Meet the Presenter

This article is based on a webinar presented by STLE member Evan Zabawski and Auburn University on Sept. 7, 2021, titled Improving Fuel Efficiency by Selecting the Right Oil. The webinar series, titled The Beard Tribology Webinar Series, is named after the late Ralph Beard, who pioneered the study of tribology at Auburn. For more information on the webinar series, visit www.eng.auburn.edu/programs/tribology/beard-tribology-webinar.html.

Evan Zabawski is senior technical advisor for Eurofins TestOil. He is an STLE Certified Lubrication Specialist™ (CLS) with diplomas in chemical engineering and 4th class power engineering. He has extensive experience training tradesmen and professionals in a variety of fields, including lubrication fundamentals, contamination control, condition monitoring and used oil analysis.

Zabawski has been an STLE member for more than 20 years, serving as chair of the Alberta Section for eight years, and also as an instructor of the Condition Monitoring course at STLE annual meetings.

Zabawski is former editor of TLT and has served as the editor for the STLE Alberta Section’s Basic Handbook of Lubrication, Third Edition. He also contributed as one of the editors for STLE/CRC’s Handbook of Lubrication and Tribology, Volume II: Theory and Design, Second Edition.

You can reach Zabawski at Evan.Zabawski@et.eurofinsus.com.

Evan Zabawski

Evan Zabawski

KEY CONCEPTS

•

Lower grade oils are not always thinner than higher grade oils.

•

So-called “winter”-graded engine oils perform better than “summer” oils at higher temperatures.

•

Ambient conditions should no longer drive engine oil selection.

•

Thinner oils offer both higher fuel efficiency and thicker oil films where needed.

One of the least expensive pathways to achieve improvements in vehicles’ fuel economy is through changes to engine lubricants viscosity. Driven by ever more stringent emission regulations, OEMs are, therefore, requiring engine oils to continue protecting engines at lower viscosities and reduced emissions. Different engine operating conditions represent a range of lubrication conditions, and to better understand the full impact of engine lubrication process, one must understand how oils perform in these conditions.

1 The focus of this article is to present an overview of the benefits of using lower engine oil grades for end-users, switching to engine oil viscosity grades as low as 0WXX in order to improve fuel efficiency.

This article is based on an Auburn University Beard Tribology Webinar presented by STLE member Evan Zabawski, senior technical advisor for Eurofins TestOil. See Meet the Presenter for more information.

Viscosity: temperature

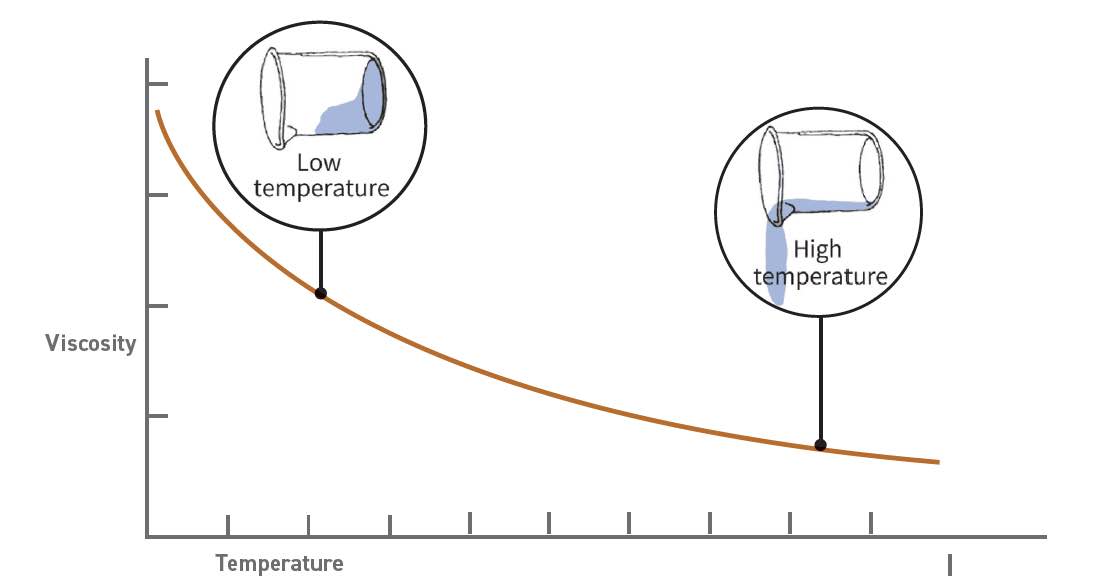

Oil viscosity is a measure of a resistance to flow. An increase in temperature will result in a decrease in viscosity

(see Figure 1). Viscosity doesn’t change linearly with temperature—i.e., if oil is heated up 10 degrees, it will thin, but if heated up another 10 degrees, it may not necessarily thin by the same amount again. Additionally, the rate at which viscosity changes differs between oils, says Zabawski.

