HIGHLIGHTS

•

A high-rate capability super–capacitor using carbon black, Portland cement and water was developed.

•

The supercapacitor contained a network that has the appearance of wiring from the interaction of hydrophilic cement and hydrophobic carbon black.

•

Electrodes prepared at high-water-to-cement ratios produced energy storage rates close to maximum due to large hydration porosity.

Finding cost effective energy storage technologies is becoming increasingly important to supplement the growing use of solar and wind as a means to generate energy from renewable sources. Technologies such as redox batteries are in development but suffer from reliance on mining minerals containing valuable metals such as cobalt and nickel. Part of the problem is the supply chain for both of these metals is problematic to maintain.

One other option under consideration is the supercapacitor. Franz-Joseph Ulm, professor of civil and environmental engineering and faculty director, Concrete Sustainability Hub at Massachusetts Institute of Technology (MIT) in Cambridge, Mass., says, “In contrast to batteries that rely on chemical redox reactions to convert stored chemical energy to electricity, supercapacitors operate in a simpler manner that does not involve any reactions. Supercapacitors take charge from a salt solution and store it on high specific area, polarized electrodes. Upon application of a voltage, charging occurs as positive ions in a salt solution migrate to a negatively charged plate while negative ions migrate to a positively charged plate. This creates an electric field enabling the capacitor to be charged. Once a request is made for power, the supercapacitor will rapidly discharge.”

A past TLT article

1 discussed the development of a supercapacitor that produced a carbon material with a very high electrochemically active surface area and pore volume from non-fat powdered milk. This approach is successful because partial carbonization preserves a nanocluster arrangement between two components present in milk, calcium phosphate nanoclusters and casein proteins.

Ulm and his colleagues recognized the potential of supercapacitors but tried to determine an approach to use inexpensive, readily available materials such as cement and water in their preparation. He says, “Cement is a material that is widely used, but its conversion to concrete is a highly energy intensive process that generates 4.2 gigatons of carbon dioxide per year or 8% of total global emissions.”

The researchers combined cement and water with a relatively low concentration of disordered microporous carbon black to produce a high-rate capability supercapacitor.

Branched carbon network

To produce this cement based supercapacitor, the researchers synthesized a series of electrode samples with different ratios of water, Portland cement and carbon black. Two other variables taken into consideration were using different types of carbon black with different surface areas, and different electrode thicknesses.

The researchers found that addition of water to cement under high pH conditions produced a branching network of pores. When carbon black was introduced, this material spread into the pores forming a branched carbon network that covers the surface of the cement.

