The Lubrizol Corp.

Examining the Rising Importance of Environmentally Acceptable Lubricants

By Joshua Dickstein, Ph.D., Technology Development Manager, Lubrizol | TLT CMF Plus November 2023

Ecological impact is a growing and important concern in marine, forestry and construction applications—and the right lubricant technology can help equipment in these industries optimize environmental friendliness.

Around the world, no matter the market, there is a growing need for environmentally benign lubricants.

Why? Every year, considerable volumes of industrial fluids make their way into the environment via machine leakage, accidental spills, and improper disposal. As the global society grows increasingly environmentally conscious, minimizing the impact of escaped fluids like hydraulic fluids, greases, metalworking fluids, industrial gear oils, and other fluids into the environment has become even more important. Biodegradability—a lubricant’s ability to be decomposed by microorganisms over time into simpler byproducts—has become a sought-after trait. Low toxicity and bioaccumulation potential have likewise become more important to better protect the environment. Not only do such spills and leaks have an impact on ecosystems, but they can lead to other consequences for companies including negative attention and publicity, and poor business results.

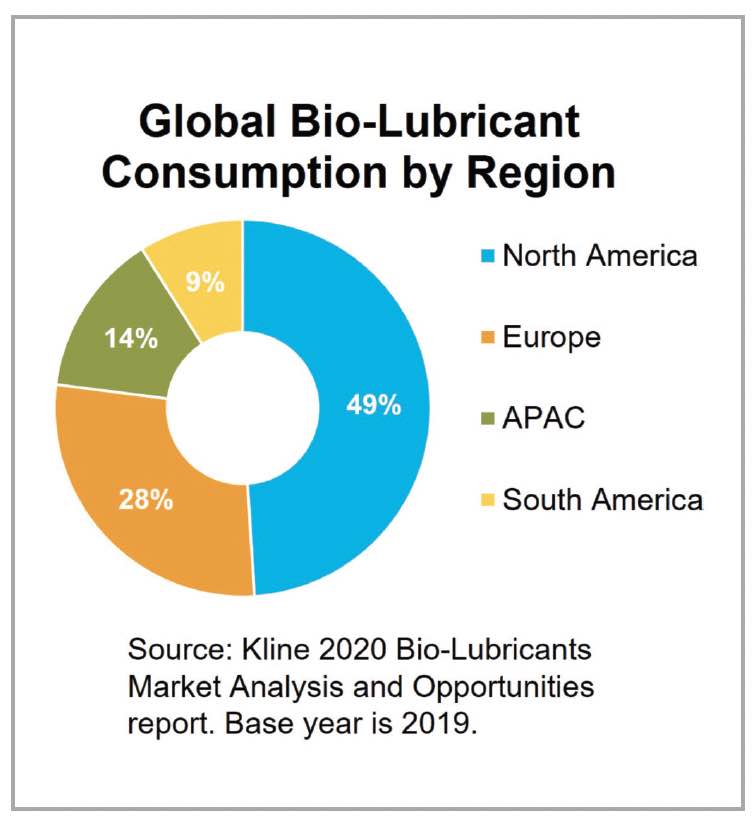

For these reasons and more, there is rising demand for environmentally acceptable lubricants (EALs and for lubricant marketers, there is sizable opportunity in developing EALs in a marketplace that is becoming more and more eco-conscious. The market for bio-based lubricants has a projected compound annual growth rate (GAGR) of ~3.5%-5.6% through 2024, with the largest markets existing in Europe and the Americas, according to recent studies by the market research firm Kline & Company and Lubrizol’s analysis.

Defining Environmental Friendliness

Defining Environmental Friendliness

As demand for EALs grows, it can be useful to define how they are situated within the broader context of sustainability. In the context of lubricants, sustainability has been defined as follows by the Union of the European Lubricants Industry (UEIL): “Lubricants created by innovative businesses enabling the use of safe, resource- saving technologies and processes which reduce the burden on the planet, local environments and benefit people and society.”

