TLT: How long have you worked in a lubrication-related field, and how did you decide to pursue a career in the lubricants industry?

Zaabel: My career in the lubricants industry spans 43 years. I joined the industry quite by accident, accepting a position in a grease laboratory as my first opportunity after graduating college with a bachelor of arts degree in biological sciences. I thoroughly enjoyed learning and running the testing on base oils, in-process greases and finished lubricants.

I was asked if I had interest in sales, which I previously did not, but the appeal of travel and seeing first-hand how things are made intrigued this young man, and I gave it a try. This decision opened the door to a truly rewarding and amazing career.

TLT: What has been your most rewarding accomplishment throughout your career in the lubricants industry?

Zaabel: I believe all accomplishments result from teamwork and are very rarely of an individual nature. Becoming an STLE Certified Lubrication Specialist™ (CLS) in the first test offered in 1994 and being among the first group certified by NLGI as a Certified Lubricating Grease Specialist are very special achievements for me. Also, in 2004 I received CITGO’s President’s Club Award for posting record grease sales results.

TLT: What is the No. 1 piece of advice you would give to a person who might be interested in starting a career in the lubricants industry?

Zaabel: As a young college graduate, I didn’t even know there was such a thing as a “lubricants industry!” Looking back over my career now, I can say that taking that first opportunity in 1981 (which was meant to be a “bridge” job until I found something better) was one of the luckiest decisions I ever made. The mix of science, engineering and business the lubricants industry provides for me to this day is and has been stimulating, rewarding and continuously fascinating.

TLT: Throughout the different segments within your career, which one has been the most interesting, challenging and/or rewarding?

Zaabel: Joining King Industries in 2017 was a bit of a departure in focus for me. My previous 37 years were entirely involved with finished lubricants and their applications. Making the transition to the manufacturing and marketing of lubricant additives has given me a new perspective on the complex and unique chemistries, chemical interactions and performance properties that must be addressed in the formulation of the finished lubes and greases. What I love about this industry is that even though I occupy a different space today, I continue to interact with the hundreds of colleagues, coworkers and friends I had the honor and pleasure to build relationships with more than 40 years.

TLT: What lubrication problems have you solved during your field experiences?

Zaabel: Here are a few of my experiences: 1.) using a semifluid grease to reduce/stop gearbox leakage and 2.) adding a surfactant to a grease that was “too water resistant.”

TLT: What are some of the most technical lubrication-based concepts or topics you have encountered throughout your career?

Zaabel: Selecting and/or recommending the correct lubricant for a given application requires a great deal of consideration and experiential skill, including understanding the operating conditions of the component, environmental conditions, performance requirements and their correlation with bench testing versus actual real-world use, cost considerations, maintenance practices by the end-user, relubrication interval expectations and many other concerns.

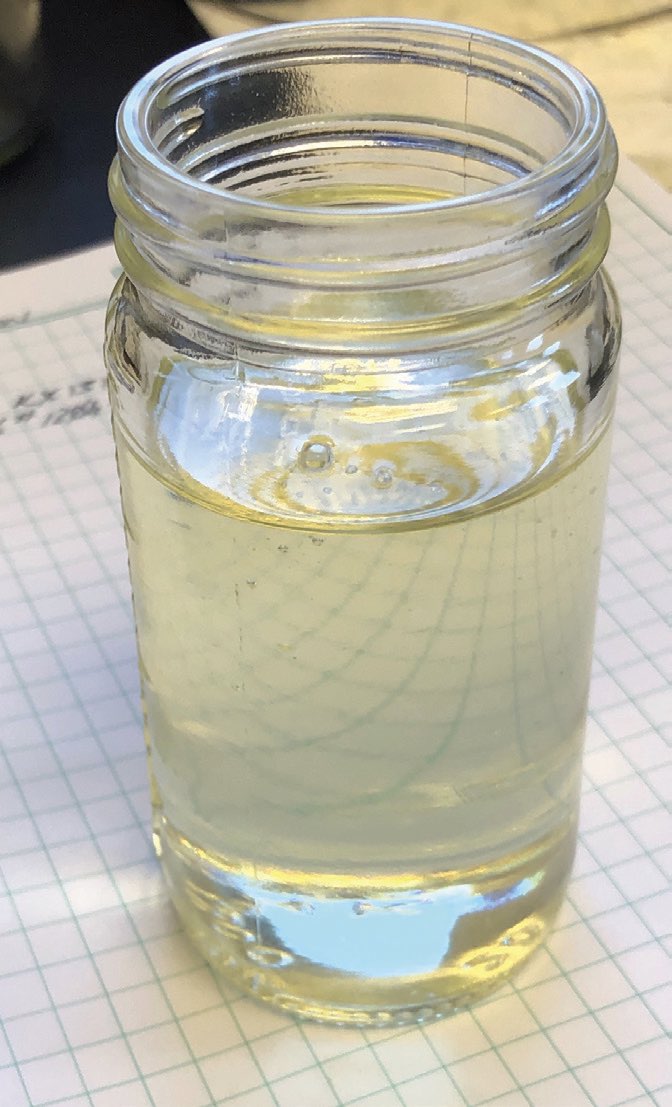

A light colored/low odor sulfurized olefin extreme pressure additive.

A light colored/low odor sulfurized olefin extreme pressure additive.

Over the years I have continued to learn of more subtle concepts like hydrogen embrittlement, pressure-viscosity coefficient, surface metallurgy variations and how these affect the design and formulation of efficient and high-performance lubricants.

TLT: What is the one thing you wish you would have learned earlier in your career?

Zaabel: It would have been helpful to have learned more about additive chemistries and performance capabilities given my current position!

You can reach Wilson Zaabel at wzaabel@kingindustries.com.