Why waviness worsens wear

By Drs. Wilfred T. Tysoe & Nicholas D. Spencer, Contributing Editors | TLT Cutting Edge August 2023

Most of us realize that roughness affects tribological behavior, but it turns out that waviness can be just as important.

Roughness is a concept with which tribologists are all too familiar. Sometimes it increases friction; sometimes it lowers it—it depends. Waviness, on the other hand, is something that only a few of us consider on a regular basis. The distinction in a roughness profile is that the short-wavelength components constitute roughness, while the longer-wavelength ones are the waviness. In the case of the two coauthors of this column, the roughness,

Ra, outside our houses (thanks to trees, cars, other buildings, etc.) is very similar, but above a cutoff wavelength of, say, 1 km, Milwaukee, Wisc., has a total waviness,

Wt, of a few meters (until you reach the Rockies), while Zurich, Switzerland, has a waviness of a few km. Less than 300 km north of Zurich lies Karlsruhe, where the

Wt is lower, and where STLE member Christian Greiner, Yulong Li, STLE member Nikolay Garabedian and Johannes Schneider at the Karlsruhe Institute of Technology and Microtribology Center have been carrying out simple, but fascinating, experiments on waviness, wear, friction and roughness, and the connections between them.

1

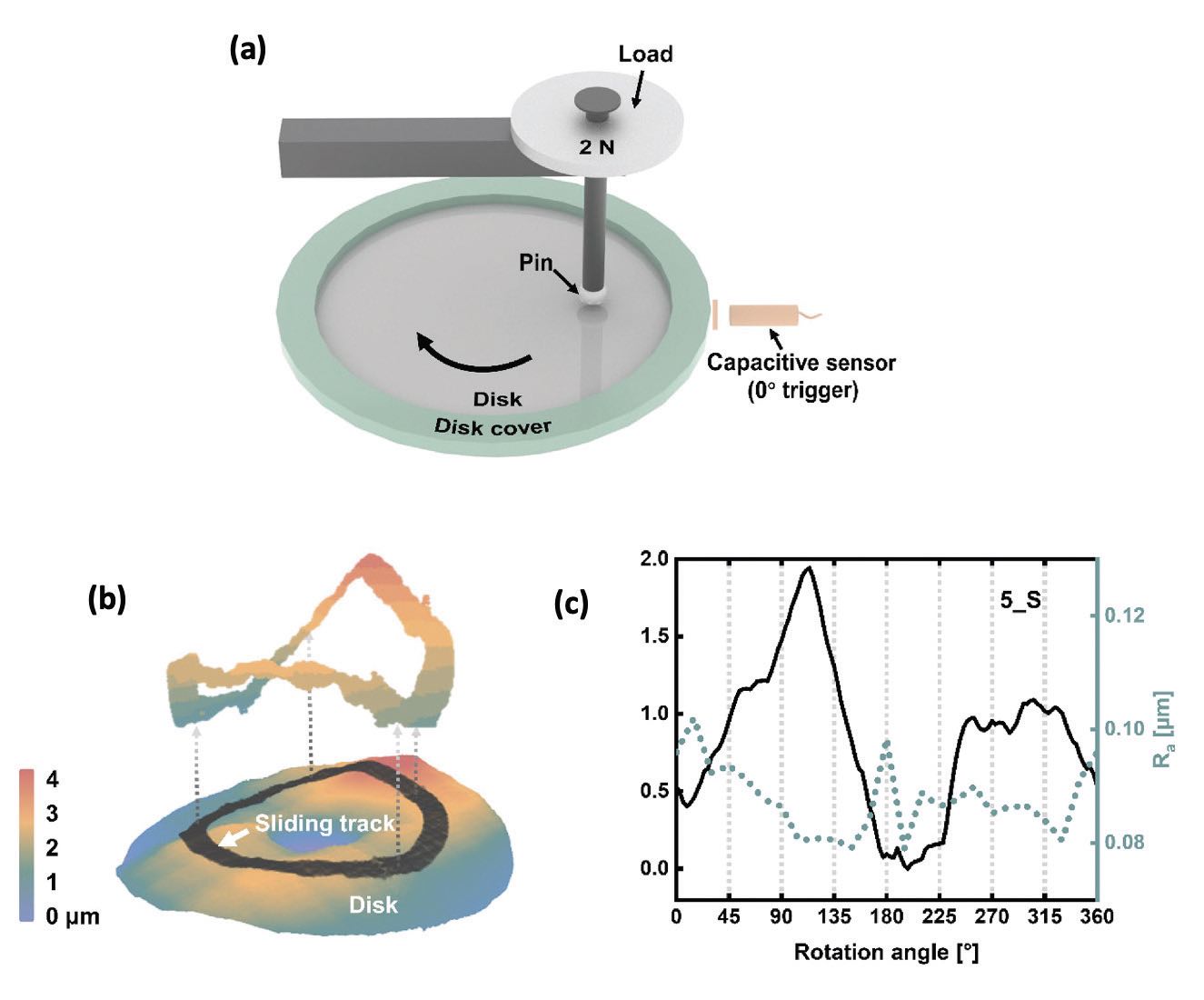

They embarked on the study after being puzzled by the very noisy friction data obtained in abrasion experiments. To examine this in detail, they carried out simple pin-on-disk experiments that involved a flat-on-flat contact between bearing-steel pins and disks, where the disks were thermally hardened to exceed the hardness of the pins The sliding surfaces were “lubricated” by a water-based slurry of alumina abrasive particles (either 5 or 13 μm average diameter). The unique aspects of these studies were that the disk was marked so that its rotational position could be monitored

