MÜNZING

FOAM BAN® Defoamers for Tank Side use in Aqueous Metalworking Fluids

By Stefanie Velez, Industrial Applications Manager, Münzing | TLT CMF Plus November 2023

Foam minimization during the use of aqueous metalworking fluids (MWFs) is required to maintain effective lubrication, heat removal, and prevent overflow of sumps. For these reasons, MWF formulations commonly contain defoamers, which control the foam as it forms by disrupting the interfacial energies that stabilize the foam bubbles. Due to many unavoidable factors, defoamers can lose persistence over time in the field. Extreme pressure, pH or temperature in the field can cause the in-concentrate defoamer to lose persistence. Contamination in the field can cause the MWF to become inherently foamier, resulting in a need for more foam control. Choosing the right tank side defoamer can increase sustainability by extending the life cycle of a MWF. Tank side defoamers are used in the field after the MWF concentrate has been diluted.

Attributes of a Tank Side Defoamer

Tank side defoamers have some of the same attributes as in-concentrate defoamers, such as fast foam break, persistence to filtration, and being washable and paint - able. But there are also other attributes that can play a role in their performance, such as spreading quickly on the surface, easy handling and short-term dilution stability.

There are five main properties to consider when choosing a tank side defoamer:

1. Foam break – how quickly the foam knocks down upon addition of defoamer

2. Foam Control Persistence – amount of defoamer required to maintain low foam levels

3. Dilution stability – level of kick out visible in the field

4. Filterability – how easily the defoamer is filtered out

5. Dosage Control – understanding the dosing system during the operation

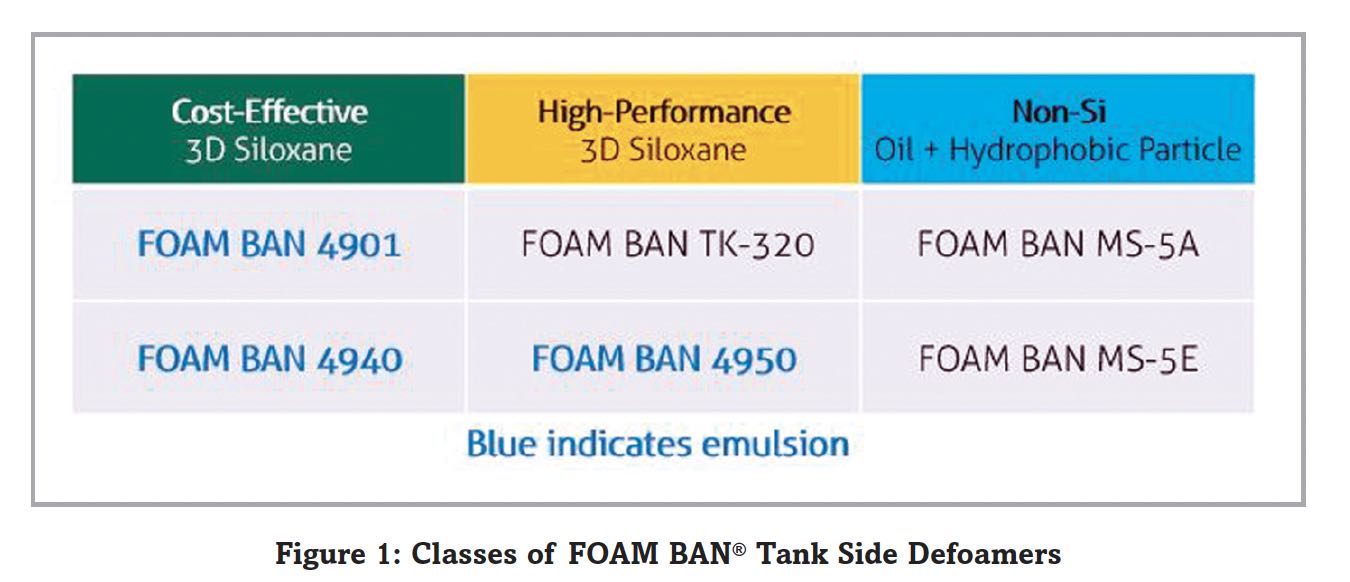

Depending on which properties are most important in the specific application, there are several different classes of tank side defoamers to consider. Cost-effective 3D Siloxane emulsions, high-performance 3D Siloxane defoamers, or the non-Si based defoamers (Figure 1).

