An oil that is greater than the sum of its parts

By Drs. Wilfred T. Tysoe & Nicholas D. Spencer, Contributing Editors | TLT Cutting Edge June 2024

Two-phase lubricants that comprise semi-miscible, high- and low-viscosity fluids provide lubricating oils with high-viscosity indices.

Despite the growth in electric-vehicle sales, there will continue to be a need for strategies to improve the efficiency of internal-combustion engines. This can be accomplished by decreasing lubricant drag by reducing its viscosity; 0W-20 engine oils are now commonly used in automobile engines. However, because an oil’s viscosity tends to decrease as it gets hotter—a tendency measured by its viscosity index (VI)—such low-viscosity oils can lead to high friction or even engine damage if they get too hot. The challenge is therefore to design low-viscosity lubricants with high VI values.

One approach has been to use two semi-miscible fluids, one with a low and the other with a high viscosity. The idea is that, at low temperatures, the low-viscosity component will dominate while, as the temperature increases, more of the high-viscosity fluid will dissolve in the less viscous component to help compensate for any decrease in viscosity caused by the higher temperature.

This approach has proven to work for a mixture of a non-polar, low-viscosity poly-alpha-olefin (PAO) mixed with a high-viscosity poly-alkylene glycol (PAG), which achieved VI values of up to 700.

However, the way in which the film structure of this fluid combination is influenced by the nature of the contacting surfaces is not well understood.

This issue was investigated by a group headed by Professor Motoyuki Murashima from Tohoku University in Japan, with Professor Noritsugu Umehara and colleagues Kodai Hirata, Takayuki Tokoroyama and Naoya Hashizume from Nagoya University in collaboration with Dr. Mao Ueda and coworkers Taku Sato, Ryoko Nagata, Kiyoshi Hanyuda and Ayano Otsuka from Shell Lubricants Japan, along with Dr. Woo-Young Lee from the Korea Photonics Technology Institute in the Republic of Korea.

They studied the behavior of a mixture of a low-viscosity mineral oil (12.7 mPa‧s) with a high-viscosity PAG (143 mPa‧s) on a high-surface-energy SUJ2 (equivalent to AISI 52100) steel, and on surfaces with low and super-low hydrogen-bond coverages with decreasing values of surface energy.