Figure 1. The extent to which a fluid resists a tendency to flow.

Viscosity: shear

Figure 1. The extent to which a fluid resists a tendency to flow.

Viscosity: shear

Another change that occurs to oil viscosity is caused by shear. Shear stability is a term that characterizes an ability of an oil to resist mechanical stress from opposing parallel forces, which can cause a temporary thinning of the oil and a loss of oil film strength.

2

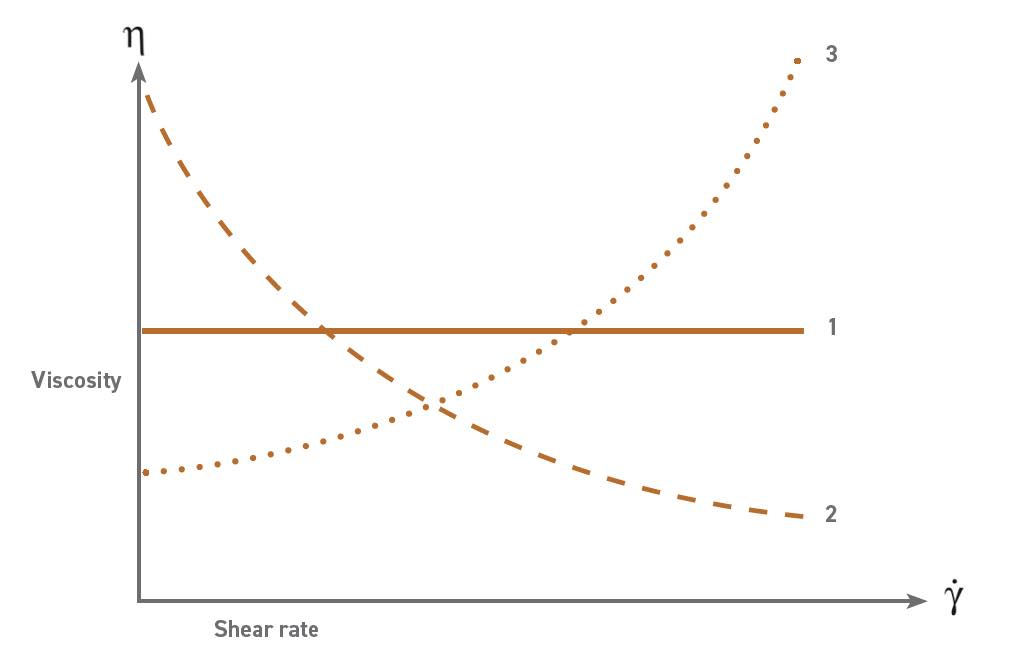

Shear stable fluids. Zabawski states that Newtonian fluids do not experience a change in viscosity

(see Figure 2). In the figure, curve #1 shows no change in viscosity. Some typical examples are monograde oil/straight grades, which in their product name typically only have one number.

Figure 2. Shear rate. Figure adapted from Mezger, T. (2011), The Rheology Handbook, 3rd revised ed. Hanover: Vincentz Network, pp. 35.

Shear thinning fluids.

Figure 2. Shear rate. Figure adapted from Mezger, T. (2011), The Rheology Handbook, 3rd revised ed. Hanover: Vincentz Network, pp. 35.

Shear thinning fluids. Non-Newtonian fluids, high viscosity index (HVI) fluids (i.e., multigrade oils) and pseudo-plastic fluids will experience a decrease in viscosity due to mechanical shear, without a change in temperature, says Zabawski. In Figure 2, curve #2 shows a decrease in viscosity. These fluids also are called thixotropic, for example, multigrade oils (i.e., oils that have two numbers in their names such as 5W30 or 10W30), he continues.

Shear thickening fluids. Non-Newtonian fluids, such as dilatant fluids (i.e., coupling fluids), will experience an increase in viscosity. In Figure 2, the fluids that follow curve #3 are showing a viscosity increase with stress over time, Zabawski says.

