Evonik Oil Additives USA, Inc.

Novel Base Oil Technologies for Automotive Driveline Fluids

By Justin Langston, Regional Technical Director Americas, Evonik Oil Additives USA, Inc. | TLT CMF Plus November 2023

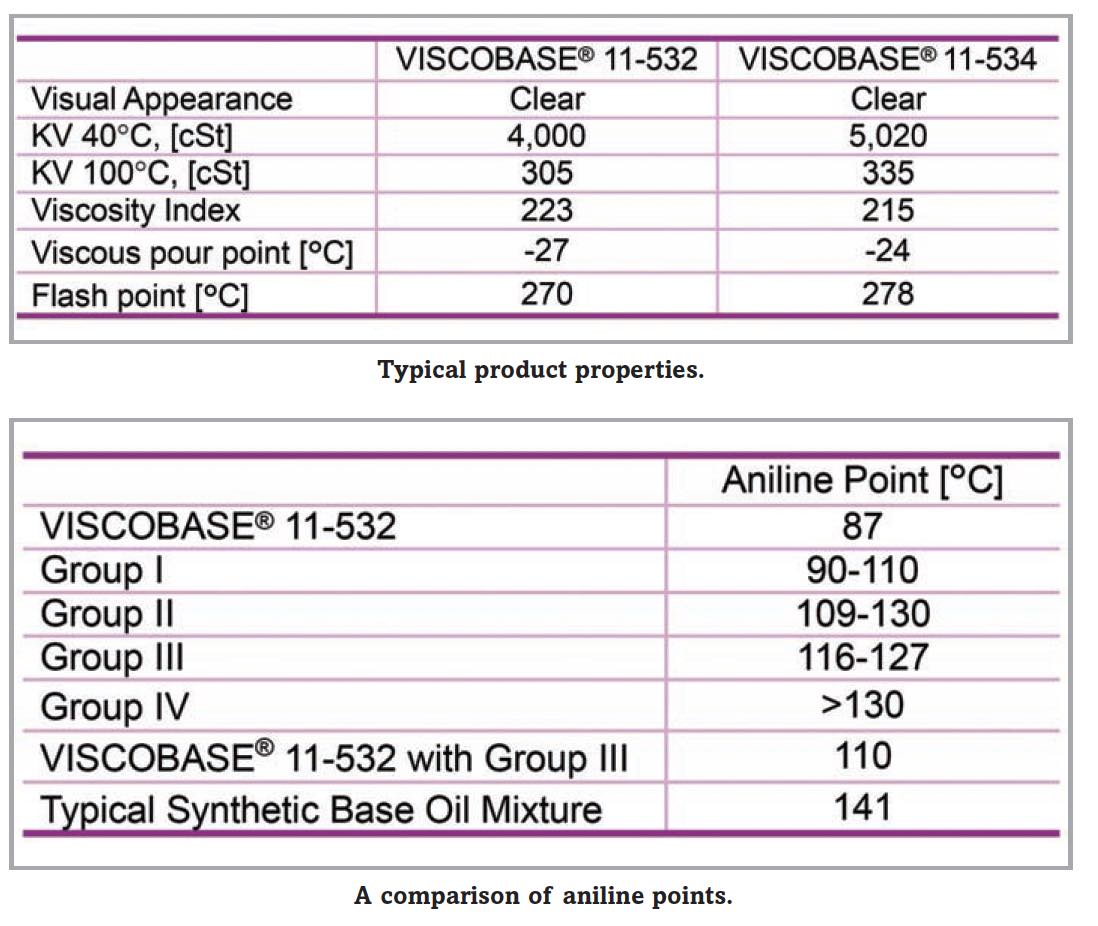

Evonik has recently added two new products, VISCOBASE® 11-532 and VISCOBASE® 11-534, to its portfolio of synthetic high-viscosity base stocks. These products have a wide range of application, including fluids for heavy- or medium-duty truck transmissions. These transmissions include manual, automatic, automated manual, and, with the overall interest in new mobility, transmissions for the electrification of commercial vehicles. Driven by the need to reduce emissions and operating costs, the market continues to explore ways to improve efficiency, lengthen oil drain intervals, and include more sustainable components.

To address these needs, the lubricant market has experienced a shift to lower viscosity grades and higher quality base stocks. Decreasing the viscosity of lubricant formulations provides improvements in efficiency, reduces emissions, and lowers equipment operating temperatures. High quality base stocks, often synthetic, provide excellent oxidative stability and their high viscosity indices and rheological properties further contribute to improvements in efficiency. However, these synthetic base stocks are often based on hydrocarbon chemistries and require energy intensive production routes. Therefore, they lack polarity required for compatibility and have higher product carbon footprints.

