•

For sustainability reasons, improving the ability to store hydrogen underground will expedite the ability to use this gas to decarbonize industrial and transportation applications.

•

A new study evaluated the ability to store hydrogen in samples taken from the Duvernay Shale, an oil and natural gas formation located in Alberta, Canada, and in Berea Sandstone located in five U.S. states.

•

Hydrogen displayed better adsorption in shale due to this material’s smaller pore size compared to sandstone.

Concern about global warming is leading to devising approaches for reducing carbon dioxide emissions. One strategy is to literally extract carbon dioxide from the atmosphere or capture it from industrial processes and sequester it in underground reservoirs.

In a recent TLT article,

1 sorbents were evaluated as candidates to extract carbon dioxide from air. Sorbents function by taking advantage of differences in water concentration at different times of the day. During daylight hours, moisture levels are low making conditions favorable for carbon dioxide capture. At nighttime, humidity levels rise creating conditions for the sorbent to release carbon dioxide. Evaluation of a series of anions was conducted. Those anions with more than one negative charge demonstrate superior performance in capturing and releasing carbon dioxide.

While a good deal of attention has been placed on carbon dioxide capture, research is underway to evaluate the feasibility of subsurface storage of hydrogen. From a sustainability standpoint, increasing the availability of hydrogen through production and underground storage will expedite the ability for this gas to be used to decarbonize industrial and transportation applications.

Dr. Tuan Ho, a chemical engineer at Sandia National Laboratories in Albuquerque, N.M., says, “Storing hydrogen underground is feasible as long as conditions are present that minimize hydrogen loss due to reaction adsorption and diffusion through earth materials. Adsorption is a very important parameter to study because if hydrogen does not desorb when pressure is reduced, then a high figure will mean that hydrogen stored underground will not be available for use at a later date. Diffusion is possible through pores and cracks in earth materials. One benefit of storing hydrogen as compared to natural gas (methane) or carbon dioxide is that leaks can be burned, producing only water, thus avoiding environmental impacts. Of concern is determining how extensively hydrogen can embrittle earth materials, which may accelerate crack formation.”

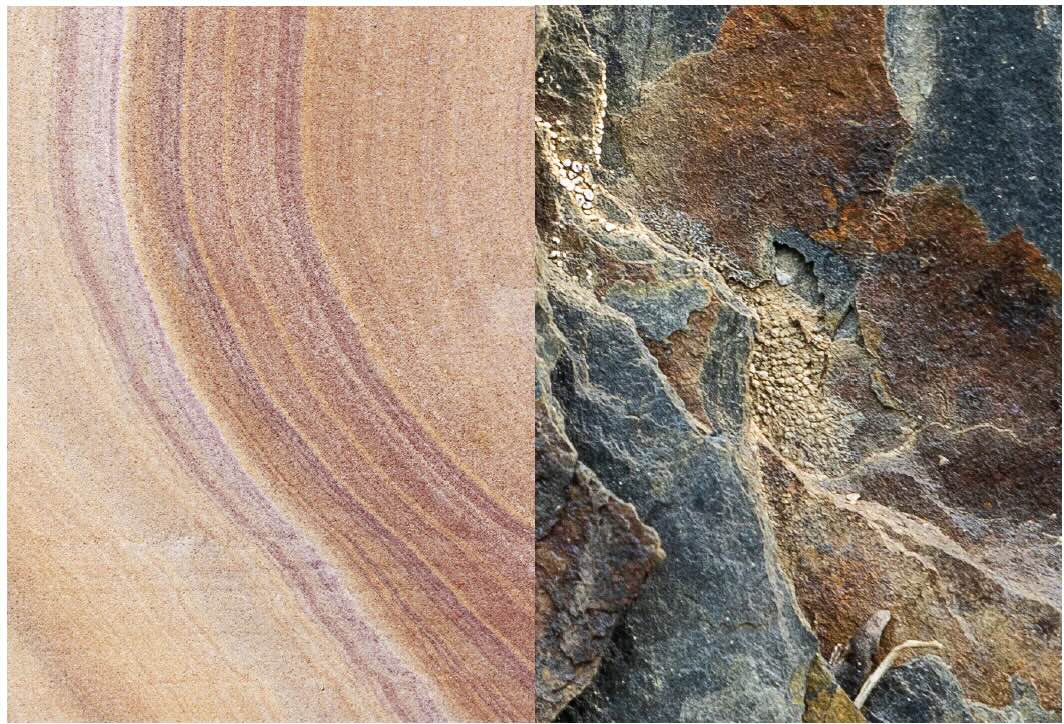

Sandstone (left) and shale (right) are two earth materials that are under evaluation for storing hydrogen gas underground.

