•

N-i-p-based perovskite solar device architecture is widely used, but its stability is not good enough for commercialization.

•

The inverted p-i-n architecture is more advantageous when used for tandem devices.

•

Modification of the surface of the p-i-n perovskite solar cell was accomplished through the use of a treatment that improves performance and stability.

Harnessing energy from the sun continues to be one of the primary options to source renewable energy. Improving the efficiency of converting solar rays into electricity remains a challenge for researchers. The focus has been to improve the efficiency of solar cells based on perovskites, which are based on organic-inorganic metal halides.

In a previous TLT article,

1 researchers working with a perovskite derived from cesium lead iodide determined that substitution of bromine for iodine and indium for lead produced a more stable material. The bromine addition reduced the number of defects leading to greater stability but also created an undesirable increase in the bandgap. This issue was rectified through replacement of some of the lead with indium. Preparation of the perovskite can be conducted without the need for special conditions, and this material also is much more stable in the presence of water. An added bonus is that it also is more environmentally friendly.

The main type of perovskite solar cells used currently is based on a n-i-p architecture. Dr. Kai Zhu, senior scientist at the National Renewable Energy Laboratory (NREL) in Golden, Colo., says, “Normal, n-i-p architectures are the most commonly used for single-junction perovskite solar cells. In fact, the highest solar cell efficiencies have been achieved to date with n-i-p architectures. While this type of perovskite solar cell architecture is efficient, its stability is not good enough and could present challenges for future commercialization.”

Dr. Joseph Berry, senior research fellow I-Physics at NREL, says, “The n-i-p-based perovskite device architecture can be produced in high volumes at high yields, but attempts to add dopants create problems for device stability. The key concern is that the performance of the n-i-p perovskite solar cells at high temperatures is quite limited.”

Problems with the n-i-p architecture led Zhu and Berry to work with the inverted p-i-n architecture. The difference between the two architectures is due to the placement of the electron transportation layer (ETL) and hole transportation layer (HTL) with respect to the perovskite. Sunlight first encounters the ETL in the n-i-p architecture. The next layer is the perovskite followed by the HTL. In the p-i-n architecture, the top layer is the ETL followed by the perovskite and the HTL, and sunlight first encounters the HTL side of the device.

Zhu says, “The advantages in working with the p-i-n architecture are a thick HTL layer is not needed (the HTL cell is about 20 nanometers thick) and a strong dopant is not required.” Berry says, “The p-i-n structure also has the advantage of being more straightforward for tandem devices.”

To achieve greater efficiencies, the p-i-n perovskite solar cells require modification of the top surface to minimize defect formation that can occur due to volatilization of the organic components in the perovskite and iodine. The researchers indicate that an ideal surface engineering approach should not affect the bulk perovskite film, not hinder charge transfer, reduce the density of defects and ensure a surface region with a built-in electric field leading to effective electron extraction.

A new type of surface treatment has now been applied to a p-i-n perovskite solar cell leading to greater stability and higher efficiency.

Surface polishing

Zhu, Berry and their colleagues modified the surface of the p-i-n perovskite solar cell by adding 3-(aminomethyl) pyridine (3-APy) to the top surface of a perovskite thin film

