TLT: How did you start working in tribology?

Rodríguez Ripoll: During my undergraduate studies in physics in Barcelona, there were no courses offered on tribology. Probably my first unaware contact with tribology was 19 years ago while doing my doctoral work on the wire drawing process of tungsten wires at the Fraunhofer Institute for Mechanics of Materials in Germany. The initial wire drawing steps of tungsten wires are performed at high temperatures, close to 1,000 C, and involve the use of graphite as lubricant to mitigate the contact conditions at the interface between the wire and the drawing die. However, at that time, I was focused on microstructure evolution and crack propagation on the wire itself so that friction or die wear were not within the scope of my research.

After finishing my doctoral degree, I joined a postdoc position as Marie Curie Fellow at the Laboratory for Tribology and Interface Nanotechnology (L-TINT) of the University of Ljubljana in Slovenia. My work was set in the framework of a large project funded by the European Commission that was led by my current employer, AC2T research GmbH, in collaboration with many renowned institutions in tribology such as the Imperial College London, Cardiff University, Mines ParisTech in France, TU Wien in Austria and the SKF Research and Development Centre in the Netherlands, to name a few. It was at that time where I first became involved with wear, lubricated contacts and lubricant-surface interactions. Having a main education in physics and materials science, it was a bit challenging at the beginning. I can still clearly remember having, for a few months, on my bedside table the blue third edition of the “Engineering Tribology” book by professor Gwidon Stachowiak.

TLT: Why do you think tribology is so fascinating?

Rodríguez Ripoll: After finishing the postdoc position in Slovenia, I joined AC2T research GmbH, the Austrian Excellence Center for Tribology, where I have been working for 12 years. As the center is fully devoted to research in tribology, I have the chance to work on a large diversity of projects, ranging from tribology of forming processes to the tribocorrosion of medical implants, and this is the most fascinating part of tribology: its enormous diversity. This interdisciplinarity also is challenging for doing research and development in tribology, as it requires a strong background in different disciplines ranging from chemistry, physics, materials science, medicine or, with the current trend of electrification, even electrical engineering. As mastering simultaneously all these disciplines is a privilege of very few, you often rely on collaboration with scientists from completely different disciplines, such as medical doctors, making your daily work passionate. In my role as leader of the research area “Wear Reduction Strategies,” I am mostly dealing with projects related to materials tribology, but I have the daily pleasure of collaborating with experts in lubricants and with colleagues like Dr. Stefan Eder, working with cutting edge simulations tools such as molecular dynamics.

Another application for self-lubricating materials is in space applications.

Another application for self-lubricating materials is in space applications.

TLT: What is a self-lubricating material, and what is it used for?

Rodríguez Ripoll: One of my major topics of research of the last six years has been on the development of self-lubricating materials. Self-lubricating materials are a broad class of compounds featuring the incorporation of one or more solid lubricants with the aim to decrease friction and wear during sliding contact. The solid lubricants can be deposited as a coating, as the well-known examples of molybdenum disulfide or diamond-like carbon, but can alternatively be embedded in a polymer or a metal matrix. In our research, we are focused on embedding solid lubricants in metal matrices for the development of self-lubricating metallic alloys. To this end, we use wear-resistant iron, and nickel-based alloys as one of our major goals is the use of self-lubricating alloys as forming tools.

The main driving force behind the development of self-lubricating materials was initially the need of reducing and controlling friction in applications for which conventional oils and greases were ineffective such as under high temperatures over 300 C or in vacuum applications. For instance, we showed that self-lubricating materials could be beneficial in high temperature forming processes that currently run unlubricated such as the forming of ultra-high strength steel (UHSS) for automotive applications. This UHSS is typically featured with an Al-Si dip coating in order to mitigate oxidation during heating and forming. However, Al-Si-based coatings are known to have poor tribological behavior at high temperatures, due to the formation of Al-Fe intermetallics by diffusion from the steel substrate at temperatures above the melting point of the Al-Si mixture, making this coating prone to adhesion. This results in buildup of material on the tool with the subsequent loss of tolerance in the formed pieces.

2

Another application for self-lubricating materials is in space applications. Nowadays the use of molybdenum disulfide coatings is widely spread to reduce friction in sliding contacts, but we believe that our developed wear-resistant self- lubricating nickel-based alloy-containing silver pockets embedded in metal sulfides could be an option in machine elements operating in vacuum conditions. Our experiments showed that the self- lubricating alloy was able to achieve a stable coefficient of friction around 0.25, while simultaneously having negligible wear and imparting a 20th-fold lower transfer of materials to the counterbody.

3 These experiments were performed under very severe contact conditions characterized by metal-to-metal contact against martensitic stainless steel in vacuum at 300 C using pressures of over 1 GPa.

TLT: How can self-lubricating materials be processed?

