KEY CONCEPTS

•

Lower carbon footprint is key to sustainability.

•

Several base oils are available to assist with developing sustainable finished lubricants.

•

Sustainable lubricants are yet to be globally defined and standardized.

The need to act on climate issues has never been more urgent. Industry-induced warming is only increasing, and over the past half century, the transportation sector has contributed faster to emissions growth than any other, suggesting an urgent need for deep decarbonization.

Original equipment manufacturers (OEMs) within the sector have started working toward ensuring that all new vehicles be zero emission by 2050—some OEMs even committed to selling only zero-emission vehicles by 2035 or earlier. In interim, OEMs are working on a mix of bridge powertrain technologies with energy diversity leading to carbon neutral operation using renewable low carbon fuels, hybrids, battery electric vehicles, fuel cell electric vehicles, hydrogen internal combustion engines (ICEs), natural gas ICEs, etc.

Although fuels used in the transportation sector contribute to the majority of the carbon footprint, lubricants can enable lowering the fuel consumption. Therefore, lubricant manufacturers are reviewing high-performance climate friendly options for their raw materials starting with base oils.

What is a sustainable lubricant?

Sustainable development is the overarching paradigm of the United Nations (UN). The concept of sustainable development was described by the 1987 Brundtland Commission Report as “development that meets the needs of the present without compromising the ability of future generations to meet their own needs.”

1

There are several extents to sustainable development—society, environment, culture and economy—they all are interconnected. Sustainability is a paradigm for thinking about the future in which environmental, societal and economic considerations are balanced in the pursuit of an improved quality of life. For example, a prosperous society relies on a healthy environment to provide food and resources, safe drinking water and clean air for its citizens.

1

The UN explains the difference between sustainable development and sustainability as follows: “Sustainability is often thought of as a long-term goal (i.e., a more sustainable world), while sustainable development refers to the many processes and pathways to achieve it (e.g., sustainable agriculture and forestry, sustainable production and consumption, good government, research and technology transfer, education and training, etc.).”

