HIGHLIGHTS

•

An electrochemical cell was developed that produces iron through reduction of iron oxide under low-temperature conditions in a chlor-iron process that is similar to the well-known chlor-alkali process.

•

When the electrochemical cell is activated, iron oxide reduction occurs at the cathode producing a film of solid iron, and sodium chloride is oxidized to chlorine gas at the anode.

•

Purified seawater is used as the source of sodium chloride, and the chlor-iron process is conducted at a temperature less than 100 °C.

Steel production is a significant contributor to greenhouse gas emissions. The 2023 STLE Report on Emerging Issues and Trends in Tribology and Lubrication Engineering

1 notes that 1.9 billion metric tons of steel generates the production of 2.6 billion metric tons of carbon dioxide, according to the World Steel Association.

In actuality, reduction of iron oxide to iron is the single most significant contributor to carbon dioxide emissions in the manufacture of steel, according to Paul Kempler, research assistant professor and director of the Electrochemistry Masters Internship Program at the University of Oregon in Eugene, Ore. He says, “Steel production accounts for approximately 8% of greenhouse gas emissions. Reduction of iron oxide with some form of carbon (such as coal or coke) produces approximately 1 metric ton of carbon dioxide per metric ton of iron. Another concern about this process is the high temperature (1,500 °C) required.”

A past TLT article

2 describes a study that developed a global emission inventory for global iron and steel plants based on nearly 20,000 individual processing plants located in nearly 4,900 individual iron and steel plants. Most of the facilities used the basic oxygen furnace with about 28% generating lower levels of carbon dioxide emissions by utilizing electric arc furnaces. The study concluded with the calculation that if carbon dioxide mitigation was carried out in each plant, then carbon dioxide emission could decline by 58.7 gigatons between 2020 and 2050. This is equivalent to two years of net global carbon dioxide emissions.

One approach for reducing emissions is to evaluate direct iron oxide reduction by electrochemical means. Kempler says, “Low-temperature electrochemical reduction of iron is an old process that was originally developed in the early 1900s. High temperature electrochemical reduction is a modern approach, and while there are advantages because molten iron is produced and can easily be moved to the next step in steel production, these electrochemical cells are more expensive due to the stringent material requirements, high temperature and corrosive operating conditions.”

Electrochemical reduction of iron oxide also has been accomplished at lower temperatures (< 200 °C). Kempler says, “Electroplating of iron occurs under either acidic or basic conditions at temperatures less than 100 °C. The challenge is that any significant consumption of mineral acids such as hydrochloric, or caustic solutions during the plating process increases the cost of the iron being produced.”

A new approach for reducing iron oxide to iron is needed that will reduce carbon dioxide emissions and run in inexpensive cells designed for low-temperature conditions. Kempler and his colleagues have now devised a reaction based on the well-known chlor-alkali process.

Chlor-iron

The chlor-alkali process involves the reaction of water with sodium chloride to produce chlorine gas, sodium hydroxide and hydrogen gas. Kempler says, “The appeal of this process is that it is run at a low temperature (less than 200 °C), has been conducted for over 100 years, and is utilized on a large scale where over 5 million metric tons of products are yielded annually just in the U.S.”

The researchers recognized that by adding iron oxide to the cell, a direct reduction to iron metal is realized. Kempler says, “We balanced the chemical equations and found that this chlor-iron process is feasible with the concomitant synthesis of sodium hydroxide and chlorine gas as by-products.”

The electrochemical cell used has a cathode chamber that contains iron oxide suspended in a strongly basic electrolyte (sodium hydroxide) with a pH above 14. Figure 3 shows the suspension being prepared. The anode chamber contains an acidified solution of sodium chloride at pH 2. The two chambers are separated by a cation-selective membrane, which enables the pH gradient to remain in a steady-state and allow for sodium ions to carry the ionic current from the anode to the cathode chamber.

Figure 3. Iron oxide, suspended in a basic electrolyte (sodium hydroxide), is added to the cathode chamber of the electrochemical cell prior to the initiation of the chlor-iron process. Figure courtesy of the University of Oregon.

Figure 3. Iron oxide, suspended in a basic electrolyte (sodium hydroxide), is added to the cathode chamber of the electrochemical cell prior to the initiation of the chlor-iron process. Figure courtesy of the University of Oregon.

