Viscosity index and classifications

By Dan Holdmeyer, Contributing Editor | TLT Lubrication Fundamentals March 2023

Operating temperature impacts viscosity at a rate that is unique to the oil in use.

Oil viscosity varies with temperature so much so that an oil’s viscosity should always be qualified with the temperature at which the viscosity is measured. This is important because lubricated equipment is subject to extreme temperatures: cold at start-up until the unit has warmed up, potentially to extremely hot at times. Thus, original equipment manufacturers (OEMs) specify maximum and minimum allowable viscosities to protect their equipment. The temperatures at which the oil reaches the maximum and minimum allowable viscosities determines the operating range.

Hydraulic pump OEMs identify the maximum viscosity allowed at system start-up to ensure the fluid will flow and avoid pump damage due to cavitation (see the February 2022 TLT Lubrication Fundamentals article titled Air entrainment, aeration, cavitation and foaming: How are they related?). OEMs also specify the minimum viscosity for the system during operation to minimize metal-to-metal contact and wear. Similar guidelines are used for gears, bearings, engines, etc., to assure the lubricant flows to the various components at low temperature start-up and protects against wear at operating temperature.

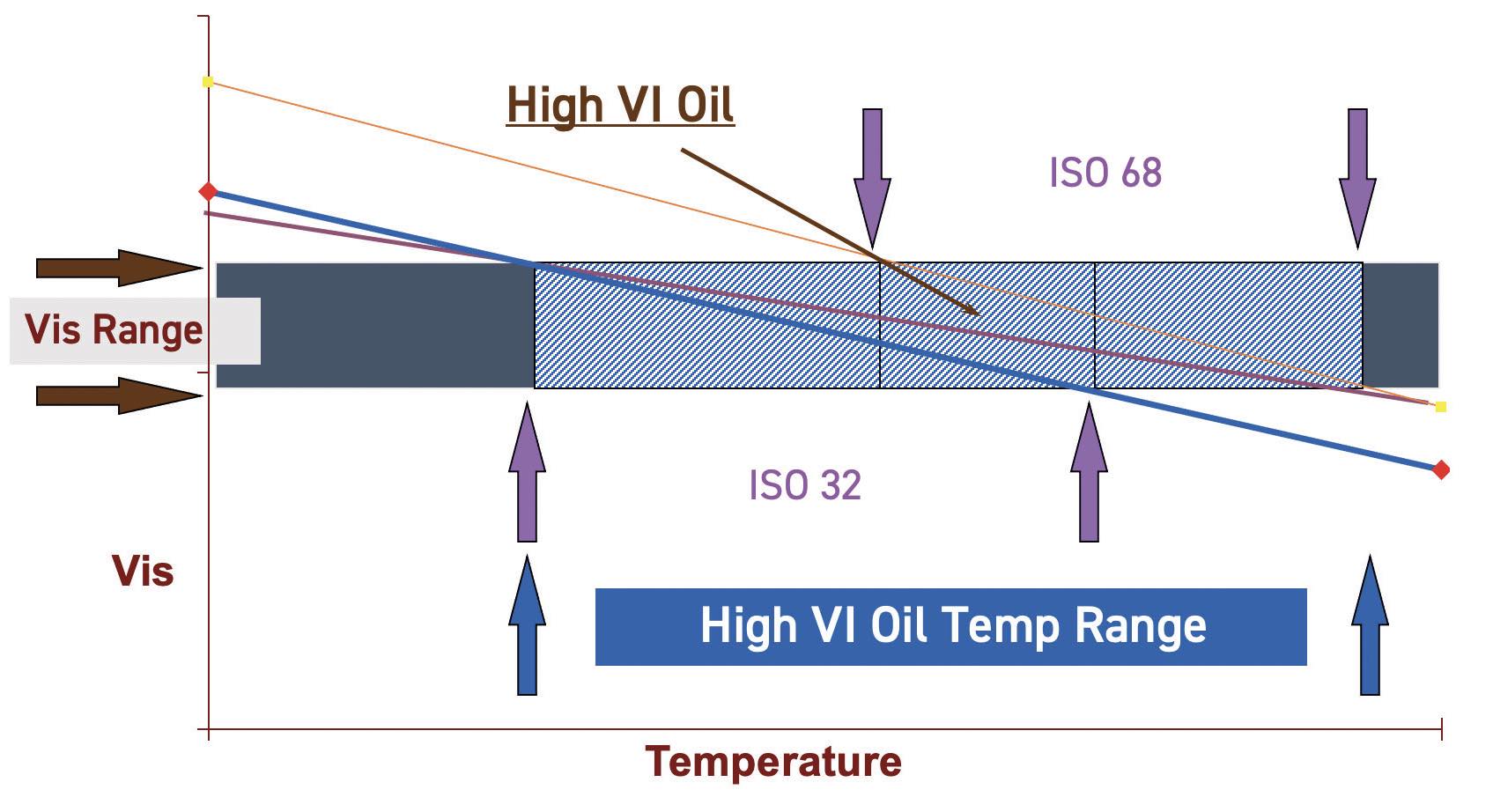

Figure 1 demonstrates the various temperature operating ranges for a given operating viscosity range. Note the operating ranges for the ISO VG 32 and the ISO VG 68 are about equal in the size of operating range. The ISO VG 32 range just starts and ends at lower temperatures relative to the ISO VG 68 range.

Figure 1. Operating ranges.

Not all oils’ viscosities change with temperature at the same rate and, thus, it needs to be quantified. Viscosity change with temperature is given a value called viscosity index (VI). Counterintuitively, the higher the VI the less the viscosity changes with temperature.