1

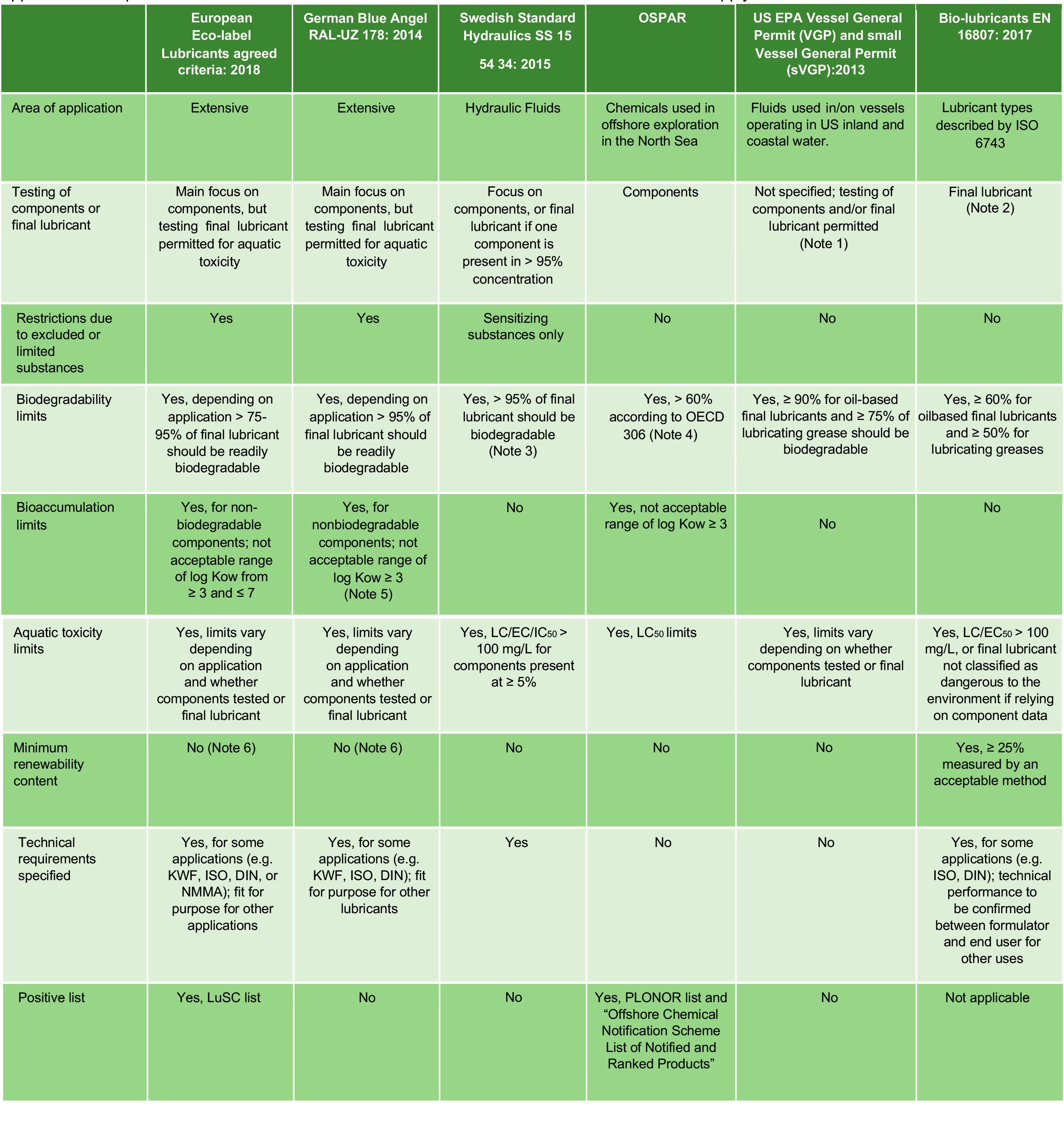

However, when it comes to defining sustainable lubricants, there is no one simple global definition or standard—moreover, many times the words

bio, sustainable and

renewable are used interchangeably—even though they have different and sometimes interconnecting meanings. To add to the confusion, a lubricant can be described as “biodegradable” without qualifying as a “biolubricant.” Table 1, developed by the Technical Committee of Petroleum Additive Manufacturers in Europe (ATC), compares different requirements of several common environmental standards, labeling schemes and specifications applicable to lubricants that have a favorable environmental profile.

2

Note 1 – Lubricants that qualify for EU Ecolabel, Blue Angel, Convention for the Protection of the Marine Environment of the North-East Atlantic (OSPAR), Nordic Swan, Swedish Standards (SS 155434 (Hydraulic) and 155470 (Grease, not considered here) or EPA Design for Environment automatically satisfy VGP criteria for an Environmentally Acceptable Lubricant (note that Nordic Swan for Lubricants no longer exists)

Note 1 – Lubricants that qualify for EU Ecolabel, Blue Angel, Convention for the Protection of the Marine Environment of the North-East Atlantic (OSPAR), Nordic Swan, Swedish Standards (SS 155434 (Hydraulic) and 155470 (Grease, not considered here) or EPA Design for Environment automatically satisfy VGP criteria for an Environmentally Acceptable Lubricant (note that Nordic Swan for Lubricants no longer exists)

Note 2 – Testing final lubricant for aquatic toxicity is not required where adequate data at 3 trophic levels is available for all intentionally-added components present ≥ 0.1%

Note 3 – Test method and criterion (i.e. > 60% or > 70%) depends on water solubility (≤ 100 mg/L or > 100 mg/L) of component or final lubricant at 20°C

Note 4 – Components that biodegrade < 60% are permitted for use offshore depending on outcome of risk assessment by operator. Products containing components that biodegrade < 20% have a substitution warning assigned. Other biodegradation methods are accepted but a correction factor is usually applied