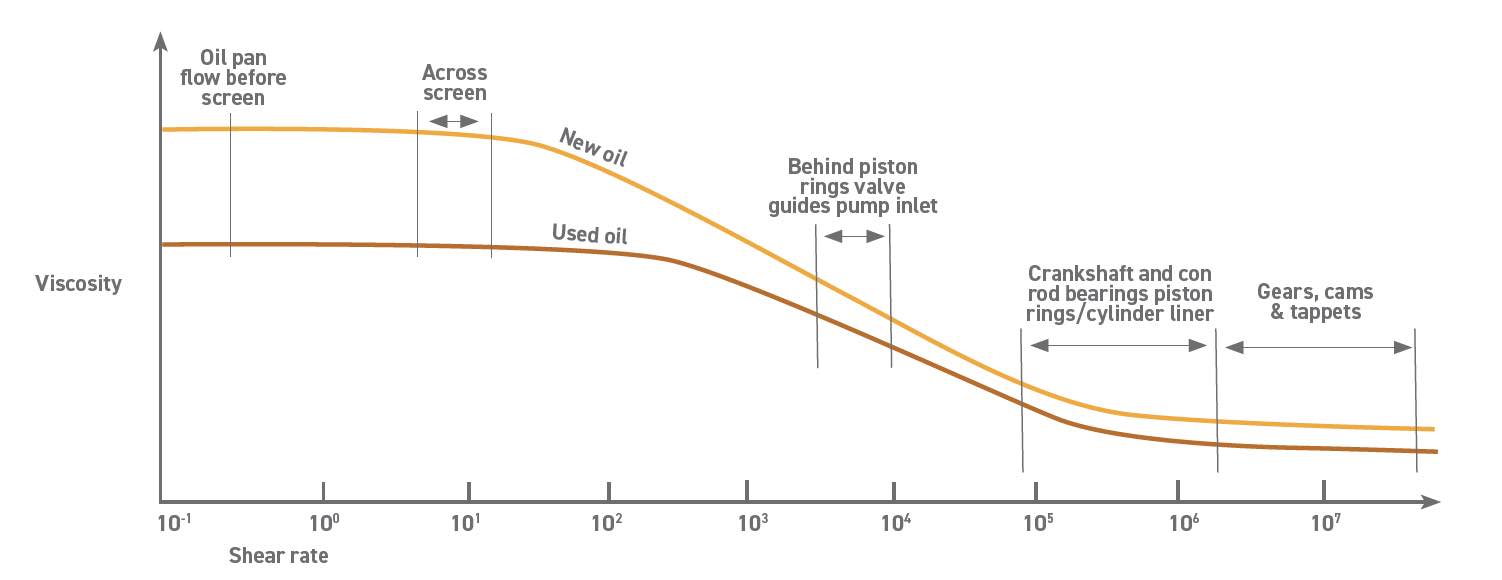

Figure 3 shows a new engine oil (orange line), and it represents the trip oil takes through an engine in one cycle, states Zabawski. He continues that the brown line is a used oil, and it is a little bit lower than the orange line, as used oil typically has a lower viscosity than new oil, and that’s because of a permanent shear, a permanent drop to the viscosity; it is an unrecoverable viscosity. The gap between both lines hints why 0W is not used everywhere—the reason is that other applications could cause permanent shear. He adds: Temporary shear, represented by the drop (from left to right) in both lines, shows that the reason multigraded oils are used in engines is to allow the viscosity to thin to a more appropriate viscosity long before the heat from combustion would bring it within expected viscosities.

Figure 3. Shear – temporary versus permanent.

Viscosity index

Figure 3. Shear – temporary versus permanent.

Viscosity index

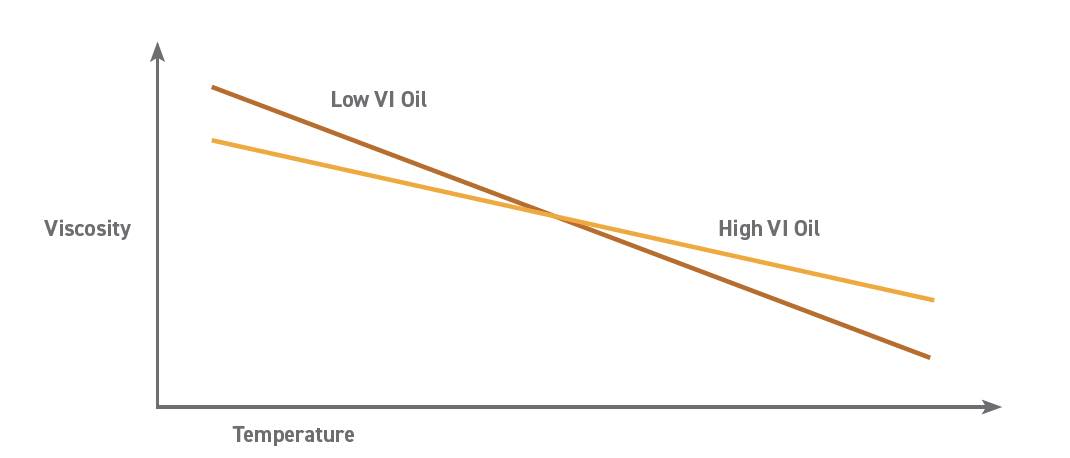

According to Zabawski, viscosity index (VI) is an arbitrary, unitless measure for the change of viscosity with variations in temperature

(see Figure 4).

Figure 4. Viscosity Index.

