TLT: A question to start with: you spent 14 years in industry and then went back to university—why?

Koch: Well, that’s a very typical career path for a mechanical engineering professor in Germany. Several years of industrial experience is usually required, especially in the practice-oriented departments such as production engineering, design engineering or machine elements. This is to ensure a close link between industry and science. Thanks to my intensive industrial experience, I know exactly what moves industry and do not run the risk of conducting research in an ivory tower. We want to solve problems for industry at the MEGT.

TLT: In your role as a professor, it is important to get young people interested in mechanical engineering and, of course, tribology. How do you achieve this?

Koch: You have to explain to young people what the social contribution of engineers, and tribologists in particular, is. And it’s best to do this in a very striking and easily comprehensible way. There is a nice study by Holmberg and Erdemir from 2017 entitled “Influence of tribology on global energy consumption, costs and emissions.”

1 It shows that 23% of the energy generated globally is lost in tribological contacts. This means that if there were no more friction tomorrow, we could shut down almost a quarter of all power plants worldwide. Of course, there will always be friction, but the study identifies a potential for reducing friction by 40% in the medium term. This corresponds to around 3,300 million tons of CO2 per year, or we could shut down almost 10% of all power plants. This is not just an incentive; in my opinion it is the lever that we must and will use to drive technology. That’s why we at MEGT have not only made “Research for Sustainability” our motto—we also do it every day. And that also inspires young people.

TLT: You say “Research for Sustainability” is the motto of MEGT. This means that research meets the major topic of sustainability. That’s more than just a trend, isn’t it?

Koch: There is enormous social pressure, especially from the younger generation. Companies that don’t have a convincing sustainability concept will hardly be able to attract young employees. Green washing alone will not be enough to convince this young generation. An important prerequisite is, of course, the political will to tackle climate change. But here the momentum is on our side. Countries and companies are almost undercutting each other with figures for when they want to be climate neutral. So we can see that something is changing, but it has to be done in concrete terms.

TLT: Can you give us an example of what you are doing with your chair on the subject of sustainability?

Koch: We recently completed the FVA project “Holistic efficiency optimization of worm gearboxes.” Thanks to a holistic optimization approach, we were able to increase efficiency under nominal load by three to five percentage points. With efficiency levels of over 90%, this represents a significant reduction in power loss and impressively demonstrates that there is still great potential to be exploited in the field of drive technology. And as you can imagine, precise friction models to describe all friction components and a deep understanding of tribology are an absolute prerequisite for such success stories.

TLT: So your research is always about reducing friction?

