Does molecular branching control boundary lubrication?

By Drs. Wilfred T. Tysoe & Nicholas D. Spencer, Contributing Editors | TLT Cutting Edge October 2023

Resonant frictional measurements as a function of film thickness reveal how the branching of organic molecules influences their molecular ordering near the surface and the transition from hydrodynamic to boundary lubrication.

Lower-viscosity fluids are preferred for lubricants that operate under hydrodynamic (fluid-film) lubrication conditions at high sliding speeds (V) and low loads (L). This leads to low friction when the V/L ratio is large, according to the well-known Stribeck curve. The downside is that such low-viscosity fluids have a greater tendency to stray into the higher-friction boundary-lubrication regime as V/L decreases. The conventional explanation for this transition from the hydrodynamic to the boundary-lubrication regime is that the film thickness decreases below the surface roughness, allowing the interfacial asperities to contact to cause the friction to increase as the velocity decreases and/or the load increases. An alternative molecular-scale explanation has been proposed: that the friction increase is due to the formation of a compact, solid-like, very viscous layer as the film thickness decreases. If this is the case, it should be possible to control the transition from the hydrodynamic to the boundary lubrication regime simply by controlling the molecular structure of the lubricant.

Professors Kazue Kurihara and Masashi Mizukami from Tohoku University in Sendai, Japan, in collaboration with Dr. Masanori Iizuka of the Nissan Chemical Corp. in Funabashi, Japan, tested this postulate by comparing the tribological properties of a planar molecule, hexadecane, which is more likely to pack into a solid-like layer, with branched molecules, isosteric acid and isosteric acid T (a mixture of two branched carboxylic acids), which are expected to order less easily. They also compared their results with those from a poly (α-olefin) (PAO)—a model, branched synthetic lubricant.

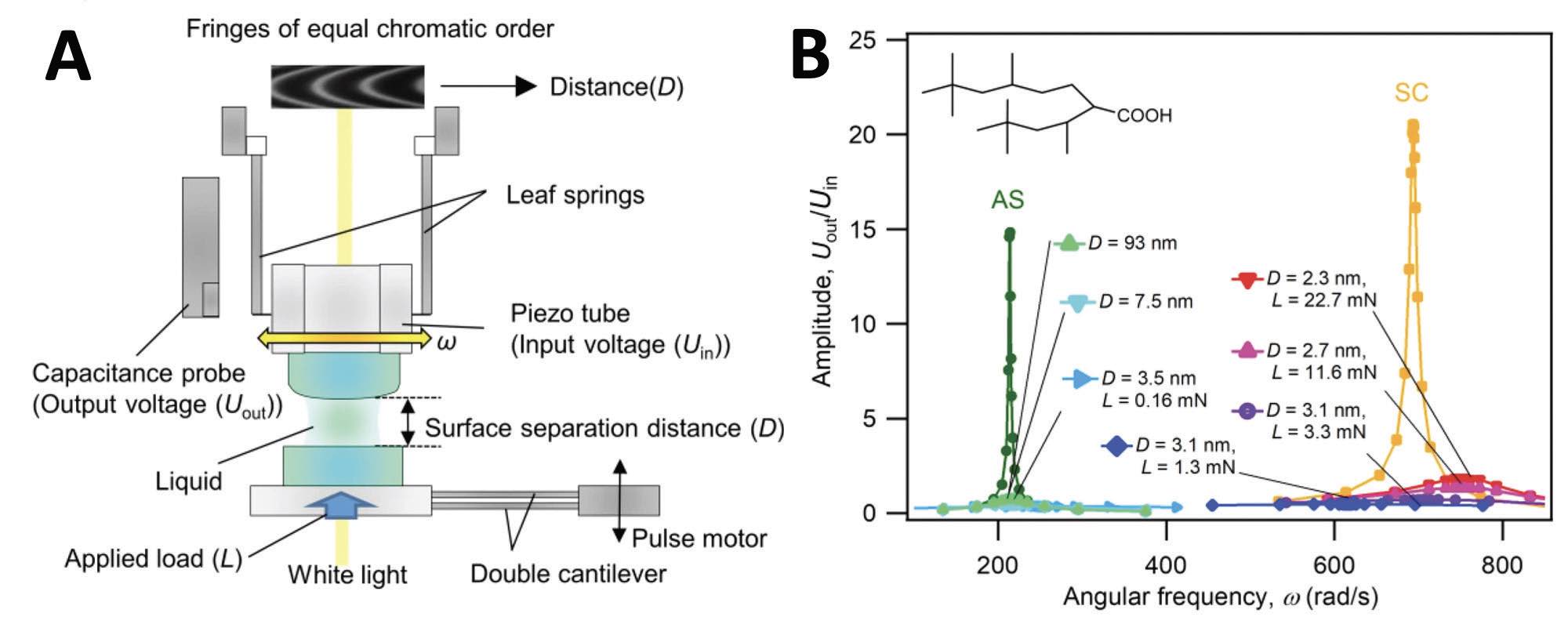

The researchers carried out their nanotribological measurements with a modified surface-forces apparatus