Tank Side Defoamer Testing and Results

Tank Side Defoamer Testing and Results

Many defoamers were evaluated in tank side recirculation with many MWFs. The test method involved using a peristaltic pump and 1000mL cylinder to run the blank MWF dilution in a recirculating test. Every time the total volume reaches 800ml, tank side defoamer is added, the foam collapse is then recorded. At the end of the test, the total number of drops required to maintain a level lower than 800mL is recorded along with a rating based on the appearance of the glass walls indicating defoamer kickout.

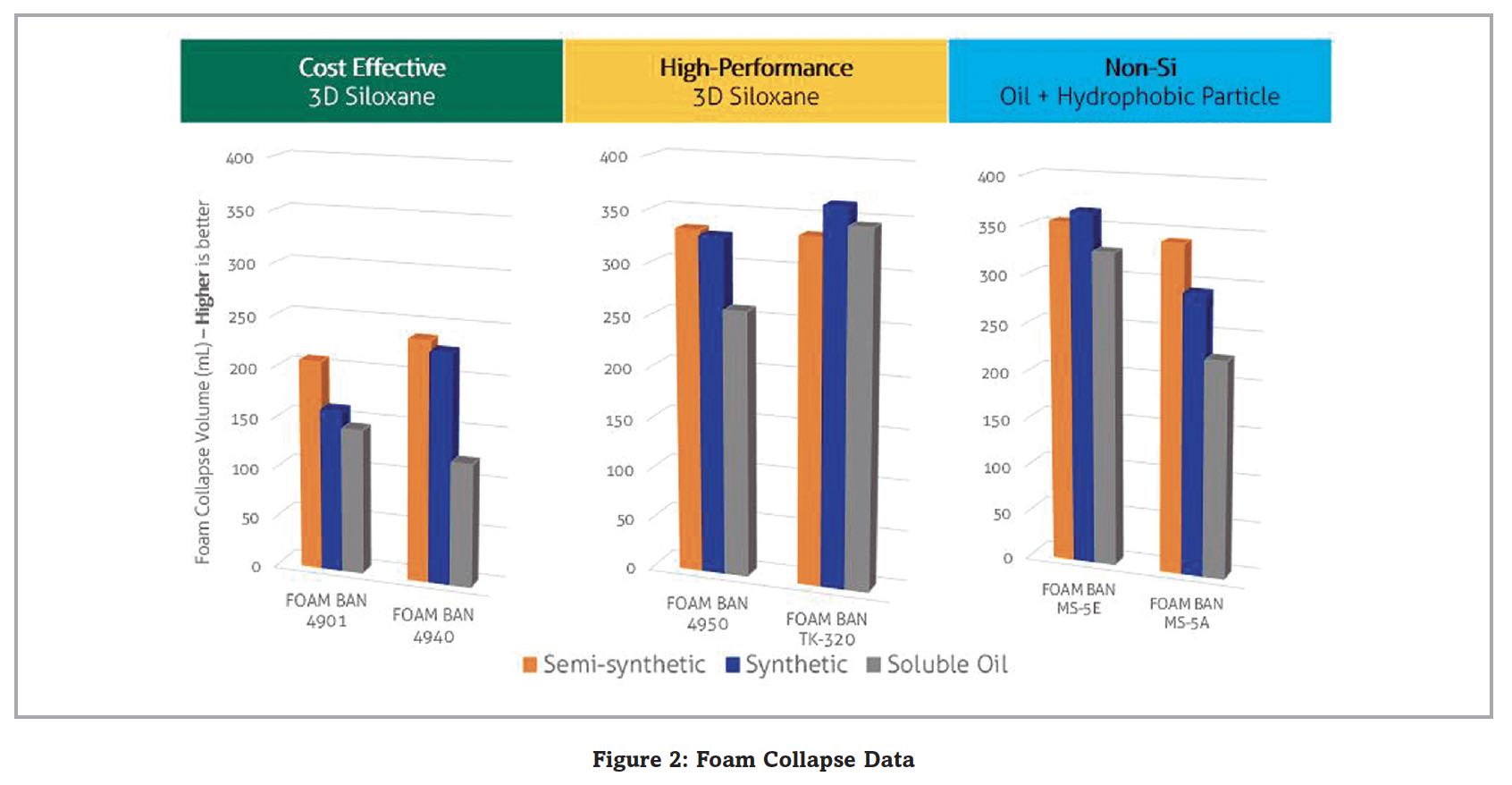

The first property to consider is the foam collapse as shown in Figure 2. Higher collapse volumes indicate better foam collapse. The high-performance 3D Siloxane and the non-Si oil based defoamers both provide significant foam collapse in all three fluid types. Specifically, FOAM BAN MS-5E provides better foam collapse compared to FOAM BAN MS-5A. The main difference between these two defoamers is the FOAM BAN MS-5E is more emulsifiable allowing the active to spread more quickly on the surface. The cost-effective 3D Siloxane defoamers provide less foam collapse compared to the other two categories.