Note 5 – Derogation for components with log Kow > 6 if no alternative is possible, and can be justified

Note 6 – The use of the term ‘bio’ (e.g. bio-based lubricant or bio-lubricant) is only permitted where the final lubricant contains at least 25% measured renewable content

Table 1. Comparison of criteria for environmental standards relevant to the finished lubricants supply chain.2

Nevertheless, even without industrywide consensus on sustainable lubricants, several options of sustainable base oils already exist that can meet sustainability or other “green” requirements as we understand it presently. They can already replace some conventional petroleum base oils without compromising our planet’s sustainable future.

Innovative molecule

Dr. Matt Kriech, chief operating officer, Biosynthetic Technologies, sheds some light on sustainability of base oils. He says, “Like all things, base oils have a spectrum of sustainability. For example, take Group III base stock that is just produced in a refinery. How sustainable is that molecule? In terms of utilization, it is more sustainable than a Group I or Group II due to better performance (e.g., better fuel economy for engines) or longer life (e.g., better drain intervals in engines)? However, compare that same Group III to one that has been sourced from re-refined oil, and then the re-refined Group III is more sustainable because it was produced from a recycled stream. The gold standard of a sustainable base oil would be one derived from oleochemistry that can be manufactured utilizing renewable energy like wind, solar and biomass, that has exceptional environmental performance (low toxicity, high biodegradability, low bioaccumulation), performs well as a lubricant and can be recycled or completely biodegrades in the environment.” William Downey, senior vice president, business development, Novvi LLC, concurs: “Indeed oleochemicals, derived from plant oils, can be manufactured with renewable energy, can have exceptional environmental and lubricant performance and can be completely recycled and biodegradable. However, oleochemistry can be used to make hydrocarbons as well.”

Dr. Mika Kettunen, technical product manager, base oils, Neste Corp., adds that another emerging new technology in addition to estolides is making isoparaffins by a carbon-carbon bond forming technology. He says, “The top benefit is the drop-in nature of the molecule to replace fossil-based Group III+ and polyalphaolefin (PAO) applications like in top-tier engine oils.” Kettunen continues: “When the molecular structure is different from crude oil or ethylene-derived base oils, there can surely be differences in performance, compatibility in present applications as well as additive technologies. Therefore, I feel that developing drop-in solutions can speed up a ramp up of novel sustainable base oils based on renewable raw materials.” Adding on Kettunen’s “drop-in” solutions point, Downey says, “Emphasis on ‘drop-in’ solutions is important. Most lubricant base oils making a sustainability claim cannot make that drop-in claim. Now it is hard to make ‘drop-in’ part of the sustainable definition, but ‘drop-in’ greatly aids the adoption of sustainable technologies. If a technology requires a different additive system, is not miscible with other base oils, needs to be segregated to be recycled or had inferior hydrolytic or oxidative stability, it really cannot be considered ‘drop-in’ and, therefore, even if sustainable, is hard for the industry to adopt.”

Kriech states that for a molecule to perfectly fit sustainable objectives, it has to be those that can be sourced, manufactured, utilized and disposed/recycled in a sustainable manner. When Kriech works on sustainable products, he considers factors such a sourcing, i.e., what the raw materials are derived from. Is it petro or oleo based? How is the material harvested? What are the environmental and socio-economic impacts from the sourced material? He adds that from a manufactured standpoint, it also is critical to look at the amount of energy and processing required to produce the material. How integrated and how far does the product have to travel to be produced? Are there harmful byproduct steams that have to be disposed of ? And from a utilization standpoint, it is important to look into environmental and finished product performance. Kriech reviews material to work with from the impact of the molecule in the environment if it is biodegradable, bioaccumulate or has toxicity concerns. Furthermore, he notes the life expectancy of the product, how it breaks down rapidly in the equipment or whether it will give extended finished product life. Other factors Kriech evaluates are efficiency, whether it helps equipment run better and if it is capable of saving cost of energy. He states the final factor to consider is if and how the material is recycled and its biodegradability. In summary, Kriech states, “Sustainability is really about the ability to maintain or meet current needs without impacting the ability to meet future needs.”

