Lead with creativity

By Dr. Hong Liang, STLE President | TLT President's Report November 2023

Creativity and analysis can lead to significant impacts on lubrication and environments.

So far we have discussed a few leadership traits. In this month’s TLT column, we’ll talk about creativity. Creativity in lubricants, energy and transportation sectors is becoming more important because of evolving challenges, technological advancements and the need for sustainability. Creativity in this context involves finding innovative ways to address traditional issues, adopting new technologies and exploring alternative approaches to operations and environmental concerns. Creativity and analytical thinking are complementary with each other. Integrating creativity into analysis can lead to more insightful and innovative solutions, while applying analytical thinking to creative processes can enhance their effectiveness and impact. A creativity and analytical thinking combined approach enhances problem-solving, decision-making and overall effectiveness. By fostering a culture that encourages both creative thinking and analytical rigor, we can achieve more comprehensive and impactful results. As a scientific and technical society, STLE has plenty of technical expertise, problem-solvers, critical thinkers, persuasive sales engineers and “nerdy” students and professors. How creative are we? I have a very good example for this.

Most of us know about phosphorus in the form of zinc dialkyldithiophosphate (ZDDP). The famous compound has been discussed at STLE annual meetings every year for more than five decades. ZDDP is known to be the most cost-effective antioxidant, anticorrosion and antiwar component in engine oils. However, phosphorus can enter the exhausting stream through consumption or volatilization. Such phenomena decrease the effectiveness of catalytic converters in automotive manufacturers to reduce exhaust gas emissions. It is called catalyst deactivation, making it difficult for auto makers to meet the EPA’s requirements of a 120,000-mile or 10-year warranty on the catalyst system.

In 2004, almost 20 years ago, it was reported that STLE Fellow Dr. Ewa Bardasz led a team at The Lubrizol Corp. that developed a new, low-volatility ZDDP technology that was tested for more than two years and 100,000 miles in New York City taxicabs. Those cars that used oil with this ZDDP technology showed an average of 46% lower volatile phosphorus, 10% lower oxides of nitrogen (NOX) and 15% lower carbon monoxide (CO) than taxicabs using oil containing traditional ZDDP technology. In that year, the team introduced its patent-pending, low-volatility ZDDP technology to provide engine oil formulators with an alternative to designing higher-cost engine oils with lower levels of ZDDP. It was an impressive achievement, was it not?

More impressive is that Bardasz explored knowledge related to the formation of soot and developed the innovative oil technology to control it. Two of her original publications can be found in Ref. 1 and 2. Her team’s work was recognized by the American Chemical Society Green Chemistry Challenge Awards Program as a part of a low volatility ZDDP collaboration between Lubrizol and Valvoline. Dr. Bardasz’s success is the testimony of creative leadership. Her ability is linking ways to think, innovate and approach challenges in unconventional and imaginative ways. Her creativity involves applying innovative and imaginative approaches to address challenges related to friction reduction, wear prevention and lubrication enhancement. Their success is the combination of creativity and analytical skills leading to significant impacts on lubrication and environments.