The lower the VI, the greater the change of viscosity of the oil with temperature and vice versa.

Initial research on VI began back in 1928. Petroleum chemists E.W. Dean and G.H.B. Davis devised a comparative 0-100 VI scale by using the Saybolt viscosity measurements of two different reference oils at both 100 F (37.8 C) and 212 F (98.89 C). The reference oils, which had the same viscosity at 212 F, were a Coastal crude, assigned a VI of 0, and a Pennsylvania crude, assigned a VI of 100:

3

•

0 VI = worst oil, naphthenic (most change)

•

100 VI = best oil, paraffinic (least change).

Once base stock refining techniques were improved, the ASTM D2270 calculation was devised to account for oils with a VI above 100. With today’s technology, it is rare to find a formulated product with a VI much below 100, and many multigrades are achieving a VI close to 200.

3 Zabawski says: It’s important to note that higher VI is a critical rheological property of a lubricant that influences fuel economy and greatly improves it.

Engine oil classification

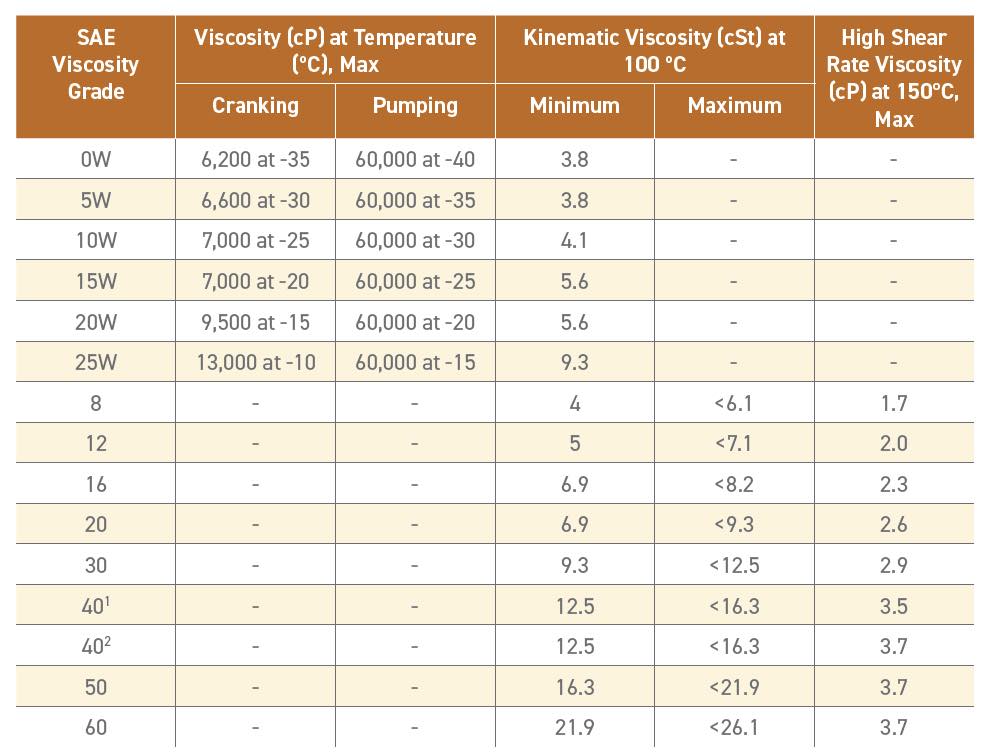

Zabawski explains that Table 1 shows SAE J300 engine oil viscosity classification for selective viscosity grades. It is important to understand the pumping viscosity and the cranking viscosity at different temperatures. Table 1 shows that 5W will perform as well or better than a 10W, but 5 degrees colder.

Table 1. SAE J300 viscosity classification. Table adapted from the Society of Automotive Engineers.

Table 1. SAE J300 viscosity classification. Table adapted from the Society of Automotive Engineers.

The cranking viscosity will get lower as test temperature decreases. However, the key here is that lower grades are not only optimal for colder climates versus higher grades of engine oils, but they are great as a year-round solution.

