Industrial and automotive gear oil tests and specifications

By Dan Holdmeyer, Contributing Editor | TLT Lubrication Fundamentals July 2024

There are specific tests used to define suitable industrial gear lubricants.

We’ve discussed typical lubricant performance tests and specifications used in addition to physical and chemical tests to determine suitable lubricants for turbine and hydraulic applications. Now let’s look at what specifications and tests are used to define suitable industrial gear lubricants before any specific OEM or segment specific tests and specifications.

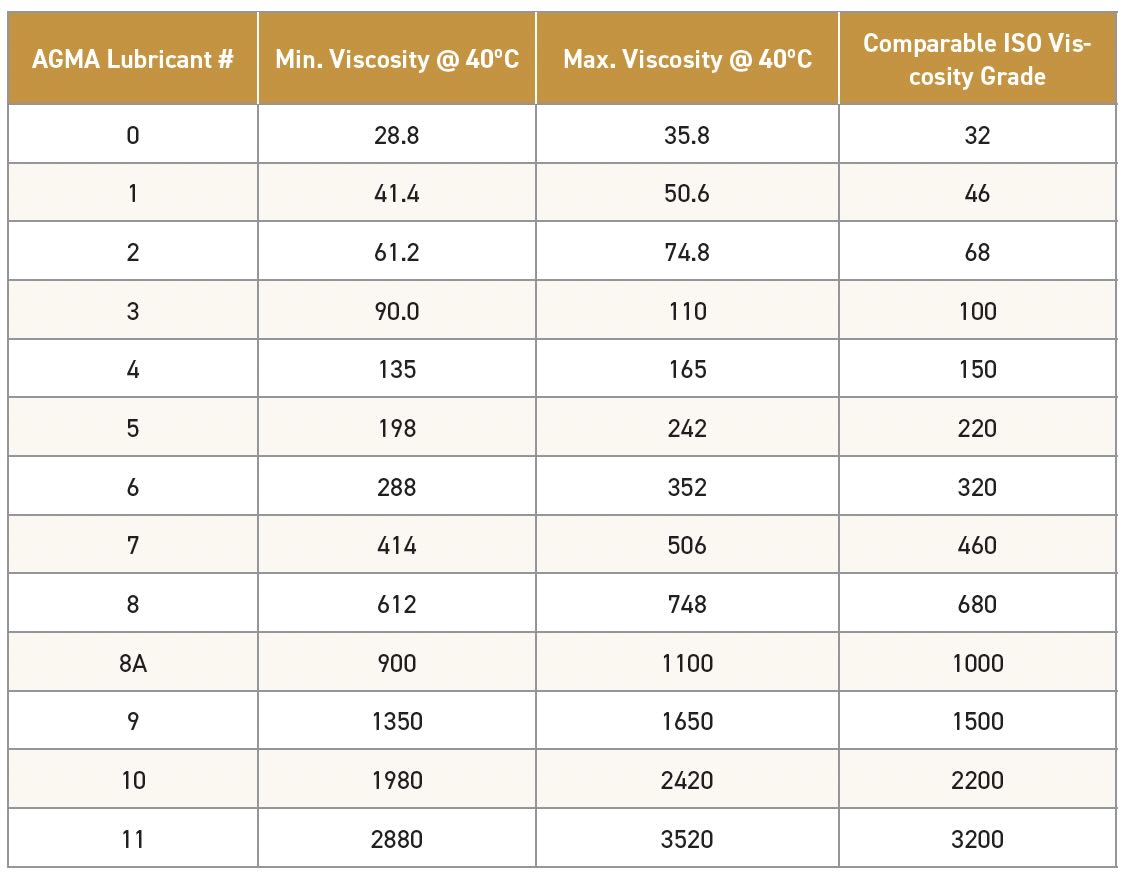

Lubricant viscosity, the most important characteristic of a lubricant for industrial gear applications, has a somewhat unique classification system established by The American Gear Manufacturers Association (AGMA). The Lubrication Committee was formed by AGMA in 1938 to study issues with gear lubrication. AGMA standards were established through the years designated as, for example, AGMA 250.xx through AGMA 251.xx. These standards were superseded by AGMA 9005-D94 where the AGMA lubricant numbers were still classified as in Table 1.

Table 1. AGMA Lubricant Number Classification

The AGMA lubricant numbers were further delineated with letter designations, most commonly EP, S and C. AGMA lubricant numbers without additional designations are inhibited (rust and oxidation inhibited) lubricants in the AGMA lubricant number viscosity range. The EP designation required specific extreme pressure additives in, and performance levels from, the lubricant within the classified viscosity range. The S designation requires the base oil to be synthetic and was first recognized in the AGMA 9005-D94 standard. This standard also no longer recommended EP oils for worm gear applications. Oils marked C are compounded with 3%-10% fatty material and frequently recommended for worm gearsets.

