NOURYON is a leading global customer solutions business that provides essential, specialty chemicals for diverse end-markets, customers, and geographies. Our customer-centric business model is focused on providing tailored solutions that improve the performance, quality, and sustainability of our customers’ products across a variety of end markets, such as lubricants, fuels, oilfield, mining, packaging, paper, cleaning goods, personal care, crop protection and nutrition, paints, coatings, and more.

•

Operations in more than 80 countries

•

13 strategically located Innovation and Application Centers worldwide

•

60 geographically distributed manufacturing sites

•

77% of R&D product pipeline focused on solutions with sustainability benefits

•

EcoVadis Platinum rating (2022)

Growing Together with Our Customers

For more than 40 years, we have been innovating lubricant solutions that play an essential role in powering people around the world, one molecule at a time. We believe that collaboration is a key enabler to success, so we devote ourselves to understanding your needs. When what’s inside matters to you, we pave the way for you to create solutions that perform.

•

Versatile chemistry portfolio, including nitrogen derivatives, anionic and non-ionic surfactants, and performance polymers

•

Extensive synthesis capabilities, offering a broad spectrum of design possibilities to research, test, and formulate the most optimal solutions for your specific need

•

Reliable global manufacturing footprint, placing us close to customer operations and facilitating your better access to our products and expertise

Our range of

Armolube® lubricant solutions has a proven track record of driving quality and performance across various functionalities and applications (see chart below).

Armolube® Anti-wear Additives

Armolube® Anti-wear Additives

Our robust phosphate ester and amine portfolio delivers ash-free, anti-wear additives made from natural raw materials. Exhibiting strong wear performance at a comparatively low treatment rate and excellent oil solubility, these additives also offer friction modification, TBN, and detergency, among other functions.

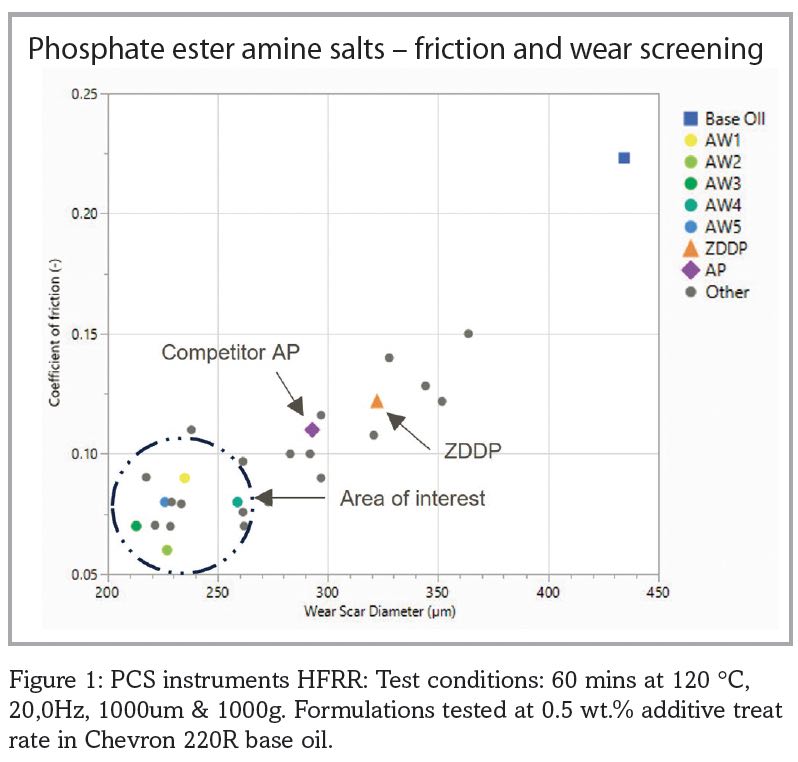

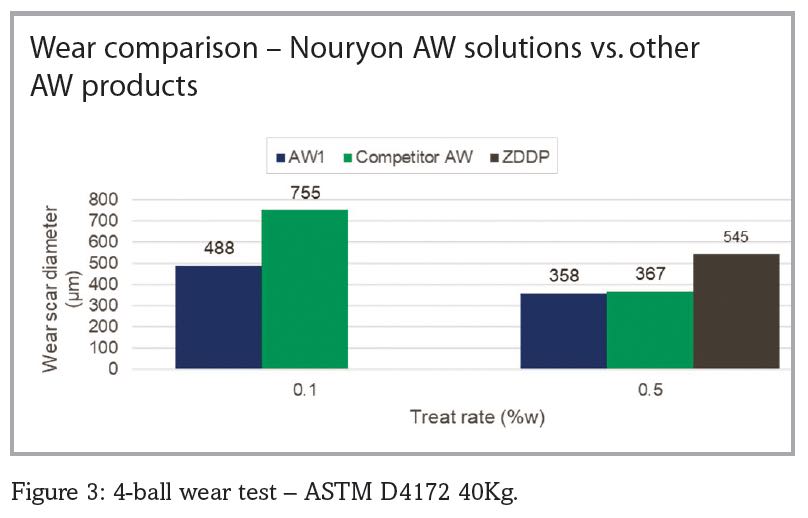

In a recent study, our phosphate ester amine salts outperformed ZDDP and competitor phosphate amine-based anti-wear products. They achieved both low friction and low wear conditions while exhibiting an ability to balance friction and wear properties based on application needs.

