Note: The move to lower emissions and sustainability is leading the automotive industry to commercialize battery electric vehicles in place of internal combustion powered vehicles. But the sustainability of battery electric vehicles has come into question due to sourcing of raw materials such as metals that need to be mined.

This issue of Tech Beat is devoted solely to discussing three research approaches underway to cost effectively recycle lithium-ion battery components that mainly are used in the cathode. The objective is to improve sustainability through the continuing reuse of metals.

KEY CONCEPTS

•

A direct recycling method known as froth flotation has been found to effectively separate two cathode materials commonly used in lithium-ion batteries.

•

In experiments conducted with a 1:1 mixture of the two cathode materials, a minimum of an 80% recovery rate was achieved.

•

Electrochemical performance showed reduced performance for the recycled cathode materials that was overcome through the addition of lithium hydroxide.

The move to a sustainable economy has accelerated the commercialization of electric vehicles that do not generate emissions. But a cradle-to-cradle analysis of lithium-ion batteries used in electric vehicles shows that sustainability is lacking. One other aspect is, the supply chain for electric vehicle batteries is more vulnerable to interruptions, which could reduce the transition away from internal combustion engines.

One approach that can both improve sustainability and reduce the complexity of the supply chain is recycling of lithium-ion batteries in general and minerals used in the preparation of cathodes. Dr. Albert Lipson, principal material scientist at Argonne National Laboratory in Lemont, Ill., says, “The cost of raw battery materials represents about 50% of the cost of a lithium-ion battery cathode.”

Two of the currently used techniques for battery recycling are pyrometallurgical and hydrometallurgical. Lipson says, “Pyrometallurgical methods refer to the use of heat to isolate metals from the battery through a process similar to smelting. Hydrometallurgical recycling refers to treating batteries with acid to dissolve specific metals. Methods such as solvent extraction are used to separate and isolate the specific metals.”

The challenge with both of those recycling methods is that only the metals are recovered. These metals require substantial processing to remake the cathode material, which is an expensive process. A third method that is under evaluation is direct recycling. Lipson says, “Direct recycling has an advantage because the value of the original cathode material can be retained by not changing the material’s structure or morphology.”

The composition of the metals in the cathode also is important in determining what recycling method makes the most sense. Lipson indicates that high cobalt containing cathode materials may be more profitably recycled using hydrometallurgical or pyrometallurgical processes due to the high value of the cobalt.

In an effort to find a suitable direct recycling option, Lipson and his colleagues decided to examine processes utilized in mining metal ores, which are similar to battery recycling because they also involve purification of metals. One such traditional approach is froth flotation.

Lipson says, “Froth flotation has two important advantages. It is relatively inexpensive and has been used commercially for a long period of time.”

In froth flotation, an aqueous mixture of metal oxide powders is treated with a collector chemical. The collector chemical, which is typically a surfactant, will selectively couple to one type of metal oxide material rendering it hydrophobic. The metal oxide slurry is fed into a froth column where air is fed at the bottom and bubbles to the top. These bubbles agitate the slurry and solution within the column and form a dense layer of froth at the top of the column. In the column, the hydrophobic metal oxide particles in the slurry attract air bubbles to the surface. This results in particles that float into the froth layer at the top of the column, and are then removed and isolated in the overflow fraction. More hydrophilic materials that do not couple to the collector chemical sink to the bottom of the column and are removed with the tailing products.

Lipson and his colleagues have now demonstrated that froth flotation can be used successfully to separate two ceramic materials commonly used in lithium-ion battery cathodes.

NMCIII and LMO

Lipson and his colleagues, in collaboration with researchers at Michigan Technological University in Houghton, Mich., evaluated mixtures of two cathode materials, NMCIII and LMO. NMCIII is a mixed metal oxide based on lithium, nickel, cobalt and manganese, and LMO is a lithium manganese oxide.

Lipson says, “NMCIII and LMO are two materials commonly used as cathode materials. In fact, a fair number of battery designs involve utilizing these two in mixtures.”

The researchers set up a series of experiments that started initially with evaluating the ability of NMCIII and LMO by themselves to be removed through froth flotation. A collector chemical, based on an amphoteric surfactant that is commonly used in mining ore flotation, was added to the aqueous slurry containing each material. A second component, methyl isobutyl carbinol (MIBC) was added as a froth stabilizer.