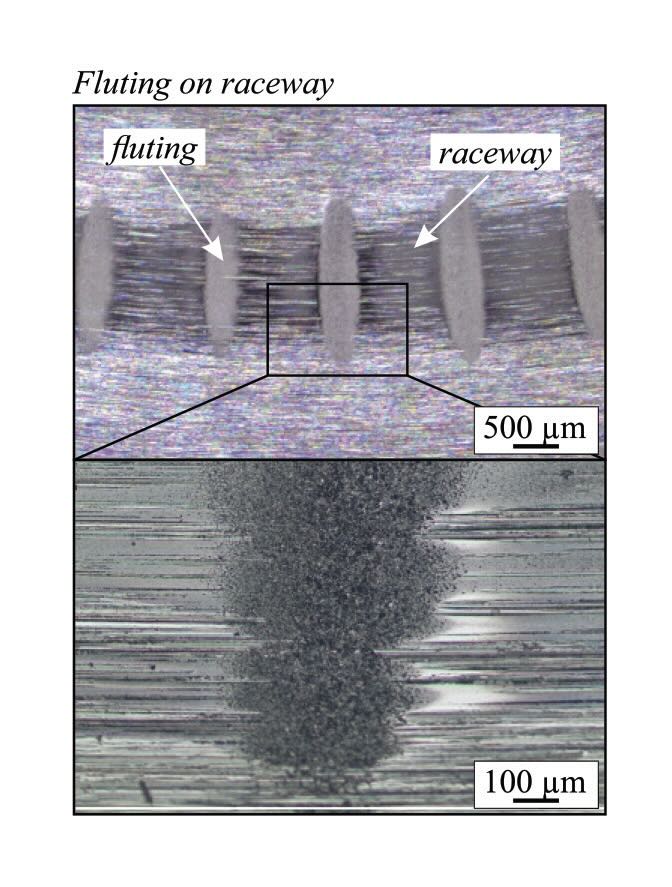

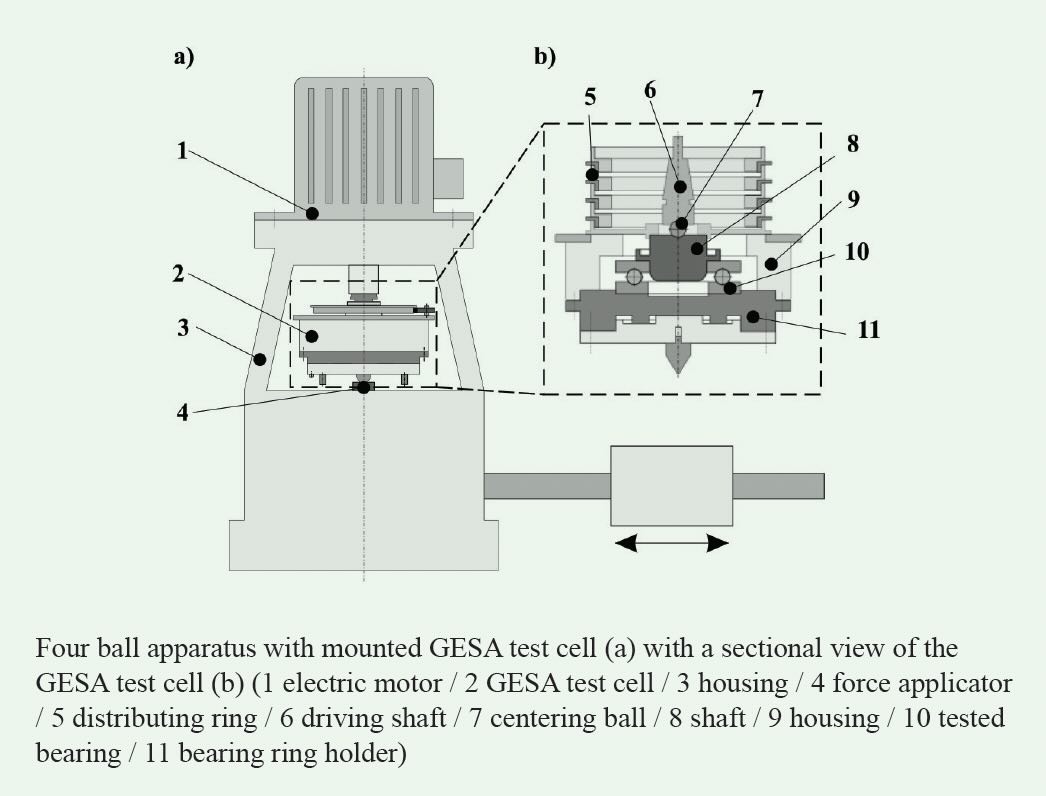

Koch: Friction reduction is a very important pillar of our research. But “Research for Sustainability” also means we have to pave the way for increasing electrification and electromobility. At MEGT, we have been working for more than 10 years on the passage of current through rolling bearings and the resulting damage such as flutings

(see Figures 1 and 2), grey frosting or lubricant aging. Ultimately, our aim is to develop analysis and design methods that can reliably predict and prevent this damage.

Figure 1. Fluting on bearing raceway caused by current passage.

Figure 1. Fluting on bearing raceway caused by current passage.

Figure 2. “GESA” test rig for investigation of bearings under current passage (impedance measurement, generating of flutings, aging of lubricants), developed by MEGT within the FVA project 650 II.

TLT: So you are working on the aging of lubricants under electrical load. That sounds very interesting. Can you tell us a little more about this?

