•

The relationship between interfacial transverse shear modulus and friction in two-dimensional materials has been determined.

•

An inverse relationship was found between frictional force per unit area and interfacial transverse shear modulus.

•

This finding represents a new friction law.

The growth in the use of two-dimensional materials such as graphene is accelerating due to their low friction properties. Gaining a better understanding of how friction occurs may provide researchers with more insight into how to produce two-dimensional materials that have superior properties, which can be used as newer devices are prepared for use in applications such as electric vehicles.

In a previous TLT article,

1 researchers took a significant step forward in understanding friction at the atomic scale by visualizing it using an

in situ transmission electron microscope. This discovery took place as a tungsten probe side-tip slid across a tungsten crystal oriented in a specific manner. As the two surfaces interacted, the tungsten probe moved across the surface in a zig-zag pathway, which represented the lowest energy barrier to overcome friction.

In studying two-dimensional materials, typically they are grown on a substrate such as silicon carbide. Researchers have found that insertion of atoms from the substrate into the two-dimensional material occurs.

While much emphasis has been placed on determining how substrates can modify the properties of two-dimensional materials, little work has been done to study the interfacial transverse shear modulus that can occur at their interphase.

Dr. Martin Rejhon, postdoctoral researcher in the chemical and biomolecular engineering department at New York University in Brooklyn, N.Y., says, “Interfacial transverse shear modulus occurs when a force parallel to the two-dimensional material is applied to the bottom layer in one direction while the substrate experiences a force in the opposite direction.”

Rejhon indicates that gaining a better understanding of interfacial transverse shear modulus is important to better understand the frictional properties of two-dimensional materials. Use of atomic force microscopy on three-dimensional materials has been found to determine the change in frictional force as the tip of the instrument moves through the surface.

Rejhon and his colleagues including Elisa Riedo, professor of chemical and biomolecular engineering at New York University, have now conducted similar work on epitaxial graphene films on silicon carbide and, from this research, identified a new fundamental law of friction.

Inverse relationship

The researchers generated monolayer and bilayer epitaxial graphene films grown on the silicon face of silicon carbide at a particular orientation. They used a technique known as modulated nanoindentation to perform modulated nano-shear experiments to determine the interfacial transverse shear modulus of the epitaxial graphene films compared to pyrolytic graphite.

