Evaluation of nanocrystalline platinum using high-cycle fatigue experiments under vacuum conditions at ambient temperature led to the discovery of autonomous fatigue crack healing.

Atomic modeling indicated that closing of the crack occurred through a cold welding process where the split surfaces move together until they eventually merge with each other in a self-healing fashion.

Under the experimental conditions, the self-healing of platinum was determined to be mechanical rather than diffusive.

The growing demand for metals that can be used to extend the performance of machinery under extreme conditions for long operating periods is ongoing. New alloys have been discovered that provide unique properties.

For example, research has been continuing to better understand the capabilities of high-entropy alloys, which are formed from equimolar amounts of multiple elements. A recent TLT article

1 discussed the use of a supercomputer to determine theoretically the physical and mechanical properties of over 370,000 high-entropy alloy compositions.

One characteristic of metal alloys that has not been discovered to date is that of self-healing. This phenomenon has been identified in other materials such as a hydrogel prepared from a glucose containing polymethacrylamide (GMPAA).

2 In this example, researchers embedded chloroplasts in GMPAA produced carbon mass when exposed to light that sealed a crack which had split the material.

Dr. Brad Boyce, staff scientist CINT at Sandia National Laboratories in Albuquerque, N.M., says, “Metal fatigue occurs through propagation of cracks under repeated (cyclic) mechanical loads and can lead to up to 90% of in-service failure. To minimize this phenomenon, microcrystalline metal alloys have been developed to minimize the formation and propagation of cracks. The assumption to date has been that development of cracks in a metal microstructure is not reversible.”

Nearly all metals have microcrystalline structures, composed of micrometer-sized grains that pack tightly against one another at grain boundaries. Those grain boundaries are important for fatigue resistance. Nanocrystalline metals, with grains at the nanometer scale, have an even higher density of grain boundaries that dominate fatigue response.

Boyce says, “The chemistry of an alloy also can contribute to the stability of grain boundaries. In past work, we studied a platinum alloy containing 10% gold and found that gold atoms migrated to the grain boundaries leading to improved fatigue resistance of the alloy. Upon stimulus, cracks were generated leading to fracture.”

A current study, originally initiated to better understand how cracks form and propagate through nanocrystalline platinum using a specialized electron microscope technique, has now led Boyce and his colleagues to determine surprisingly that crack formation was reversed after a period of time in what is reported as the first observation of self-healing of a metal alloy.

Cold welding

Cold welding

The researchers conducted high-cycle fatigue experiments through the use of in situ tensile testing in a transmission electron microscope under vacuum conditions at ambient temperature. Experiments were performed on 40 nanometer thick platinum films that were selected to be transparent for imaging purposes in the transmission electron microscope. Cycling was performed at 200 hertz, and the instrument was able to run experiments up to 1 million cycles. Videos of the experiments were captured using a camera system at 15 frames per second.

Fatigue crack initiation was detected after 80,000 total fatigue cycles with propagation observed for another 240,000 cycles. The crack appeared to be microstructurally small with individual grains near the tip substantially modifying propagation. Suddenly between 644,000 and 684,000 cycles, the researchers observed autonomous fatigue crack healing. Based on observations, the healing resulted in an 18-nanometer reduction in crack length with no evidence of the crack reopening. After an additional 116,000 cycles, the crack began to grow in a new direction.