This is helpful for understanding how EALs can minimize environmental impact. Specifically, according to standards set by the U.S. Environmental Protection Agency (EPA), EALs by definition must meet strict criteria set for:

•

Biodegradability: The capacity of lubricants to be de com posed by microorganisms over time into:

–

A combination of simpler byproducts (primary biodegradation)

–

Carbon dioxide and water (ultimate biodegradation)

•

Minimal Aquatic Toxicity: Low toxicity to aquatic organisms according to tests defined by the Organization for Economic Cooperation and Development (OECD) and EPA test guidelines.

•

Bioaccumulative potential: The buildup of chemicals within the tissues of an organism over time.

Meanwhile, in recent years, the lubricants industry has seen increasing stringency of several widely recognized standards and labels that certify varying levels of eco-friendliness. Many of them require that fluids bearing the label definitionally meet the requirements of EALs. Some of these include:

•

The European (EU) EcoLabel, which certifies products with a guaranteed, independently verified low environmental impact. The label places limits on the amount of hazardous ingredients formulators can include in formulations, how biodegradable the formulation is, and whether it contains components that are persistent and bioaccumulative.

•

Blue Angel, the German Ecolabel, which the country awards to a wide variety of environmentally friendly products. Blue Angel is similar in stringency to the EU EcoLabel, but places additional requirements on how to properly dispose of labeled formulations.

•

EPA’s Vessel General Permit (VGP) which will soon be replaced with the Vessel Incidental Discharge Act (VIDA), establishes a framework for the regulation of discharges incidental to the normal operation of a vessel under a new Clean Water Act.

Major Opportunities for EALs

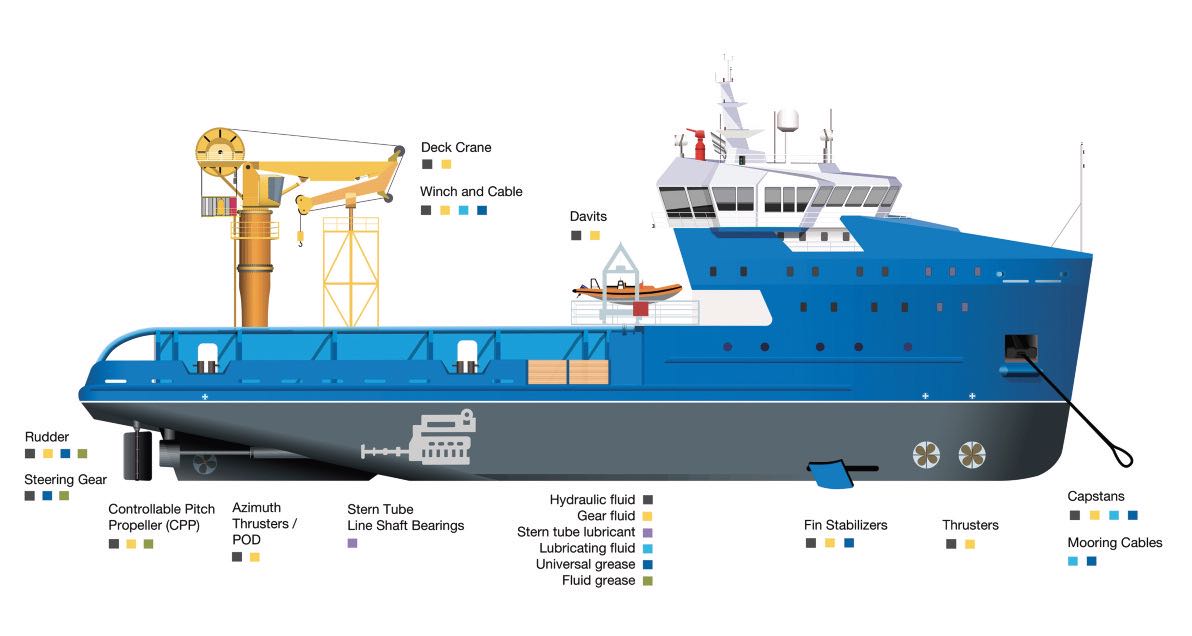

Inland water, forestry, marine and construction applications represent the areas where EALs can make the most impact. Take the marine industry as a critical example. Massive, complex cargo ships are home to dozens of applications where EALs can help improve environmental impact. Hydraulic fluids, gear oils, stern tube lubricants, greases, and other lubricating fluids can be found throughout a broad range of important equipment, including:

•

Steering and propulsion equipment, including rudders, controllable pitch propellers, stern tubes, fin stabilizers, thrusters and more.

