Executive Summary

Most readers agree that the use of biolubricants comes with more concerns about microbiological degradation. Biolubricants have a tendency to be more sensitive to microbes because of their biological components. However, there are strategies to help mitigate the risk, such as processing, filtration, testing and monitoring.

Q.1 Do you think that biolubricants are more sensitive to microbiological attacks? Please explain.

Yes, but it depends on which type of biolubricant. Those based on vegetable oils and unsaturated fatty acids will be more prone to microbiological degradation, rather than biolubricants based on saturated esters, and other synthetic base stocks based on renewable ones (estolides).

Yes, I do. Biolubricants may degrade faster than mineral and be a field prone to microbiological attacks.

Yes. Made from biodegradable materials, I would expect them to be more susceptible to natural processes.

Yes, especially to fungi attacks due to high biological values.

Yes. The biological components may be more reactive.

No. Biolobricants are made of biofeedstock as opposed to chemical feedstock. That having been said, after processing into (bio) base oil, the characteristics should be comparable.

Depends on the composition and overall resistance to microbial attack. I would imagine testing on microbial resistance would be part of the testing for new products.

Yes, the hydroxyl groups in the backbone are susceptible to attack.

No. The source of the lubricant should not affect the response to biological attack.

Yes, biobased oils are prone for attack by microbes.

Yes, because biolubricants components are food for microorganisms, and they generate a better environment for thriving the organisms.

Yes, it will be a source of nutrition for microorganisms.

They will be due to different structures than synthetic or fossil-based materials. Natural materials are more similar to the nutrient.

No, I think that biolubricants and mineral oil lubricants are equally subject to attacks; however, the rate of degradation of biolubricants is faster.

Is there a relation between biodegradable esters and biostability?

Yes

89%

No

11%

Based on an informal poll sent to 15,000 TLT readers.

Yes, I do think biolubricants are more subject to growth attacks. Special care such as robust filtration, careful monitoring and exposing them to ozone or refractive light spectrum may be required to control growth.

Biolubricants with water contamination would be more prone to microbiological attacks simply because their components would be easier for the microorganisms to break down.

Yes. The structure of natural biobased lubricants lends itself to microbiological attack. They are, at the end of the day, biodegradable.

Not necessarily. Bacterial attacks also depend on many other factors, e.g., lubricant temperature. By the way, some lubricants that are not “bio” are very sensitive to microbial development.

Whether fluids are man-made or biobased, if they have the same functional groups, they are still susceptible to microbiological attacks—example, biobased fire-resistant (FR) fluids versus polyolester FR fluids.

Not if they are properly formulated.

Yes. The purpose of a biolubricant is to avoid attack by bacteria or to protect the lubricants from microbial attack.