In response to these unmet needs, Evonik developed VISCOBASE® 11-532 and 11-534. These novel, high-viscosity base stocks offer unique solvency and low-temperature performance advantages. They work well with a wide range of base oils, providing formulation flexibility, and have low product carbon footprints, allowing for more sustainable formulations. These products take advantage of Evonik’s global supply chain and are available globally. Additionally, they provide high viscosity index, high flash points, and oxidative stability. They are also sulfur-free.

Balanced Polarity

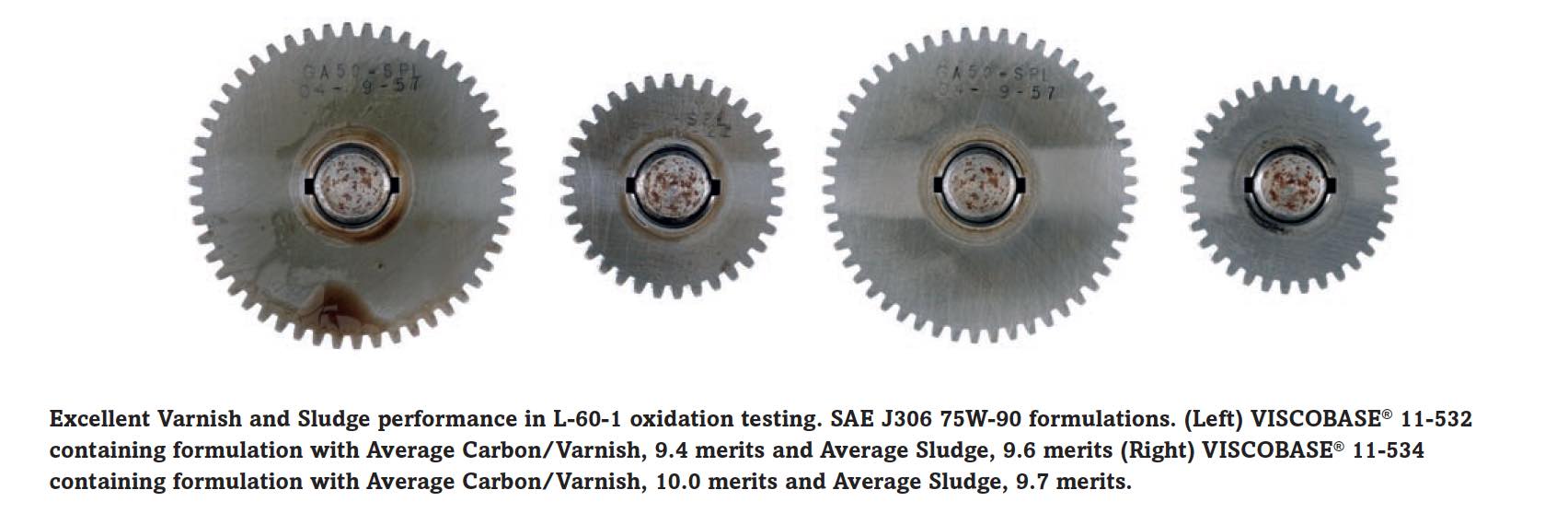

VISCOBASE® 11-532 and 11-534 offer balanced polarity, which is demonstrated by their aniline points. When combined with Group II or Group III base stocks, the aniline point of the mixture is around 110 degrees C. This is lower than the aniline point of typical synthetic base oil mixtures and results in a number of advantages, including additive package compatibility. The balanced polarity of VISCOBASE® promotes cleanliness. This is exemplified by CEC L-48-1 and L-60-1 oxidation stability tests in which VISCOBASE® improves glassware cleanliness and reduces varnish and sludge on the test gear and pinions. Results suggest that the improved varnish and sludge ratings are accomplished by keeping the byproducts of oxidation in the lubricant through enhanced solvency. Otherwise, the byproducts of oxidation could precipitate from the lubricant resulting in sludge and varnish that could decrease efficiency through insulation and higher operating temperatures.

Compatibility with seals and elastomers is also influenced by the polarity of base oil. Formulators need to achieve a careful balance of seal swell without extracting chemical compounds from the seals which would result in embrittlement. VISCOBASE®-containing formulations display excellent performance in static and dynamic elastomer compatibility testing. In particular, observations made during dynamic tests indicate that typical failure mechanisms, resulting in shaft wear and lubricant leakage, are eliminated when using VISCOBASE® high viscosity base stocks.

Dispersancy

Dispersancy

The unique technology used in the synthesis of VISCOBASE® base fluids enables their modification with dispersant functionalities while keeping the other properties unchanged. The dispersancy included in VISCOBASE® 11-534 can further improve oxidative stability performance. In both the CEC L-48-1 and L-60-1 oxidation stability tests, the dispersant version of VISCOBASE® provided additional improvements in glassware cleanliness, as well as varnish and sludge merits. This improvement is achieved through the addition of dispersant functionality that is built into VISCOBASE® 11-534.