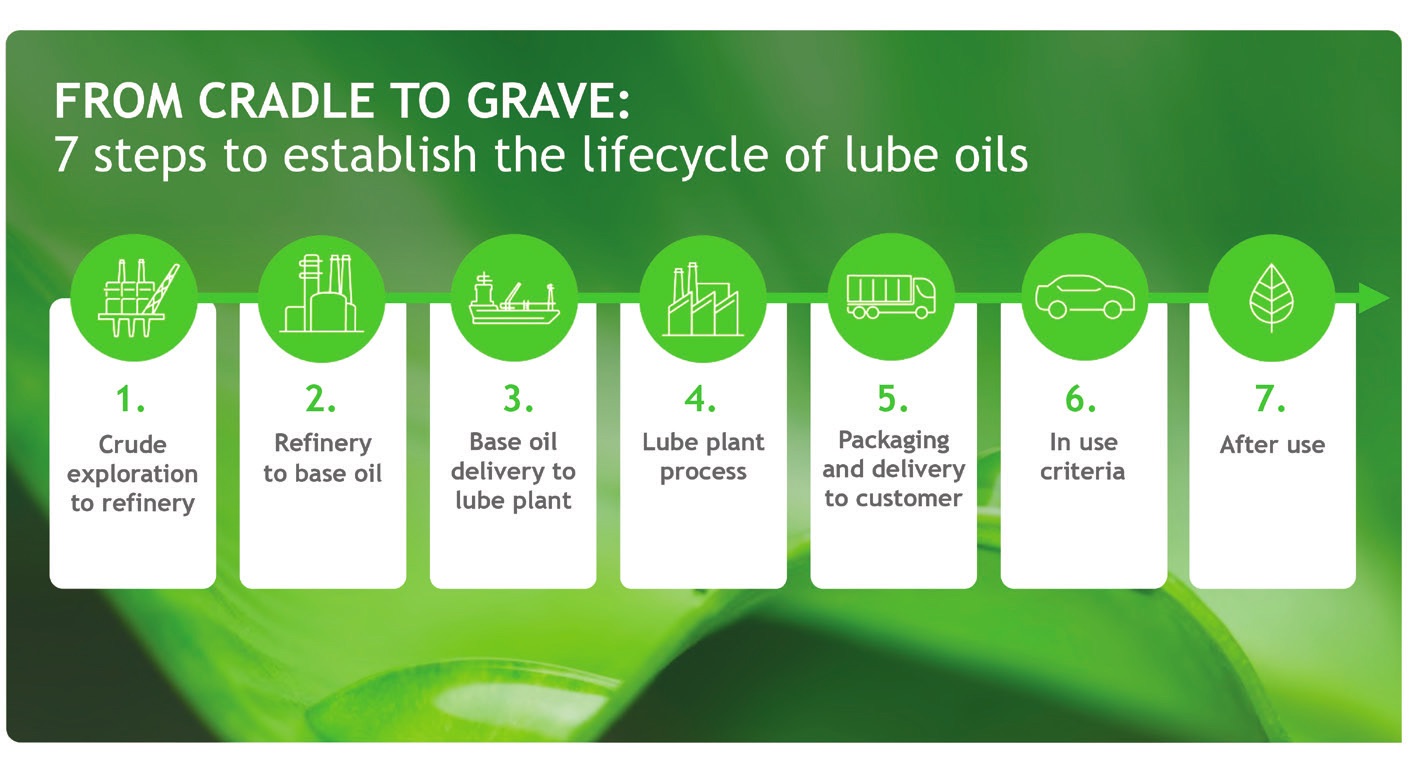

Kettunen adds that the main impact on product carbon footprint comes from the use of biogenic carbon that the plants take from atmosphere by photosynthesis compared to using fossil carbon-based base oils. However, it is important to remember, he says, that as lubricants are made to lower friction and energy consumption, the better energy efficiency they bring in the use phase, the better is the overall impact on greenhouse gas (GHG) emissions. Energy savings of a higher quality lubricant can often be much higher than its own carbon footprint, but it always depends on the reference it is compared with case by case. “At the moment, the lubricants industry is getting organized in many industry bodies in order to get aligned on common methodology to conduct Life Cycle Assessment (LCA) comparably across the industry,” Kettunen says. Seven steps to establish the life cycle of lube oils are shown in Figure 1.

Figure 1. Seven steps to establish the life cycle of lube oils.3

Figure 1. Seven steps to establish the life cycle of lube oils.3

Various performance attributes of sustainable base oils depend primarily on the type of base oil. Kriech states, “Natural oils or natural esters offer good lubricity, excellent viscosity index and good environmental and sustainable aspects. However, natural oils oxidize and hydrolyze rapidly and, therefore, have a short useful life in industrial applications. Synthetic esters offer superior oxidative and hydrolytic stability as compared to natural oils while maintaining excellent lubricity, viscosity index and other attributes.” He continues: “Many synthetic esters, though, are weak when it comes to hydrolytic stability breaking down when exposed to water and heat. Fully saturated synthetic esters offer superior performance as compared to partially saturated synthetic esters. Secondary esters, like estolides, offer both excellent oxidative stability and good hydrolytic stability.” According to Kriech, all sustainable base oils can be suit to purpose, depending on formulations and application of the finished product.

Kriech states that depending on a type of base oil,

environmental fate also can be different. “Best-case scenario is the material rapidly biodegrades (readily or ultimately biodegradable classification), is not toxic and non-bioaccumulate before it biodegrades. The worst-case scenario would be the complete opposite,” he says. “Base oils fall on a spectrum depending on the type of chemistry. “Esters and estolides made from natural oils tend to have excellent environmental sustainability,” Kriech adds.