Figure 1 illustrates the expanded operating temperature range for the given OEM-specified operating viscosity range of a high VI oil compared to the ISO VG 32 and 68 oils. A high VI oil provides a wider operating temperature range than an oil whose viscosity changes more with temperature changes.

The VI is typically listed on an oil’s technical data sheet along with the viscosities at the standard temperatures of 40 C and 100 C, or 100 F and 210 F. However, if you are like me and want to have an idea of how that number is calculated, this article includes a synopsis of the spirit of ASTM D2270. To get the details, please refer to the latest version of ASTM D2270. ASTM D2270 is the standard to determine VI using kinematic viscosity at 40 C and 100 C, and ASTM D567 is the standard for kinematic viscosity measured at 100 F and 210 F.

An oil’s VI is calculated using the oil’s viscosity at standard temperatures of 40 C and 100 C and referencing those against the viscosities of two reference fluids. One of the reference fluids has a VI of 0 and was originally interpolated from a Texas Gulf naphthenic crude oil. The other reference oil was a paraffinic crude oil from Pennsylvania for a VI of 100. The equation for calculating VI was

VI = [(L-U)/(L-H)] x 100

where L and H are taken from a table in ASTM D2270 of reference oil viscosities at the standard temperatures of 40 C and 100 C, and:

• L is the kinematic viscosity of the 0 VI naphthenic crude oil at 40 C that has the same kinematic viscosity of the test oil at 100 C.

• H is the kinematic viscosity of the 100 VI paraffinic crude oil at 40 C that has the same kinematic viscosity of the test oil at 100 C.

• U is the kinematic viscosity of the test oil at 40 C.

You may have noticed in the previous paragraph we said it was the equation. Since the early development of the VI scale, better refining and synthesis have created higher VI oils, above 100 VI. Therefore, ASTM has evolved the formula into a quadratic equation with at least one added variable for fluids with a VI greater than 100. The original equation is still used for oils below 100 VI. For this article, we’ll stay with the notion that VI is based on a scale between two reference crude oils, one naphthenic and one paraffinic.

For industrial applications, oils are classified and called out by the viscosity at 40 C with a range of plus 10% or minus 10%. For example, an ISO viscosity grade 100 could have a viscosity as low as 90 cSt or as high as 110 cSt at 40 C (see Table 1). Most mineral industrial oils will have a VI of around 95 to 105. If the VI is greater than 120, it may be called a high VI oil.

Table 1. ISO viscosity grades

Many industrial applications operate near 40 C (approximately 100 F), so identifying the oil viscosity at 40 C is convenient. Then to determine the operating range of the oil in a specific OEM’s application, the oil’s VI helps interpolate the minimum and maximum operating temperatures.

In automotive applications, the operating temperature is around 100 C, and so a minimum viscosity is identified by the engine OEM to minimize engine component wear. At engine start-up temperatures in cold climates, OEMs have two major concerns: the ability to turn-over the engine and quickly lubricate the entire engine. Thus, The Society of Automotive Engineers (SAE), along with ASTM, established low temperature tests to quantify the maximum viscosity to address those concerns. Those are a cold-cranking simulator ASTM D5293 test method and a mini-rotor viscometer ASTM D4684 test method to measure the fluidity at specific temperatures. As an example, an SAE 10W oil’s viscosity results from these tests cannot be greater than a maximum value at a certain temperature to be an SAE 10W, specifically the viscosity test results cannot be greater than 7,000 centiPoise (cP or mPa•s) at -25 C for the cold-cranking test nor can the viscosity be greater than 60,000 cP at -30 C for the mini-rotor viscometer test.

SAE J300 established nomenclature for engine oil classifications with numbers followed by “W” (for winter) to categorize low temperature performance results in the cold-cranking and mini-rotor viscometer tests conditions followed by numbers to categorize the viscosity at operating temperature. SAE has set up both engine oil (SAE J300) and gear oil (SAE J306) classifications.

When first introduced to SAE engine oil classifications, many people initially think a multigrade SAE 10W-30 engine oil thickens, or increases in viscosity, with increased temperatures. An SAE 10W-30 engine oil has the viscosity of an SAE 10W at low cold starting temperature and the viscosity of an SAE 30 at the high operating temperature, and yet the oil’s viscosity does decrease with increasing temperature, just not as quickly as a mono-grade SAE 10W.

Utilizing Figure 1, we can imagine the plotted ISO VG 32 viscosity line as an SAE 10W, the ISO VG 68 line as an SAE 30 and the high VI oil line as an SAE 10W-30 oil, to understand the SAE multigrade oil viscosities. The multigrade SAE 10W-30 provides a wider operating temperature range than each of the individual single grade, SAE 10W and SAE 30, oils.

In the industrial market, oils have no “multigrade” naming structure like SAE established for the automotive market. High VI industrial oils are still classified by ISO VG (approximately the oil’s viscosity at 40 C) and may be further qualified with “high VI.”

The American Gear Manufacturers Association (AGMA) also has a viscosity classification system. AGMA classifications align closely with the ISO viscosity grade system and, in fact, AGMA has adopted the ISO VG naming convention.

What’s interesting is the broader range of viscosities for the SAE engine and gear oils compared to the ISO VG ranges. Also, confusing to first time users may be that an SAE 90 gear oil classification has some of the same viscosities at 40 C as in the SAE 40, SAE 50 and SAE 60 engine oil classifications. ISO viscosity grades 150, 220 and 320 also overlap some of the SAE 90 gear oil viscosities.

Despite the observations in the previous paragraph, I trust that helps clarify VI and classifications.

Dan Holdmeyer is retired from Chevron Lubricants and is based in Washington, Mo. You can reach him at dan.holdmeyer@gmail.com.