TLT: How long have you worked in the lubrication industry, and how did you decide to pursue your career?

Chen: Freshly out of academic research environments in 2000, I started to work for Crompton as a process development chemist in the crop protection chemical division. In my first years at Crompton, my passion shifted smoothly from cutting edge academic research to applied industrial chemistry while I gained broad experience as a process development scientist and R&D project leader. In 2006, several groups were consolidated into a centralized synthesis and process development team, and I began to get involved in lubricant additive projects. Later, Crompton became Chemtura, and now we are a part of LANXESS. Throughout these changes, I’ve remained focused on antioxidants, and, over the past 17 years, I’ve developed deep expertise in aminic antioxidant chemistry and manufacturing.

TLT: What have been your most rewarding experiences and accomplishments throughout your career in the lubrication industry?

Chen: I feel rewarded by interacting with talented coworkers, not only in R&D, but in other functional areas such as regulatory affairs, purchasing and customer service. This gives me the opportunity to learn different skills for problem solving that I can use to facilitate teamwork. I am a handson person, and I enjoy R&D lab work. It’s also rewarding to see my projects get to the plant trial stage. However, the most satisfying accomplishment is seeing a new product through to commercialization. Then I know that the hard work has paid off for my company and our customers. I also enjoy reviewing literature and patents to stay abreast of new developments. I’m always on the lookout for high performing products with improved hazard profiles. Lubricant additives is kind of a small community. When I read high quality scientific articles and patents, even from competitors, I know we’re collectively pushing the lubricant additive industry forward.

TLT: Throughout the different segments within your career, which one has been the most interesting, challenging and/ or rewarding?

Chen: Each particular job or task presents its own challenges. When I worked on carbon-hydrogen bond activation in professor Hartwig’s group, I went through the whole “Dictionary of Organometallic Compounds” and found the proverbial needle in the haystack: two compounds that catalyze this unique type of reaction. The catalyst design was deducted from fundamental knowledge of thermodynamics, kinetics and reaction mechanisms. In industry, I worked on two totally different classes of chemicals. The crop protection active ingredients that I worked with were mostly pure solids. Achieving high selectivity in a reaction was always important, but purification was typically the more challenging aspect. I always aimed for simple, effective and low-waste processes. As a lubricant additive scientist, I’ve faced other challenges but also have more fun. Lubricant additive chemicals are often complex mixtures in liquid form. I remember in one of the first lubricant team meetings, I was told not to worry about the exact molecular weight of antioxidant mixtures or small variations in the composition of the same product made at different sites. Very soon afterward, I understood why my senior colleagues said those things because it was very difficult, or even impossible, to figure out the structures of some components and to describe them with a single formula. Over the last 17 years, with great support from my colleagues, I was able to improve methods for characterizing and quantifying components in complex mixtures. Now, some of these methods are even used at our manufacturing sites for routine quality control.

TLT: What are some of the most technical lubricant-based concepts or topics you have encountered throughout your career?

Chen: By far the most complicated challenge is the development of safer, environmentally benign chemicals. Lubricant additive chemistry has evolved over the past 20 years, pushed by new fuel economy standards, environmental regulations and performance requirements. While manufacturers have phased out some ingredients, scientists have been busy optimizing their portfolios of additives to meet the latest market requirements. One good example of this innovation process was summarized by STLE member Vincent J. Gatto and his colleagues in their 2007 article titled “Redesigning Alkylated Diphenylamine Antioxidants for Modern Lubricants.”

