HIGHLIGHTS

•

Non-Newtonian fluids exhibit a change in viscosity when stressed.

•

The root cause for how thickening occurs under shear is due to frictional particle-particle interactions.

•

Particle-particle interactions were identified by suspending piezoelectric nanoparticles in the viscous liquid glycerol.

Friction is a key property that we tribologists deal with in everyday applications. The objective is to minimize it in most cases. Most of the frictional effects that are encountered occur at the macroscale, but when two surfaces interact with each other, atomic-scale friction must be present. As atoms are interacting with each other, the results of this process will determine the magnitude of friction created that will become evident on the macroscale.

In a past TLT article

1 atomic-scale friction was visualized for the first time through the use of a technique known as

in situ transmission electron microscopy. An electrochemically etched tungsten probe side-tip made contact with a tungsten substrate. Asperities from the two surfaces slide past each other and were then separated by controlling the lateral and longitudinal movement of the probe. This resulted in the visualization of real-time friction that showed a zig-zag sliding pathway as atoms from the two surfaces interacted with each other.

The behavior of most fluids (including lubricants) is Newtonian in nature, which means that the fluid’s viscosity does not change once stress is applied. But there are fluids such as greases that do exhibit a change in viscosity when stressed. Dr. Hojin Kim, postdoctoral scholar in the Pritzker School of Molecular Engineering (PME) at the University of Chicago in Chicago, Ill., says, “Non-Newtonian fluids are quite intriguing because they can be very flowable when untouched but then assume a solid nature when sheared.”

As an example, mixing corn starch with water at the right ratio will produce a dense suspension known as an oobleck that exhibits liquidity when untouched but will quickly stiffen due to an increase in viscosity after being subjected to shear. Researchers have speculated on the origin of this phenomenon at the atomic scale and originally felt that the cause was due to fluid-mediated lubrication forces. More recently simulations have directed researchers to believe that frictional particle-particle contacts are the reason for this sudden increase in viscosity.

Kim says, “Determining the nature of frictional particle-particle contacts has proven to be very difficult to determine. Conducting experiments in dense suspensions with many particles crowded into a small space is very challenging to do.”

Attempts have been made through the use of particle center-to-center spacing, microscopy imaging and extracting information from particle center-to-center spacing. Besides suspensions, work has been done unsuccessfully with emulsions and larger hydrogel particles.

Kim and his colleagues in the University of Chicago’s PME, Stuart Rowan, the Barry L. MacLean Professor, and Aaron Esser-Kahn, a professor of molecular engineering, working with Heinrich Jaeger, the Sewell Avery Distinguished Service Professor of Physics, developed a new approach for studying the fundamental physics of non-Newtonian fluids and determining empirically that frictional particle-particle interactions are at the root cause for thickening under shear.

Piezoelectric nanoparticles

Kim and his colleagues determined that introducing piezoelectric nanoparticles to a dense suspension will provide an indication of the frictional particle-particle contacts that are taking place under stress. He says, “Piezoelectric particles generate an electric dipole moment that leads to the formation of charges on their surfaces when placed under pressure. The application of shear creates frictional interactions through deformation of these particles and produces electric signals that can be measured.”

The researchers suspended two types of piezoelectric nanoparticles, zinc oxide and barium titanate, in the viscous liquid glycerol at different volume fractions. Upon application of an oscillating shear to the top and bottom of the liquid suspension, the electric charge buildup was monitored by AC conductance, and the fluid’s rheological properties were measured by viscosity.

