HIGHLIGHTS

•

A new method for producing wind turbine blades uses a robot that is able to conduct postprocessing.

•

The robot successfully trimmed flashing leftover from bonding, grinding and sanding.

•

Potentially, scaling up this process so that robots can conduct postprocessing more efficiently will hopefully not sacrifice quality and reduce production costs.

The manufacturing sector has turned to robots to improve not only productivity but because of the lack of available labor. Advances in robot intelligence have led to their growing use not just to do mundane tasks but to become partners with those working with them in manufacturing facilities.

One approach in designing robots is to have them emulate the way animal act, work and function. In a previous TLT article,

1 research detailing the preparation of a lionfish-inspired robot was discussed. This robot is powered through the use of a redox flow battery that contained a liquid catholyte and a solid anode. Two pumps, powered by the battery, were used to move the pectoral fin and tail of the lionfish-inspired robot. In this fashion, the redox flow battery acted as an electrolyte hydraulic system. This initial effort resulted in the robot generating an energy density of 124 watt hours per liter with an average discharge voltage of 1.00 V.

Wind turbine blades are essential in generating power as they function in a similar manner to airplane wings or helicopter rotors in facilitating the conversion of wind energy into electricity. To achieve maximum efficiency, wind turbines need to be produced meticulously to ensure each blade produced meets the required specifications.

Wind turbine blades are produced by bonding the high pressure half with the low pressure half to form a seam. Hunter Huth, robotics engineer at the National Renewable Energy Laboratory (NREL) in Golden, Colo., says, “The upwind side of the seam is the leading edge and has a high curvature, and the downwind side of the seam is the trailing edge that comes to a sharp point. The shape of these areas is critical for the aerodynamics of the blade.”

Wind turbine blades are prepared from glass fiber reinforced composites based on an epoxy or polyester matrix. Once the seam is formed, postprocessing operations including trimming flashing leftover from the bonding process, grinding to achieve the desired aerofoil shape, sanding and painting are needed to complete the manufacture of the wind turbine blade.

Huth says, “With wind turbine lengths regularly exceeding 100 meters, these postprocessing operations require a team of individuals that must conduct intensive work that takes one day of time to produce the finished blade. In doing these operations, work is done at height on scaffolding where individuals must wear full high density polyethylene suits to protect themselves from composite dust that is generated.”

Due to the severe operating conditions, developing automation to do postprocessing seems to be a logical strategy if the right type can be found. Huth says, “Standard automation using preprogrammed paths lacks the flexibility needed because of the large size of the wind turbine blades. With the high capital investment being a significant barrier, a robot that can increase the number of wind turbine blades produced in a given time frame, reduce cost and not sacrifice quality is required.”

Such an approach has now been developed.

KRC4 robot controller

The researchers used a robot that utilized a KRC4 controller, which is a system that can integrate movement with operations that are conducted with a computerized numerical control (CNC) machine typically used in working on metals and plastics. Huth says, “The automation used was not intended to interact with individuals in the manner of a cobot but for high throughput in manufacturing finished wind turbine blades efficiently, safely and at a lower cost.”