Downey notes that Kriech’s three environmental fate standards—biodegradable, non-toxic and non-bioaccumulative—are central to the European Union (EU) Ecolabel standard, an important measure of a lubricant’s sustainability. “Additionally, hydrocarbons, innovative sustainable synthetic base oils, also are available for the industry to consider, which meet those three important standards. This technology delivers volatility, oxidation and low-temperature performance similar to or better than PAOs, are carbon negative cradle to gate and still meet Ecolabel standards,” continues Downey.

Part of the solution when looking from cradle to grave is an understanding of the elements that generate reduced CO

2 emission benefits. Downey says, “For example, let’s take a look at a standard 0W-20 GF-6 passenger car motor oil (PCMO) tested over 100,000 miles made with carbon negative, PAO-like base oil versus a Group III. First, a carbon negative base oil allows a carbon neutral finished product composition, therefore achieving CO

2 reductions from the base oil itself making it more sustainable. By ensuring usage of not only carbon negative but, importantly, a high-performance base oil, that helps lower fuel consumption, which will result in lower emissions. Secondly, when looking at CO

2 reduction potential, we should analyze initial fuel economy as well as retained fuel economy, as superior retained fuel economy is another route to achieve the highest possible level of CO

2e savings.” The key here is to ensure we start with the strong foundation—an already carbon negative, high-performance base oil.

Re-refined base oils

While product-orientated LCAs start at the beginning of a product’s life cycle (cradle to grave), a typical LCA in waste management is quite different and starts at the end of a product’s life cycle (gate-to-grave system boundary). Therefore, another path to produce sustainable lubricants is through re-refined base oils. With improved technologies, used oils are widely available as a renewable resource. By continuing to reduce GHG emissions from the manufacturing side, while implementing innovation, utilizing most advanced technical expertise, Matthew Munz, vice president of base oil sales, Heritage-Crystal Clean, LLC, believes that re-refined base oils become one of the sustainable base oils in the market. Today, by re-refining the oil, a molecule can be re-used multiple times. “Oil re-refining is an environmentally responsible way to manage used oil encouraged by the EPA for its sustainability benefits, such as reducing pollution and conserving energy,” Munz says.