In late 2002 and early 2003, AGMA, along with the American National Standards Institute (ANSI), approved ANSI/AGMA 9005- E02 to supersede AGMA 9005-D94. ANSI/ AGMA 9005-E02 mentions the former AGMA grade equivalents, but switched to using the ISO viscosity grade classifications per ASTM D2422 and ISO 3448 and dropped the designations S, EP and C. In 2016, ANSI/ AGMA 9005-F16 superseded ANSI/AGMA 9005-E02. Each update incorporates updated test methods and criteria to meet current industry needs. For example, the F16 version added the FE8 rolling bearing test. Additionally, use of the term antiscuff is encouraged versus extreme pressure (EP), as EP is determined to be too general and does not adequately indicate the type of lubricant, or the type of performance required.

The ANSI/AGMA 9005-F16 standard requires specific results for many of the same performance tests we discussed previously for turbine and hydraulic applications, and some are modified for the higher viscosity fluids required in larger and more heavily loaded gears, particularly for the antiscuff oils.

The rust test (ASTM D665) part B only, copper strip corrosion (ASTM D130) and foaming sequence I/II/III (ASTM D892) are all included in ANSI/AGMA 9005-16F and are run the same, as described in the May 2024 TLT Lubrication Fundamentals article titled “Testing and specifications.”

Oxidation testing for inhibited gear oils is the same also utilizing ASTM D943, but it is likely called “resistance to aging” versus Turbine Oil Oxidation Stability Test (TOST). The required results also are much lower than for turbine oils that may reach 10,000 hours and above. Inhibited gear oils are required to pass a minimum of 1,500 hours for viscosity grades 32 to 68, 750 hours for viscosity grades 100 and 150 and 500 hours for viscosity grades 220 and 320.

Antiscuff and compounded gear oils are subjected to ASTM D2893 for measuring their “resistance to aging.” The test is run at 121ºC and reported as the percent increase in kinematic viscosity at 100ºC. The maximum increase allowed for viscosity grades 32 through 320 is 6%. Maximum percentage increases of 8, 10 and 15 are allowed for viscosity grades 320, 460 and 680, respectively.

Demulsibility, ASTM D2711, is used to determine how quickly the gear oil can separate from water that’s been driven into the oil. Water in gear oil applications is often agitated enough to emulsify in the oil, and thus this test is designed to simulate those conditions. Water contamination is common in industrial gearsets from leaky oil coolers, frequent equipment water washdowns and the gearbox breathing in humid conditions. With proper demulsibility the water can be decanted after overnight or weekend shutdowns.

Four square gear oil test, or FZG per ASTM D5182, is a test machine operated at 1,450 rpms for approximately 15 minute or 21,700 revolutions per stage. Each progressive stage’s load is increased at a prescribed rate as is the initial oil temperature. The test gear teeth are examined at the end of each stage until it is rated as a “fail” due to the amount of scuffing or scoring. This test is sometimes referred to as the FZG visual method. There are a maximum of 12 stages and the results are generally reported as the “fail stage.”

The FE8 rolling bearing test, DIN 51819- 3 (for oils, -2 is for greases), is for mechanical testing of lubricant wear protection of roller bearings in operating conditions found in heavily loaded gearboxes. The test demonstrates the lubricant’s protection against roller and raceway pitting, and for a phenomenon called white etching cracking. Wind turbine applications lead to the need for the FE8 rolling bearing test.

ANSI/AGMA 9005-F16 does not require FZG nor FE8 roller bearing testing of inhibited or compounded designated oils, just the antiscuffing designated lubricants. ANSI/AGMA 9005-F16 is a standard used by many industrial gear OEMs to indicate minimum lubricant performance to protect their equipment.

Some other antiscuffing performance tests that OEMs may require with specific performance results are common but are not included in ANSI/AGMA 9005-F16.

FZG micropitting, FVA 54/7, is a recently published standard DIN 3990-16 to measure a lubricant’s load carrying capacity to resist micropitting of the gear teeth. Micropitting on the flank of the gear teeth has been an issue particularly in wind turbine gearsets.

Following are a few other older tests still used by many OEMs to determine antiscuffing, or as called back then, EP, performance. Some consider the performance test methods required in the ANSI/AGMA 9005-F16 to more closely match real-world conditions and give better indications of a lubricant’s performance level in service.

The Falex method, ASTM D2670 or ASTM D3233, were slight variations of measuring wear protection of fluid lubricants via the “Falex Pin” rotating while squeezed between a pair of Vee Blocks submerged in the test lubricant.