Rodríguez Ripoll: Self-lubricating materials can be processed using several techniques such as sintering or deposited as coatings. The coatings can be divided into thin films with thickness in the micron- range and typically deposited using physical (PVD) and chemical vapor deposition techniques (CVD), and thicker coatings with thickness in the millimeter range deposited by thermal spray or laser deposition processes. In our work we focus on laser deposition processes such as laser metal deposition or direct energy deposition. Laser deposition processes can be used for the deposition, refurbish or repair of functional layers with tailored mechanical and chemical properties capable of protecting against wear and corrosion in industrial applications ranging from metal forming tools to aircraft turbine components. Particularly relevant nowadays is that laser deposition processes are additive manufacturing techniques that offer a great flexibility and efficiency compared to traditional subtractive manufacturing processes. This ensures that our developed self-lubricating metallic alloys are printable. Additionally, laser metal deposition can be suitably combined for surface functionalization of components manufactured using other additive manufacturing techniques able to produce extreme complex shapes, such as those relying on powder bed fusion methods.

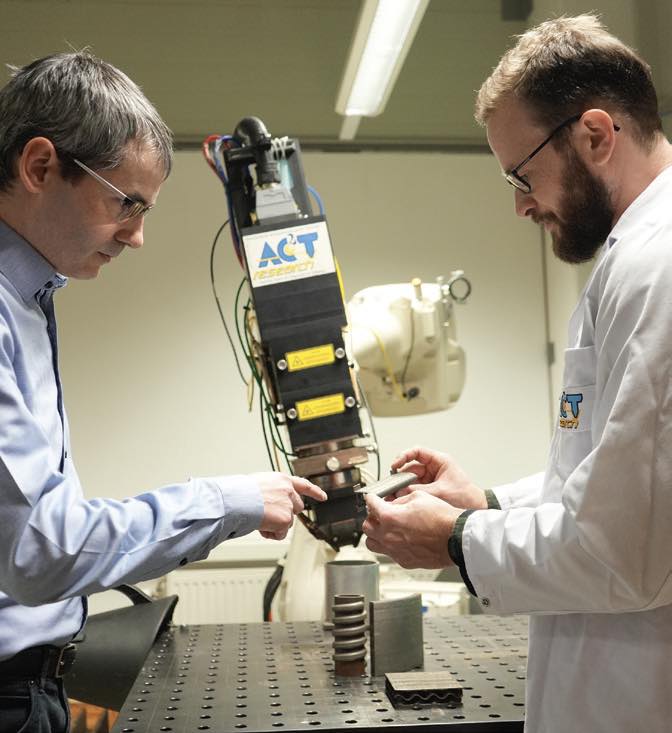

Deposition of a self-lubricating alloy using a 10 kW high-power direct diode laser mounted on a six-axis manipulation robot. From left to right: Manel Rodríguez Ripoll and Kurt Pichelbauer. Photo courtesy of AC2T.

Deposition of a self-lubricating alloy using a 10 kW high-power direct diode laser mounted on a six-axis manipulation robot. From left to right: Manel Rodríguez Ripoll and Kurt Pichelbauer. Photo courtesy of AC2T.

TLT: Could it be possible, in the near future, to have lubricant-free factories for forming nonferrous alloys?

Rodríguez Ripoll: While our vision is to eliminate the use of lubricants in forming and machining processes, the goal is still too far to be reached in many applications, particularly in forming of non-ferreous alloys such as aluminum due to the severity of the contact conditions and the high affinity of aluminum for adhering to tool steels that results in adhesive wear and galling. However, we can set some intermediate and achievable milestones. A straightforward possibility is the use of self-lubricating forming tools for allowing minimum quantity lubrication in some applications, thus reducing the lubricant-related costs in forming and machining operations. Another possibility where we are currently working is, in those cases where the use of lubricants is unavoidable such as during aluminum forming, exploit the use of self-lubricating materials for enabling the use of greener lubricants. In the past, some green lubricants such as long chain alcohols were unsuccessfully envisaged for being used in the cold forging of aluminum alloys. However, this reasoning implicitly assumes that the tool needs to remain made of martensitic tool steel. In our work, we try to move away from this thinking and focus on the development of self-lubricating materials that enable the use of lubricants and lubricant additives with a higher environmental compatibility, thus paving the way to a greener cold forging industry. It is crucial to focus on the complete tribosystem and consider that the use of materials with an intrinsic low interfacial friction could result in a game changer that enables the use of more environmentally acceptable lubricant chemistries.

Visual inspection of a printed self-lubricating coating on an additive manufactured component. Photo courtesy of AC2T.

Visual inspection of a printed self-lubricating coating on an additive manufactured component. Photo courtesy of AC2T.

TLT: What are the future challenges in the research of self-lubricating materials?

Rodríguez Ripoll: Most of the works reported in literature on self-lubricating metals focused on iron and nickel-based alloys, which have an excellent wear resistance and can be readily applied in forming and machining processes. In our research, nickel-based alloys have shown, so far, a more promising tribological behavior in a temperature range covering up to 600 C. However, the development of iron-based alloys with a similar or even better tribological behavior would be of great advantage, as iron is a non-critical raw material, environmentally compatible and affordable.