•

Ship engines, responsible for powering the ship across vast distances.

•

Operational equipment, including deck cranes and winches and cables for maneuvering cargo pods from place to place, along with davits, responsible for lowering and retrieving dinghies and other smaller vessels.

At any of these points, critical fluids can escape into the environment, whether via user error, machine damage, or another event. It’s also worth considering that many such applications are below the waterline, meaning leakages would necessarily infiltrate the marine ecosystem. Given the scale of these ships and the sheer volume of fluids required to keep them operational, loss of such fluids can make a major impact on oceanic and marine life. Minimizing the harm resulting from such losses is increasingly critical.

Maintaining Optimal Performance in EAL Formulations

Maintaining Optimal Performance in EAL Formulations

Importantly, EALs must maintain the same critical performance characteristics as conventional lubricants in order to deliver the required levels of equipment protection and functionality. But original equipment manufacturers (OEMs) and fluid formulators do face some challenges when it comes to developing EALs that reliably deliver the kinds of performance required in critical marine applications.

For example, a priority for any industrial fluid is the protection of equipment. Preventing the premature wear of metal surfaces as they come into contact with each other is the core function of a lubricant—for EALs and conventional formulations alike. But some of the most reliable classes of anti-wear additives do not meet EAL criteria for biodegradability—meaning they must be excluded from any formulation to be an EAL.

The same holds true for many other important performance requirements industrial fluids must demonstrate. An industrial gear oil (IGO), for instance, typically incorporates extreme pressure additives. Sulfurized olefins are a reliable solution for these needs, but do not display the biodegradability required in accordance with EAL standards. A variety of conventional chemistries frequently used as antiwear agents, demulsifiers, antifoam agents, corrosion inhibitors, friction and viscosity modifiers cannot be used in the composition of an EAL.

For lubricant marketers looking to capitalize on these needs, working collaboratively with the right partner can be beneficial to develop environmentally certified and performance-validated fluids. A true partner should be able to offer reliable chemistry expertise and EAL-compatible solutions, enabling lubricant marketers to expand EAL marine offerings quickly.

Case Study: EAL Solutions from Lubrizol

The Lubrizol Corporation has committed its formulation expertise to bringing robust EAL solutions to market, offering industrial lubricant marketers an ideal solution to meet growing demand for EALs.