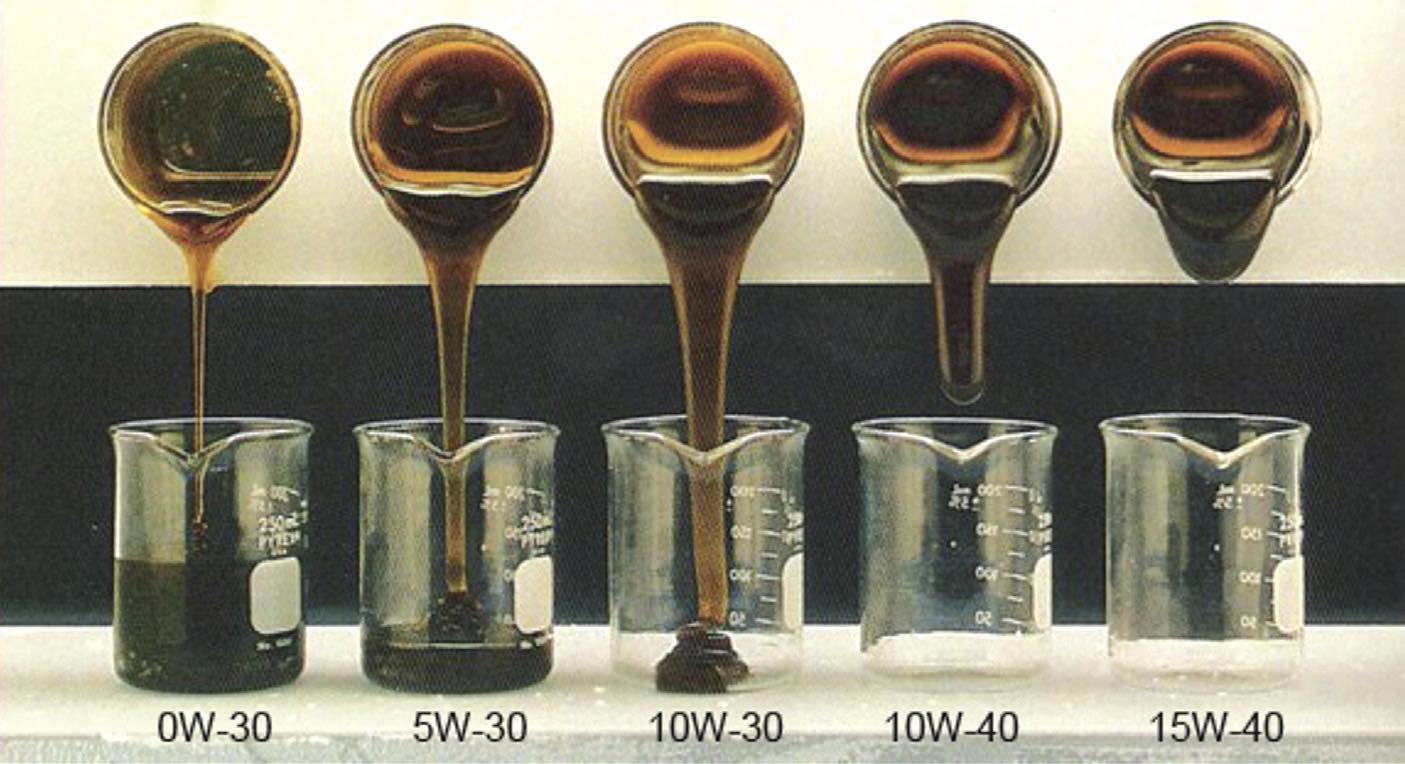

Per Zabawski, as recently as 10 years ago, some automotive manufacturers still recommended the use of 10W-30 year-round and suggested 5W-30 only be used if the ambient temperature went below freezing. The recommendation of 10W-30 has dropped in favor of 5W-30 for most automotive applications, but it is slow to shift from 5W-30 to 0W-30, even though 0W-30 has been commercially available for decades, he adds. This could be due to the stigma of 0W oils being winter oils perpetuated by common demonstrations

(see Figure 5) of 0W oils being winter oils.

4

Figure 5. Cold pour comparison at -35 C.

Figure 5. Cold pour comparison at -35 C.