(see Figure 1a), and its local roughness and waviness profile was precisely characterized

(see Figures 1b and 1c), using a cutoff wavelength, in this case, of 80 μm. The overall surface profile was characterized as shown in Figure 1c. They carried out several experiments over nearly 1 km sliding distance with the two alumina particle sizes, and two disks with different

Wt values of around 2 and 7 μm.

Figure 1. a.) Schematic of the pin-on-disk tribology test; the disk rotates clockwise. b.) The surface profile of the 7.33-mm wide sliding track from optical surface profilometry data (color key shows height). c.) Waviness profile and local roughness distribution along a typical sliding track prior to testing. Figure adapted by kind permission from Ref. 1.

Figure 1. a.) Schematic of the pin-on-disk tribology test; the disk rotates clockwise. b.) The surface profile of the 7.33-mm wide sliding track from optical surface profilometry data (color key shows height). c.) Waviness profile and local roughness distribution along a typical sliding track prior to testing. Figure adapted by kind permission from Ref. 1.

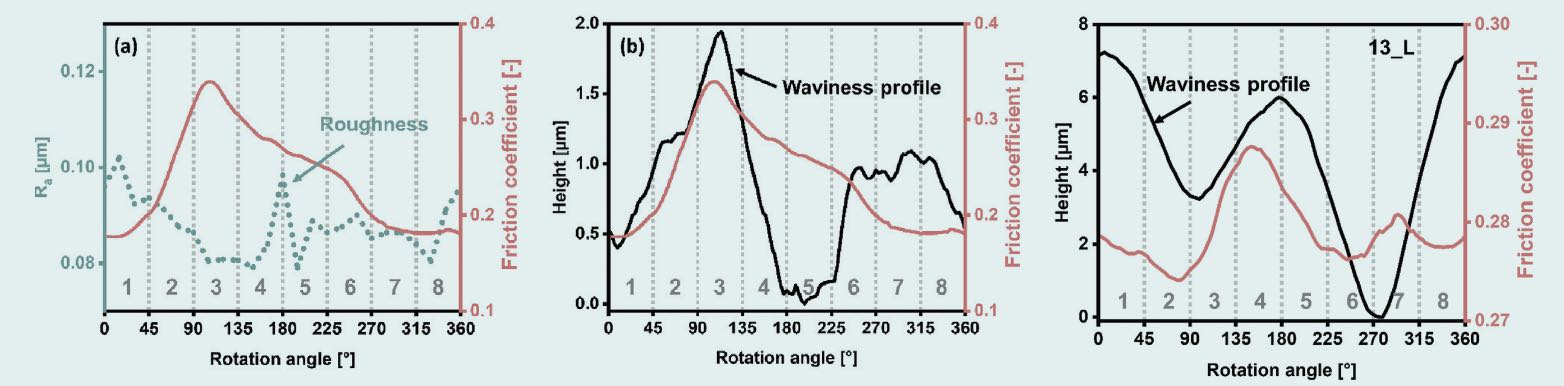

The results were surprising. Firstly, the smaller-abrasive-particle slurry led to large μ fluctuations (0.2) on the 2 μm-

Wt disk, while the larger-abrasive-particle slurry μ fluctuations were a factor of 5 lower. In contrast, on the 7 μm-

Wt disk, the larger-particle slurry showed the larger μ fluctuations. Examination of the wear track following tests with the smaller particles on the lower-waviness disk revealed that the local friction coefficient showed a marked variation as a function of rotation angle, and was found to correlate much better with

waviness than with

roughness (see Figure 2)! Astonishingly a “hill” in the waviness of only 2 μm led to an increase in μ of over 90%. Similar results were seen with the larger particles on the larger-waviness disk, but the larger particles on the lower-waviness disk showed almost constant friction coefficient as rotation angle varied.

Figure 2. Comparison of the local friction coefficient with local roughness distribution and waviness profile following testing with the 5-μm slurry and lower-waviness disks: a.) friction coefficient and roughness distribution and b.) friction coefficient and waviness profile. From Ref. 1 by kind permission.

Figure 2. Comparison of the local friction coefficient with local roughness distribution and waviness profile following testing with the 5-μm slurry and lower-waviness disks: a.) friction coefficient and roughness distribution and b.) friction coefficient and waviness profile. From Ref. 1 by kind permission.