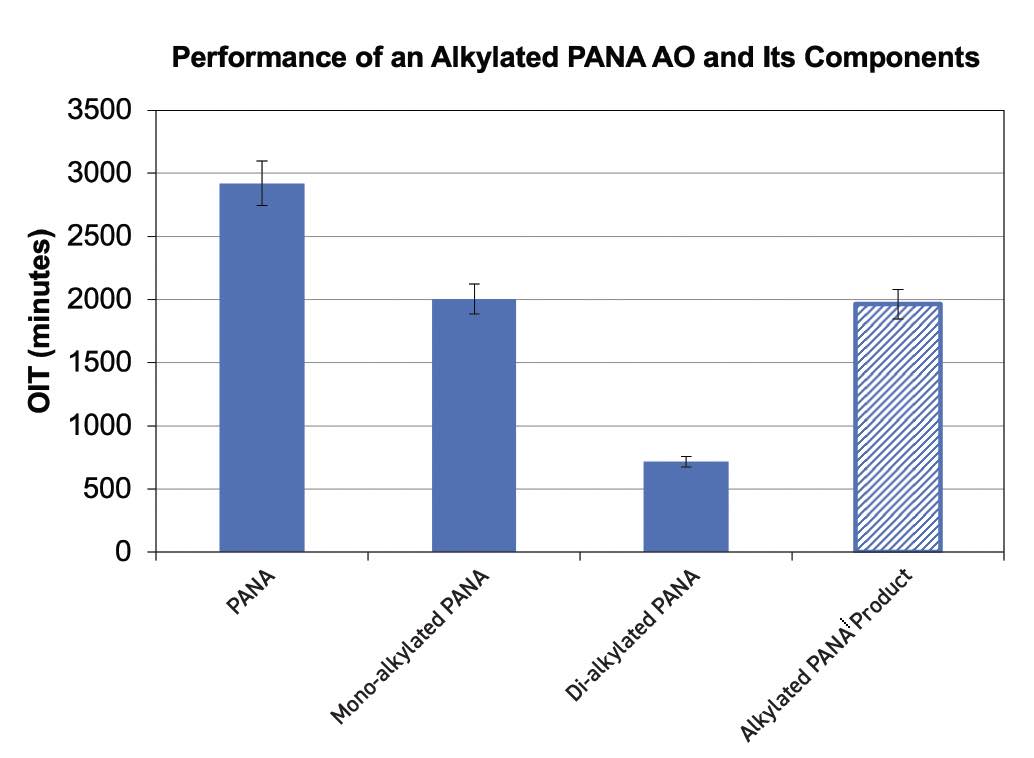

1 We conducted similar studies not only on alkylated diphenylamines (DPAs) but also on alkylated phenyl-α-naphthylamine (PANA) antioxidants

(see Figure 1). Returning to my previous comment about complex mixtures, these two cases illustrate how a closer look at the chemical details often leads to new insight.

Figure 1. The Rotating Pressure Vessel Oxidation Test (RPVOT) evaluation of an alkylated PANA product and its individual pure components, 0.5% in Group II base oil. OIT = oxidation induction time.

Figure 1. The Rotating Pressure Vessel Oxidation Test (RPVOT) evaluation of an alkylated PANA product and its individual pure components, 0.5% in Group II base oil. OIT = oxidation induction time.

Importantly, now we are focused not only on performance but also on the many health, safety and environmental aspects. Ecofriendliness is quickly becoming the most important product requirement and a driving force to make changes to existing products. For successful and fast new product development, R&D scientists have to work closely with product safety and regulatory experts such as toxicologists. Computer modeling can be used to quickly eliminate dead ends. It’s crucial to do toxicity screening and studies of environmental fate early in the development cycle to minimize the risk, cost and lead time of new compositions.

Finally, I’ve found it very useful to stay in close contact with regulatory professionals. Those conversations raise my awareness of new regulatory guidelines, so I don’t feel blindsided. They also allow scientists to provide feedback to regulatory policy makers in a timely manner.

TLT: What is the one thing you wish you would have learned earlier in your career?

Chen: I wish that I had known more about tribology when I started to work on lubricant additives. This topic is not really taught in colleges and universities, but it is so important to modern life. STLE does a great job communicating to a broad audience, and I encourage the society to continue outreach efforts to younger audiences.

TLT: What is the No. 1 piece of advice you would give to a person who might be interested in starting a career in the lubrication industry?

Chen: My advice is that you need to be prepared to jump over some hurdles before starting to have fun. I say this because lubricants are considered to be a “mature industry,” but anyone working in the field knows that we still have a lot to learn. In the beginning it may not be obvious if innovation plays a role, but I can tell you that there’s plenty of work to be done. If you have a passion for R&D, you will be rewarded with a successful career. Additionally, you need to find a good mentor— someone who can show you the ropes and give you practical advice. In my 23 years at LANXESS, I have worked with many outstanding scientists and engineers. All have taught me a lot about industrial chemistry, engineering, operation, safety, etc., but two stand out as true mentors: Dr. Joseph Feiccabrino and Dr. Joseph Stieber. These two people influenced me in so many ways and, more importantly, embodied the career path I am following. They were passionate about industrial research and had a lot of pride in their work. The lubricant additive industry needs young professionals to carry the torch and to contribute to a better, safer and smoother world.

REFERENCE

1.

Gatto, V. J., Elnagar, H. Y., Moehle, W. E. and Schneller, E. R. (January/March 2007), “Redesigning alkylated diphenylamine antioxidants for modern lubricants,”

Lubrication Science, 19 (1), pp. 25-40.

You can reach Dr. Huiyuan John Chen at huiyuan.chen@lanxess.com.