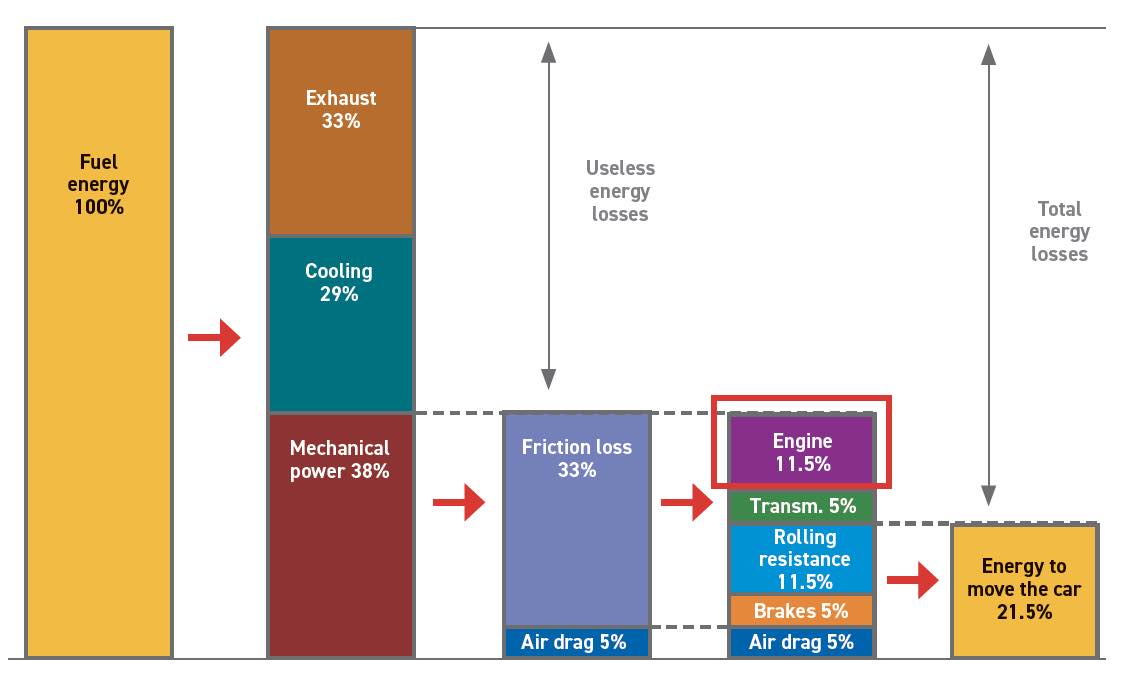

According to Zabawski, better viscosity indicates improved fuel economy, and while looking at energy consumption in a passenger car

(see Figure 65), it can be seen that energy losses are inevitable among all major components. However, the greater amount of loss comes from the ring/cylinder interface, largely due to surface area, e.g., a small 350 V8 has around 600 square inches

(see Figure 7). The ring/cylinder interface also sits at around 160 C (320 F) or higher. There also is no hydrodynamic, nor elasthydrodynamic, film throughout the entire stroke as the piston has to stop, turn around and come back repeatedly. There is instead a boundary lubrication, mixed lubrication and hydrodynamic lubrication fluctuation caused by variances in speed and temperature throughout each stroke. It’s one of the hardest places in the engine to lubricate well, says Zabawski.

Figure 6. Energy consumption in passenger cars. Figure courtesy of Holmberg, K., Andersson, P. and Erdemir, A. (2012), “Global energy consumption due to friction in passenger cars,” Tribology International, 47, pp. 221-234.

Figure 6. Energy consumption in passenger cars. Figure courtesy of Holmberg, K., Andersson, P. and Erdemir, A. (2012), “Global energy consumption due to friction in passenger cars,” Tribology International, 47, pp. 221-234.

Figure 7. Average ring cylinder temperatures.

