Slick yet stuck

Jamie Benson | TLT Scholarship Essay May 2022

Reconciling superlubricity and superadhesion in articular cartilage.

Jeanie S. McCoy Scholarship

The Jeanie S. McCoy Scholarship is awarded annually to recognize female college and high school students pursuing careers in tribology. This scholarship started in 2019, administered by the STLE Presidential Council, that was created to honor STLE Life Member Jeanie McCoy, who was a member of STLE for more than 66 years, joining in the early 1950s when the lubrication industry was clearly male dominated. McCoy passed away in July 2019.

The 2021 recipient is Jamie Benson, a graduate research assistant in the Materials Tribology Laboratory at the University of Delaware working with Dr. David Burris. Benson’s research primarily focuses on understanding the mechanical and tribological mechanisms driving hydration and lubrication in articular cartilage in order to develop analytical tools to model and predict how ordinary activities (i.e., walking, standing) affect tissue health and function. After finishing her doctoral studies, Benson plans to pursue a postdoctoral position in translational biomechanics. She hopes to ultimately form her own group in a clinical-academic setting that bridges the gap between basic science, translational medicine and public health policy to develop comprehensive solutions for musculoskeletal diseases.

As a requirement for receiving the McCoy scholarship, students must submit an essay for publication in TLT discussing their goals, plans and interests in pursuing a future career in the field. For more information about the McCoy scholarship, visit www.stle.org.

