Elastic shakedown...or not elastic shakedown?

By Drs. Wilfred T. Tysoe & Nicholas D. Spencer, Contributing Editors | TLT Cutting Edge April 2024

New numerical simulations suggest that plastic deformation during running-in continues for far longer than previously assumed.

When metals first come into contact, the deformation processes involved are a combination of elastic and plastic responses, the former being controlled by the elastic modulus of the material and the latter being a consequence of dislocation behavior that contributes to the material’s hardness. Since the mid-20th century, however,

1 it has been believed that, in well-designed mechanical systems, the plastic deformation processes are completed after a small number of contact cycles (the running-in period), and that the interface then reaches equilibrium, after which only elastic deformation needs to be considered. This entire process is denoted as elastic shakedown and was thought to result in a characteristic and essentially unchanging roughness profile. This idea was the basis for several important contact models, including that of Greenwood and Williamson.

2

A recent paper in STLE-affiliated journal Tribology Letters by Lucas Frérot (Sorbonne University, Paris) and Lars Pastewka (University of Freiburg, Germany)

3 suggests that the conventional, 20th century elastic-shakedown picture is an oversimplification. The authors used a numerical model, in which a rigid indenter is repeatedly pressed into contact with an initially flat, elastoplastic solid, representing a metal surface, for example. Upon each contact, the indenter shape is changed—to simulate the misalignment of the contacting surfaces in a real situation, such as sheet-metal forming—but its roughness properties remain the same and are characterized by both Gaussian height distribution and self-affinity.

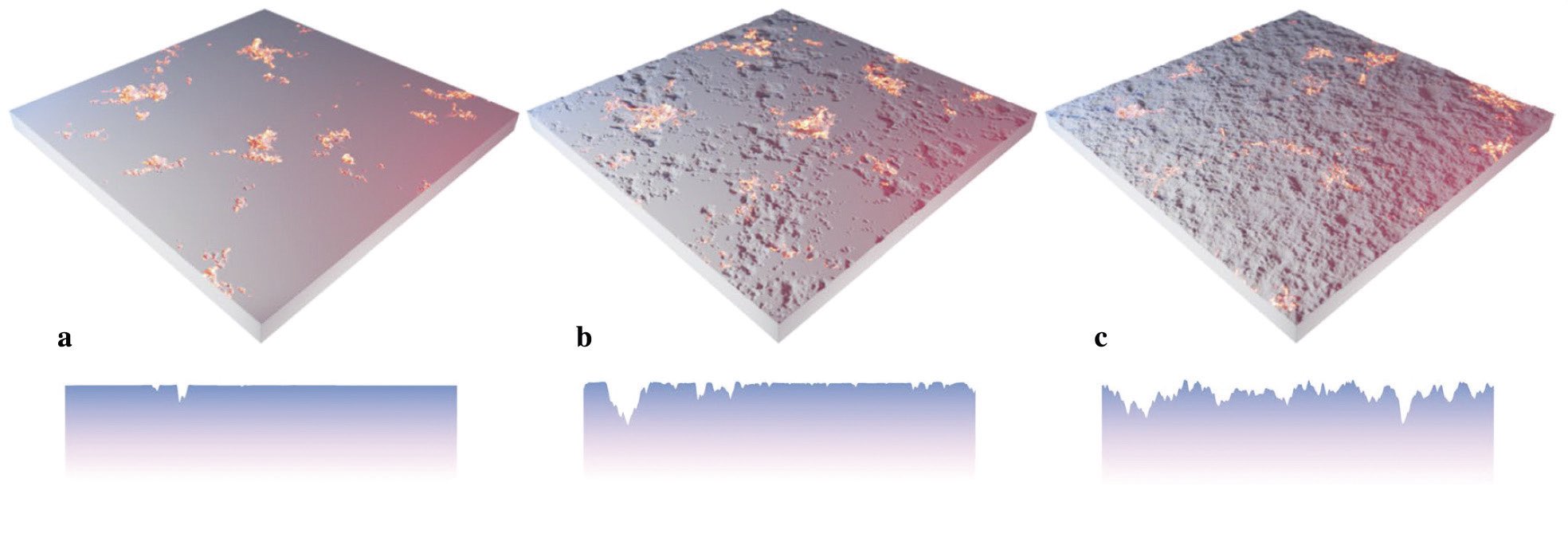

As the sequence of 90 indentations proceeds, roughness develops on the initially flat surface

(see Figure 1), thanks to the accumulation of residual plastic deformation.

Figure 1. Evolution of surface roughness through repeated elastic-plastic indentation. Highlighted areas on the 3D views show where plastic energy is dissipated at the specific step that is shown. The panels show the topography after a.) 1, b.) 10 and c.) 90 indentations. The bottom row shows the evolution of 1D cross-sectional roughness for the surfaces above. Published with permission from Ref. 3.

Figure 1. Evolution of surface roughness through repeated elastic-plastic indentation. Highlighted areas on the 3D views show where plastic energy is dissipated at the specific step that is shown. The panels show the topography after a.) 1, b.) 10 and c.) 90 indentations. The bottom row shows the evolution of 1D cross-sectional roughness for the surfaces above. Published with permission from Ref. 3.

A number of unexpected observations emerged from this simulation. While the calculated root-mean-square (RMS) roughness reached a steady state early in the indentation series, the plastic deformation processes were still happening after 90 cycles, especially at the microscopic scale and in the subsurface region. The long-wavelength roughness indeed rapidly converged, but the small-wavelength components did not. Furthermore, while the indenter’s roughness distribution was Gaussian and self-affine, the emerging roughness on the countersurface was quite different; the height distribution showed clearly exponential tails, and no signs of self-affinity were detected over the entire wavelength range investigated.

The apparent continuation of subsurface plastic deformation well beyond the point at which it is neglected by classical theories is likely to reawaken debates concerning the evolution of the microstructure of the subsurface “tribomaterial,” as discussed many years ago by Rigney and Karthikeyan.

4 It also has potential consequences for service-life estimates or predictions concerning fatigue. However, while Frérot and Pastewka’s numerical simulations are a significant advance on previous studies, a number of simplifying assumptions had to be made, so it is clear that further work will be necessary to determine the practical implications of these new findings.

REFERENCES

1.

Johnson, K.L. (1966), “A review of the theory of rolling contact stresses,”

Wear, 9 (1), pp. 4-19.

2.

Greenwood, J.A. and Williamson, J.B.P. (1966), “Contact of nominally flat surfaces,”

Proc. Roy. Soc. London A, 295 (1442), pp. 300-319.

3.

Frérot, L. and Pastewka, L. (2024), “Elastic shakedown and roughness evolution in repeated elastic–plastic contact,”

Tribology Letters, 72, Article 23.

4.

Rigney, D.A. and Karthikeyan, S. (2010), “The evolution of tribomaterial during sliding: A brief introduction,”

Tribology Letters, 39, pp. 3-7.

Eddy Tysoe is a distinguished professor of physical chemistry at the University of Wisconsin-Milwaukee. You can reach him at wtt@uwm.edu.

Nic Spencer is emeritus professor of surface science and technology at the ETH Zurich, Switzerland, and editor-in-chief of the STLE-affiliated Tribology Letters journal. You can reach him at nspencer@ethz.ch.