HIGHLIGHTS

•

Concern has increased about the potential harmful effects of perfluoro- and polyfluoroalkyl substances (known as PFAS) to animals and human beings.

•

PFAS removal from water has proven effective using granular activated carbon and anion exchange resins, but challenges persist with removing solid PFAS from exhausted carbon and resins.

•

PFAS removal from water has proven effective using granular activated carbon and anion exchange resins, but challenges persist with removing solid PFAS from exhausted carbon and resins.

Perfluoro- and polyfluoroalkyl substances (known as PFAS) have become of significant concern for users and manufacturers of lubricants in the recent past. The concern is due to PFAS causing health effects in animal studies and potentially being considered to be harmful to human beings.

The concern about potential PFAS health risks originates from the difficulty in decomposing them. This class of chemical substances are known as “forever chemicals.” In lubricants, PFAS are used to manufacture fluorinated lubricants, and are precursors to fluoroelastomers used in seals. Their presence in a wide range of applications means they are found throughout the environment, specifically in ground water used for consumer and industrial use.

Regulatory agencies have initiated programs to limit the use of PFAS as a means to reduce their presence in the environment. In the European Union (EU), The European Chemicals Agency (ECHA) is now considering a proposal from authorities in member countries to ban approximately 10,000 PFAS substances from use in the EU.

1 The U.S. EPA is proposing maximum contaminant levels for six PFAS substances in drinking water.

2 For two of the substances, perfluorooctanoic acid (PFOA) and peflurooctanesulfonic acid (PFOS), EPA is proposing maximum contaminant levels of 4.0 parts per trillion.

Feng Xiao, associate professor in the department of civil and environmental engineering at the University of Missouri in Columbia, Miss., says, “PFAS removal from water can be accomplished using granular activated carbon (GAC) and anion exchange (AIX) resins. While effective, challenges persist with removing solid PFAS from exhausted carbon and resins.”

Using inorganic salts (such as sodium chloride) or methanol has been tried but is ineffective because PFAS is far more hydrophobic than inorganic anions such as chloride. Thermal methods such as smoldering and thermal desorption have shown promise but require a high amount of energy and are time consuming. Incineration of PFAS-spent media is another option that is very expensive and can generate toxic chlorinated/brominated dioxins and furans.

With the concern rising about PFAS contaminating lubricant manufacturing and end-user facilities through a number of ways including water, a new approach is needed to effectively remove it from spent media. High-frequency induction heating has now been determined to be a technique for removing PFAS from spent media in a fast and effective manner.

The Joule effect

Xiao and his research group determined that a technique known as high-frequency induction heating can be used to effectively remove PFAS from spent media in only a few minutes at elevated temperatures

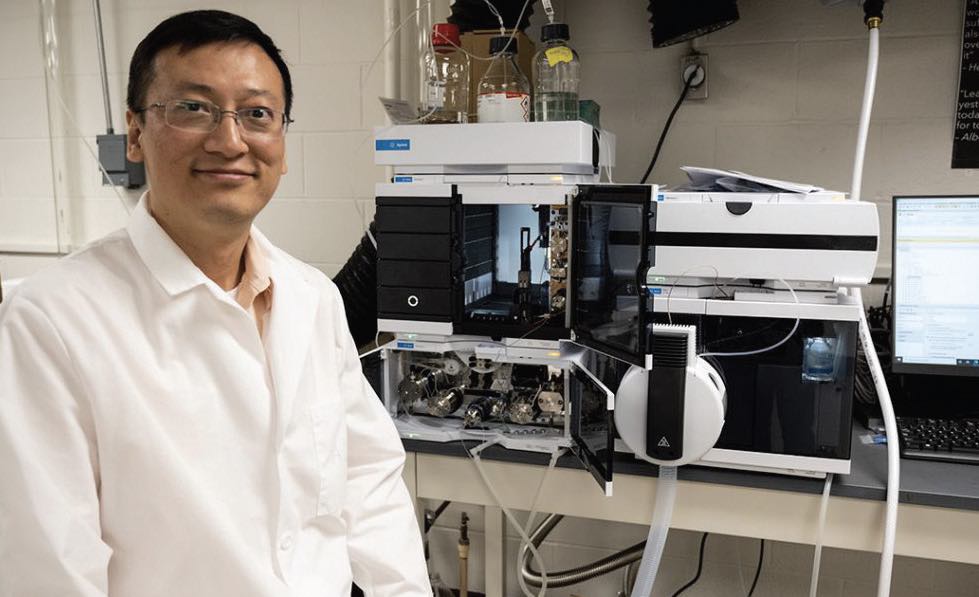

(see Figure 2). He says, “Induction heating utilizes the Joule effect, which involves the production of heat in a metallic reactor by electromagnetic induction without the need for direct contact between the heater and the reactor.”

Figure 2. Associate professor Feng Xiao led a research team that has developed a new technique known as high-frequency induction heating that can efficiently remove PFAS from spent media. Figure courtesy of the University of Missouri.

Figure 2. Associate professor Feng Xiao led a research team that has developed a new technique known as high-frequency induction heating that can efficiently remove PFAS from spent media. Figure courtesy of the University of Missouri.

An inductive reactor was used in conducting experiments with all six PFAS in the EPA regulation (including PFOA and PFOS) and five derivatives.

Xiao says, “Heating PFAS samples by high-frequency induction heating for less than 40 seconds resulted in the degradation of greater than 90% of the PFAS. If the induction time was extended to greater than 40 seconds, more than 99.5% of the PFAS was decomposed. Each of the PFAS substances had different rates of decomposition, which meant that extending the induction heating time to two to three minutes was needed to completely degrade the potassium salt of PFOS.”

As part of this study, Xiao and his students also decided to better understand how PFAS undergo phase transitions (melting and evaporation). Based on thermogravimetric analysis and differential scanning spectroscopy, the researchers found preliminary evidence that the rate-determining step in the decomposition of PFAS are phase transitions.

A final advantage of the induction method is safety because the use of an open flame is not required, and combustion does not occur. Xiao says, “One concern is that we noticed corrosion in the reactor probably due to the interaction of reactive fluorine species (such as fluorine radicals and hydrogen fluoride) with the reactor to produce metal fluoride. We previously determined that adding amendments to PFAS prior to heating minimizes the formation of fluorine derivatives reducing the possibility of corrosion.”

Future work will entail gaining a better understanding of the decomposition mechanism for PFAS. Xiao adds, “We also will be using this inductive heating approach to develop practical solutions for applications where PFAS is present and must be removed.”

Additional information can be found in a recent article

3 or by contacting Xiao at

feng.xiao@missouri.edu.

REFERENCES

1.

Click here.

2.

Click here.

3.

Xiao, F., Sasi, P., Alinezhad, A., Sun, R. and Ali, M. (2023), “Thermal phase transition and rapid degradation of forever chemicals (PFAS) in spent media using induction heating,”

ACS ES&T Engineering, https://doi.org/10.1021/acsestengg.3c00114.