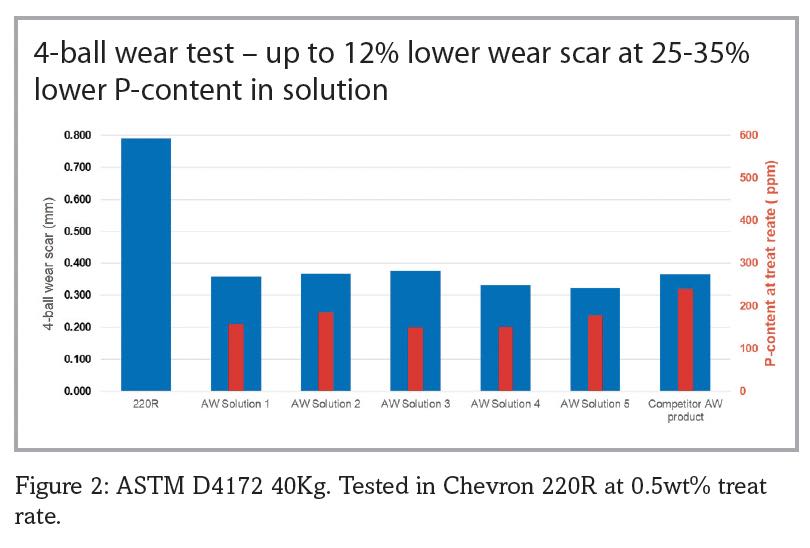

4-ball wear test results indicated lower wear scar diameter (WSD) values than the Competitor anti-wear product (AW) and the ZDDP, while also offering a considerably lower friction coefficient.

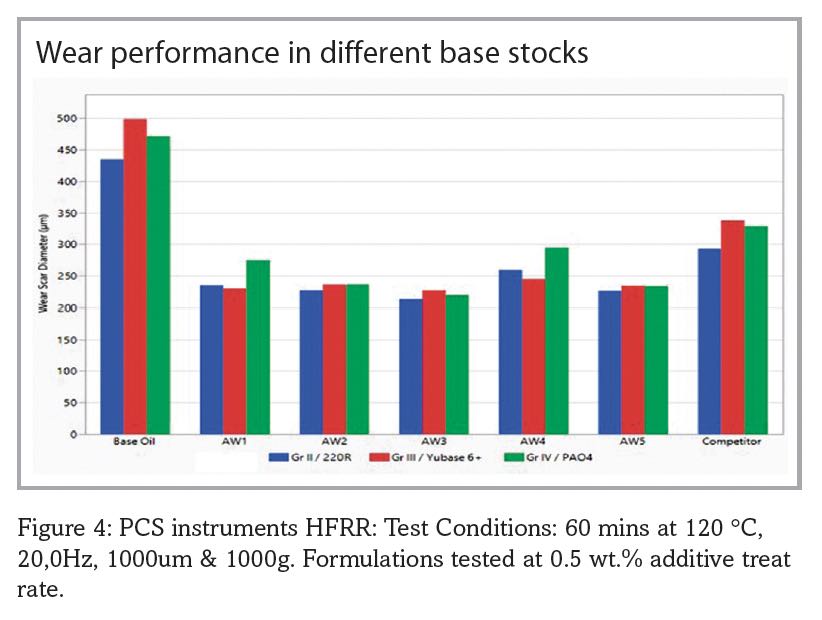

A wear performance test across different base stocks showed consistent favorable anti-wear functionality with minor variability being attributed to solubility differences between the base stocks.