Sandstone (left) and shale (right) are two earth materials that are under evaluation for storing hydrogen gas underground.

Ho points out that earth materials are not homogeneous but consist of a range of organic and inorganic components. He says, “Hydrogen may chemically react with some of these species. For example, there is the possibility hydrogen may react with pyrite (FeS

2) and produce toxic hydrogen sulfide. Another issue is the possibility of microbial activity in underground storage areas, which consumes hydrogen, leading to its loss.”

To assess the stability of hydrogen underground, Ho and his colleagues used low field nuclear magnetic resonance (NMR) to evaluate the potential for hydrogen to adsorb on two earth materials, sandstone and shale.

Kerogen

The researchers pumped hydrogen into a specialized zirconium oxide cell that can operate up to a pressure of 10,000 psi. Contained in the cell was a sample of either a Duvernay Shale or a Berea Sandstone. Duvernay Shale is an oil and natural gas formation located in Alberta, Canada. Berea is a formation located in the states of Kentucky, Michigan, Ohio, Pennsylvania and West Virginia. The temperature of all of the experiments was maintained at 300°K.

Figure 3 shows the setup for the gas adsorption system.

Figure 3. Evaluating the ability of storing hydrogen underground is conducted by using the gas adsorption system shown in the fume hood. Figure courtesy of Craig Fritz, Sandia National Laboratories.

Figure 3. Evaluating the ability of storing hydrogen underground is conducted by using the gas adsorption system shown in the fume hood. Figure courtesy of Craig Fritz, Sandia National Laboratories.

Measurement of transverse relaxation time (T

2) during the NMR experiments proved to be very useful in evaluating the adsorption of hydrogen on both earth materials. As a control, hydrogen performance also was measured in the absence of both earth materials.

Ho says, “The relaxation distribution for hydrogen in the presence of sandstone under pressures ranging from 300 to 5,000 psi produced one peak that is characteristic of the gas in its free form. In contrast, two peaks were observed in the NMR spectrum for hydrogen stored in the presence of shale. One peak represents free hydrogen while the second peak was attributed to adsorbed hydrogen.”

The experiments with shale indicate that as much as 10% of sorbed hydrogen in shale may be lost. No such loss was observed with sandstone. Hydrogen’s greater adsorption is probably due to the smaller pore size of shale compared to sandstone.

Modeling studies were carried out with the organic matter kerogen. Ho explains, “Shale is an earth material that consists of many different minerals including kerogen. This high molecular weight organic material is insoluble in most common organic solvents and found in sedimentary rock. Kerogen was formed from a number of organic precursors such as plants, and algae that have been heated and compressed by geological processes over millions of years.”

The researchers included methane in the study because of its potential presence in underground storage environments that previously contained natural gas. Modeling scenarios that were examined included pure hydrogen or methane, a 1:1 binary mixture of two gases and methane under a constant partial pressure of 44 psi.

Ho says, “Methane was found to display much higher adsorption on kerogen than hydrogen. This was due to methane’s stronger interactions with kerogen. While this suggests that hydrogen gas can be stored in shale, there is still the possibility that as much as 30% residual methane leftover in a depleted gas reservoir could contaminate hydrogen when the latter is injected.”

This study provides guidelines for how to evaluate whether a specific underground storage area previously holding natural gas may be suitable for maintaining hydrogen. Ho says, “We will be determining the interaction of free hydrogen with crude oil. In addition, the individual minerals present in shale will be characterized for their affinity to adsorb hydrogen.”

Additional information can be found in a recent article

2 or by contacting Ho at

taho@sandia.gov.

REFERENCES

1.

Canter, N. (2024), “Direct air carbon capture,” TLT,

80 (3), pp. 18-19. Available

here.

2.

Ho, T., Dang, S., Dasgupta, N., Choudhary, A., Rai, C. and Wang, Y. (2024), “Nuclear magnetic resonance and molecular simulation study of H

2 and CH

4 adsorption onto shale and sandstone for hydrogen geological storage,”

International Journal of Hydrogen Energy, 51 (Part A), pp. 158-166.