Koch: Of course. In an ongoing DGMK (German Society for Sustainable Energy Carriers, Mobility and Carbon Cycles e.V.) project, lubricant aging due to combined mechanical and electrical stress is being investigated by means of extensive experiments and lubricant analyses. For this purpose, test conditions will be derived in which the lubricants—oils and greases—are specifically subjected to electrical damage. Based on this, the damaged lubricants are analyzed using extensive analysis methods, e.g., infrared (IR) spectrography, inductively coupled plasma (ICP) analysis, rheological investigations, remaining useful life estimation routine (RULER) method or nuclear magnetic resonance (NMR) spectroscopy. Aging and damage mechanisms are identified from these results. The results of the project enable the user to select lubricants specifically for the expected electrical load, which means bearing current and bearing voltage, switching frequency and lubrication condition. And with the right lubricant selection damage or premature failure of components can be reduced or avoided. You can see from this example that we at MEGT want to solve specific and relevant problems from industry.

TLT: If we look at your career, what has been your most rewarding accomplishment in tribology?

Koch: During my time in industry, my first task was to integrate the friction model that I developed during my doctorate into the Schaeffler Bearinx software. Until then, it was only possible to calculate bearing losses using the well-known Palmgren catalog equations. The methods implemented back then are still the basis for calculating friction in Bearinx today. That makes me proud. But of course the method alone is no added value. I also had the good fortune to use these new methods in customer projects in many pilot projects together with the application engineering department. That was a great time.

In my new role, I am very proud of the rolling bearing dynamics software LaMBDA, which has been developed at MEGT over decades. This is a multi-body simulation with highly developed contact routines. The special thing about it is that it is not purely research software. The tool has been undergoing further development at the FVA for over 10 years and also is used by many industrial companies to solve problems in daily practice.

Oliver Koch at the RPTU University of Kaiserslautern-Landau. Copyright RPTU, Hans-Georg Merkel.

Oliver Koch at the RPTU University of Kaiserslautern-Landau. Copyright RPTU, Hans-Georg Merkel.

TLT: Throughout the different segments within your career, which one has been the most interesting or challenging?

Koch: That’s a difficult question. Ultimately, every task has its own challenge. At the beginning of your career, it’s often technical questions and tasks that are incredibly challenging. I was lucky enough to work on a great team at Schaeffler with incredibly highly qualified employees. In such a team, you can solve almost any technical task.

Later on, leadership became more and more important and took up more of my time. This task also can be very fulfilling, for example, when you develop employees over a long period of time and see how positively their careers develop. I also really enjoy strategic work on the management team, especially when you can stay in charge for so long to see what works and what does not.

A big challenge on my way back to university was adapting to a different employee profile. While my teams at Schaeffler were mostly made up of employees with a lot of professional experience, this is obviously not the case at the university. Although my research assistants are excellent and very committed, they naturally lack experience. As a consequence, this requires a change in leadership behavior.

TLT: Let’s close the circle by coming back to the younger generation. What is the No. 1 piece of advice you would give to a person who might be interested in starting a career in the field of tribology?

Koch: Tribology is an incredibly fascinating and socially important discipline. I’ve already talked about its importance for climate change. Let yourself be inspired! Don’t talk about work-life balance. If you’re passionate about your job, then it’s a natural part of your life and doesn’t need to be artificially separated. Furthermore, I can only recommend that everyone in the early career phase build up and use networks. The importance of personal networks cannot be overestimated. Take every opportunity to network. STLE, for example, offers an excellent platform for meeting interesting people. I myself have been coming to the STLE Annual Meeting & Exhibition regularly for over 10 years, and it’s a fixed date on my calendar. You can get very involved in research associations or standardization committees. At the end of the day, I haven’t met any professionally successful person who doesn't have an excellent network.

REFERENCE

1.

Holmberg, K. and Erdemir, A. (2017), “Influence of tribology on global energy consumption, costs and emissions,”

Friction, 5, pp. 263-284,

https://doi.org/10.1007/s40544-017-0183-5.

You can reach Oliver Koch at oliver.koch@rptu.de.