HIGHLIGHTS

•

Microbials are emerging as a potential approach for harvesting energy particularly in remote locations.

•

Synergism among three bacteria is used to develop micro-biophotovoltaic cells.

•

The three bacteria species are vertically stacked in the cell and convert power initiated from photosynthesis eventually to electricity.

As industrial processes move toward using artificial intelligence (AI) with the development of the Internet of Things (IoT), there will be demand for devices that can operate more remotely in unattended environments using wireless sensor networks. From the lubricant standpoint, this may include operations that take place in remote areas such as wind turbines, mining and forestry. Data on the condition of lubricants operating in these environments will need to be constantly monitored to ensure that machinery is operating properly.

Energy harvesting is a logical approach for making sure power is available to ensure devices can operate properly in remote locations. In a previous TLT article,

1 researchers developed a metal-air scavenger that is able to extract chemical energy from metals present in the soil of a specific location and generate power through the use of a battery. Metal is oxidized at the anode triggering a series of chemical reactions that lead to a free energy difference between the metal surface and oxygen. The energy density for the metal-air scavenger was found to be 10 times higher than that of the best energy harvesters available at that time.

Seokheun Choi, professor, Department of Electrical and Computer Engineering, director, Bioelectronics and Microsystems Lab (BML), director, Center for Research in Advanced Sensing Technologies and Environmental Sustainability (CREATES), at the State University of New York (SUNY) in Binghamton, N.Y., says, “Identification of technologies that can operate in a self-sustaining manner in remote locations has been difficult. To be effective, these technologies will need to not only generate power but also store it. Candidates such as supercapacitors and lithium-ion batteries are not suitable because both will need to be frequently recharged.”

Another option is to examine the use of biological systems to generate and store power in remote locations. Choi says, “Microbial energy harvesters such as microbial fuel cells and microbial solar cells have been developed and are appealing because they are well suited for use to power smaller energy devices that are steadily shrinking in size to the miniature scale.”

Efforts to develop microbial energy harvesters have not proven to be successful due to limited power output and unsustainability caused in part by the use of only one microbial species. A new approach has now been developed to use more than one microbe in a biobattery system that can generate power effectively in remote locations over a long period of time.

Micro-biophotovoltaic cells

Choi and his colleagues have developed micro-biophotovoltaic cells by taking advantages of the synergism they found in using three bacteria species,

Synechocystis sp., Bacillus subtilis and

S. oneodensis. He says, “The three bacteria species are placed in a typical microbial fuel cell configuration that contains an anodic compartment, cathodic compartment and a salt bridge between them. The working anode and counter cathode electrodes were both prepared with graphite. A silver/silver chloride reference electrode also was included in the setup.”

To place all three bacteria species in the same cell, the researchers conducted a layer-by-layer electropolymerization deposition process that produced a multi-layered, conductive microbial structure. Each bacteria species is confined within a quasi-solid state polymer layer that are coupled together to facilitate cross-feeding interactions between species.

The electropolymerization was carried out on poly(3,4-ethylenedioxythiophene)polystyrene sulfonate (PEDOT:PSS) through the use of 3,4-ethylenedioxythiophene and sodium alginate. This produced a three-dimensional network that entraps and connects bacteria to the anode.

Choi says, “The three bacteria species were vertically stacked in the cell in a specific order to take advantage of how they generate power.

Synechocystis sp. is placed in a chamber on the top of a module because this species undergoes photosynthesis and needs to be exposed to light. This results in the production of carbohydrates that are used by the other two bacteria species and initiates a flow of metabolites to the next bacterium,

Bacillus subtilis. Bacillus subtilis is a helper bacterium that uses production of riboflavin to facilitate electron transfer to the next bacterium,

S. oneodensis. This third bacterium is positioned on the bottom of the chamber because it is most effective at generating electricity by using the organic molecules produced by the other two bacteria as fuel in aerobic respiration at the anode.”

To enable the bacteria to utilize water, carbon dioxide and oxygen in photosynthesis and respiration, the researchers passivated the cell with sodium polyacrylate, keeping it wet and gas permeable.