(see Figure 1a), which uses atomically flat mica surfaces and can measure the distance between them by interferometry. They measured the frictional properties by rapidly shearing the contact and measuring the response as a function of driving frequency. Figure 1b shows typical results that illustrate the expected resonant behavior, which can be analyzed to yield values of a viscosity parameter, b

s. The measurements were made for all fluids as a function of film thickness down to values smaller than molecular dimensions.

Figure 1. a.) Schematic drawing of the resonance shear measurement system. b.) Resonance curves of isostearic acid confined between mica surfaces, which also show results for the surfaces separated by air (AS), corresponding to no friction and for mica sheets in direct contact (SC), i.e., a “no-sliding” condition. The numbers indicated within the plots show the separation (D) and load (L). Published with permission from Ref 1.

Figure 1. a.) Schematic drawing of the resonance shear measurement system. b.) Resonance curves of isostearic acid confined between mica surfaces, which also show results for the surfaces separated by air (AS), corresponding to no friction and for mica sheets in direct contact (SC), i.e., a “no-sliding” condition. The numbers indicated within the plots show the separation (D) and load (L). Published with permission from Ref 1.

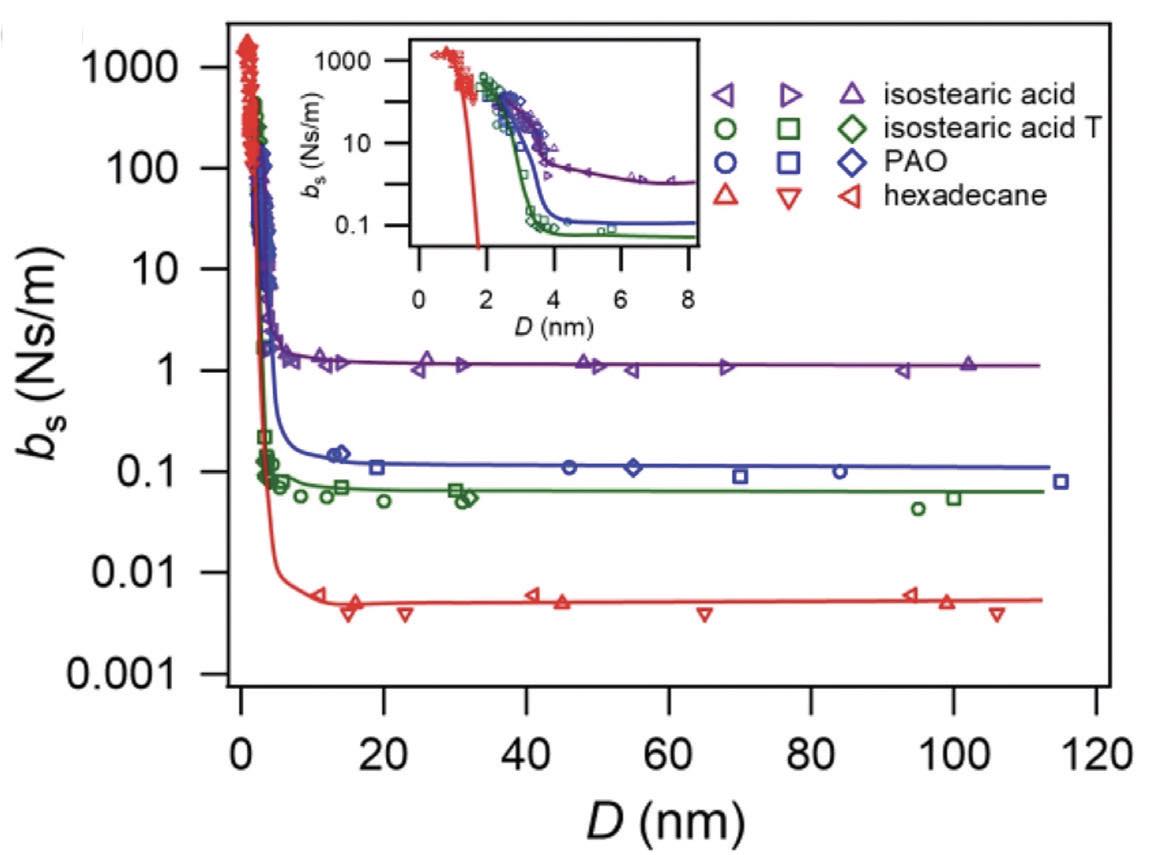

The resulting measured values of the viscosity parameters are plotted as a function of the film thickness in Figure 2. The film close to the surface is much more viscous than the bulk.