Jamie Benson

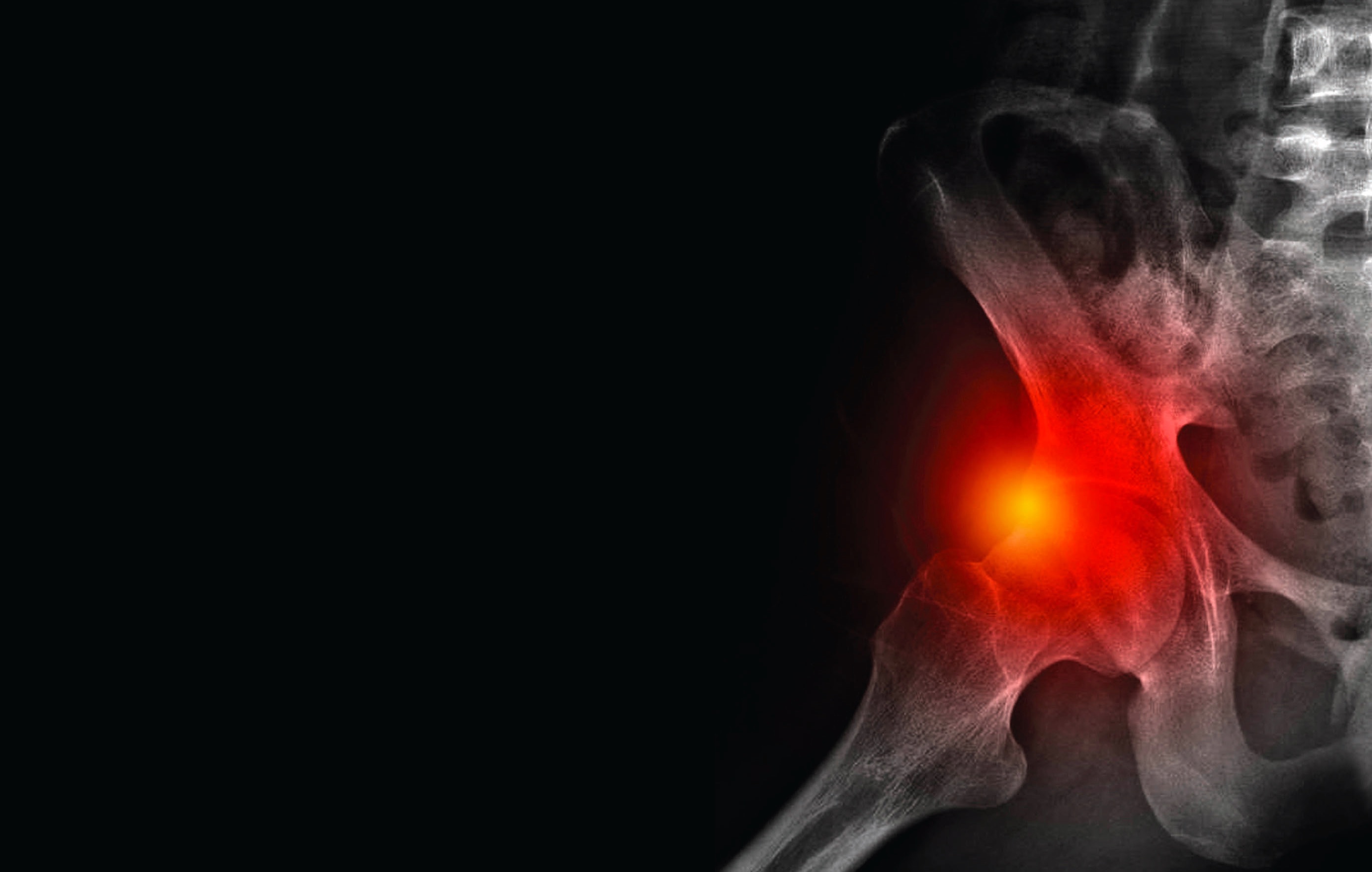

Cartilage is simple, yet complex: It is made of 80% water and 20% solid matrix, yet it endures a lifetime of “wear and tear” without failing. This idea resonated within me long after I first heard it in my undergraduate biomaterials course. Even our best materials are lucky to survive a decade in a modern joint replacement, and many fail in less than a year. For the last several decades, there has been a push to beat the creep and wear problems of polyethylene in joint replacements with even stiffer and stronger materials that look and behave less and less like cartilage—as it turns out, this was a flawed strategy. As an undergraduate conducting research at the Hospital for Special Surgery, I witnessed efforts to change course by engineering artificial cartilage with hydrogels that are, like cartilage, soft and composed primarily of water. Despite their compositional similarities, there were immense functional disparities between these materials and natural tissue. While these efforts are progressing, existing hydrogels are far too soft and far too delicate to survive the extreme mechanical and tribological conditions of the joint environment. My long-term goal is to create

functionally biomimetic cartilage, but to accomplish this, we need to resolve how the unique functions of natural cartilage depend on measurable and controllable material attributes.

As a member of the Materials Tribology Laboratory at the University of Delaware, we have started to probe and elucidate these structure-function relationships. Most notably, my group discovered that contrary to conventional wisdom, exercise is synonymous with joint wear; movement can actually guard against joint disease through a purely sliding-induced mechanism that we have termed “tribological rehydration.” This discovery opened a door to a new area of cartilage research. With about 10 papers published or nearing submission within the last five years, our research has helped move the field significantly, but a critical missing piece remains.

The majority of cartilage research is focused on lubrication mechanisms and its ability to mitigate adhesion to maintain super-low friction coefficients. Traditionally in tribology, lubricants with low surface energies are used to mitigate adhesive contacts and reduce friction. However, cartilage is a soft, sticky material primarily lubricated with water (high surface energy lubricant) and yet still exhibits friction coefficients lower than our best manmade non-stick materials (i.e., Teflon). Not only does this deviate from the traditional lubrication framework, but it also uncovers questions about the adhesive properties of cartilage. While lubricity and adhesion are generally viewed as mutually exclusive phenomena, anyone having cracked a knuckle has experienced the rupture of an adhesive contact strong enough to create an audible noise. This leads to the question:

How can cartilage exhibit both superlubricity and superadhesion?

This apparent lubrication-adhesion paradox implies that there is a fundamental difference in the relationship between adhesion and friction in cartilage. My doctoral work proposes that adhesion is a functional mechanism in cartilage and joints and is (1.) the result of a conformal interface between rough surfaces, (2.) attributed to interfacial suction consistent with a multi-asperity contact and (3.) a necessary contributor to create an environment to drive flows for lubrication. With the unique ability of my lab to design and create

in situ instruments capable of isolating interfacial mechanics, quantifying interfacial permeability and systematically assessing cartilage adhesion and friction across length scales, my work will clarify the functionality of cartilage adhesion and friction for the first time. Understanding this relationship will provide a more comprehensive understanding of the mechanical, tribological and biological functions of cartilage, which can be used to guide the development of truly biomimetic cartilage replacements and reduce the impact of diseases like osteoarthritis whose consequences we have suffered for far too long.

You can reach Jamie Benson at jmbenson@udel.edu.