The Timken OK Load test, ASTM D2782, evaluated lubricant EP properties of lubricating fluids by rotating a tapered roller bearing cup under load against a steel block submerged in the lubricant.

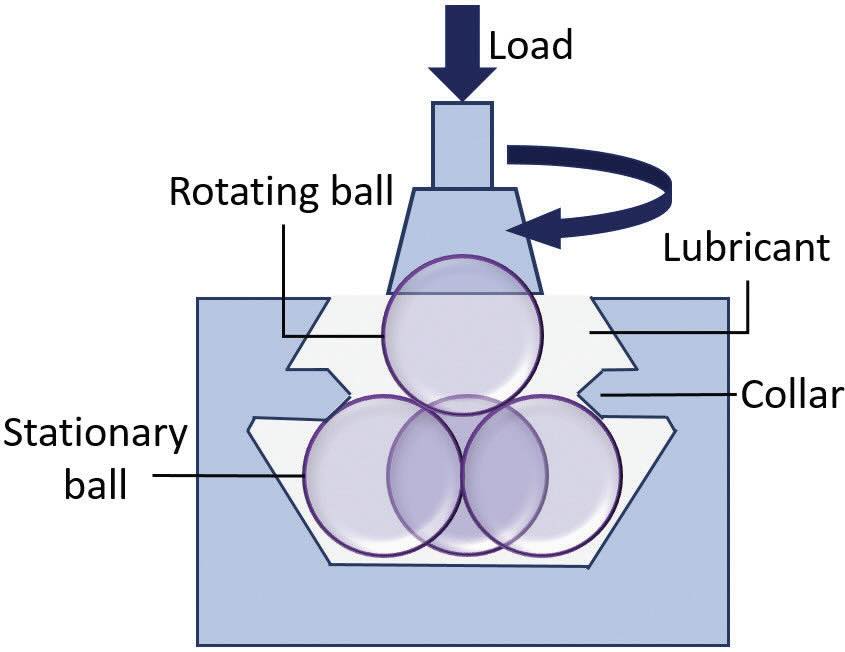

The four-ball method, load wear index ASTM D2783 and ASTM D4172, are standard test methods for determining wear protection and EP properties of a lubricant. Three steel balls are locked in the test stand. A fourth steel ball is rotated, under load, on top of the three stationary balls. This test, as well as the Falex method and the Timken OK Load test, simulates steel surfaces sliding over each other versus a rolling friction action. The four-ball method requires a series of increasing load runs where scar diameters on the steel balls are measured between each run and compared against a standard to determine wear protection a pass or fail (see Figure 1). Finally, the test is run until seizure of steel balls, or the weld point. The results are reported as load wear index and weld point.

Figure 1. Four-ball wear test. Figure courtesy of by Morshed, A., Wu, H. and Jiang, Z. (2021), “A comprehensive review of water-based nanolubricants,” Lubricants, 9 (9), 89, https://doi.org/10.3390/lubricants9090089.

Industrial lubricants are not nearly as heavily monitored and regulated as automotive gear lubricants. Therefore, looking for a few specifications for automotive gear lubricants will assure the end-user has the correct lubricant unless a specific OEM has some additional requirements specific to their product.