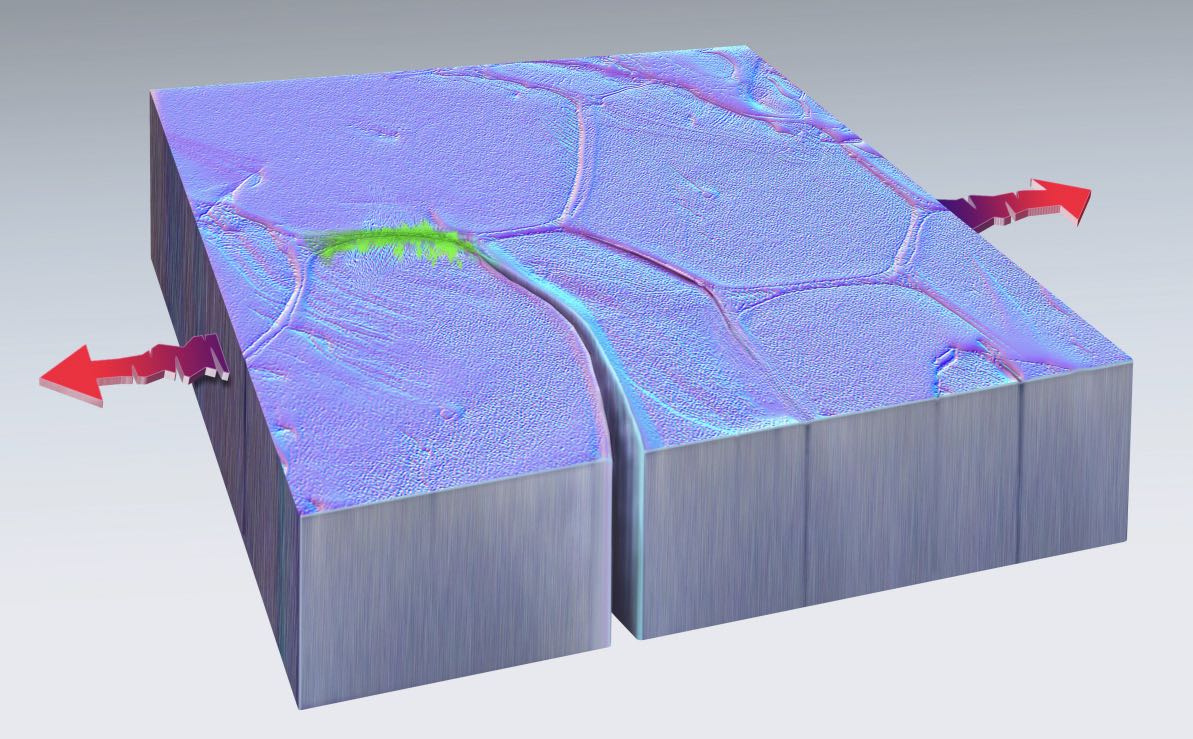

Figure 3 shows a schematic of the self-healing process. Pulling forces (red arrows) at each end of the platinum nanocrystal (depicted in blue) are creating the environment for the formation and then self-healing of a crack (shown in green).

Figure 3. The formation and self-healing (shown in green) of a crack is initiated through pulling forces (red arrows) at each end of a platinum nanocrystal (shown in blue). Figure courtesy of Sandia National Laboratories.

Figure 3. The formation and self-healing (shown in green) of a crack is initiated through pulling forces (red arrows) at each end of a platinum nanocrystal (shown in blue). Figure courtesy of Sandia National Laboratories.

Boyce says, “Atomistic modeling of the phenomenon indicated that the closing of the crack occurred through a cold welding process where the split surfaces move together until they eventually merge with each other. This analysis suggests the self-healing process is mechanical rather than diffusive. In the process, the tensile testing is creating strain causing hundreds of atoms to weld to each other producing the self-healing. For diffusion to be considered, high temperatures would be needed to facilitate atoms to weld to each other. This is not taking place under the ambient conditions of the experiment.”

Boyce indicated that the cold welding process appears to require interactions of the crack with the applied load and with a triple junction present in the microstructure. He says, “The location where two grain boundaries meet is known as a triple junction.”

Five conditions potentially present in a microcrystalline structure need to be examined to better understand the self-healing process, according to Boyce. The five conditions are inhomogeneous microstructural stresses that locally close the crack tip, grain boundary migration, a deflected crack, inhibited crack flank oxidation and also moving or arrested crack.

The demonstration of self-healing under vacuum conditions leads to the consideration of whether this effect may be taking place undetected in real-world applications to extend the operating life of machinery by slowing down fatigue crack propagation rates. Observing this process in ambient atmospheric conditions may be more challenging because most metals generate a protective oxide coating when exposed to air.

Boyce says, “Our intention is to study other materials such as steel, which are in greater use commercially to determine if cold welding can occur as a self-healing process.”

Additional information can be found in a recent article

3 or by contacting Boyce at

blboyce@sandia.gov.

REFERENCES

1.

Canter, N. (2022), “Designing high-entropy alloys,” TLT,

78 (11), pp. 12-13. Available

here.

2.

Canter, N. (2019), “Self-healing through carbon fixing material,” TLT,

75 (1), pp. 12-13. Available

here.

3.

Barr, C., Duong, T., Bufford, D., Milne Z., Molkeri, A., Heckman, N., Adams, D., Srivastava, A., Hattar, K., Demkowicz, M. and Boyce, B. (2023), “Autonomous healing of fatigue cracks via cold welding,”

Nature, 620, pp. 552-556.