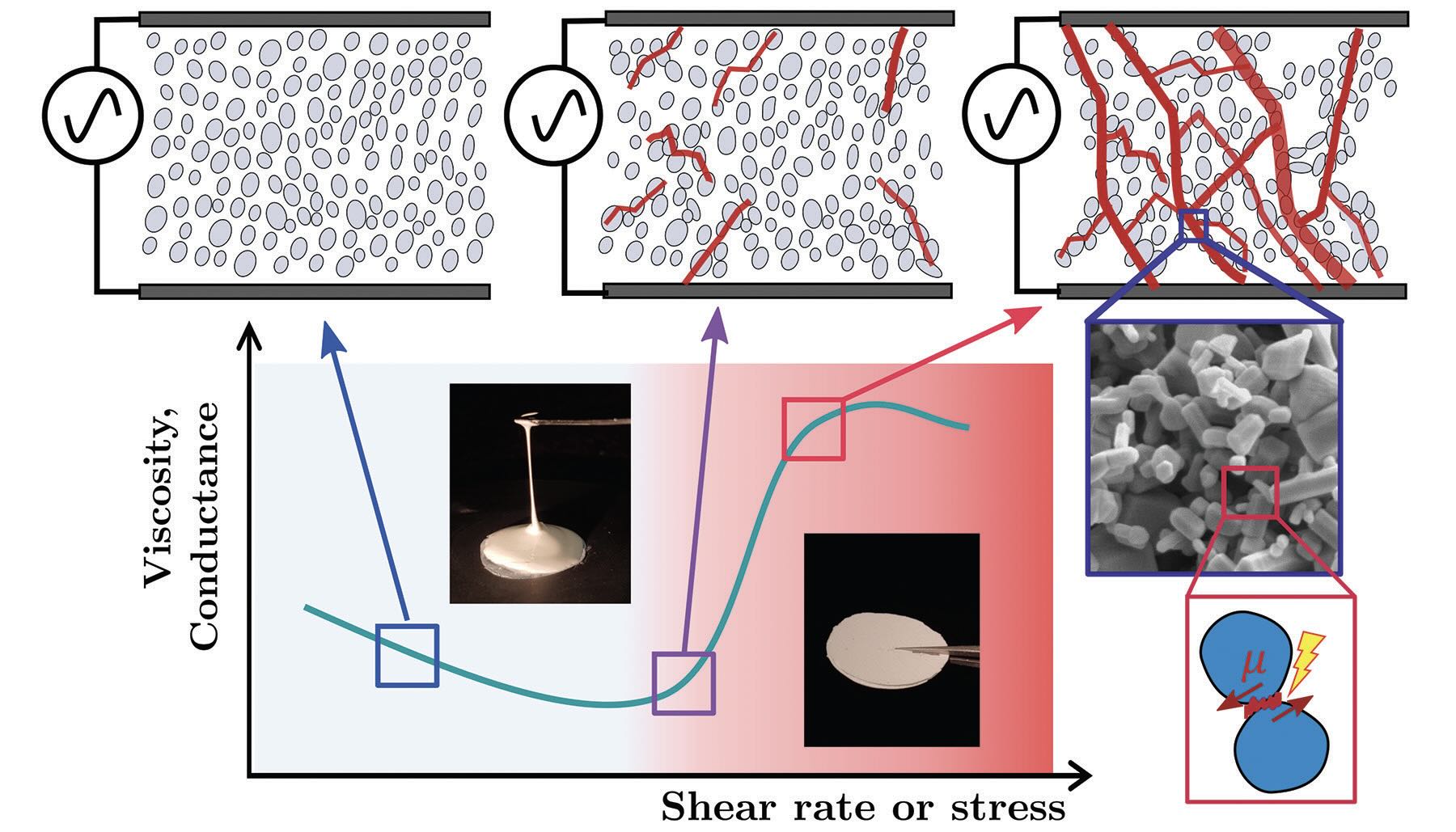

As shown in Figure 2, once the shear rate reached a certain value, weakly frictional interactions started to take place which were observed by the researchers as increases in AC conductance and viscosity. Upon further stress, a frictional network forms as the suspension becomes more viscous in nature.

Figure 2. As stress increases in a non-Newtonian fluid, frictional particle-particle interactions increase, eventually leading to the formation of a network as the fluid becomes more viscous in nature. Figure courtesy of the University of Chicago.

Figure 2. As stress increases in a non-Newtonian fluid, frictional particle-particle interactions increase, eventually leading to the formation of a network as the fluid becomes more viscous in nature. Figure courtesy of the University of Chicago.

Kim says, “We used a rheodielectric setup with two parallel plates in conducting our studies. Dynamic viscosity was measured in real-time through the top plate electrode.”

To confirm that the increase in AC conductance and viscosity is due to frictional particle-particle contacts, sodium chloride was added at a concentration of 0.1 mole per liter to a suspension of zinc oxide in glycerol. Kim says, “Sodium chloride acts to reduce repulsion between piezoelectric nanoparticles, which changes the overall rheological properties of the suspension. Once shear is applied, strong thinning of the suspension is observed. However, when the large shear force causes thickening, the frictional contact is observed.”

Further confirmation of this frictional effect among piezoelectric nanoparticles was done by conducting a polymerization. The researchers added zinc oxide to a mixture of two liquid monomers [dipentaerythritol hexakis 3-mercaptopropionate and tri(ethylene glycol) divinyl ether], which will form a crosslinked polymer.

Kim says, “The polymerization reaction was conducted for two purposes. First, we wanted to better understand that the change in AC conductance arises from the contact-induced piezoelectric response. Second, our intention was to study that the properties of the resulting solid and gelation kinetics can be tuned under varying conditions of shear.”

The researchers observed a strong correlation between the onset of piezochemical reaction kinetics and the onset of shear induced thickening.

Future work will entail adding low concentrations of piezo-electric particles to probe the onset of large local stresses in suspensions containing other particle types. A second aspect is to improve the sensitivity of measuring the frictional interactions in suspensions to better assess when thickening will initiate.

Additional information can be found in a recent paper

2 or by contacting Rowan at

stuartrowan@uchicago.edu and Jaeger at

h-jaeger@uchicago.edu.

REFERENCES

1.

Canter, N. (2022), “Visualizing atomic-scale friction,” TLT,

78 (12), pp. 20-21. Available

here.

2.

Kim, H., Kahn, A., Rowan, S., Jaeger, H. (2023), “Stress-activated friction in sheared suspensions probed with piezo-electric nanoparticles,”

Proceedings of the National Academy of Sciences, 120 (49), e2310088120.