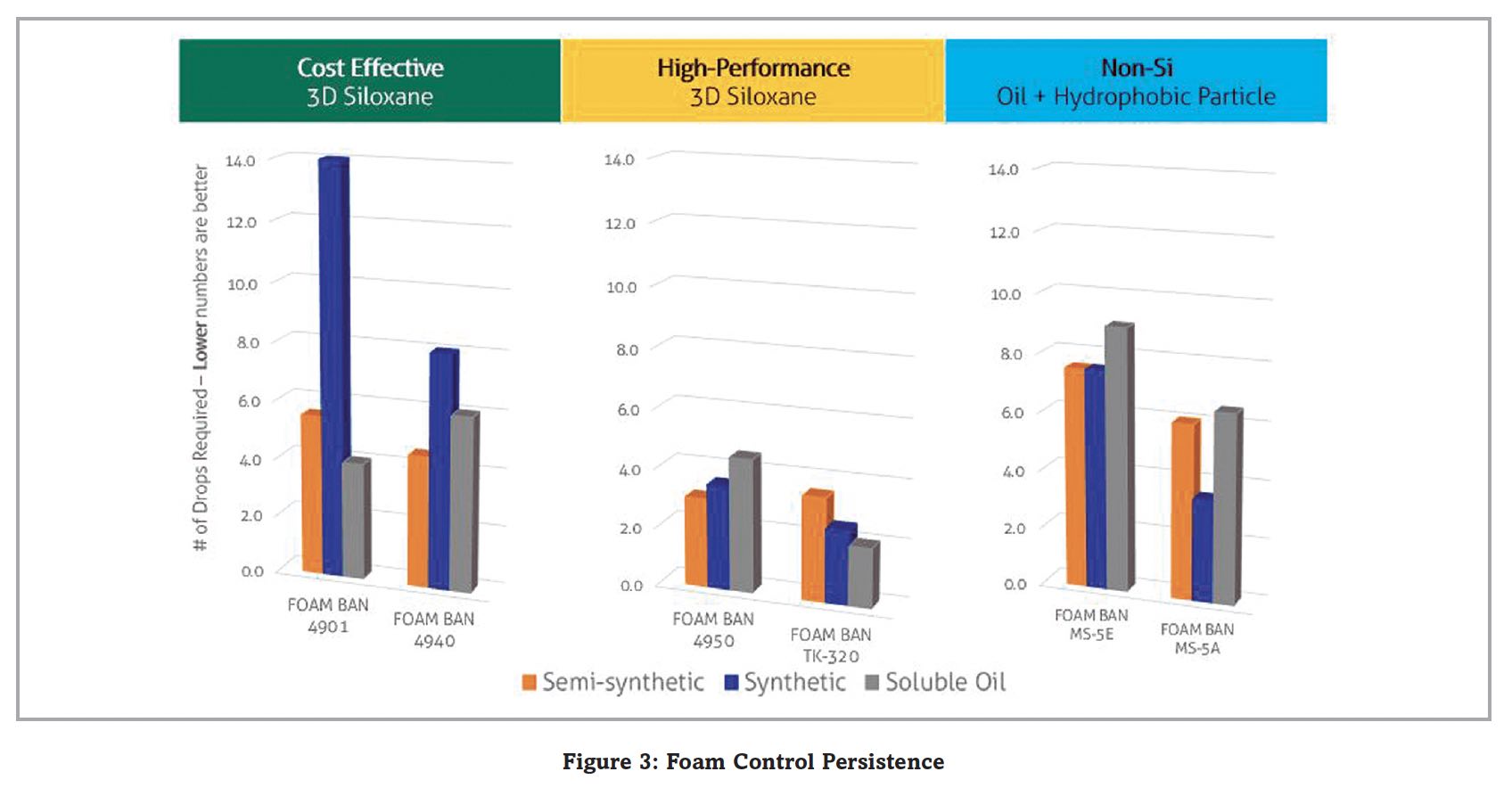

The second property to consider is the foam control persistence (Figure 3). Lower number of additions required indicates better persistence to shear. The high-performance 3D Siloxane products provide significant improvement in foam control persistence as compared to the other two categories. Within the non-Si group, it is observed that the less emulsifiable defoamer is more persistent. The cost-effective