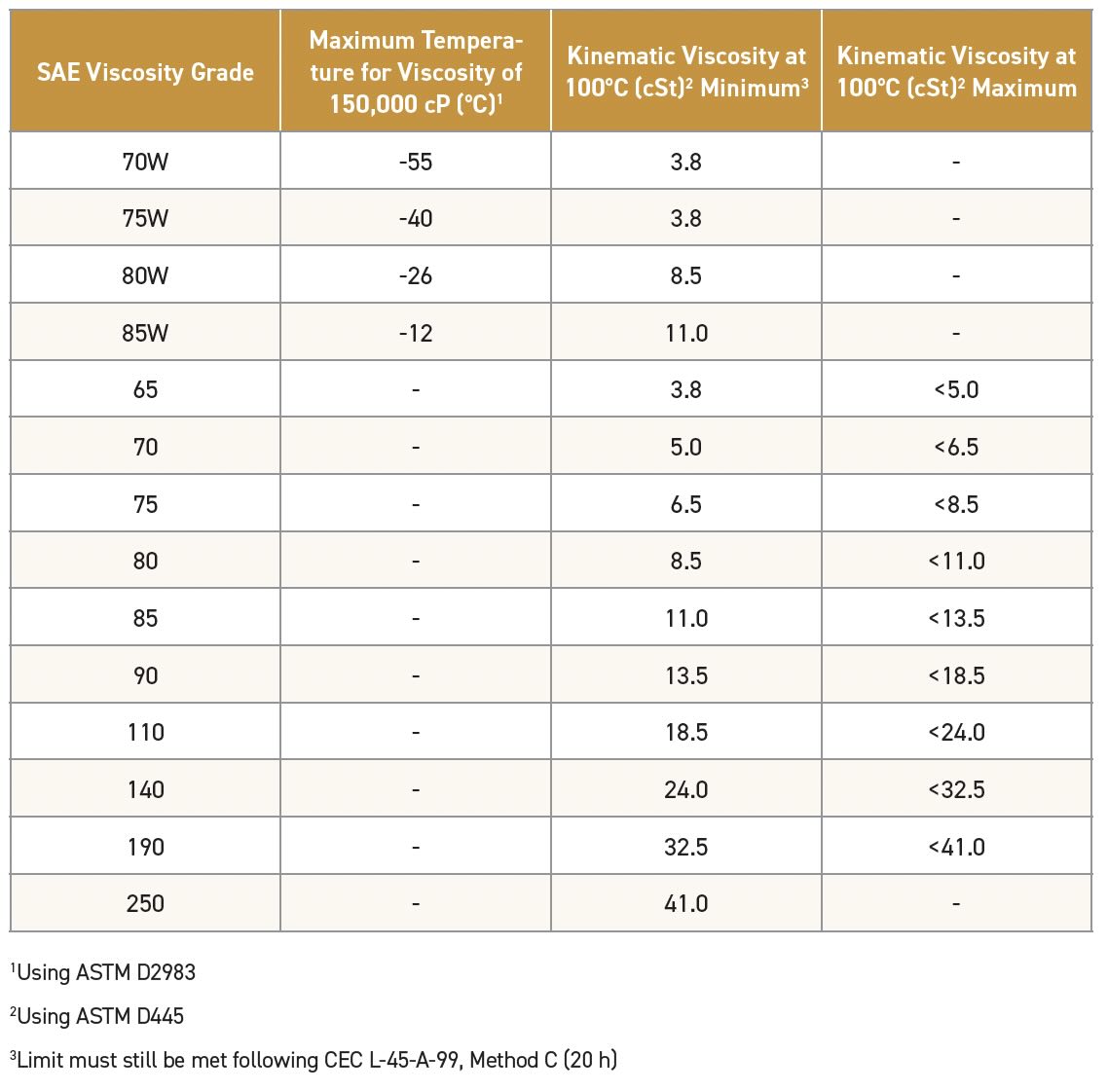

Automotive gear lubricants have unique viscosity classifications established by SAE International called SAE J306 (see Table 2). SAE J306 establishes minimum viscosities at 100ºC for each viscosity classification to protect gears and bearings at operating temperatures. It also establishes the highest temperature at which the lubricant’s viscosity does not exceed 150,000 cP per ASTM D2983. This ensures the lubricant will move and protect the gears and bearings of the unit at low temperature start-up.

Table 2. SAE J306 Standard

The differentials of rear wheel-drive vehicles are heavily loaded with a lot of sliding friction between the gear teeth requiring specific lubrication properties containing up to 6.5% antiscuff additive. The American Petroleum Institute (API) Category GL-5, ASTM D7450, was the standard for axle lubricants for years. A myriad of API GL-5 performance requirements included low-speed high-torque and high-speed shock load tests (ASTM D6121), along with other corrosion (ASTM D130 copper strip), foaming (ASTM D892) and oxidation tests for lubricant used in manual transmissions and final drive axles (ASTM D5704).

Fortunately, the performance specifications for API GL-5 are defined in the most recent version of ASTM D7450, too complex to cover completely here, but API regulates the use of the API GL-5 designation so end-users can be confident an oil with the API GL-5 designation meets the minimum requirements.

Frictional requirements for axles equipped with limited-slip differentials are normally defined by the axle manufacturer.

SAE issued SAE J2360 around 1998, although its origin dates back much further in military history. SAE felt the need for SAE J2360 to provide gears, seals and bearing better protection and improve efficiency. Some of the additional tests required by SAE J2360 are seal compatibility, oxidation/ deposit control and storage stability. Furthermore, light and heavy-duty equipment field trials are required, and the results reviewed by an independent panel of experts. If approved, then the lubricant can be listed on the Qualified Products List (QPL) for SAE J2360 for automotive differential applications. Again, any lubricant listed on the QPL for SAE J2360 does meet the minimum requirements.

Dan Holdmeyer is retired from Chevron Lubricants and is based in Washington, Mo. You can reach him at dan.holdmeyer@gmail.com.