For example, the

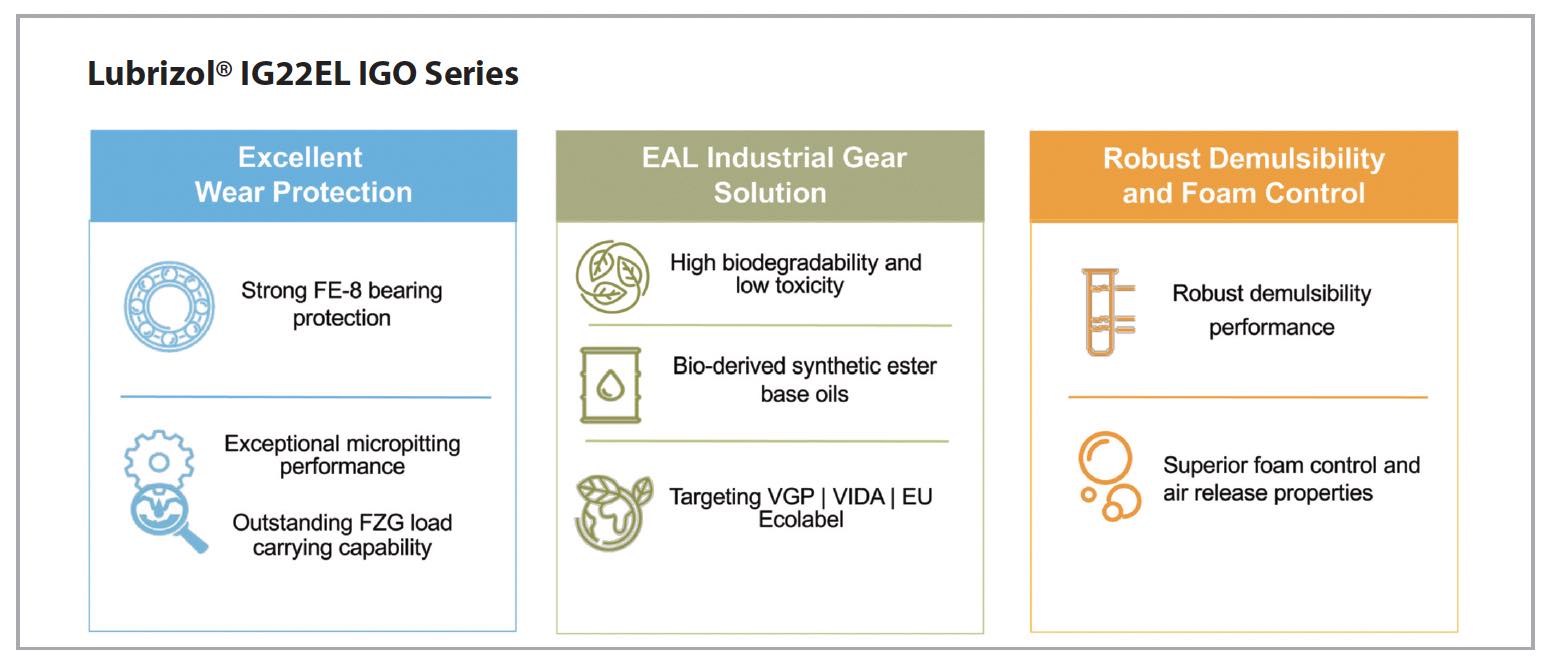

Lubrizol® IG22EL EAL IGO Series—a high-performance chemical additive package and related finished fluids —delivers all of the performance characteristics required in demanding industrial gear applications for an all-around solution with environmental protection. Benefits include:

•

Excellent Wear Protection. Lubrizol IG22EL solutions offer strong FE-8 bearing protection, exceptional micropitting performance, and outstanding FZG load carrying capabilities.

•

Robust Demulsibility and Foam Control. Along with its robust demulsibility performance, Lubrizol IG22EL offers superior foam control and air release properties required in industrial gear applications.

•

EAL Compliance. The Lubrizol IG22EL EAL IGO finished fluids are highly biodegradable, demonstrate low toxicity, and are formulated with bio-derived synthetic ester base oils. The solution is compliant with VGP, VIDA and EU EcoLabel requirements.

Lubrizol IG22EL has demonstrated these characteristics through a robust series of bench and mechanical testing and is well-suited for the most demanding industrial applications. The Lubrizol IG22EL EAL IGO finished fluids have also achieved broad industrial and environmental specification coverage.

The Lubrizol IG22EL EAL IGO Series is a part of the company’s EcoAssurant™ Portfolio, a broad offering designed to elevate the environmentally protective qualities of EAL lubricants in industrial applications, worldwide. Solutions include:

•

A complete suite of components and additives listed on the Lubricant Substance Classification (LuSC) list for worry-free formulating.

•

Fully formulated solutions that eliminate the costs and complexities associated with formulating and blending.

For the industrial lubricant marketer, selecting the right additives partner allows you to enhance your eco-conscious reputation and lead the way with products that have been tested and certified as biodegradable, non-bioaccumulative and minimally toxic to aquatic life. Further, environmentally certified and performance validated additive solutions can give you a competitive edge by enabling your business to speed its EAL offerings to market with confidence. Working with the right supplier can allow your business to expand its offering of highly valued products, gain greater share of market and enter new markets.

Lubrizol is committed to providing the global lubricants industry with the right solutions needed to lessen our impact on the environment while enabling next-generation machinery and equipment for a greener future.

To learn more, contact your Lubrizol representative, or visit

www.Lubrizol.com to learn more about EcoAssurant.