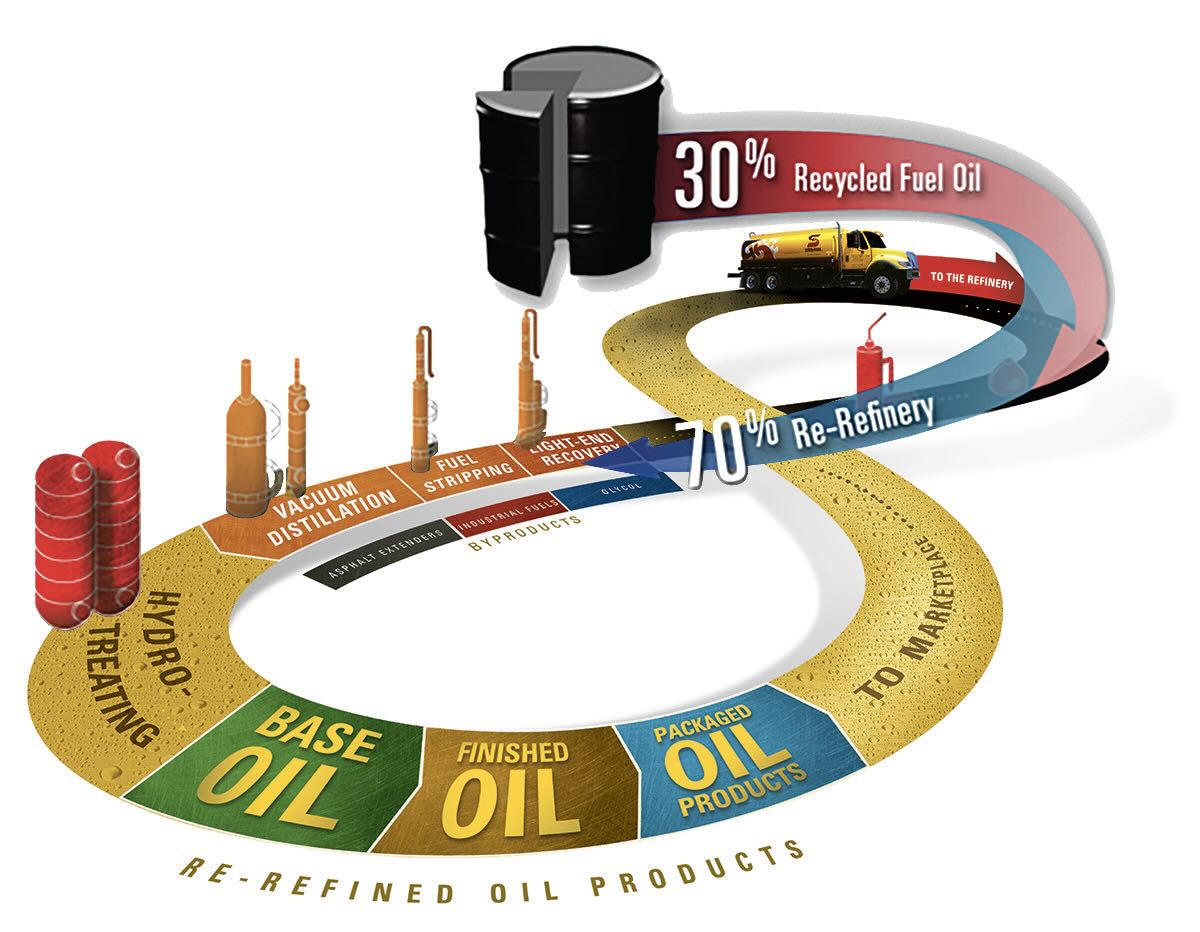

Verified Quality

Education: For years, there has been misinformation and a misconception that re-refined base oils are the same as recycled oils and lag in quality. Safety-Kleen has turned that outdated thinking on its head. While recycled oils exist in the industry, re-refined base oils are not the same thing, and that is why Safety-Kleen and smaller and new re-refiners alike have aligned to educate the public. The strength of our feedstock quality, as well as our world-class manufacturing and process enhancements made over four decades, has resulted in our KLEEN+ line of base oils, which have been proven to be technologically superior and of greater quality than many base oils derived from crude. Using complex distillation and hydrotreating processes, our proprietary processing produces base oils that are more resistant to heat or breakdown, leading to better lubricating performance. KLEEN+ base oils are used to produce finished lubricants that perform better than traditional petroleum-based lubricants. By collecting and re-refining used oil that has already been refined, Safety-Kleen closes the loop for the life cycle of oil, setting us apart from other base oil producers, all while minimizing the environmental impacts of our industries.