Figure 2. Viscosity parameters (bs) of isostearic acid, isostearic acid T, PAO and hexadecane as a function of the film thickness, D. The solid lines are included as a guide to the eye. The insets show magnifications of the plots at short distances. Published with permission from Ref 1.

Figure 2. Viscosity parameters (bs) of isostearic acid, isostearic acid T, PAO and hexadecane as a function of the film thickness, D. The solid lines are included as a guide to the eye. The insets show magnifications of the plots at short distances. Published with permission from Ref 1.

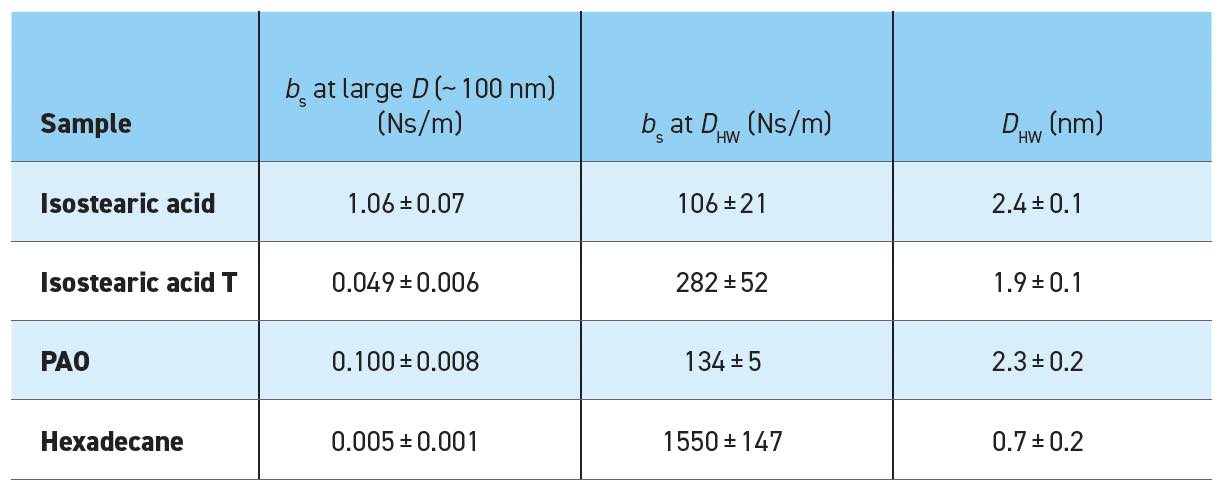

The measured values are summarized in Table 1 along with the hard-wall distances, D

HW, of all molecules. First, the b

s values at large distances correlate well with the bulk viscosities of the fluids; the bulk viscosity controls the bulk friction as expected for hydrodynamic lubrication. However, the viscosity increases dramatically close to the surface where the fluid with the lowest bulk viscosity (hexadecane) has the most viscous surface film. Similarly, the branched chains have a lower viscosity for thicknesses at the hard-wall separation than for hexadecane, but much higher than in the bulk, suggesting that they are still ordered. The trends accord very nicely with the postulate that closer packing leads to denser and more viscous boundary films that exhibit high friction.

Table 1. Selected parameters of the investigated liquids

Thus, while roughness effects undoubtedly still play a role in the transition from the hydrodynamic to the boundary lubrication regimes, these results show that such effects may be mitigated or even avoided by the judicious choice of the molecular structure of the lubricating fluid.

REFERENCE

1.

Iizuka, M., Masashi, M. and Kurihara, K. (2023), “A macro and nanoconfined tribological study of linear and branched molecules,”

Tribology Letters, 71, p. 71.

Eddy Tysoe is a distinguished professor of physical chemistry at the University of Wisconsin-Milwaukee. You can reach him at wtt@uwm.edu. N

ic Spencer is emeritus professor of surface science and technology at the ETH Zurich, Switzerland, and editor-in-chief of the STLE-affiliated Tribology Letters journal. You can reach him at nspencer@ethz.ch.