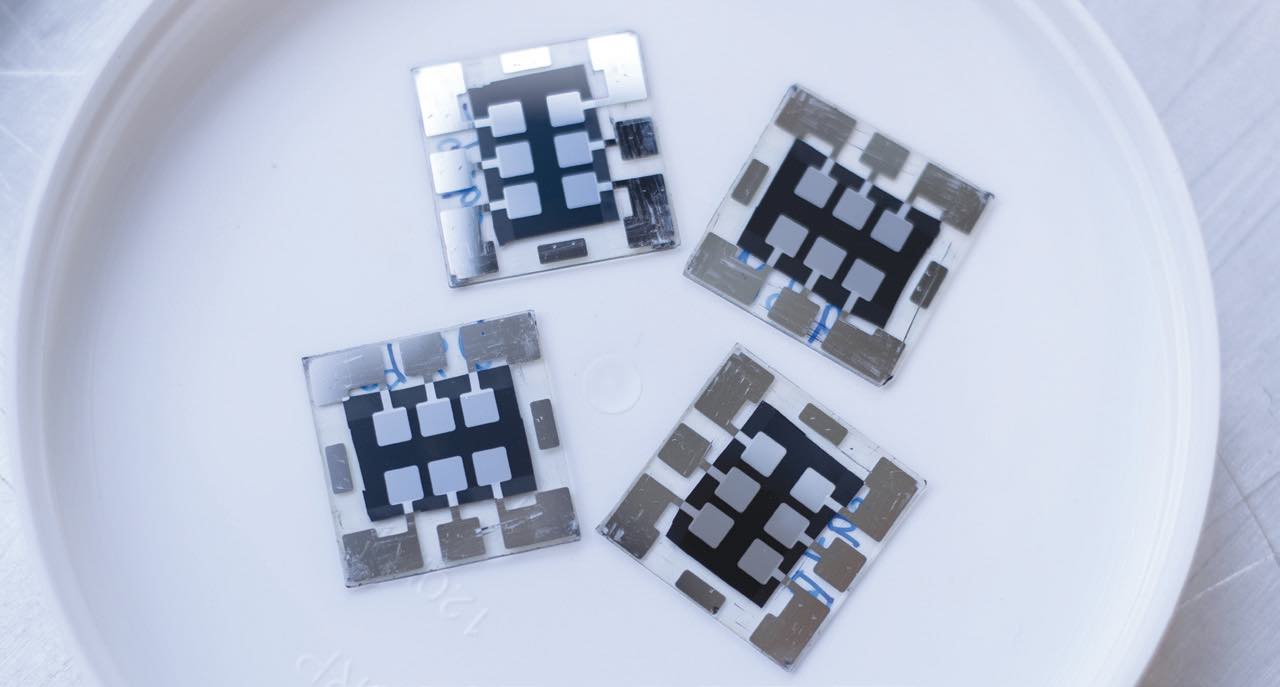

(see Figure 3). Zhu says, “3-APy is well suited to furnish two functions in modifying the perovskite surface. The amine group reacts with a formamidinium cation present to form a bulkier amidinium 1+ cation with the release of ammonia. This results in a reduction of perovskite surface roughness leading to a minimization of surface potential fluctuations associated with surface steps/terraces. The pyridine ring facilitates the formation of iodine vacancies, which leads to surface doping to create an electric field to enhance perovskite performance and stability.”

Figure 3. Surface polished p-i-n solar perovskite solar cells are shown. Surface treatment improves their stability even under high humidity conditions. Figure courtesy of the National Renewable Energy Laboratory (NREL).

Figure 3. Surface polished p-i-n solar perovskite solar cells are shown. Surface treatment improves their stability even under high humidity conditions. Figure courtesy of the National Renewable Energy Laboratory (NREL).

The 3-APy is added to the perovskite through a spin coating process. Berry says, “This approach is very effective in improving the surface and performance of the perovskite solar cell. Reduction of the surface roughness reduces shifts in chemical potential that can have negative consequences. Adding the 3-APy is similar to polishing the perovskite, which provides a more consistent surface.”

The researchers verified the surface polishing effect through the use of atomic force microscopy, Kelvin probe force microscopy and scanning electron microscope images.

Performance testing of the surface modified perovskite cell was conducted by exposure to sunlight at 55 C in ambient air. A control cell also was evaluated that was not treated with 3-APy. The modified cell retained approximately 87% of its maximum power conversion efficiency after 2,428 hours of sunlight exposure. In contrast, only 76% of the maximum power conversion efficiency was retained by the control after nearly half the sunlight exposure (1,368 hours). The surface modified perovskite solar cell also shows good performance under high humidity conditions. In testing done at 85 C under 85% relative humidity, the cell retained 94% of its maximum power conversion efficiency after 850 hours.

Berry says, “The low cost perovskite solar cell developed has shown good performance efficiency and reliability at a small scale in the laboratory. The next step for this work is to determine if the surface polishing can retain its effectiveness when used in large area devices.”

Additional information can be found in a recent article

2 or by contacting Wayne Hicks, public affairs specialist at NREL, at

Wayne.Hicks@nrel.gov.

REFERENCES

1.

Canter, N. (2020), “More stable inorganic perovskite,” TLT,

76 (2), pp. 18-19. Available

here.

2.

Jiang, Q., Tong, J., Xian, Y., Kerner, R., Dunfield, S., Xiao, C., Scheidt, R., Kuciauskas, D., Wang, X., Hautzinger, M., Tirawat, R., Beard, M., Fenning, D., Berry, J., Larson, B., Yan, Y. and Zhu, K. (2022),” Surface reaction for efficient and stable inverted perovskite solar cells,”

Nature, 611 (7935), pp. 278-283.