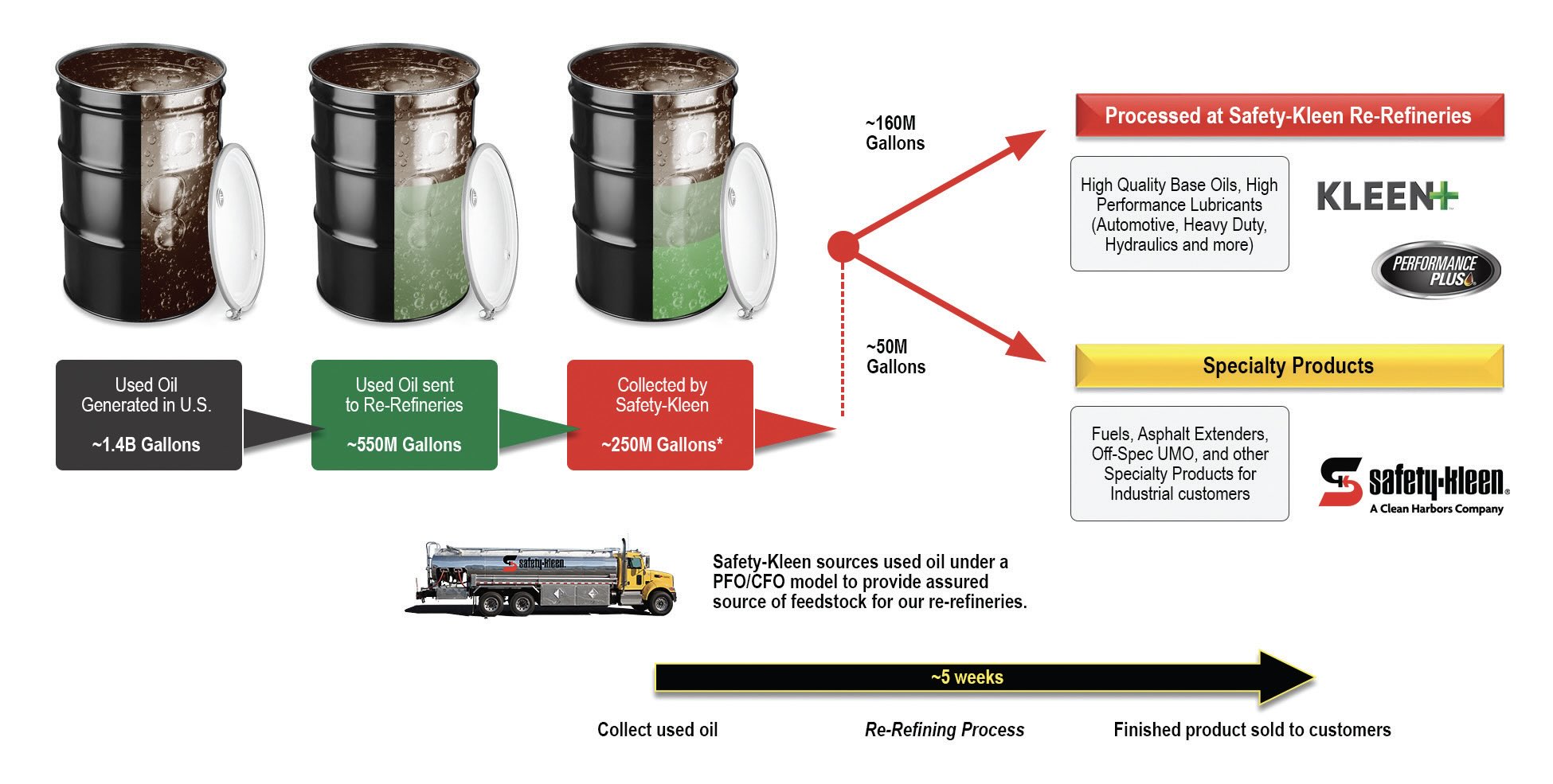

Of the 1.4 billion gallons of used oil generated in the United States, approximately 550 million gallons are sent to re-refineries. Safety-Kleen collects approximately 250 million gallons (45%) of that used oil.

Every gallon of used oil is extensively profiled at our oil terminals. Approximately 40 million gallons of water and contaminants are removed and properly recycled or discarded before being introduced into our re-refining network. From there, our stringent requirements and advanced processes separate another 50 million gallons, which do not meet our standards for base oil feedstock and are used in other Specialty products such as fuels, asphalt extenders, and other products for industrial customers. This leaves approximately 160 million gallons, which are hydrotreated and further processed to generate the four different oil grades we provide to the market today.

Safety-Kleen’s commitment to quality is the driving force behind the stringent processes used to produce high-quality, environmentally responsible re-refined base oils used to manufacture superior finished lubricants and by-products that return to the market.

Disruption: Re-refined base oils can be used in every sector, but are primarily used in the automotive, industrial, heavy duty, and agriculture. The benefits of using quality re-refined base oils have no bounds and have been found to be more reliable and of the same or better quality than those derived from crude. Unlike virgin crude oil, re-refined base oils offer a sustainable solution to renew and reuse a natural resource.

Re-refined base oils can be used to produce automotive engine oils, transmission fluids, gear oils, heavy-duty motor oils, driveline fluids, hydraulic fluids, and industrial lubricants (EP gear oils, process oils, way oils, greases, and more). For years, Safety-Kleen has offered three different cuts of KLEEN+ base oil: RHT-70 (very light and often used as a cutter stock), RHT-120 (light and primarily used to produce passenger car engine oils and light hydraulics), and RHT-240 (heavy and used for heavy-duty diesel engine oils and hydraulic fluids). As a part of Safety-Kleen’s commitment to quality and innovation, that offering now includes KLEEN+ RST4 – a full synthetic Group III base oil created to produce high quality, full synthetic products that offer unparalleled quality, unmatched reliability, and unimaginable sustainability.