Armolube® Friction Modifiers

Armolube® Friction Modifiers

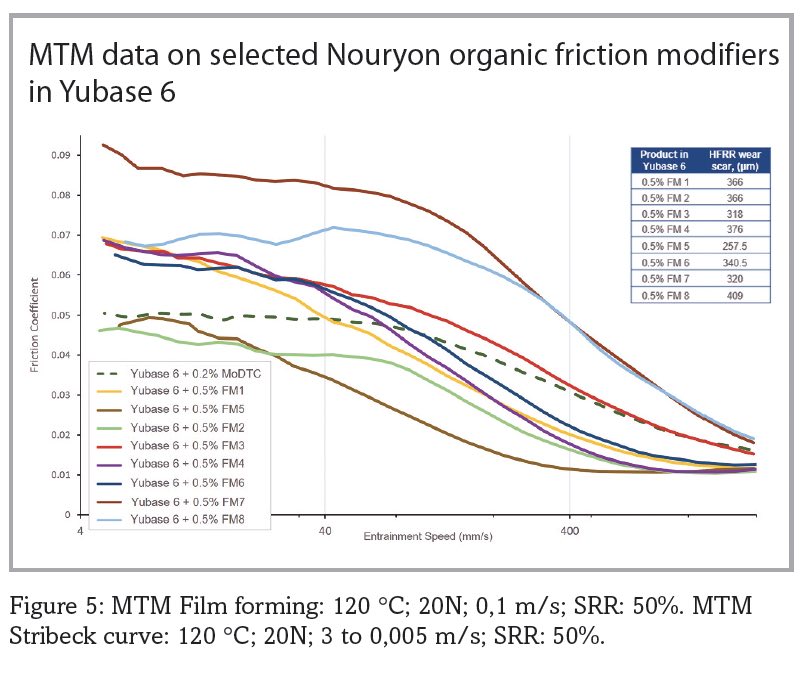

Fuel economy improvement remains a major challenge facing the automotive market, but having the right ingredients can help. Our strong amine derivative design capabilities equip you with the ability to tailor friction properties to meet diverse application and performance demands as well as sustainable options (Fig. 5).

•

Ash- and metal-free components derived from natural raw materials

•

Numerous primary, secondary, and tertiary fatty amines

•

Ethoxylated fatty amines with multifunctional properties

•

Neutralized fatty amine salts that allow for tailored friction and wear performance

•

Esters of fatty acids, polyacids, and/or alkanol amines that can deliver superior friction performance, film-forming characteristics, and synergistic benefits when used with MoDTC and/or ZDDP

•

Functionalized fatty amides to provide a combination of better product properties and friction performance

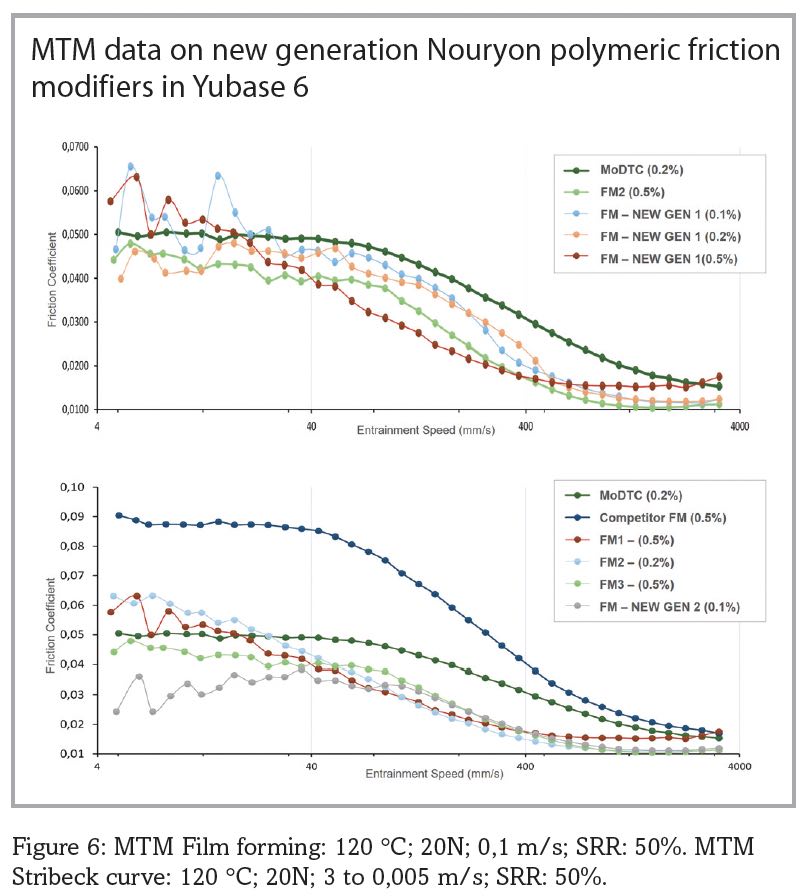

Our latest polymeric friction modifiers are able to deliver competitive performance in the boundary regime at a comparatively low treat rate of 0.2 wt% (Fig. 6, top) and across all friction regimes at a comparatively low treat rate of 0.1 wt% (Fig. 6, bottom).

Armolube® Thickener Precursors

Armolube® Thickener Precursors

We offer various precursors for the manufacture of polyurea grease thickeners, including three made from sustainable feed sources – Armolube® TM 97, Armolube® 18D, and Armolube® 12D.