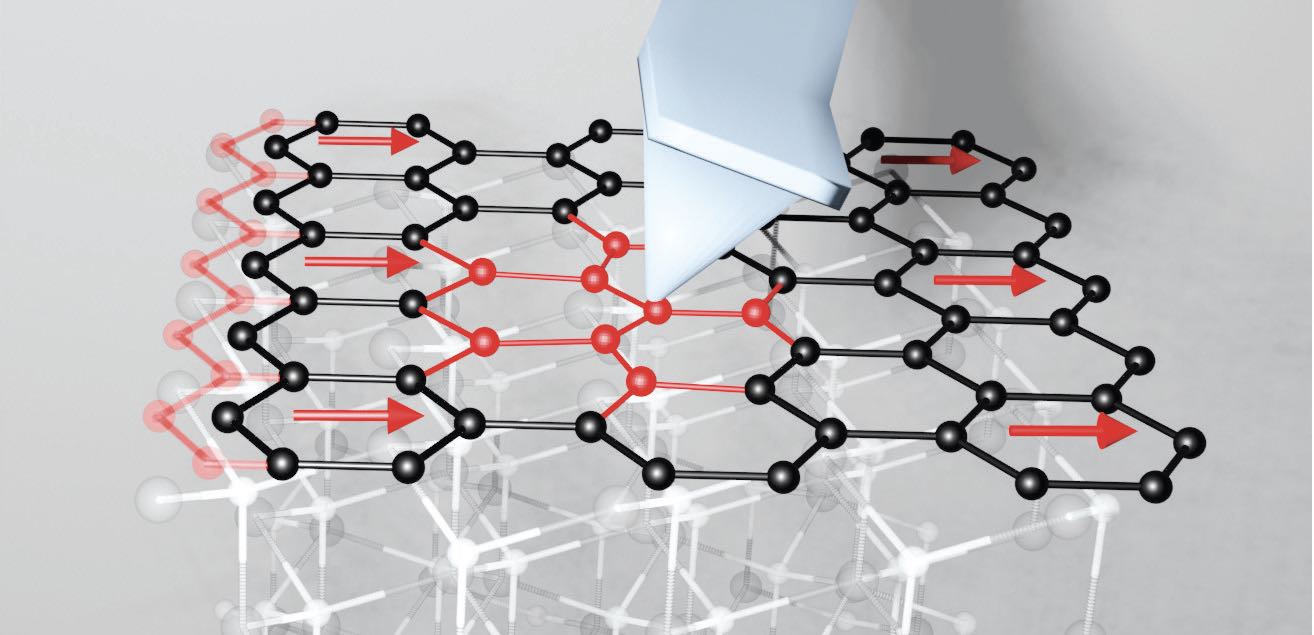

Rejhon says, “We take a tip of an atomic force microscope and pull atoms from a graphene layer at an indentation depth of 1.4 angstroms to force them to slide over the substrate in the range of 0.3 angstroms. The lateral force is then recorded during the tip retraction, from which the interfacial shear modulus is obtained

(see Figure 2). The epitaxial graphene is directly grown on silicon carbide with a buffer layer present between the two materials. This layer has a combination of 70% sp

2 carbons with a graphene bonding structure and 30% sp

3 carbons with a graphite bonding structure.

Figure 2. This schematic shows how the tip of an atomic force microscope pulls atoms from a graphene layer creating a lateral force from which interfacial shear modulus is measured. Figure courtesy of New York University.

Figure 2. This schematic shows how the tip of an atomic force microscope pulls atoms from a graphene layer creating a lateral force from which interfacial shear modulus is measured. Figure courtesy of New York University.

In doing the evaluation of various graphene films, the researchers recognized that stacking order of the graphene layers is a factor in influencing the magnitude of the modulus. Rejhon says, “Stacking order in graphene represents how the two-dimensional layers are oriented toward each other. In an AA stacking arrangement, the layers have identical lateral coordinates. For the other stacking orientation known as AB, one of the layers is shifted laterally with respect to an adjacent layer.”

The epitaxial graphene films have different stacking arrangements with some combining AA with AB. Through the assistance of density functional theory, the researchers determined that a material with one graphene layer, a buffer layer and silicon carbide and a disordered mixture of AA and AB stacking exhibited the lowest interfacial transverse shear modulus.

The researchers also evaluated the frictional forces that are detected as the atomic microscope tip moves through a layer of graphene atoms. Rejhon says, “We measured the friction force per unit area and then compared it to the interfacial transverse shear modulus using different analytical functions. The best fit is an inverse relationship between frictional force per unit area and interfacial transverse shear modulus.”

Further modeling by the researchers validated this finding, which represents a new friction law. At higher interfacial transverse shear modulus values, the larger amount of energy stored elastically in the sticking regime means that there is a lower level of friction. When the interfacial transverse shear modulus is lower, the barrier for the atomic microscope tip to move is larger due to a higher degree of friction.

The researchers intend to verify this new friction law by evaluating different materials such as hexagonal boron nitride. Rejhon says, “We also intend to determine how changing the substate from silicon carbide also will influence the shear interfacial modulus and corresponding frictional properties.”

Additional information can be found in a recent article

2 or by contacting Rejhon at

martin.rejhon@nuy.edu and Riedo at

elisa.riedo@nyu.edu.

REFERENCES

1.

Canter, N. (2022), “Visualizing atomic-scale friction,” TLT,

78 (12), pp. 20-21. Available

here.

2.

Rejhon M., Lavini, F., Khosravi, A., Shestopalov, M., Kunc, J., Tosatti, E. and Riedo, E. (2022), “Relation between interfacial shear and friction force in 2D materials,”

Nature Nanotechnology, 17, pp. 1280-1287.