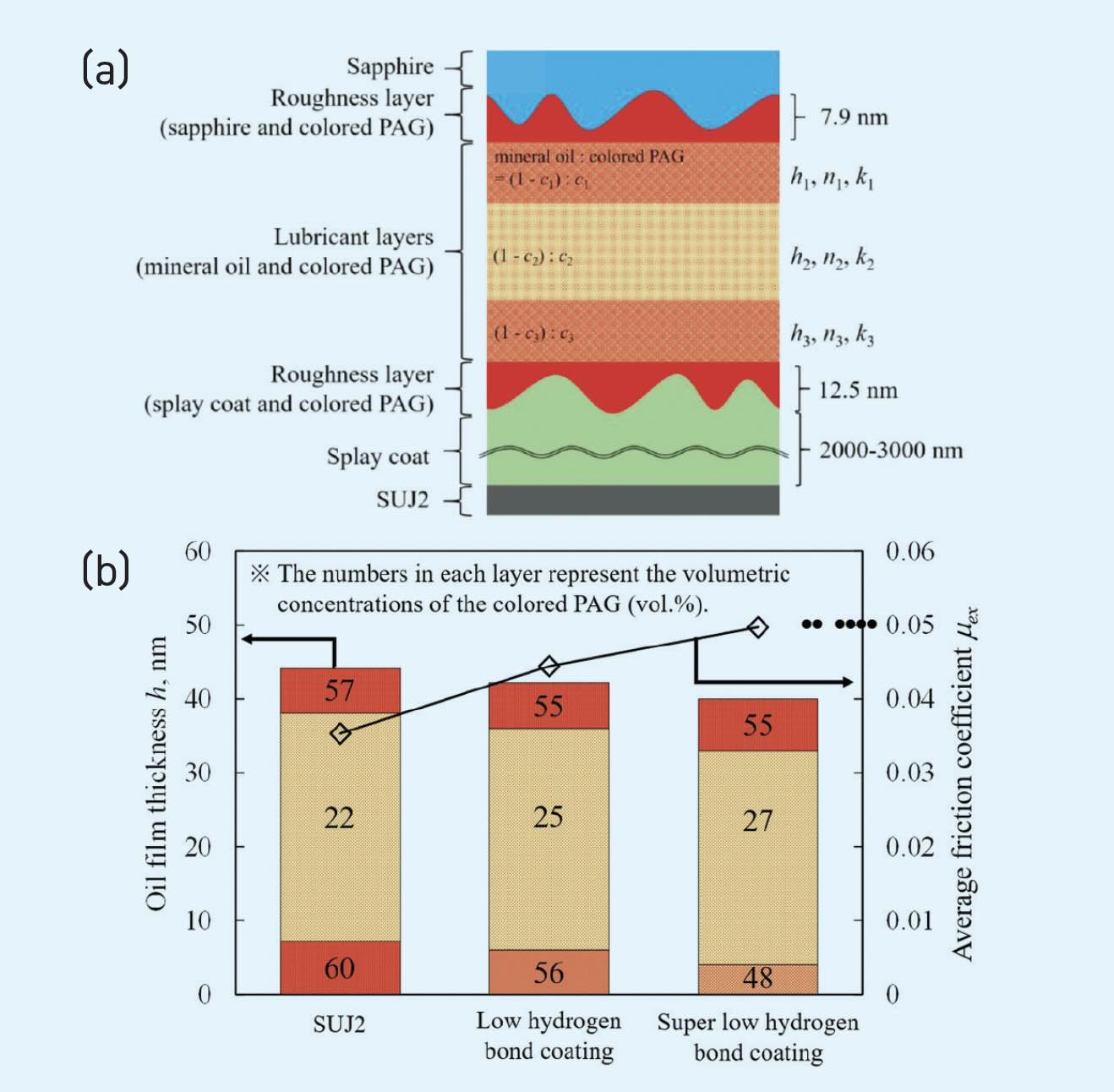

The structure of a thin lubricant film was analyzed using surface-reflectance spectroscopy and the results interpreted using the film structures depicted in Figure 1a on page 100, where the real and imaginary parts of the dielectric constants for each component of the films are labeled. The influence of the substrate on the friction is shown in Figure 1b, indicating that the friction coefficient increases as the surface energy decreases.

Figure 1. (a) Optical model of the layers of the interfacial film structures formed using a two-phase lubricant. (b) The results of an analysis of the reflectance spectra of oil films formed from the two-phase lubricants on a steel substrate, and ones with a low hydrogen bond coverage and a super-low hydrogen-bond coverage. The resulting experimental friction coefficients are shown as open diamonds. The film thickness of each layer and its composition are displayed where the numbers in each box of the bar graph indicate the volumetric concentration of high-viscosity poly-alkylene glycol (PAG) in each layer. Published with permission from Ref. 1.

Figure 1. (a) Optical model of the layers of the interfacial film structures formed using a two-phase lubricant. (b) The results of an analysis of the reflectance spectra of oil films formed from the two-phase lubricants on a steel substrate, and ones with a low hydrogen bond coverage and a super-low hydrogen-bond coverage. The resulting experimental friction coefficients are shown as open diamonds. The film thickness of each layer and its composition are displayed where the numbers in each box of the bar graph indicate the volumetric concentration of high-viscosity poly-alkylene glycol (PAG) in each layer. Published with permission from Ref. 1.