High Viscosity Index

In addition to the balanced polarity and improved carbon footprint, VISCOBASE® 11-532 and 11-534 contribute to high viscosity index formulations while exhibiting excellent shear stability. This combination provides outstanding temperature-viscosity behavior that remains stable over the lifetime of the fluid. When combined with a 4-centistoke Group III base stock, viscosity indices of about 170 are obtained. This is about 10-20 points higher than other synthetic, high-viscosity base stocks, and translates into broader temperature operating window, superb low temperature performance, and improvements in transmission efficiency.

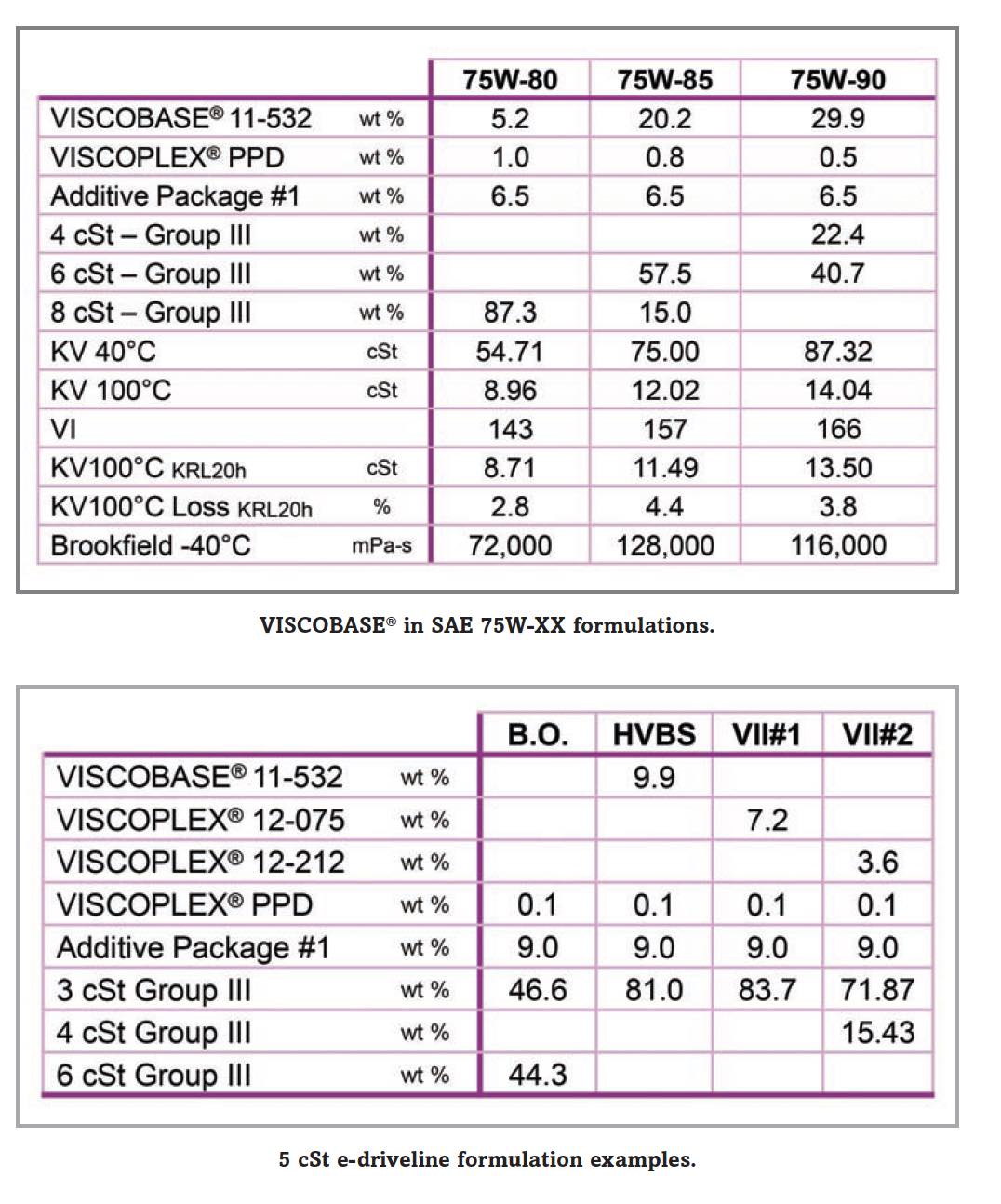

SAE J306 Formulation Examples

VISCOBASE® 11-532 and 11-534 can be used to formulate a wide range of automotive gear lubricants from 75W-80 to 75W- 140 while meeting the rheological and exceeding the low-temperature requirements of SAE J306. For example, VISCOBASE® 11-532 can be combined with high performance additive packages, Group III base oils, and VISCOPLEX® PPD to achieve SAE 75W-80, -85, and -90 grades. These formulations also meet shear stability requirements, with all staying in-grade following a 20-hour KRL shear stability test.