Where Performance Meets Sustainability

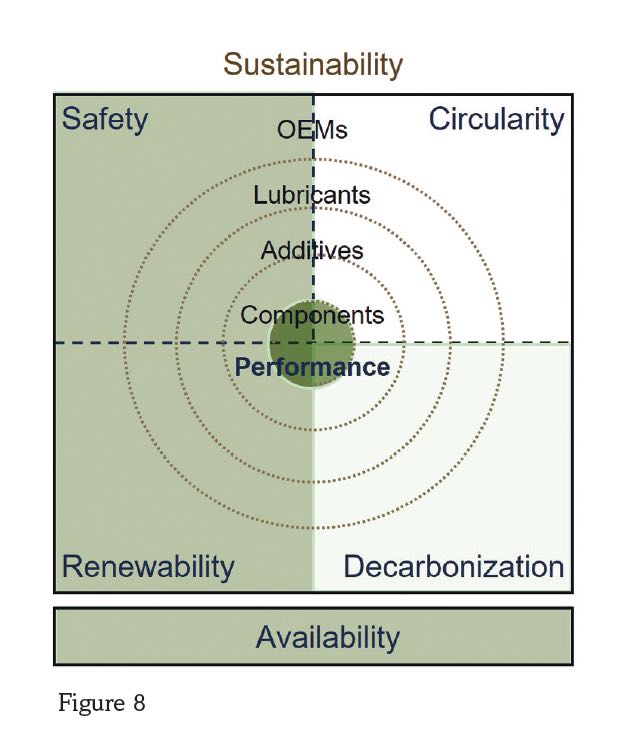

To help meet the growing demands for increasingly sustainable products, we create innovative tailored solutions in close partnership with our customers. Our design process (Fig. 8) is focused on:

•

Developing natural-derived, ash-free, and zinc-free solutions that meet or surpass customers’ performance objectives

•

Using partly or fully bio-based and renewable raw materials to allow flexibility and stability (e.g., tallow/vegetable-based)

•

Aligning with global and regional health/safety regulations

•

Allowing reliable access to our products and expertise in every region across the globe

•

Continuing reductions of our carbon footprint, waste, and water use, aspiring to be a net-zero organization by 2050

See our full sustainability report at

nouryon.com/sustainability

Armolube® Emulsifiers

Armolube® Emulsifiers

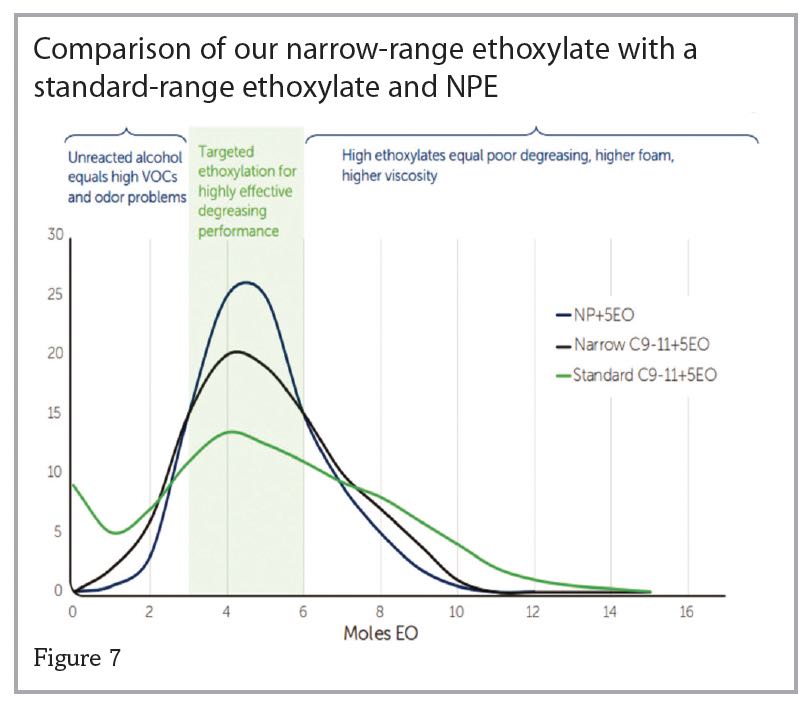

Our unique non-ionic, narrow-range ethoxylates provide targeted, cost-efficient, high-performing, and sustainable solutions (Fig. 7).

•

Improved performance at lower-use concentration

•

Faster wetting and spreading

•

Lower foam than standard ethoxylates

•

Superior temperature handling

•

Qualified for use in Safer Choice-certified products, as reviewed by EPA’s Safer Choice Program

•

Can be used to formulate EU Ecolabel products

Learn more by contacting us at lubes.fuels@nouryon.com or visit nouryon.com/markets/fuels-and-lubricants.