Kao Chemicals

Today’s Metalworking and Cleaning Challenges: Mastering Formulation Challenges for Sustainable Solutions

By Dr. Sabine Wohlfahrt, Kao Chemicals GmbH, Emmerich, Germany | TLT CMF Plus November 2023

Kao Chemicals is a supplier of surfactant technology for highend technical applications, particularly in the field of metalworking. With its global metalworking competence center, the company focuses on developing emulsifiers, co-emulsifiers, and solubilizers. Kao’s unparalleled expertise in metalworking stems from its production of specialty surfactants, primarily managed through the global metalworking competence center located at Kao Chemicals Germany, a division of Kao Chemicals Europe.

In this article, we will explore the Kao Metalworking Toolbox and the advantages of incorporating Kao additives into lubricant formulations. A particular emphasis will be placed on the corrosion and staining inhibition support provided by AKYPO® (ether carboxylic acid) and FOSFODET (low-foaming phosphate ester), as revealed by the latest findings from our application laboratory. The ultimate objective of all these discoveries is to achieve formulations that are not only low-foaming but also environmentally friendly and sustainable.

Metalworking and Cleaning Formulations Hurdles Demand Effective Solutions

Metalworking and cleaning fluids play a vital role in various industrial processes, and as technology and regulations evolve, formulators face a multitude of challenges in achieving optimal performance, sustainability, and safety.

The main challenges are the following:

•

Foam control: Excessive foam in metalworking fluids can lead to operational issues, reducing process efficiency and causing potential damage to equipment.

•

Fluid stability and longevity: The stability and longevity of metalworking fluids are essential for consistent performance and reducing maintenance efforts.

•

Water quality and hardness tolerance: The presence of hard water and dissolved salts can affect fluid performance and stability.

•

Enhanced performance: Industries continually seek improved performance to meet higher machining demands and achieve superior results.

•

One fluid fits all alloys and operations: Creating a universal fluid that works effectively across different alloys and machining operations is a complex challenge.

•

Increasingly severe and diverse machining conditions: As machining processes become more rigorous and diversified, fluids must adapt to varying conditions.

•

Corrosion & staining protection: Preventing corrosion and staining is crucial for extending the lifespan of equipment and maintaining product quality.

•

Cost effectiveness – efficiency of additives: Industries seek to balance performance with cost-effectiveness, optimizing additive efficiency.

•

Sustainability and safe handling requirements: Environmentally friendly and safe-to-handle formulations are becoming essential due to regulatory pressures and environmental concerns.

•

Stable global availability and usability: Consistency in the availability and usability of additives is vital for smooth operations on a global scale.

•

Shrinking additive toolbox: The restriction on certain additives due to regulatory or supply chain challenges limits the formulation options.

