What a difference an OH makes!

By Drs. Wilfred T. Tysoe & Nicholas D. Spencer, Contributing Editors | TLT Cutting Edge April 2023

Ricinoleic acid appears to reduce friction and wear drastically for steel-silicon nitride pairs, compared to closely related fatty acids. The distinguishing factor is an extra hydroxyl group.

Fatty acids have long been known to reduce friction under boundary-lubrication conditions, although the mechanisms also have been robustly debated.

1 The differences in performance of fatty acids are partially explained by chain length, but also by the degree of unsaturation, which can lead to variations in surface packing densities and in the amount of interchain crosslinking.

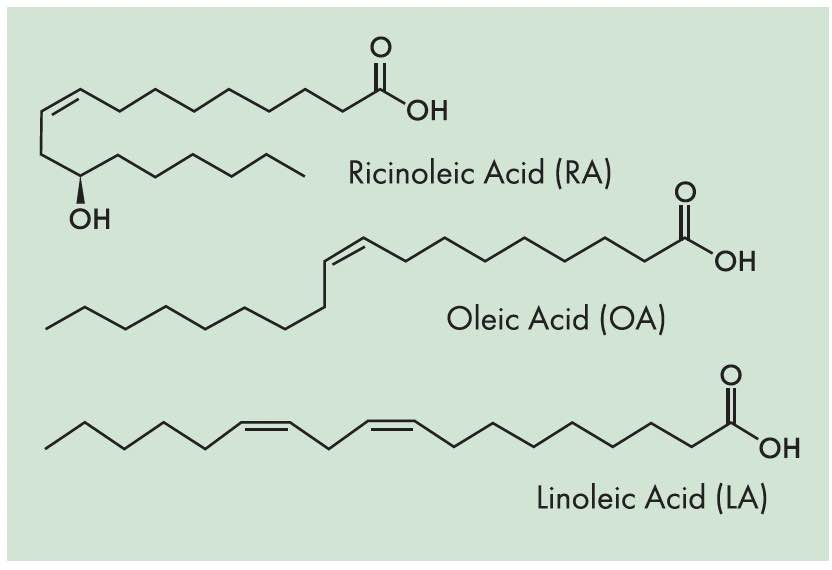

In a recent study comparing oleic acid (OA), ricinoleic acid (RA) and linoleic acid (LA)

(see Figure 1) as lubricants of a steel-silicon nitride sliding pair,

2 Maria-Isabel de Barros Bouchet and her colleagues Yun Long, Jean-Michel Martin and Frederic Dubreuil of the École Centrale de Lyon, France, showed that there are other chemical factors that can influence the effectiveness of fatty acids in lubrication.

Figure 1. Molecular structures of ricinoleic, oleic and linoleic acids.

Figure 1. Molecular structures of ricinoleic, oleic and linoleic acids.

The three acids have different viscous properties due to their different structures and compositions. RA, with its mid-chain hydroxyl group, shows higher viscosity at all temperatures due to intermolecular hydrogen bonding. In order to maintain a uniform viscosity of 11 mPa.s

-1 for all three acids, the authors carried out reciprocating tribological tests, between a steel pin and a silicon nitride disk, at temperatures of 60 C (OA), 50 C (LA) or 100 C (RA). The load was 70 N and the friction coefficient, μ, was measured at 3 mm.s

-1. The μ value for RA, after running in for one hour, was 0.014, compared to ≈4x higher values for the other two acids. The wear scar on the RA-lubricated steel pin was found to be considerably shallower than those formed when using OA or LA as lubricants. By reducing the temperature to 80 C or below, μ for the RA-lubricated system fell below 0.005, even at extremely low speeds, at which fluid-film lubrication can be neglected.

Scanning electron microscopy/energy dispersive spectroscopy (SEM/EDS) analysis of the steel surfaces after RA-lubricated sliding indicated only the presence of carbon, oxygen and iron. In contrast, the other cases showed considerable amounts of silicon and, for OA, also nitrogen, suggesting transfer of Si

3N

4. Raman analyses revealed that while sliding under OA and LA resulted in significant wear debris, consisting of iron oxides and C/Si-based materials, no debris could be detected in the RA case. X-ray photoelectron spectroscopy (XPS) analyses showed the presence of carboxylate in all three cases—implying that the acids were all chemisorbed to the steel surfaces—but that the RA-lubricated sample had the largest surface concentration of C-OH groups. Lateral-force microscopy experiments found that the RA-lubricated sample uniquely displayed low-friction patches across the surface, with atomic force microscopy (AFM) confirming that there was only minimal scratching of that sample following tribological testing.

The wealth of analytical data obtained following tribological testing allowed the authors to propose a mechanism to explain why the RA so effectively lubricates the steel/Si

3N

4 pair. The RA produces an OH-terminated layer (in contrast to the CH

3-terminated layers formed by the other acids), which leads to reduced adhesive and lateral forces, as has been previously observed in other systems. The OH termination on the RA-formed layer then appears to inhibit the transfer of silicon nitride and limit iron oxide wear-particle formation.

This work is an exquisite combination of tribological and surface-analytical approaches that not only yields a detailed molecular-scale understanding of a potentially important lubricant additive, but also points the way to future, targeted design of better friction-modifier additives.

REFERENCES

1.

Spikes, H.A. (2015), “Friction modifier additives,”

Tribology Letters, 60, pp. 1-26.

2.

Long, Y., Martin, J-M., Dubreuil, F. and De Barros Bouchet, M-I. (2022), “Achieving superlubricity of ricinoleic acid in the steel/Si3N4 contact under boundary lubrication,”

Tribology Letters, 70, p. 109.

Eddy Tysoe is a distinguished professor of physical chemistry at the University of Wisconsin-Milwaukee. You can reach him at wtt@uwm.edu.

Nic Spencer is emeritus professor of surface science and technology at the ETH Zurich, Switzerland, and editor-in-chief of STLE-affiliated Tribology Letters journal. You can reach him at nspencer@ethz.ch.