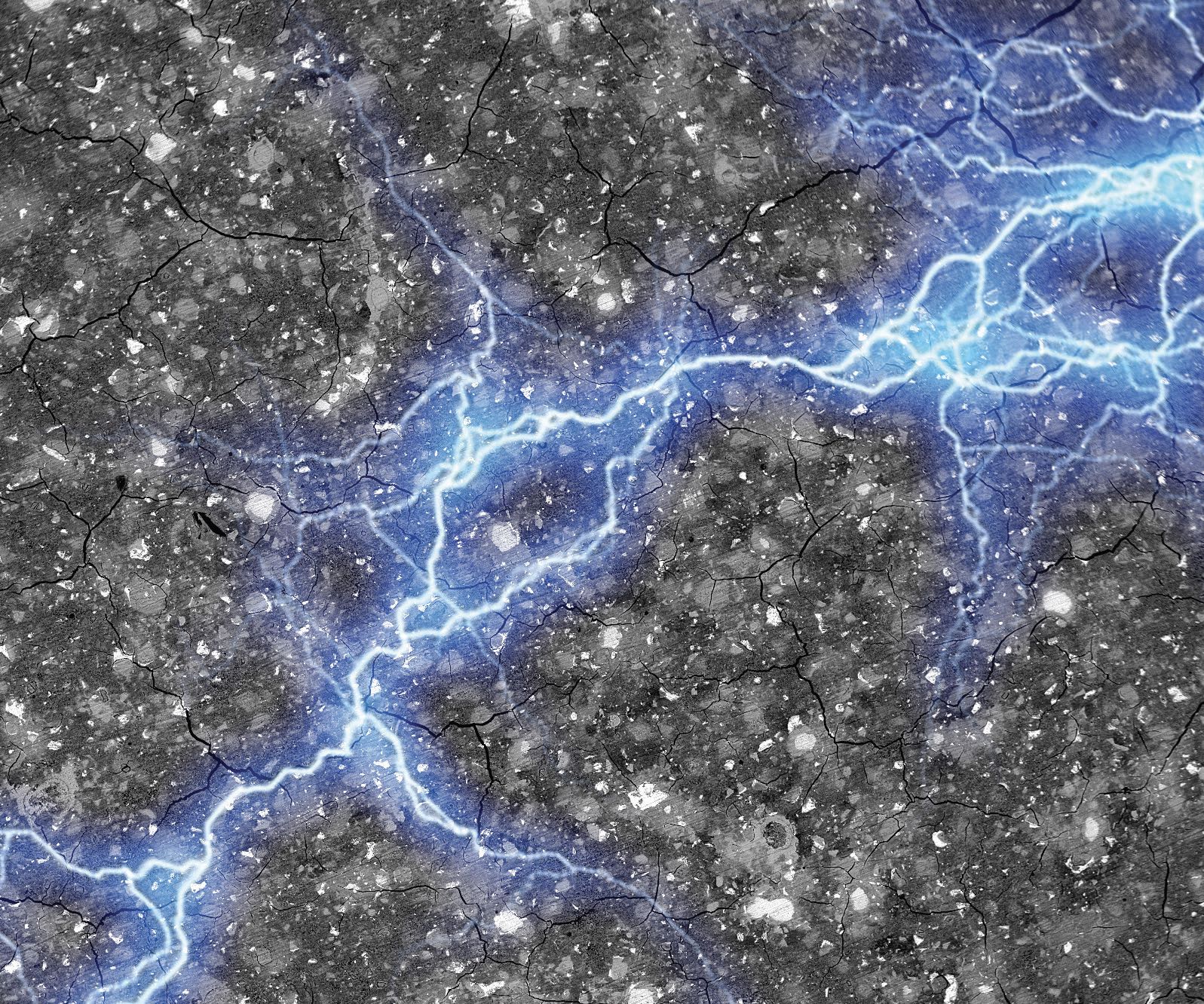

Ulm says, “We took advantage of the interaction between hydrophilic cement and hydrophobic carbon black to produce the network that has the appearance of wiring

(see Figure 3). By using water at a concentration above the stoichiometric amount used in manufacturing concrete (42%), we were able to synthesize a micrometer/submicrometer hydration porosity suitable for storing energy.”

Figure 3. A supercapacitor prepared from abundant raw materials has the potential to be used as an inexpensive approach for storing energy to supplement renewable sources. Figure courtesy of MIT.

Figure 3. A supercapacitor prepared from abundant raw materials has the potential to be used as an inexpensive approach for storing energy to supplement renewable sources. Figure courtesy of MIT.

Once this network is established on the cement, the material is soaked in a standard electrolyte, potassium chloride, to enable charged particles to accumulate on the carbon surface. Placement of two plates composed of carbon-cement separated by a thin space or insulating layer leads to the production of a supercapacitor.

The researchers found that electrodes prepared at high water-to-cement ratios produced energy storage rates close to maximum due to large hydration porosity. Ulm says, “A trade-off exists between energy storage and strength properties, which becomes important if the supercapacitor is used as part of a structure such as a residential house. Typically, concrete is prepared at a strength that is 50%-55% higher than the application need. When adding carbon black to fill the empty pores of the cement, the strength of the supercapacitor can be reduced to between 40% and 45%. This is caused by an increase in hydration porosity leading to stress concentrations around the micrometer-sized pores. The best approach to ensure the supercapacitor exhibits sufficient strength is to custom design water-to-cement ratios that meet specific applications.”

The initial supercapacitor built by the researchers was a one-millimeter-wide device that had the ability to produce 1 volt of electricity. By placing three of these units together, enough stored energy was available to power a light-emitting diode bulb.

Ulm says, “We are looking to scale up supercapacitor storage capacity to enable it to be used in a number of applications. For example, integrating the supercapacitor into a home will allow for the owner to utilize renewable energy sources and have a backup that can be used when they are not available. Another application is to build the supercapacitor into a road or highway to be used to power electric vehicles as they are in operation.”

Ulm indicates that his colleagues are working on evaluating a supercapacitor that can provide 12 volts of electricity in the lab. He adds, “This technology shows great promise, but we still have a ways to go before a supercapacitor is designed to power a home or electric vehicles.”

One other benefit of this supercapacitor is that this application can improve the positive carbon footprint found in the manufacture of cement. Additional information can be found in a recent article

2 or by contacting Ulm at

ulm@mit.edu.

REFERENCES

1.

Canter, N. (2017), “Enhanced capacitor performance using natural precursor,” TLT,

73 (10), pp. 12-13. Available

here.

2.

Chanut, N., Stefaniuk, D., Weaver, J., Zhu, Y., Horn, Y., Masic, A. and Ulm, F. (2023), “Carbon-cement supercapacitors as a scalable bulk energy storage solution,”

Proceedings National Academy of Sciences, 120 (32), e2304318120.