defoamers varied in performance depending on the fluid type, specifically they worked well in semi-synthetic and soluble oil formulations.

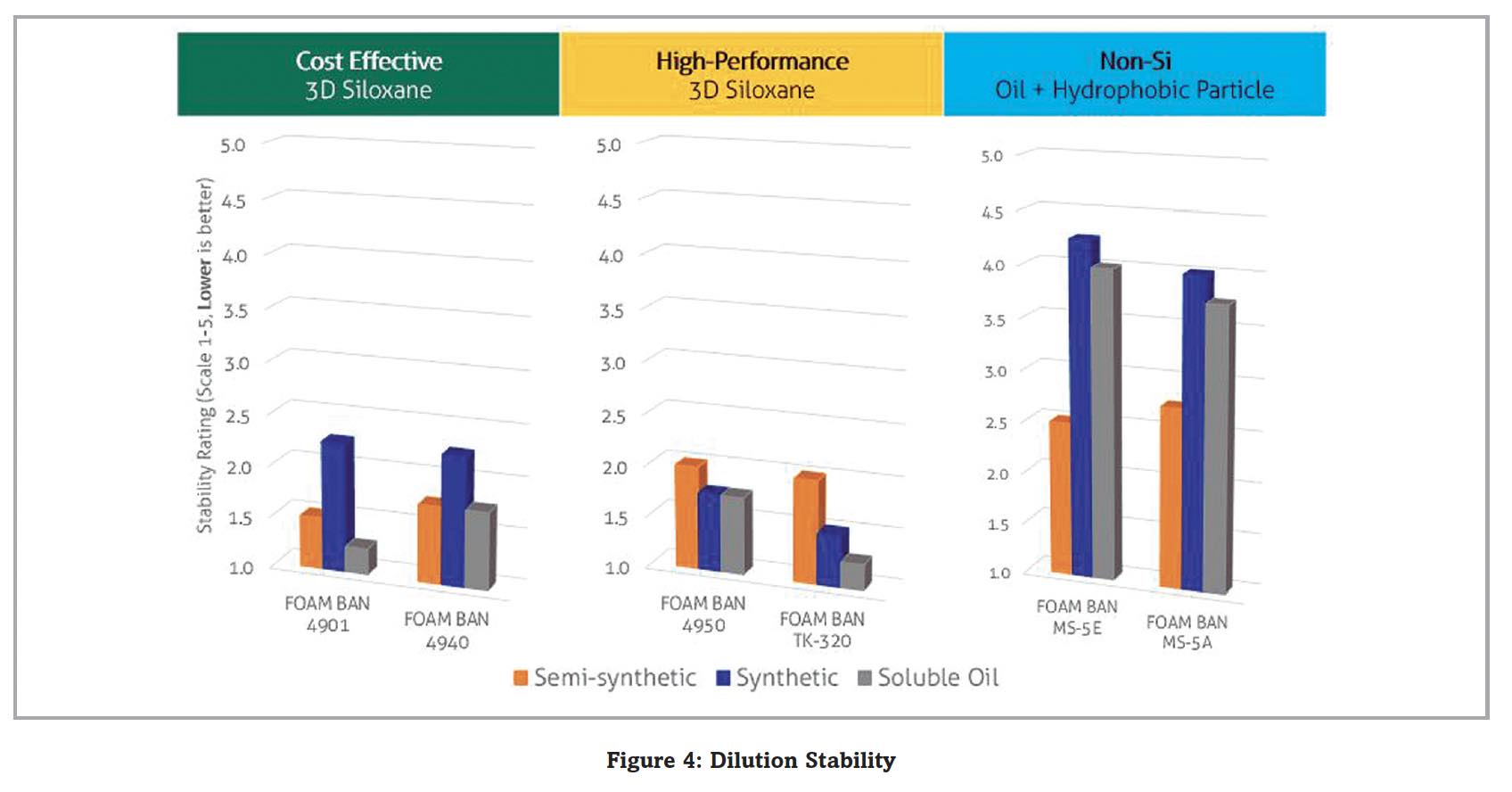

The third property is the dilution stability (Figure 4). Lower ratings indicate better stability in the dilution. All of the 3D Siloxane based defoamers provide good stability in the dilutions, while the non-Si based defoamers showed more kick-out after the test.