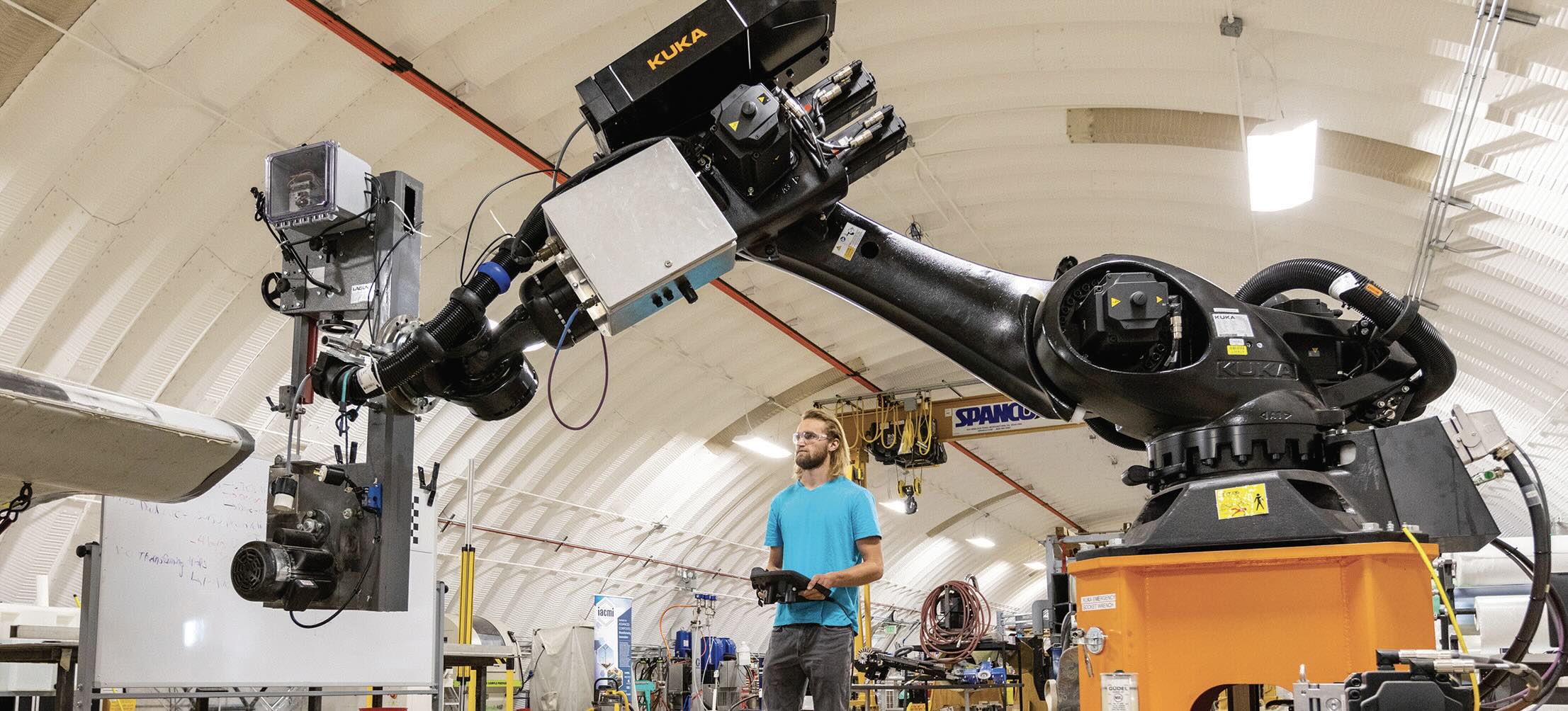

Figure 3 shows an image of the robot used.

Figure 3. A robot that utilized a KRC4 controller was programmed to be able to effectively conduct three postprocessing steps required in the manufacture of wind turbine blades. Figure courtesy of the National Renewable Energy Laboratory.

Figure 3. A robot that utilized a KRC4 controller was programmed to be able to effectively conduct three postprocessing steps required in the manufacture of wind turbine blades. Figure courtesy of the National Renewable Energy Laboratory.

In the trimming operation, the robot is equipped with a custom band saw that was designed to be mounted to the robot. The toolpath used by the saw was set up to efficiently remove flashing that is left over from the bonding process. Tool speeds were adjusted to account for straight cuts and curved cuts for removing the hanging flashing from the wind turbine blade.

The grinding process did not achieve the desired-leading edge shape. Huth says, “The robot was not able to produce the desired-leading edge shape. We found inconsistency with the band gap partly due to the presence of glue and fiberglass on the surface of the blade that was left over from the trimming process. In some areas, too much material was removed leaving layers of fiberglass material exposed while creating depressions.”

Sanding used a black sandable primer to cover the leading and trailing edge. In both cases, the operation was successful in removing the desired 10 centimeters of material.

Huth indicates that the next phase is to speed up the three postprocessing steps by having the robot use an algorithm to see the surface, identify features and then use the proper tool to complete the operation. He says, “We also are considering having one robot do each of the three operations instead of having a robot do the three processes sequentially.”

Concurrently, a comprehensive techno-economic model (TEM) is under development to assess the labor costs, capital costs and production rates with the ultimate objective to ascertain the commercial viability of using robots in wind turbine blade production. Huth says, “This goal is challenging because each manufacturer has a different design, but we are working to enable the robot to be able to accomplish the three tasks regardless of the type of blade and to also attain the desired return on investment.”

Additional information can be found in a recent article

2 or by contacting Huth at

hunter.huth@nrel.org.

REFERENCES

1.

Canter, N. (2019), “Robot powered by hydraulic/energy storage system,” TLT, 75 (10), pp. 12-13. Available

here.

2.

Huth, H., Nichols, C., Lambert, S., Sindler, P., Berry, D., Barnes, D., Beach, R., Sabet, S. and Snowberg, D. (2024), “Toolpath generation for automated wind turbine blade finishing operations,”

Wind Energy, 27 (8), pp. 816-826.