Facing the Challenges: KAO Chemicals’ Metalworking Toolbox

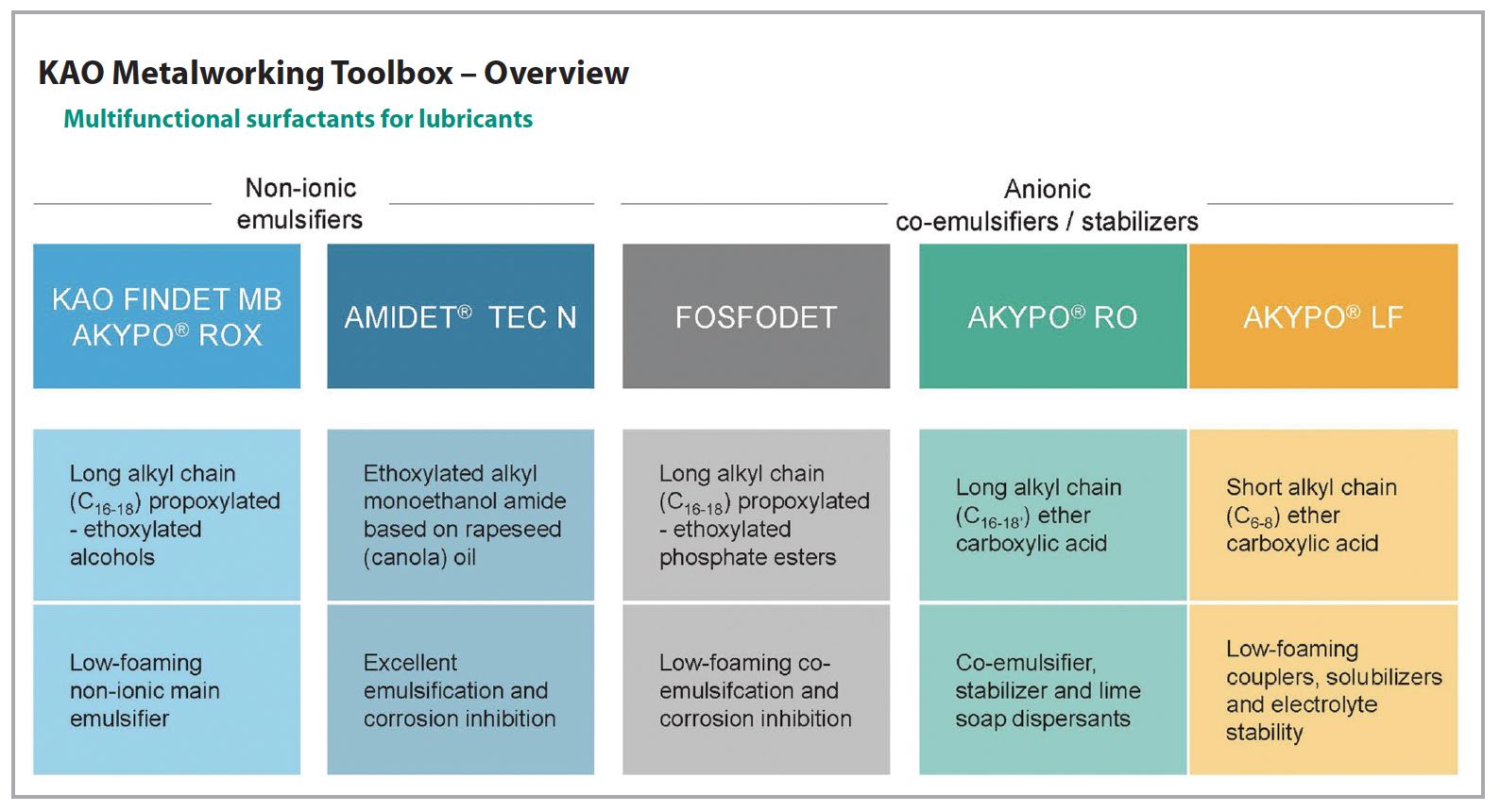

Kao Chemicals’ Metalworking Toolbox offers innovative solutions to the several critical hurdles that demand effective solutions within the metalworking industry. The toolbox comprises multifunctional surfactants designed to boost performance, effectiveness, and sustainability. Furthermore, the solutions presented consider prevailing global regulations and limitations.

Global regulatory pressure on alcohol ethoxylates, limitation of raw materials, foaming behavior, and the need for corrosion protection are key challenges faced with main emulsifiers. To address these issues, Kao Chemicals presents two non-ionic main emulsifier solutions:

•

KAO FINDET MB & AKYPO® ROX: A low-foaming emulsifier with high efficiency, excellent environmental profile, and global registration. It offers improved hard water stability and compatibility with various base oils. Three polarity (HLB) grades available:

•

KAO FINDET MB-212

•

AKYPO® ROX RS-0606N

•

AKYPO® ROX RC-0960N

•

AMIDET® TEC N: Derived from rapeseed oil with a renew able carbon content of 70%, this emulsifier provides high efficiency for formulations with high water content, corrosion-inhibiting properties, and favorable environmental characteristics.

The global regulatory pressure and restricted use of additives like chlorinated paraffins, foaming behavior, and impact on renewable carbon content demand effective solutions. Kao Chemicals presents the multifunction phosphate ester, FOSFODET, which acts as a low-foaming co-emulsifier with corrosion inhibition properties, especially on aluminum, and improved hard water and electrolyte stability. FOSFODET is ideal for straight oils, water miscible soluble oil, semi-synthetic and synthetic formulations. Product range with different EO degree:

•

FOSFODET CS-0602

•

FOSFODET CS-0606

•

FOSFODET CS-0609

Challenges with Stability and Solutions with AKYPO®

Challenges with Stability and Solutions with AKYPO®

Addressing issues such as short fluid longevity, water hardness, foaming behavior, corrosion, tramp oil rejection, and microbial growth is necessary for fluid stability. Kao Chemicals introduces AKYPO® LF, a long-term emulsion stabilizer that enhances foam control and tramp oil rejection in metalworking fluids. Additionally, AKYPO® multifunctional co-emulsifiers, such as AKYPO® RO and AKYPO® LF, improve emulsion stability, fluid cleanliness, and corrosion protection. In detail:

•

AKYPO® RO and TEC AM VG enhances foam control of metalworking fluids by limited foam formation tendency and fastest foam collapse rates when combined with fatty acids.

•

AKYPO® LF has a positive effect on the self emulsification of the formulation.

•

AKYPO® LF is beneficial for the tramp oil rejection behavior of metalworking fluids because of its hydrophilic and anionic structure.