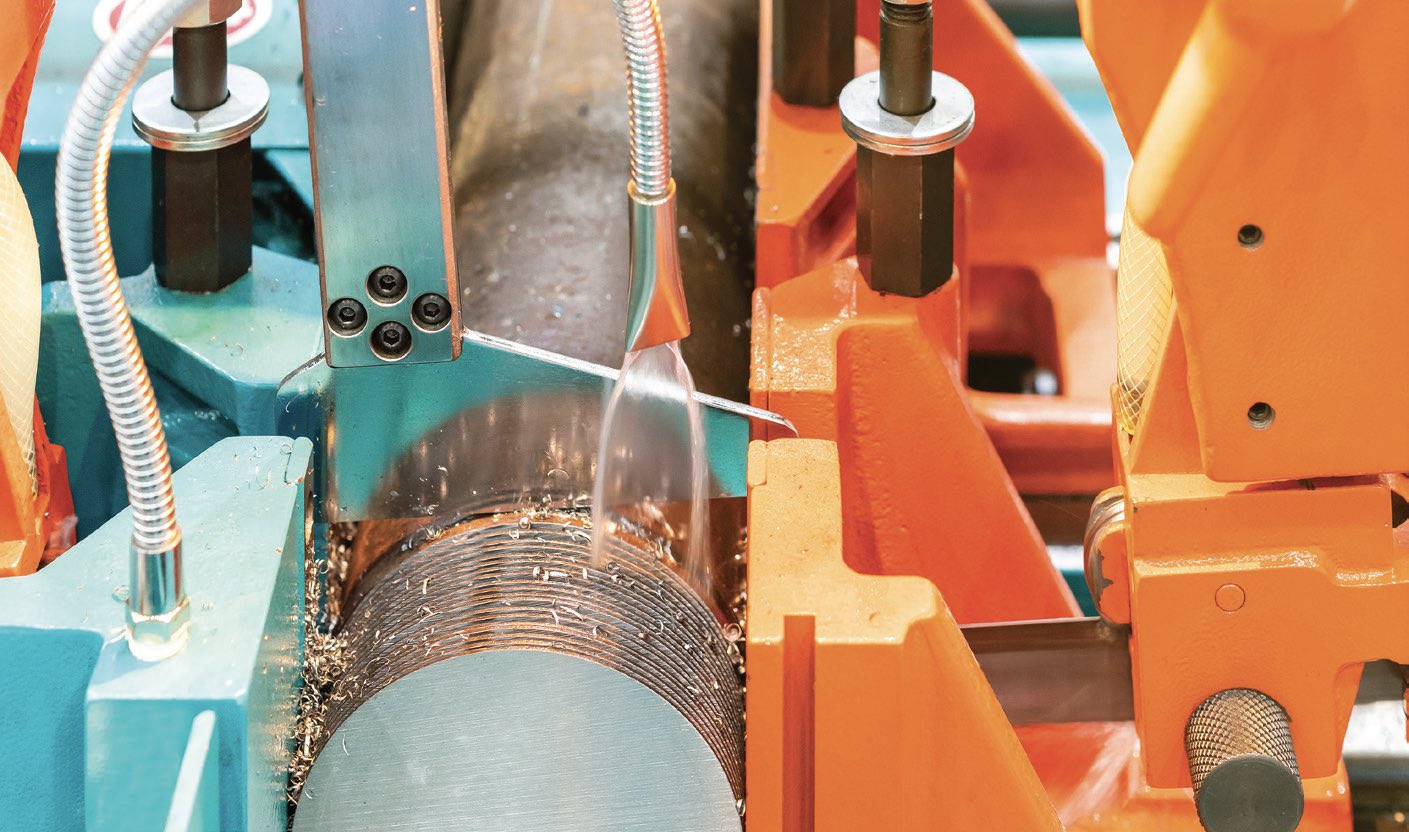

Yes, absolutely! It is the main drawback for water-based or emulsifiable metalworking fluids (MWFs).

No, not if they are formulated properly.

Many biolubricants are biodegradable, and biodegradable lubricants are more sensitive to biodegradation. The lubricants industry hires smart people to make sure that lubricants are

stable in use. If lubricant enters the environment, we want it to degrade to minimize long-term harm.

Maybe. Susceptibility of biolubricants to microbiological issues will likely be directly related to the type of environmental situation in which they must perform.

Yes. If biolubricants are biodegradable, then that means they’re more susceptible to microbiological attack.

I think so. In general, vegetable-based biolubricants have some chemical bonds that are more likely to be attacked by microorganisms, compared to petroleum derivatives.

I assume they are, but this is based on what is probably a poor understanding of how biolubricants degrade. I assume some biolubes degrade from environmental/chemical factors (e.g., heat, moisture), and some degrade by direct microbial attack. I further assume that biolubes that degrade by microbial attack are, by definition, more sensitive than lubricants that don’t degrade by that microbial attack.

Is there a relation between phosphate additives and microbiological growth?

Yes

76%

No

24%

Based on an informal poll sent to 15,000 TLT readers.

In general, yes. However, structures that have branching could provide some resistance to microbes at normal use concentrations.

Q.2 Do you think there is a relation between surface tension and microbiological stability in emulsifiable metalworking fluids? Why?

Yes, the lower the surface tension, the higher the microbiological instability in my view.

Yes, the higher surface tension contributes to higher stability. High tension prevents microbiological attacks from the surface.

Yes. Higher surface tension puts stress on cells, which should reflect a lower concentration of microbes.

Yes, again the hydroxyl group raises surface tension.

If there is a low surface tension, then there are areas of a lubricant tank where the fluids don’t move. A biological attack can occur more easily in still water.

Yes, lower surface tension may inhibit microbial growth.

According to my results, I didn’t find a relationship, but according to the literature results, there is one.

Surface tension is critical to the stability of emulsion mixtures, inverted or not.

Do amines play a key role in microbiological growth?

Yes

84%

No

16%

Based on an informal poll sent to 15,000 TLT readers.

It would depend upon the individual product and the types of surfactants used. I don’t think microbiological stability is directly tied to surface tension.

Yes. Tighter emulsions lend themselves to reject tramp oils. Much of the bio-instability in emulsifiable oils is at this oil-water interface.

No—or not at first order. Other factors (surfactant type, temperature, other additives) take over, and by far.

I don’t believe so.

That would be difficult to prove. Maybe.

Yes. Increasing the surface tension will provide a friendly environment (food) for microbial growth.

Surface tension does not directly affect microbiological stability. It is possible to develop a stable fluid over a wide range of surface tensions.

Probably. Those with years of direct experience will be the best sources for this information.

I do not see the relation. Surface tension is more related to the presence of surfactants into the system. Unless the surfactant also presents a secondary function as biocide, I do not see a correlation between its presence (reducing the surface tension) and the microbiological stability in MWFs.

I assume there is, but I couldn’t tell you whether a low or high surface tension would be more beneficial to microbial stability. If I had to guess, I would say wettability (i.e., low surface tension) provides greater stability since the microbes find it easier to interact with the fluid.

Yes.

Yes, as surface tension is depending on microbiological stability.

In order to provide stable emulsions, surface tension at the oil/water interface must be reduced. A stable emulsion should have relatively better resistance to microbes than an unstable emulsion.

Editor’s Note: Sounding Board is based on an informal poll sent to 15,000 TLT readers. Views expressed are those of the respondents and do not reflect the opinions of the Society of Tribologists and Lubrication Engineers. STLE does not vouch for the technical accuracy of opinions expressed in Sounding Board, nor does inclusion of a comment represent an endorsement of the technology by STLE.