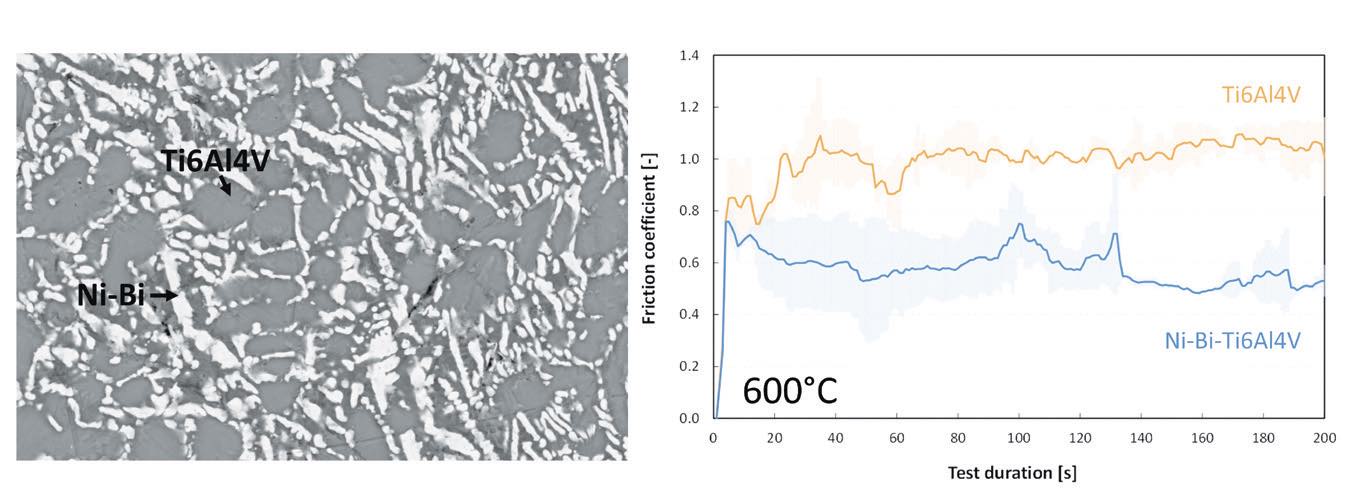

But what I personally think would be a great breakthrough would be the development of self-lubricating titanium alloys. Despite the enormous advantages of titanium alloys, such as high strength-to-weight ratios, excellent corrosion resistance and good biocompatibility, their applicability in components and machine elements is severely limited by their poor tribological behavior. Unfortunately, the major challenge when incorporating solid lubricants into titanium alloys is to maintain the lubricious phase or compound intact after processing, particularly when using laser deposition processes. The reason is that titanium is particularly prone to form intermetallic compounds or solid solution when adding soft metals with low shear such as silver, thus preventing them from unleashing their lubricious potential. In the case of transition metal dichalcogenides such as MoS

2, the high affinity of titanium to sulfur results in the decomposition of the solid lubricant compound and the formation of titanium sulfides. We have done some initial attempts that resulted in the development of a self-lubricating Ti6Al4V alloy containing bismuth as solid lubricant that is able to outperform Ti6Al4V in terms of friction by almost 50% in unlubricated self-mating titanium contacts at 600 C

(see Figure 1).4 Still the resulting coefficient of friction is probably too high for most relevant applications, so that there is plenty of room for improvement on the way to having machine elements such as bearings made of self-lubricating titanium alloys.

Figure 1. Microstructure of a self-lubricating Ni-Bi-Ti6Al4V alloy (left) and its resulting frictional performance at 600 C in an unlubricated self-mating titanium contact using a conventional Ti6Al4V alloy as reference (right).

You can reach Manel Rodríguez Ripoll at Manel.Rodriguez.Ripoll@ac2t.at

Figure 1. Microstructure of a self-lubricating Ni-Bi-Ti6Al4V alloy (left) and its resulting frictional performance at 600 C in an unlubricated self-mating titanium contact using a conventional Ti6Al4V alloy as reference (right).

You can reach Manel Rodríguez Ripoll at Manel.Rodriguez.Ripoll@ac2t.at.

REFERENCES

1.

The h index is a quantitative metric based on analysis of publication data using publications and citations.

2.

Torres, H., Ripoll, M. R. and Prakash, B. (2019), “Self-lubricating laser claddings for friction control during press hardening of Al-Si-coated boron steel,”

Journal of Materials Processing Technology, 269, pp. 79-90, click

here.

3.

Torres, H., Rojacz, H., Čoga, L., Kalin, M. and Ripoll, M. R. (2020), “Local mechanical and frictional properties of Ag/MoS

2-doped self-lubricating Ni-based laser claddings and resulting high temperature vacuum performance,”

Materials & Design, 186, 108296, click

here.

4.

Torres, H., Pichelbauer, K., Budnyk, S., Schachinger, T., Gachot, C. and Ripoll, M. R. (2023), “A Ni-Bi self-lubricating Ti6Al4V alloy for high temperature sliding contacts,”

Journal of Alloys and Compounds, 944, 169216, click

here.