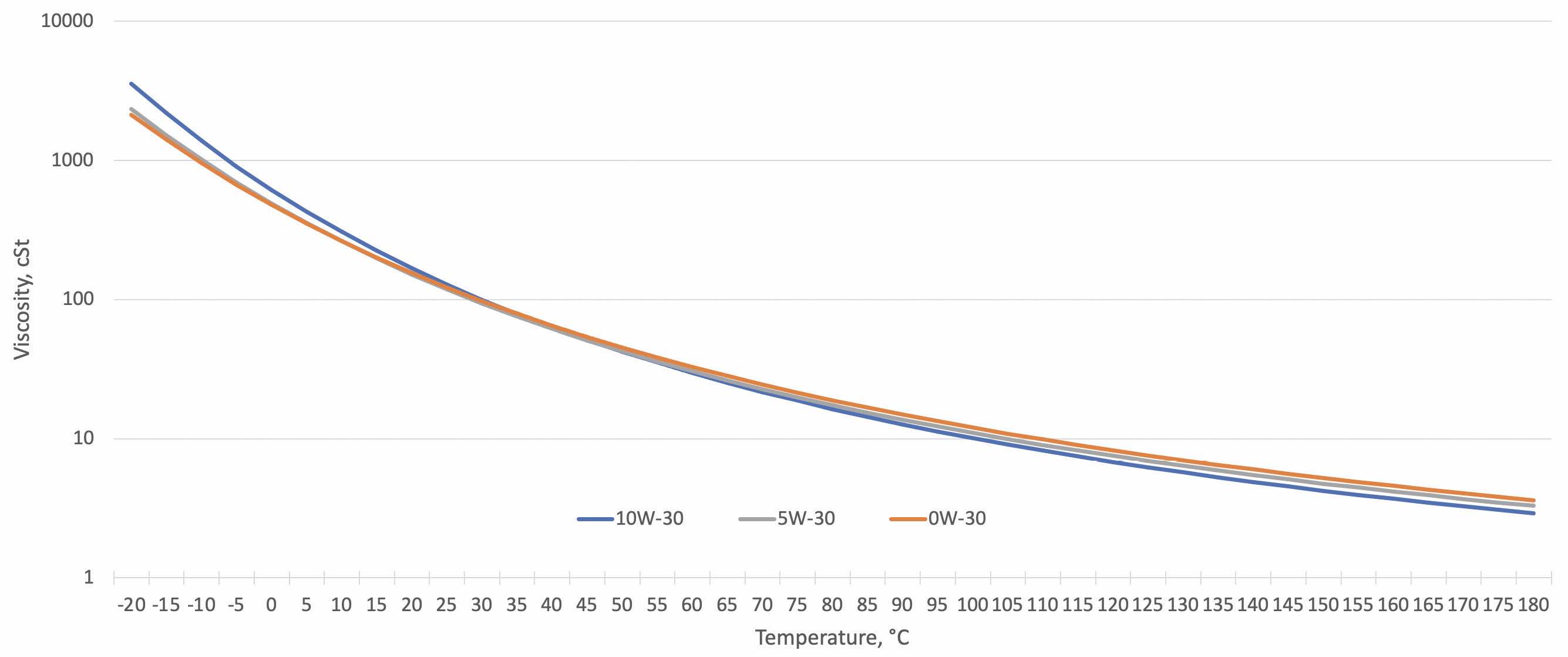

Figure 8 shows a comparison of different viscosities—10W-30, 5W-30 and 0W-30, and at a temperature of 160 C or higher gives the surprising revelation that 0W-30 oil is about 10% thicker than either of the other two at that temperature, Zabawski says. This is due to the VI, which should make sense. For an oil to be relatively thinner than another at cold temperatures, but equal at a warmer temperature, it must have less variance in viscosity with temperature, he adds. Therefore, as the oil’s temperature increases, it will not thin out as much and provide a superior film of lu brication that is able to provide better lubrication (reduce friction and wear) and better sealing (increase compression and power).

4 Looking back to Figure 6, the engine section outlined in the red square, if the friction losses were reduced by 2%, then that could translate to some significant savings in fuel, says Zabawski.

Figure 8. 0W consideration.

Figure 8. 0W consideration.

Therefore, when comparing a vehicle operated in the Upper Peninsula of Michigan in January, the coldest month of the year, versus one operated in Death Valley in July, the hottest month of the year, it should be considered that either engine will do everything in its power to operate at the same overall temperature regardless of ambient conditions, Zabawski explains. Barring a few degrees either way, this shows that geographic location and ambient temperatures are of little concern as compared to the temperature at the point of lubrication. The 0W-30 would provide superior lubrica- tion in critical areas like the ring/cylinder interface, as compared to 5W-30 or 10W-30, he adds.

Why are engine oils getting thinner?

Per Zabawski, it is generally agreed that fuel economy is improved when a lower viscosity lubricant is used in place of a higher viscosity lubricant. This is reflected in the shift in use of lower viscosity engine oils.

He continues that in response to the energy crisis caused by the 1973 oil embargo, the U.S. Congress enacted the Corporate Average Fuel Economy (CAFE) regulations in 1975. The goal was to decrease energy consumption by increasing fuel economy in passenger vehicles. Whereas:

•

National Highway Traffic Safety Administration (NHTSA) sets and enforces CAFE standards.

•

EPA calculates average fuel economy and greenhouse gas standards.