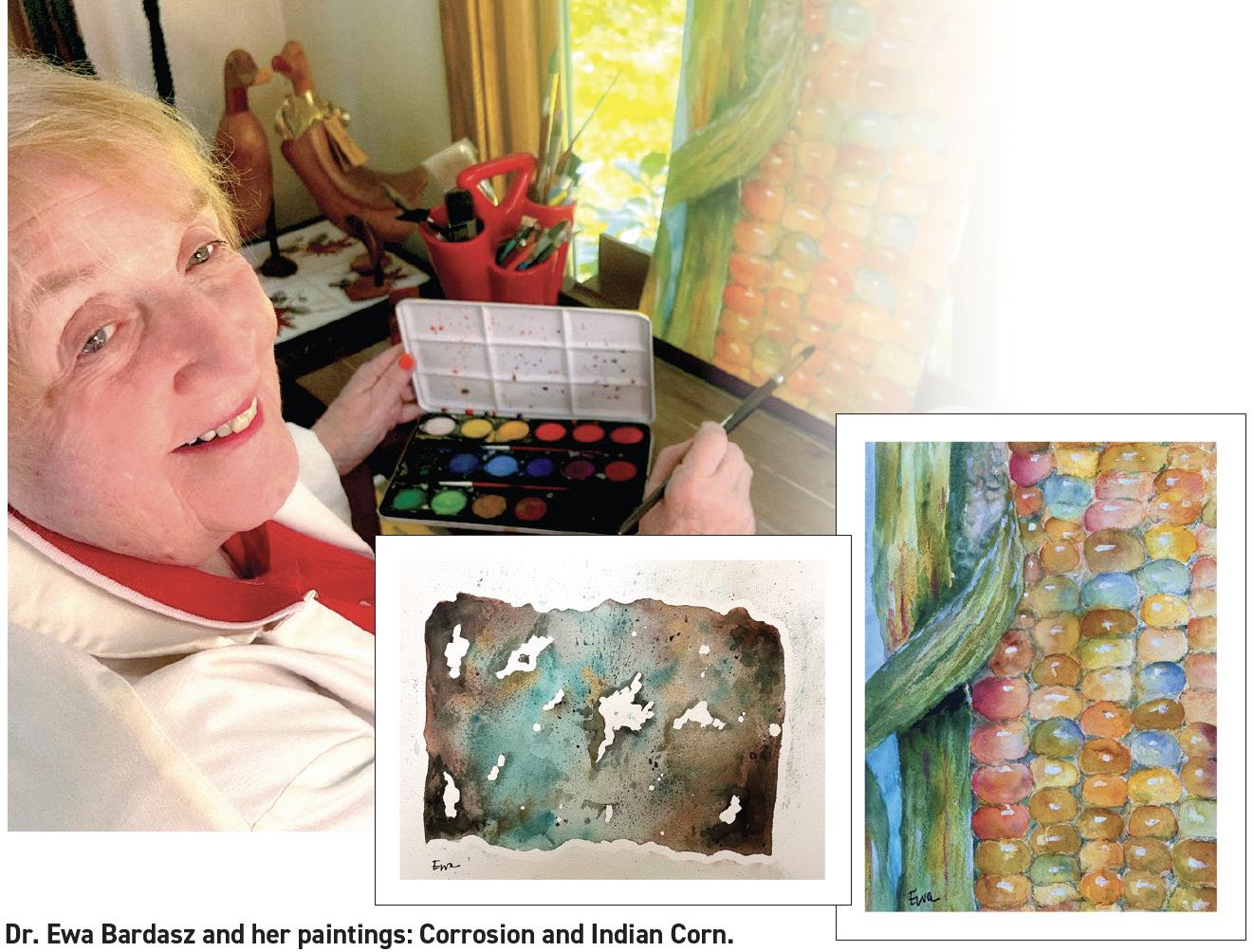

Talking about creativity, after retiring a few years ago, Dr. Bardasz remains active in professional and artistry fields. As a hobby she took on watercolor painting. The photo in this column shows her painting an Indian corn at her home studio. The color, texture and their combination remind her of the connection between sources of sustainable lubricants and the beauty of nature. With the upcoming holidays for many countries, and for the Thanksgiving holiday in the U.S., this picture is a wonderful gift to all of us. Our members are gifted and talented. We have a strong foundation to innovate and lead the field, no doubt.

REFERENCES

1.

Bardasz, E.A., Schiferl, E., Curtis T., et al. (2010), “Controlling lubricant derived phosphorous deactivation of the three way catalysts part 1: Assessment of various testing methodologies,”

SAE International Journal of Fuels and Lubricants, 3 (2), pp. 369-377.

2.

Bardasz, E.A., Schiferl, E., Vilardo J., et al. (2010), “Controlling lubricant-derived phosphorous deactivation of the three-way catalysts part 2: Positive environmental impact of novel ZDP technology,”

SAE International Journal of Fuels and Lubricants, 3 (2), pp. 925-937.

Dr. Hong Liang is Oscar S. Wyatt Jr. Professor of the J. Mike Walker ’66 Department of Mechanical Engineering at Texas A&M University in College Station, Texas. You can reach her at hliang@tamu.edu.