A further filtration test comparing a 3D Siloxane defoamer vs a non-Si oil based defoamer was completed. It was concluded that the non-Si oil based defoamers may have a tendency to clog filters more easily as compared to both cost-effective and high performance 3D Siloxane based defoamers.

The fifth property to consider is the dosage control, and depending on the dosing system at the end user, different defoamer types may be more optimal.

•

Good dosing system = high performance 3D Siloxane defoamers are most effective

•

No defined dosing system = over-dosing can be a risk when using high-performance 3D Siloxane defoamers, cost effective or non-Si defoamers are more optimal

•

Lower viscosity of the FOAM BAN® tank side defoamers compared to in-concentrate defoamers, leads to easier handling and spreading of the actives in the field

Conclusion

Conclusion

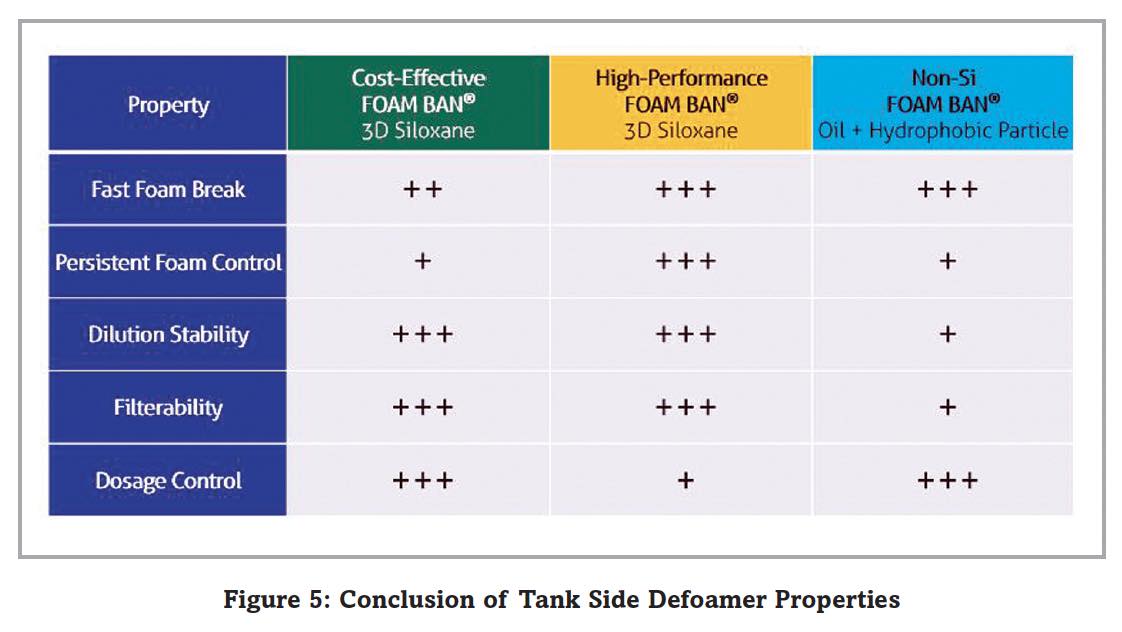

As shown in Figure 5, the cost-effective 3D Siloxane FOAM BAN® defoamers provide good dilution stability, average knockdown and foam control persistence and would be optimal for operations with high risk of over-dosing. The high-performance 3D Siloxane FOAM BAN® defoamers have optimal compatibility, knockdown and foam control persistence for operations with well defined dosing systems. The non-Si FOAM BAN® defoamers have good knock down and are low-cost but tend to show poor persistence, stability and filterability. The conclusion is, the most optimal tank side defoamer choice depends significantly on the specific application, system type and desired performance features that are required.