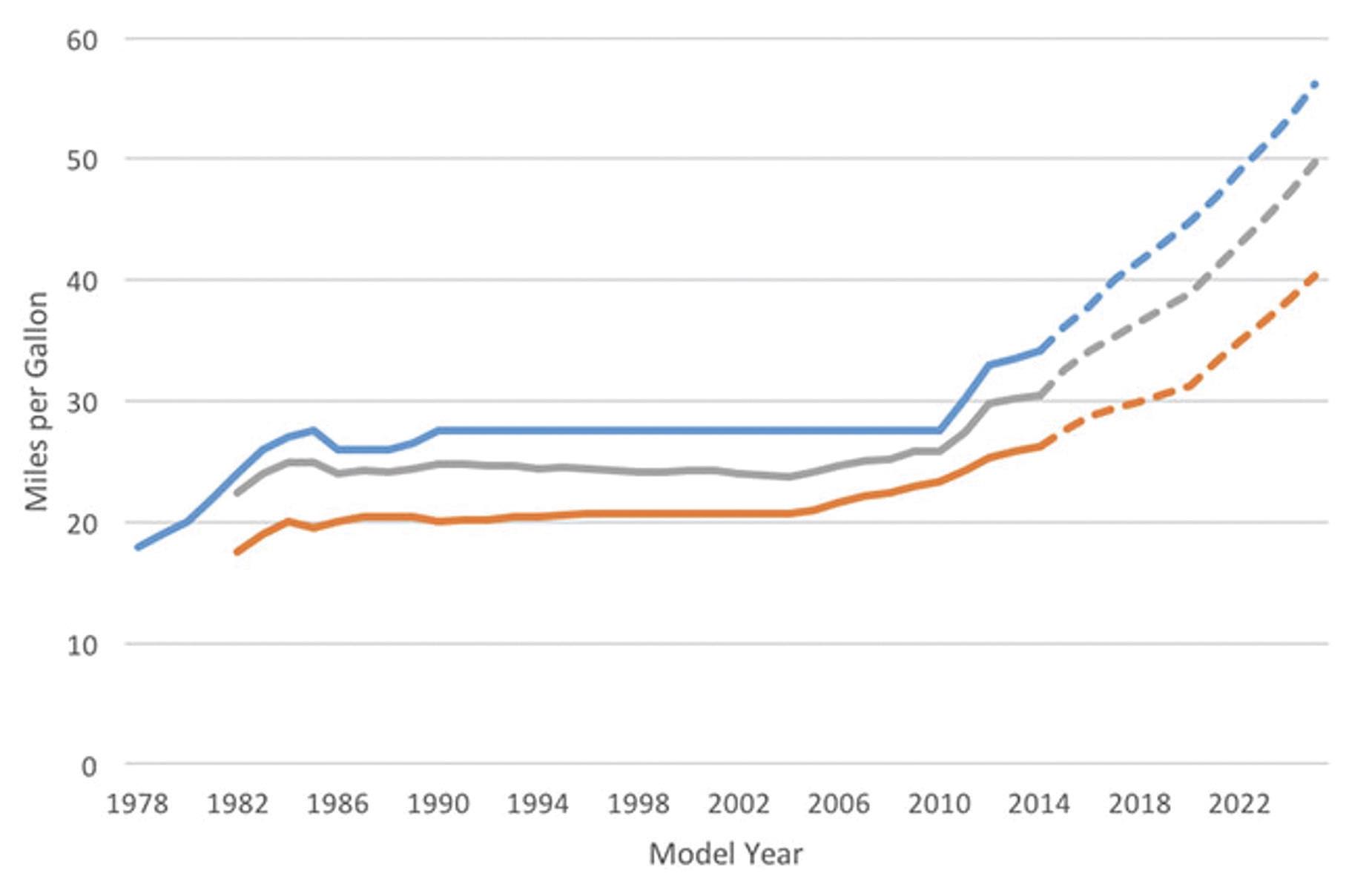

Since 1978, a new, higher target is set for each model year. For example, for the 2022 model year, it must meet 39.79 mpg for full-size passenger cars and 28.73 mpg for half-ton trucks

(see Figure 9). Non-compliance results in a penalty of $5.50 per 0.1 mpg, per vehicle sold (not built) in North America, says Zabawski.

Figure 9. Miles per gallon driven trend for light trucks (orange line), total fleet (gray line) and passenger cars (blue line). Figure adapted from the National Highway Traffic Safety Administration (NHTSA).

Figure 9. Miles per gallon driven trend for light trucks (orange line), total fleet (gray line) and passenger cars (blue line). Figure adapted from the National Highway Traffic Safety Administration (NHTSA).

It is well documented that using lower viscosity engine oils can greatly improve fuel economy. Ford and Honda started specifying 5W-20 oils as factory and shop fill in the early 2000s, strictly to meet CAFE ratings.

•

Ford found 5W-20 decreases fuel consumption by an average of 0.6%.

•

Honda only did it to be green; they are far ahead of the CAFE ratings.

Conclusion

Conclusion

Increasing fuel costs have made fuel efficiency one of the most important issues for the automotive industry. Use of low viscosity lubricants is known to be an effective way to achieve better fuel economy. Selecting engine oil developed to improve vehicle fuel efficiency can be as simple as selecting a “thinner” product. Zabawski states that 0W motor oils are well formulated to meet the demands of today’s modern engines providing optimal lubrication, protection to critical engine parts and thicker oil film where needed, while resulting in improved fuel economy regardless of various ambient conditions.

REFERENCES

1.

Fatemi, A., Pauschitz, A. and Topolovec-Miklozic, K. (2022), “23rd International Colloquium Tribology: Industrial and Automotive Lubrication.”

2.

Haffner, S. (2018), “Shearly staying in grade,”

Lubes’N’Greases. Available

here.

3.

Zabawski, E. (2014), “Viscosity, viscosity, viscosity!” TLT,

70 (6), p. 6. Available

here.

4.

Zabawski, E. (2013), “Zero Double-U Massacree,” TLT,

69 (5), p. 6. Available

here.

5.

Holmberg, K., Andersson, P. and Erdemir, A. (2012), “Global energy consumption due to friction in passenger cars,”

Tribology International, 47, pp. 221-234.

Dr. Yulia Sosa is a freelance writer based in Peachtree City, Ga. You can contact her at dr.yulia.sosa@gmail.com.