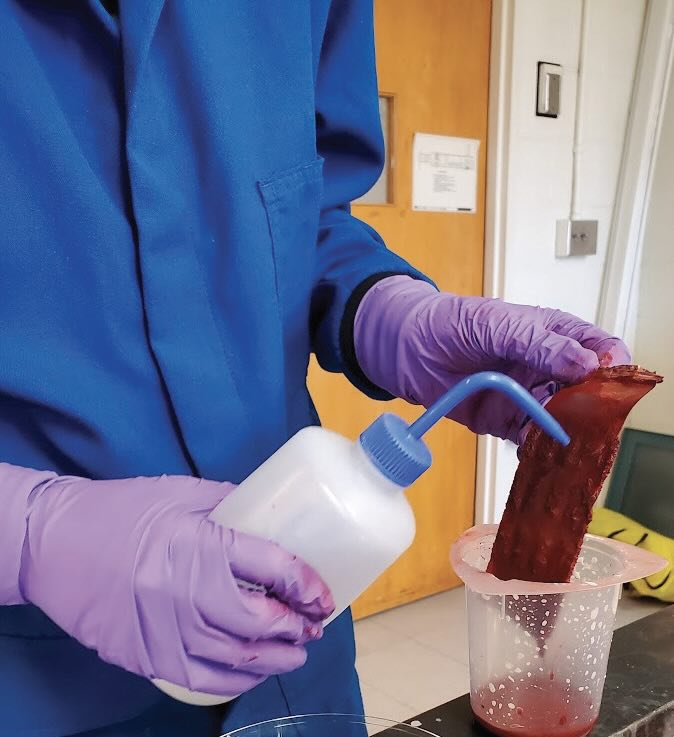

When the electrochemical cell is activated by applying a voltage across the electrodes, iron oxide reduction occurs at the cathode, and a film of solid iron can literally be removed from the reaction setup

(see Figure 4). In the anode, sodium chloride is oxidized to chlorine gas, which also produces sodium hydroxide in the cathode compartment. To catalyze the formation of chlorine gas, a thin film of ruthenium oxide on a titanium current collector was used.

Figure 4. During the chlor-iron process, a thin film of iron is produced and can be removed from the electrochemical cell. Figure courtesy of the University of Oregon.

Figure 4. During the chlor-iron process, a thin film of iron is produced and can be removed from the electrochemical cell. Figure courtesy of the University of Oregon.

Purified seawater, which is readily available, is used as the source of sodium chloride. The chlor-iron process was conducted at a temperature less than 100 °C.

Kempler says, “Initial work with relatively pure iron oxide afforded a 95%-98% yield of pure iron, which is comparable to the composition of iron produced in a blast furnace. We found that adding alumina and silica as impurities affected the electivity of the reaction but were not incorporated into the metallic film. One of the reasons is that plating out a pure metal such as iron is easier as compared to alloys.”

Finding the right membrane to separate the anode and cathode chambers proved to be a challenge for the researchers. Kempler says, “We tried several other membranes before finding one made from Nafion 2030 that was effective. Other membranes proved to be porous leading to sodium hydroxide diffusing into the low pH anode chamber resulting in a loss of performance.”

The researchers developed a semi-batch process that allowed for repeated removal of iron film through an electrowinning process. Kempler considers it similar to what is done commercially to plate out elemental nickel and zinc.

Future work will involve scaling up the process and also evaluating different types of iron oxide that are naturally available. Kempler says, “We are seeking to work with suppliers of iron oxide to assist us in further evaluating and commercializing the chlor-iron process.”

The researchers believe this approach is more sustainable because it is electrified and produces no direct carbon dioxide emissions. An added benefit is that the two byproducts, chlorine gas and sodium hydroxide, also can be used commercially improving the economics of the process.

Additional information can be found in a recent article

3 or by contacting Kempler at

pkempler@uoregon.edu.

REFERENCES

1.

www.stle.org/2023EmergingTrendsReport

2.

Canter, N. (2024), “Decarbonization of global iron and steel plants,” TLT,

80 (1), pp. 20-21. Available

here.

3.

Noble, B., Konovalova, A., Moutarlier, L, Brogden, V. and Kempler, P. (2024), “Electrochemical chlor-iron process for iron production from iron oxide and salt water,”

Joule, 8 (3), pp. 714-727.