Lower Viscosity E-driveline Examples

Lower Viscosity E-driveline Examples

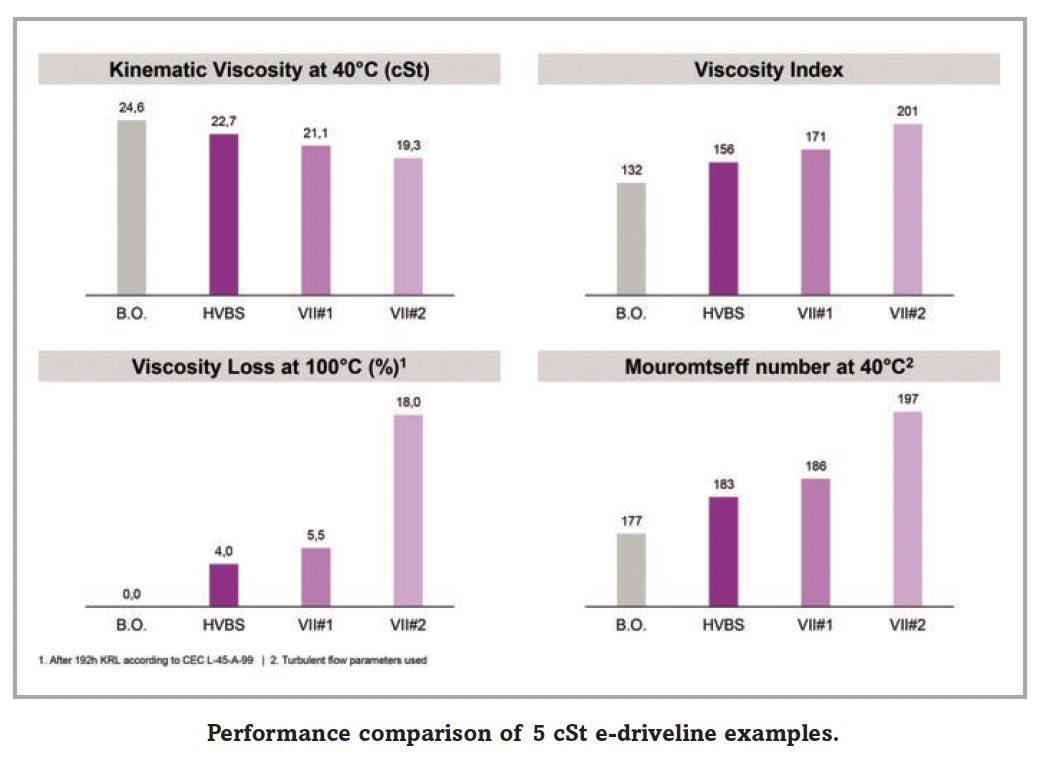

As the automotive industry continues to shift towards electric vehicles, there is a growing need for more efficient e-driveline formulations. One way to achieve this is by increasing the viscosity index with highquality VI improvers. However, as the viscosity index is increased, there is typically a trade-off in shear stability with traditional VI improvers. VISCOBASE® is particularly suitable for formulations demanding low levels of viscosity loss. VISCOBASE® 11-532 and 11-534 have excellent shear stability, and the viscosity loss of these e-driveline ex - amples is less than 5% for a 192-hour KRL.

High viscosity index formulations have lower viscosities at 20 and 40 degrees Celsius which can also have a positive impact on thermal properties. By calculating and comparing Mouromtseff numbers, it can be established that lowering the viscosity improves the fluid’s ability to transfer heat away from the motor, resulting in improved efficiency. Mouromtseff numbers are determined from measured values for density, viscosity, heat capacity, and thermal conductivity and constants for turbulent flow that represent the sensitivity of heat transfer to each property.

Takeaways

Takeaways

VISCOBASE® 11-532 and 11-534 provide shear-stable thickening and high-VI formulations. Unlike other high viscosity base stocks, VISCOBASE® is polar and exhibits a balanced solvency which promotes compatibility with elastomers and seals. These features make VISCOBASE® a versatile formulation tool for heavy- and medium-duty truck transmission lubricants with high-efficiency and long drain interval targets. Additionally, VISCOBASE® 11-532 and 11-534 are suitable for low-viscosity e-driveline fluids and rheological testing indicates that they should improve the heat transfer capability.

The author would like to acknowledge those who have contributed to this article, namely Eva Wittig, Helmut Melchior, Gabriela Fedor, and Thomas Schimmel. He also acknowledges Dan Davis, André Dawson, Katja Nothdurft, Stefan Maier, and Katrin Schoeller for their application testing and product development.