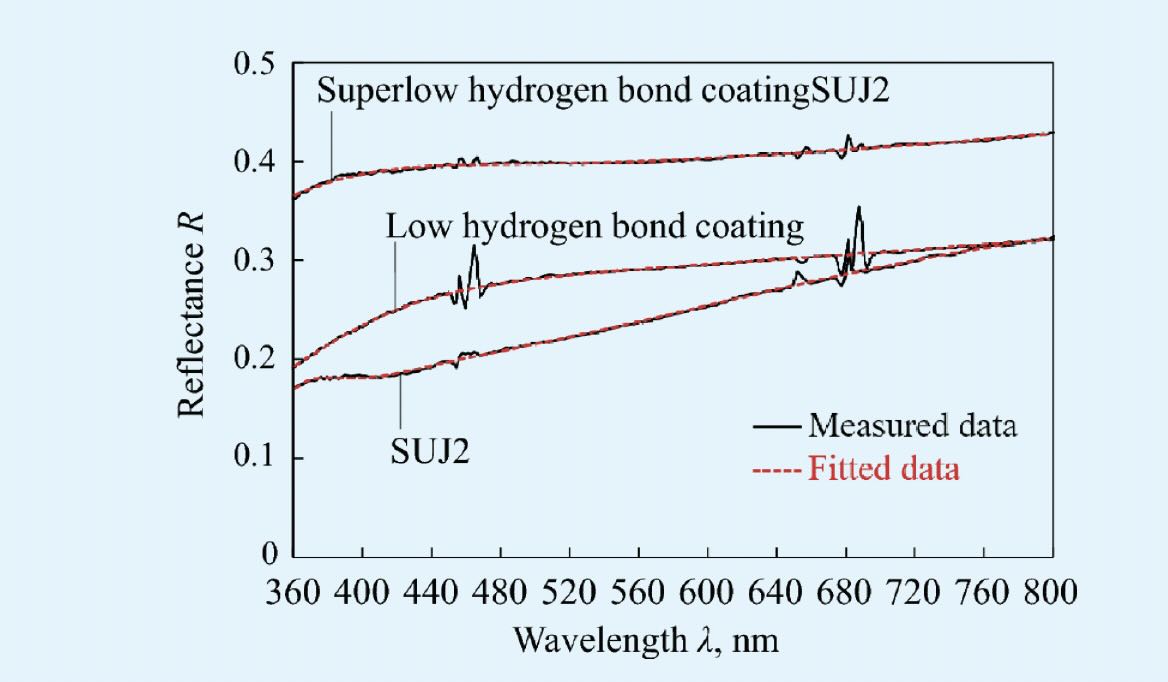

The reflectance spectra collected for films on the various surfaces are displayed in Figure 2. Fits to an optical model are shown as red lines and the resulting film structures are depicted in Figure 1b. This reveals that the major influence is a change in the thickness and composition of the film adjacent to the substrate, which becomes thinner and contains less high-viscosity PAG as the surface energies and the hydrogen-bond coverages decrease. The friction of this film structure was analyzed using a simple model that reproduced the experimental results very well, indicating that that the coverage of the more polar PAG is influenced by its interaction with the substrate. This, in turn, leads to a lubricant film in which the load is supported by the high-viscosity surface film while friction is reduced by the presence of the low-viscosity component.

Figure 2. Measured reflectance spectra (black lines) and fitted spectra (red lines) on SUJ2 (AISI 52100) steel, a low hydrogen-bond-coverage coating and a super-low hydrogen-bondcoverage coating. Published with permission from Ref. 1.

Figure 2. Measured reflectance spectra (black lines) and fitted spectra (red lines) on SUJ2 (AISI 52100) steel, a low hydrogen-bond-coverage coating and a super-low hydrogen-bondcoverage coating. Published with permission from Ref. 1.

This work illustrates how judiciously selected mixtures of polar and non-polar lubricants with different individual viscosities can have combined viscosities that are relatively independent of temperature and shows how their film structures and properties can be influenced by changing the nature of the substrate. Clearly this interesting study will have relevance in the ongoing quest to increase the energy efficiency of combustion engines.

REFERENCE

1.

Hirata, K., Murashima, M., Umehara, N., Tokoroyama, T., Lee, W-Y., Hashizume, N., Sato, T., Nagata, R., Hanyuda, K., Otsuka, A. and Ueda, M. (2024), “Clarification of the effect of surface energy on tribological behavior of two-phase lubricant using reflectance spectroscopy and hydrodynamic analysis,”

Tribology Letters, 72, 32.

Eddy Tysoe is a distinguished professor of physical chemistry at the University of Wisconsin-Milwaukee. You can reach him at wtt@uwm.edu.

Nic Spencer is emeritus professor of surface science and technology at the ETH Zurich, Switzerland, and editor-in-chief of STLE-affiliated Tribology Letters journal. You can reach him at nspencer@ethz.ch.