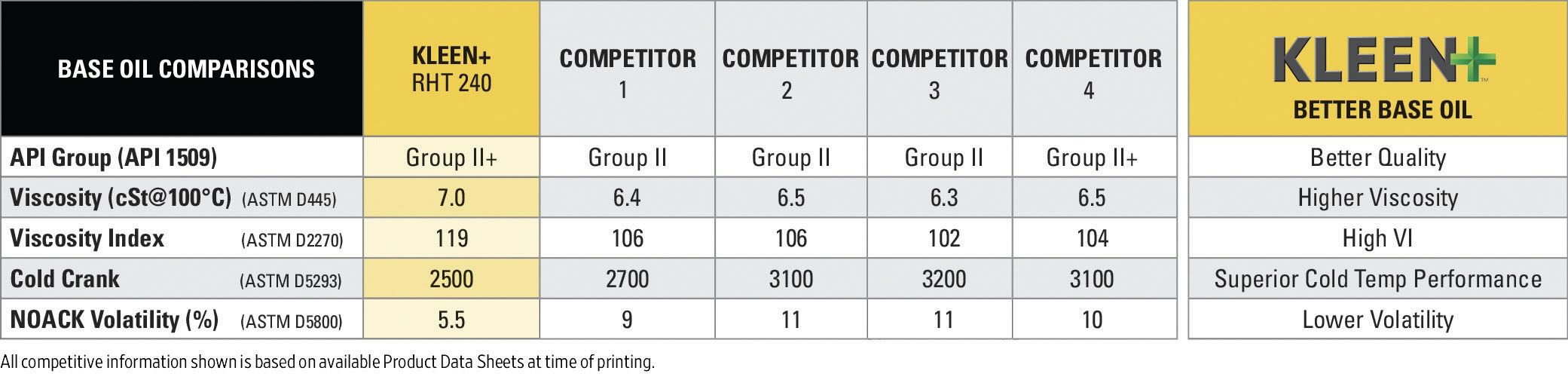

Even as technology changes, one constant remains - better finished lubricants are made using better base oils, especially when combined, tested, and validated with the best additives. KLEEN+ base oils are Group II+ and Group III base oils that achieve the balancing act of low volatility and cold temperature performance. This engineering feat enables our customers to meet performance objectives, lower blending costs, and eliminate corrector stock issues. Compared to other Group II and Group II+ base oils, KLEEN+ RHT 240 offers higher viscosity, higher viscosity index (VI), superior cold temperature performance, and lower volatility.

While quality has been proven and continues to set Safety-Kleen apart, the reliability and sustainability offered are trusted by over 350,000 customers who have turned to Safety-Kleen for our KLEEN+ base oils and Performance Plus® lubricants.

Safety-Kleen has a larger national network and greater commitment to sustainability than any manufacturer or traditional distributor of finished lubricants. This commitment has led Fortune 500 companies with Sustainability Initiatives and Goals to demand a sustainable solution without sacrificing quality, power, performance, or protection. KLEEN+ base oils are that solution as they offer a superior balance between low volatility, cold temperature performance, and oxidative stability — all while being better for the environment.

In 2023 alone, it is estimated that Safety-Kleen’s closed-loop process avoided more than 1.9 million metric tons of greenhouse gas emissions for our customers - equivalent to the greenhouse gas emissions avoided by planting 32 million tree seedlings grown for 10 years.

Verified Sustainability

KLEEN+ base oils have redefined how fleets and companies of all sizes look at base oils and finished lubricants. They have been proven to play a significant role in corporate sustainability since they are produced using less energy and lessen the use of the world’s natural resources, all while lowering their dependence on foreign oil.

Safety-Kleen’s proprietary closed-loop process significantly reduces greenhouse gas emissions.

Every gallon of KLEEN+ base oil avoids 10.06 kilograms of greenhouse gases or carbon dioxide equivalent (CO2e) compared to a conventional crude extracted and equivalent product. This avoidance reflects a 78% reduction in greenhouse gas emissions compared to base oils derived from crude oil. Key reasons for the lower carbon footprint of KLEEN+ base oils are lack of disposal via combustion (waste management) and lower total energy needed to process used motor oil into re-refined base oil compared to the energy required to process crude oil into base oil.

An independent study by Ramboll, an independent and globally recognized environmental consulting firm, verified the results as shown in a Life Cycle Assessment (LCA). This LCA analyzed the carbon product footprint of KLEEN+, and the results allow Safety-Kleen to provide GHG Avoidance Certificates to customers to support the avoided CO2e achieved when using KLEEN+ base oils or finished products formulated with KLEEN+. The assessment was performed in accordance with the more rigorous and globally accepted ISO 14040, 14044, and 14067 standards to provide consistency, transparency, and comparability. You can learn more about the independent LCA by visiting safety-kleen/kleenplus.

“KLEEN+ represents the ideal mixture of quality and sustainability. We are redefining the quality standards and expectations of re-refined base oils,” said Senior VP of Safety-Kleen Oil, Dr. Joel Garrett. “KLEEN+ base oils not only extend the life of engines and equipment, but they also reduce the carbon footprint for end users. This combination is the most advanced solution in the lubrication industry today, and the results are quality, reliable, and sustainable automotive oils, heavy-duty lubricants, and hydraulic fluids.”