‘Biodegradable lubricants can be approved by leading manufacturers for use in applications such as agriculture, forestry, inland waterways and those that have a potential oil-to-sea interface.’

‘Biodegradable lubricants can be approved by leading manufacturers for use in applications such as agriculture, forestry, inland waterways and those that have a potential oil-to-sea interface.’

The process of re-refining used oil to return it to a usable paraffinic base oil can be briefly described as follows: Through a vacuum distillation process, water and other containments are removed creating three basic products: light fuel, which is sold back into the market, asphalt, which also is sold back into the market place, and vacuum gas oil (VGO), which is sent to the hydrotreater for further processing. Once the VGO goes into the hydrotreating process, it is treated in a hydrogen rich environment under high pressure and temperatures. This process removes additional contaminants such as nitrogen, sulfur and other metals from the VGO producing the high-quality paraffinic base oils. These high quality mostly Group II base oils can then be returned to the market into many applications such as PCMOs, heavy-duty engine oils (HDEOs), industrial oils, agricultural products, form oils, manufacturing of viscosity index improvers and many other industries.

Munz states that with advancements in technology and improved feedstocks, re-refined oils are no longer looked upon as lower quality base oils. “Most re-refined base oils have full approvals for PCMOs and HDEOs, which meet and exceed industry standards,” he continues. Munz says, “The rise in Group IIIs and improved quality of motor oils, in general, creates a better feedstock for re-refiners, therefore a higher quality base oil to provide back to our customers.” Per Munz, there are many other benefits to re-refined oil for the environment:

•

Properly disposed and collected used motor oil keeps the oil from polluting ground water and drinking water sources. It reduces emissions by not being burned as fuel.

•

Motor oil doesn’t lose its properties—it just gets dirty or “used,” so re-refining saves a valuable energy resource.

•

Less energy is used to produce re-refined oil as compared to making base oils from crude.

•

Re-refining can slow the future exploration of untouched habitats protecting the environment from future harm, which also relates to sustainability.

•

As more and more applications use re-refined oil, it encourages technological advances.

•

A single gallon of used motor oil can create the same 2.5 quarts of lubricating oil as 42 gallons of crude oil.

High-perfomance base oils

Major global oil producers have placed sustainability at the top of their priority list. According to STLE Past President Dr. Selda Gunsel, president, Shell Global Solutions U.S., vice president, Global Lubricants and Fuels Technology, Shell, “Sustainability is absolutely a key part of activity from the materials we use and processes we develop and implement, right to the impact we can have on helping our customer’s sustainability journeys.”

Gunsel further explains that she considers the CO

2 emissions from the complete life cycle of products from cradle to grave, which includes raw materials, manufacturing, in-use and end-of-life emissions: “Examples of reducing the CO

2 footprint include the use of re-refined base oils, biobased oils and increasing efficiency in our own plants, such as using green electricity.” In addition, another example is selection of sustainable packaging solutions, including the use of recycled content in bottles, where possible. “To do all of this, we are making sustainability and carbon calculations a normal part of the way in which we work,” adds Dr. Gunsel.

Gunsel states that it is important for a manufacturer to offer biodegradable oils. “Biodegradable lubricants are mainly combinations of selected biosourced bases (e.g., vegetable, rapeseed and sunflower oils), which are non-toxic and have special additives, which give them their desired properties,” she says. “Biodegradable lubricants can be approved by leading manufacturers for use in applications such as agriculture, forestry, inland waterways and those that have a potential oil-to-sea interface. Although such environmentally acceptable lubricants (EALs) comprise only a small percentage of the total lubricant industry, their use is expected to increase.”

