Is understanding tribocorrosion too simple for you? Just add protein!

By Drs. Wilfred T. Tysoe & Nicholas D. Spencer, Contributing Editors | TLT Cutting Edge August 2024

Elucidating the role of proteins in the tribocorrosion mechanisms taking place in implanted CoCrMo has proven to be challenging. Some recent experiments shed light on this complex behavior.

Clearly those of us who work in tribology are not scared by complexity. But there are individuals for whom friction, wear and lubrication do not represent sufficient challenges, so they seek out intersections between the complex field of tribology and other complex phenomena, such as corrosion. This tends to multiply the degree of complication. Adding a third phenomenon, such as protein adsorption, might seem like sheer masochism. However, the resulting field of biotribocorrosion is not just an intellectual exercise but a vitally important research area for the application of metallic, sliding implants, such as those used in the knee and hip.

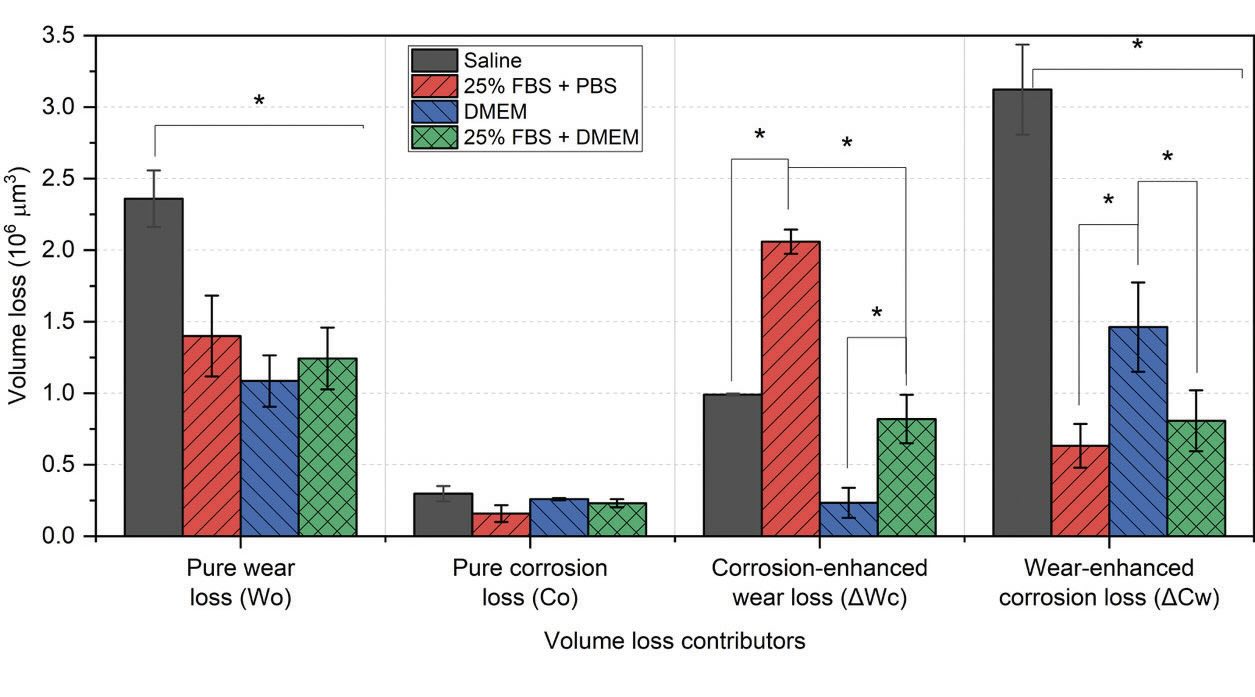

Tribocorrosion has additional complexities because of the synergies that can occur between two processes: wear-induced corrosion

(ΔCW) and corrosion-induced wear

(ΔWc). These can occur in addition to pure mechanical wear

(W0) and pure corrosion

(C0) so that the resulting total volume loss

(Vtotal) is represented by the formula:

Vtotal =

W0 +

C0 +

(ΔWc + ΔCW). (1)

The brave souls who have embarked on the saga of unraveling the biotribocorrosion mechanisms occurring with implants based on the commonly used CoCrMo alloy are Mohamad Taufiqurrakhman and Thawhid Khan at the University of Leeds (UK), together with Michael Bryant, now at the University of Birmingham (UK). Their approach

1 was to carry out reciprocating sliding experiments with an alumina ball on a CoCrMo flat, while controlling both the electrical potentials and the fluid composition. Running an experiment under open-circuit potential yielded

Vtotal, which is comparable to the real situation in the implant, where all four factors mentioned previously contribute. The pure corrosion components

(C0 + ΔCW) could be derived from the corrosion current measured during simple immersion and sliding tests, where the charge transferred is converted to volume loss via Faraday’s law. Cathodically protecting the CoCrMo during sliding by applying a negative potential switched off the corrosion to yield

W0. The remaining quantity

, ΔWc, was obtained by difference from Eq. 1. These measurements were then carried out in saline solutions (or a protein-free culture medium called DMEM) with and without the inclusion of fetal bovine serum.

The results

(see Figure 1) show that the addition of protein reduces pure (electrochemical) corrosion but significantly elevates corrosion-enhanced wear. On the other hand, the wear-enhanced corrosion was significantly reduced in the presence of protein. This leads to several interesting conclusions. First of all, the protein appears to play a role in passivating the bare metal surfaces formed by mechanical wear, thereby rapidly bridging the gap before a passivating oxide film can reform. On the other hand, the adsorption of proteins on the bare metal surface and wear debris leads to increased wear compared to a surface that is simply repassivated by oxidation, presumably due to the formation of protein-wear debris aggregates that function as third bodies, thereby increasing abrasive wear.

Figure 1. Compilation of the volume loss components over the 2-h tribocorrosion tests (n = 3; SD bar; *p < 0.05). Reproduced from Ref. 1.

Figure 1. Compilation of the volume loss components over the 2-h tribocorrosion tests (n = 3; SD bar; *p < 0.05). Reproduced from Ref. 1.

This series of elegant, relatively simple experiments has highlighted the complexity of protein involvement in tribocorrosion, while showing that the synergies between wear and corrosion can be differently affected by the presence of protein. These are the first steps in understanding a fascinatingly complex interplay of mechanisms that can occur in biological systems, which need to be better understood, in order to optimize the longevity of implanted alloys.

REFERENCE

1.

Taufiqurrakhman, M., Khan, T. and Bryant, M.G. (2024), “Investigating the roles of protein on the cobalt alloy surface degradation for biomedical implant through tribocorrosion mechanisms,”

Tribology Letters, 72, 54.

Eddy Tysoe is a distinguished professor of physical chemistry at the University of Wisconsin-Milwaukee. You can reach him at wtt@uwm.edu.

Nic Spencer is emeritus professor of surface science and technology at the ETH Zurich, Switzerland, and editor-in-chief of STLE-affiliated Tribology Letters journal. You can reach him at nspencer@ethz.ch.