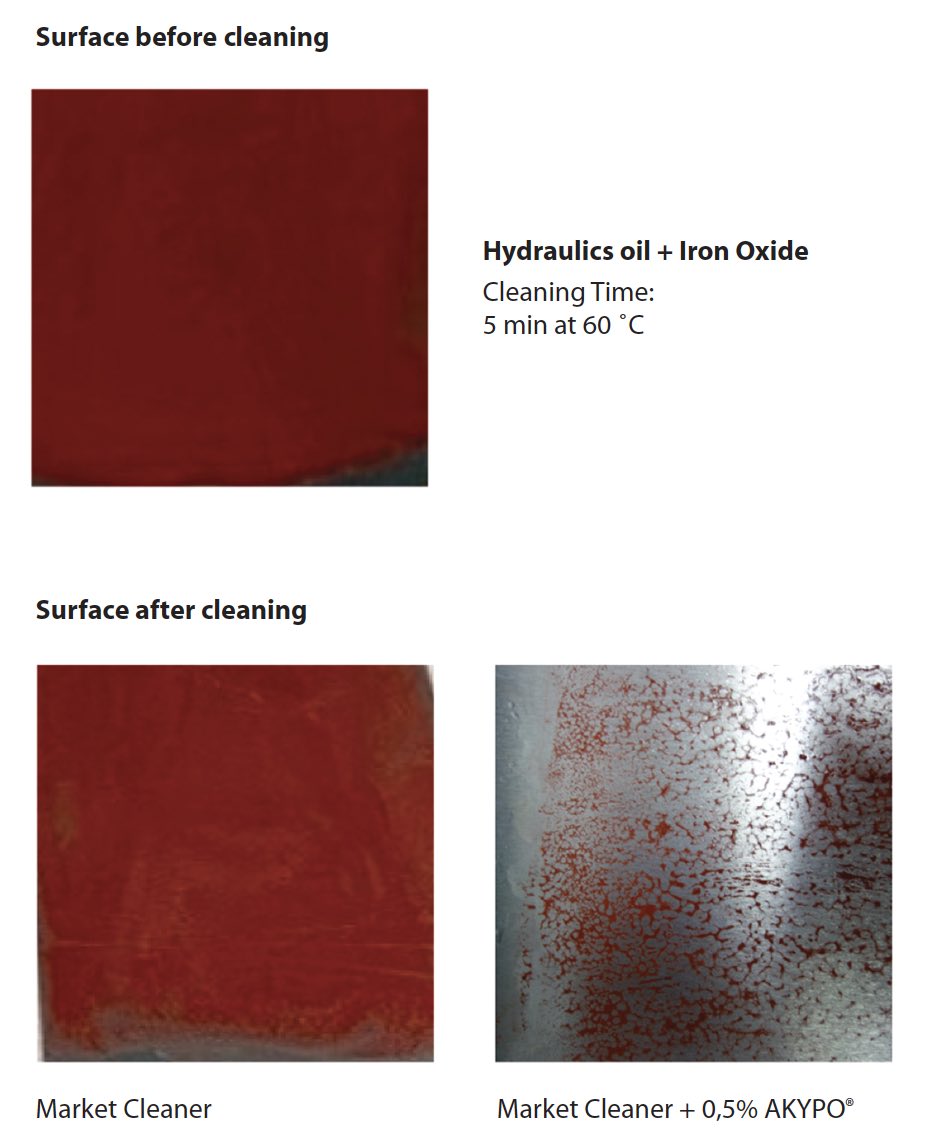

Apart from its significant advantages in metalworking formulations, AKYPO® also offers notable benefits in metal cleaning. It enables increased active cleaner content, leading to reduced water consumption and lower CO

2 emissions during transport. Moreover, it facilitates the formulation of more efficient and longer-lasting cleaner solutions, minimizing waste generation. Especially in the presence of particles the cleaning efficiency will be significantly improved.

In the dynamic landscape of metalworking and cleaning fluid formulation, the challenges presented are indeed multifaceted. However, the comprehensive solutions provided by the Kao Metalworking Toolbox meet the challenge. As the metalworking industry deals with foam control, fluid stability, enhanced performance, and the pursuit of eco-friendly formulations, Kao Chemical’s multifunctional additives stand as reliable partners.

Designed with a deep understanding of the intricacies of global regulations and constraints, these solutions show Kao Chemical’s dedication to quality. Efficiently becoming part of the changing industry, they improve how emulsions work, make it easier to handle hard water and electrolytes, and bring in a new era of formulations with less foam. The toolbox’s offerings go beyond just operational advantages, also protecting equipment and product quality by preventing corrosion and staining.

Also, Kao Chemicals’ dedication to worldwide availability is significant. With products spanning the globe and rooted in renewable sources, the brand not only enhances operational efficiency but also helps conserve resources, particularly by extending the life of fluids and saving water.

In a world that thrives on innovation, the Kao Metalworking Toolbox stands as an exemplar, leading the path to advanced and eco-friendly metalworking fluids. Its versatile additives represent both progress and responsibility, balancing operational excellence with environmental awareness. As the industrial scene evolves, Kao Chemical’s solutions stand as a crucial partner, working towards efficiency, longevity, and a greener future.