Evaluation of the cell was conducted under 12 hour light and then dark cycles at a constant humidity of 64% and a constant temperature of 30 C. An output power density of approximately 50 microwatts per square centimeter was achieved for more than 22 days. Choi says, “This result indicates that the micro-biophotovoltaic cell can sustain high performance for a long period of time and is suitable to be used in remote locations.”

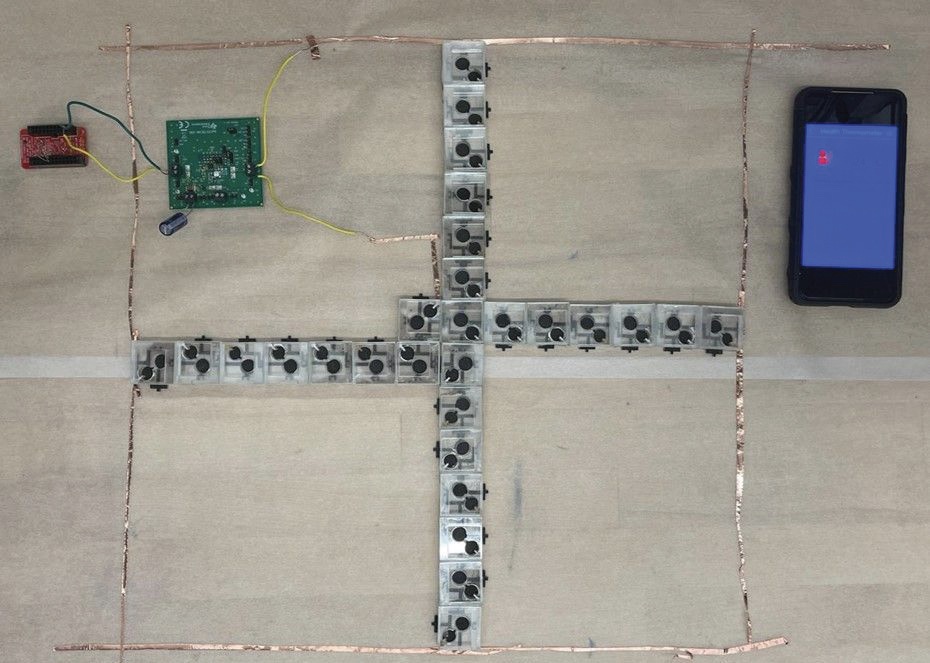

Modules can be connected to each other in series or in parallel to increase power generation. Choi says, “This ‘plug-and-play’ approach has the potential to use micro-biophotovoltaic cells in a wide range of applications. For example, we built a 24-biobattery stack in series and parallel

(see Figure 2) that was used to successfully monitor a low-power Bluetooth temperature monitoring system.

Figure 2. The micro-biophotovoltaic cells that generate electricity remotely are connected to each other in a 24-biobattery stack in series and parallel to monitor a low-power Bluetooth temperature monitoring system. Figure courtesy of the State University of New York in Binghamton, N.Y.

Figure 2. The micro-biophotovoltaic cells that generate electricity remotely are connected to each other in a 24-biobattery stack in series and parallel to monitor a low-power Bluetooth temperature monitoring system. Figure courtesy of the State University of New York in Binghamton, N.Y.

This advance in biobattery development has the potential to be used to power sensors monitoring lubricant systems in remote locations. Choi says, “Optimization is underway to boost the power output. Self-healing packaging also is under investigation to automatically repair the biobattery when used in remote environments.”

Additional information can be found in a recent paper

2 or by contacting Choi at

sechoi@binghamton.edu.

REFERENCES

1.

Canter, N. (2020), “New power source: Extracting energy from the environment,” TLT,

76 (8), pp. 12-13. Available

here.

2.

Elhadad, A., Liu, L. and Choi, S. (2022), “Plug-and-play modular biobatteries with microbial consortia,”

Journal of Power Sources, 535, 231487.