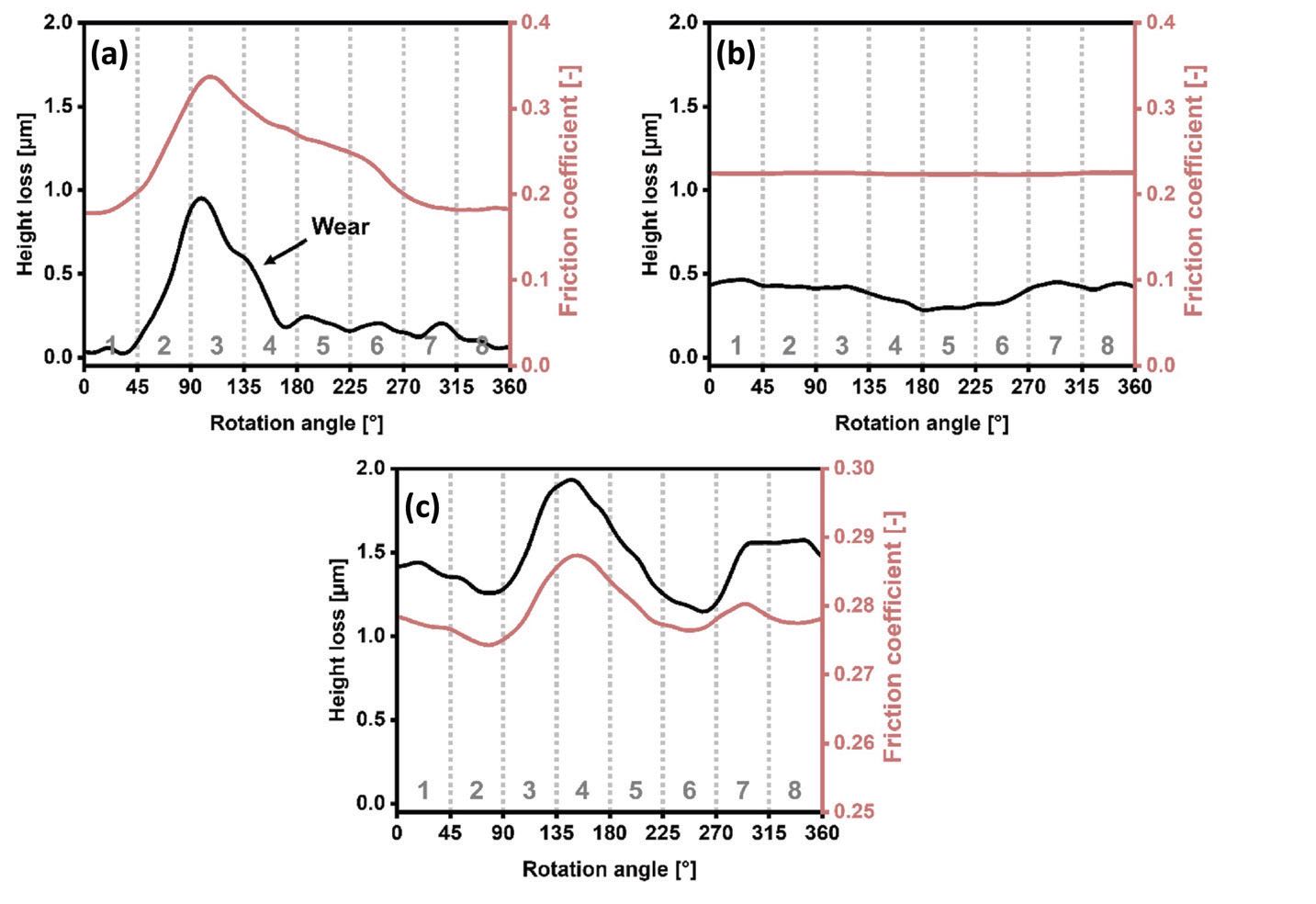

For all combinations of particle size and waviness, wear showed a strong correlation with post-testing local friction coefficient

(see Figure 3).

Figure 3. Comparison of the friction coefficient and wear-induced height loss for a low-waviness disk tested with both a.) the 5-μm and b.) the 13 μm slurry and c.) the large waviness disk tested with the 13-μm slurry. From Ref. 1 by kind permission.

Figure 3. Comparison of the friction coefficient and wear-induced height loss for a low-waviness disk tested with both a.) the 5-μm and b.) the 13 μm slurry and c.) the large waviness disk tested with the 13-μm slurry. From Ref. 1 by kind permission.

Thus, it appears there is an intimate correlation between waviness, local friction coefficient/friction fluctuations and wear in these systems. This is something that has not been generally considered in the literature, in which the focus has been on roughness. It also appears that the relative values of

Wt and abrasive

size are important in determining these relationships. While this area clearly needs further exploration, it also is apparent that these new data may have far-reaching implications for the design of engineering systems in which abrasive wear is a significant issue.

REFERENCE

1.

Li, Y., Garabedian, N., Schneider, J. and Greiner, C. (2023), “Waviness affects friction and abrasive wear,”

Tribology Letters, 71, p. 64.

Eddy Tysoe is a distinguished professor of physical chemistry at the University of Wisconsin-Milwaukee. You can reach him at wtt@uwm.edu.

Nic Spencer is emeritus professor of surface science and technology at the ETH Zurich, Switzerland, and editor-in-chief of STLE-affiliated Tribology Letters journal. You can reach him at nspencer@ethz.ch.