Downey agrees with Gunsel’s assessment of the growth potential for EALs as well as her view that CO

2 emissions from the complete life cycle need to be considered. “Indeed, it is important to start with the carbon footprint of the product itself. Raw materials of the lubricant are the one area that a lubricant manufacturer and marketer can control directly. Starting with a base oil that is carbon negative, and then building a lubricant with excellent oxidation stability, fuel economy and perhaps most important, great retained fuel economy, is the best way to avoid and reduce CO

2 emissions across the life of the lubricant,” says Downey.

Describing gas-to-liquid (GTL) base oils, Gunsel says that they offer opportunities for sustainability, as they enable the development of lubricants that enhance fuel economy/energy efficiency, can extend service life and help increase equipment life. Specifically, according to Gunsel, GTL base oils exhibit considerably superior performance compared to most hydrocarbon base oils, including low-temperature viscosity, low volatility and high oxidative stability, making them suitable for wide range of premium lubricants and greases as well as specialty applications. “One clear example is that GTL base oils enable blending of top-tier low viscosity, energy efficient engine oils, e-transmissions and industrial lubes, which result in significant avoided CO

2 emissions for customers during the service life of the lubricants,” says Gunsel.

There are always some trade-offs, including when it comes to sustainability. Gunsel says, “As the world’s needs for mobility, construction and industrial production increase, so too will the demand for lubricants. There is a need to balance this increase in demand with the environmental impact of lubricants. Customers and consumers expect lubricant marketers to offer sustainable products and services and make it easier for them to make sustainable choices. Motorists and OEMs want both greater fuel economy and lower-carbon alternatives for their current and future mobility needs, while industrial customers want to extend the life of their machinery while reducing their overall net carbon footprint. Therefore, product performance and cost act as table stakes, which need to be balanced with carbon footprints and the investment needed to design lower carbon sustainable alternatives.”

Lower carbon alternatives are now available. Lubricant marketers can now offer customers options of more sustainable products with the highest performance. And as further noted by Downey, “When considering sustainable base oils that deliver all key performance features, biodegradability of these oils should not be overlooked, as it is important to consider products with 100% renewable carbon content and a negative carbon footprint. This gives lubricant marketers a lower carbon alternative and a reduced net carbon footprint.”

Next steps

Indeed, the lubricants industry needs to accelerate sustainable lubricants manufacturing while using sustainable base oils. There are numerous approaches that exist, as seen previously. However, aside from the great benefits of each base oil, there are a few limitations to which a finished lubricants producer should study in detail, for example:

•

limited global availability

•

performance limitations

•

molecule size challenges

•

biodegradability

•

a need of a combination of credits generated from nature-based solutions to naturalize the GHG emissions.

Above all, lubricants producers should not overlook that not only base oils, but lubricants additives too, have a large effect on the sustainability of the products, especially for the automotive industry with relatively high additive treat rates that impact finished product’s sustainability.

Nevertheless, with the industry moving toward lower and lower viscosity base oils and newer applications, which call for exclusive performance characteristics, a strategic focus on developing new solutions is vital to a lower carbon footprint, which is the key to sustainability and ultimately our future. The next step is to agree on what a sustainable lubricant is, and measure its sustainability, but that is a challenge of its own.

REFERENCES

1.

UNESCO. (2021), “Sustainable development.” Available

here.

2.

Technical Committee of Petroleum Additive Manufacturers in Europe (ATC) AISBL. (2018), “Different approaches to biolubricants.” Available

here.

3.

Kettunen, M. (2019),

“Sustainability: What does it mean for base oils and finished lubricants?” The 23rd ICIS World Base Oils & Lubricants Conference.

Dr. Yulia Sosa is a freelance writer based in Peachtree City, Ga. You can contact her at dr.yulia.sosa@gmail.com.