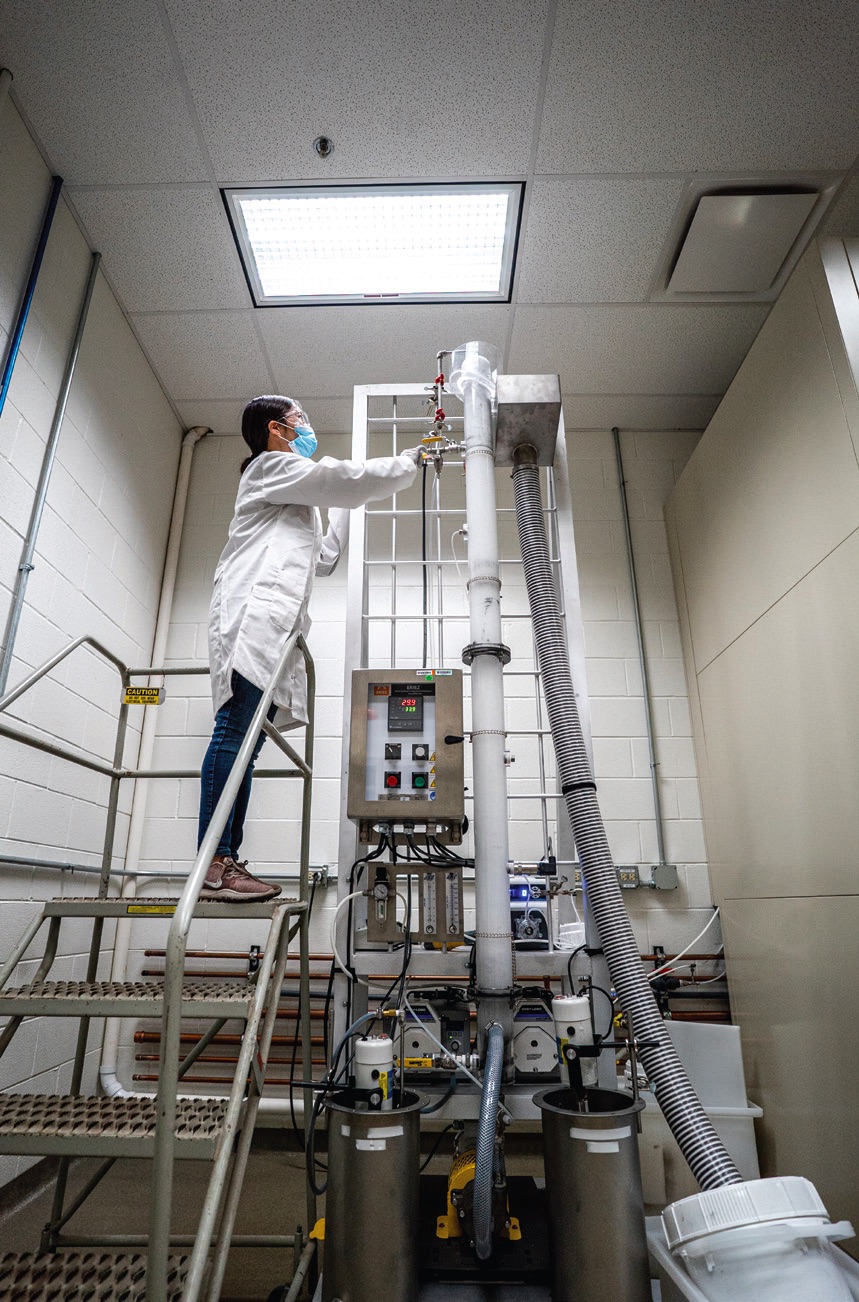

The initial experiments were conducted using a one-liter Denver flotation cell, and these results are currently being scaled up to kilogram quantities at Argonne National Laboratory using a froth flotation column shown in Figure 1.

Figure 1. A one-liter Denver flotation cell was used to separate cathode materials by a technique known as froth flotation. Figure courtesy of Argonne National Laboratory.

Figure 1. A one-liter Denver flotation cell was used to separate cathode materials by a technique known as froth flotation. Figure courtesy of Argonne National Laboratory.

Mixtures of NMCIII and LMO in a ratio of 1:1 were added to the Denver cell, and an optimum separation was found at a collector chemical dosage between 150 and 183 ppm. After a single froth stage, NMCIII was obtained at a concentration of 83% and a recovery rate of approximately 90%.LMO was found in the tailing product at a concentration of 92% at a recovery rate of approximately 80%.

NMCIII and LMO were then evaluated for electrochemical performance. Lipson says, “We built coin cells where both recycled cathode materials were blended with carbon black and polyvinylidene difluoride as the binder, which was then placed in a test battery with lithium metal as the anode and a blend of LiPF6, ethylene carbonate and ethyl methyl carbonate as the liquid electrolyte. The recycled cathode materials have somewhat reduced performance due to a loss of 7%-8%.

X-ray diffraction analysis of recycled NMCIII showed evidence of hydrogen cations substituting for lithium ions due to a slight contraction in the layers of the cathode material. Lipson says, “We compensated for this issue by adding a base, lithium hydroxide, that prevented lithium loss.”

The results of this work showed that froth flotation is a potential approach for recycling cathode materials. Future work will be to expand the ability to use froth flotation to recycle additional cathode materials. Lipson says, “We also will be scaling-up froth flotation to determine if kilogram quantities of cathode materials can be recycled from end-of-life batteries efficiently.”

Additional information can be found in a recent article

1 or by contacting Argonne National Laboratory at

media@anl.gov.

REFERENCE

1.

Folayan, T., Lipson, A., Durham, J., Pinegar, H., Liu, D. and Pan, L. (2021), “Direct recycling of blended cathode materials by froth flotation,”

Energy Technology, 9. Available

here.