TLT: How did you learn about tribology?

Nakano: The trigger for tribology was a “strange feeling” I had about the friction taught in high school physics. I learned the so-called law of friction, but I felt that it was somehow different from the other phenomena that appeared in physics.

After going on to the university with keeping the strange feeling in my mind, I had, by chance, an opportunity to listen to a famous tribologist: professor Yoshitsugu Kimura of the University of Tokyo. In his lecture, I first learned about tribology—it was 1991. The following year, I started to study tribology under his supervision and obtained my doctorate five years later. Since then, I have been studying tribology as a university researcher.

TLT: You’ve been involved in tribology research for 30 years. What is appealing to you about the field?

Nakano: Somewhat unbelievable, but you are right. Friction is a common physical phenomenon that occurs everywhere in our daily lives. It seems to be easy to understand, but in reality, it is not. To me, the gap between its appearance and essence is the biggest attraction.

There are various reasons for producing the gap. Even on an apparently rigid surface, it is not rigid, showing elasticity, plasticity and so on. Even on an apparently smooth surface, it is not smooth, having irregularities of various scales. Even on an apparently physical phenomenon, abnormal chemical reactions often occur. How many examples of “apparent” like these do we have in tribology? To quote the famous Wolfgang E. Pauli’s words, friction may be a “devilish” phenomenon.

However, because of such a chaotic situation, various researchers with various backgrounds gather in tribology. Each researcher, based on his or her belief, is confronting inherent imperfections included in friction. Even if the subject is the same, each researcher is looking at each landscape. I can learn a lot from discussions with researchers who have a completely different perspective from myself. In addition to the diversity of phenomena, I think that researchers’ diversity also is an attraction of tribology.

TLT: What is your belief in research?

Nakano: The driving force of my research is always the desire to understand phenomena. Regarding friction, eliminating the strange feeling over 30 years is nothing but my strongest driving force. However, what sort of status allows us to say we understand it? Or, at least, what sort of status makes us feel we understand it? The definition of understanding itself is the vital problem that determines the belief in research.

In my case, the most important thing is to be “simple.” I am believing that a simple picture drawn after deep thinking should be beautiful. In Antoine de Saint-Exupéry’s memoir “Wind, Sand and Stars (French title: Terre des Hommes),” there is a wonderful passage: “...

perfection is finally attained not when there is no longer anything to add, but when there is no longer anything to take away...” This is exactly my belief in research.

TLT: What is your most focused research right now?

Nakano: It is the transition between two types of friction. In the early stage of lectures on mechanics, we teach students two types of friction: static and kinetic friction. For example, by showing them a book placed on an inclined table, we explain the transition from “stick” to “slip” states. A steep slope we encounter on hiking also is a good example. To ensure our safety, we unconsciously try to find static friction (

see Figure 1).

Figure 1. On a steep slope of Kamakura in 2016, Nakano (left) and Popov (right) were trying to find static friction without knowing that they would, four years later, publish a paper indicating that static friction might be an illusion.

Figure 1. On a steep slope of Kamakura in 2016, Nakano (left) and Popov (right) were trying to find static friction without knowing that they would, four years later, publish a paper indicating that static friction might be an illusion.

However, according to my latest study with professor Popov, static friction is not always necessary to describe a stick state: As a matter of fact, kinetic friction is sufficient.

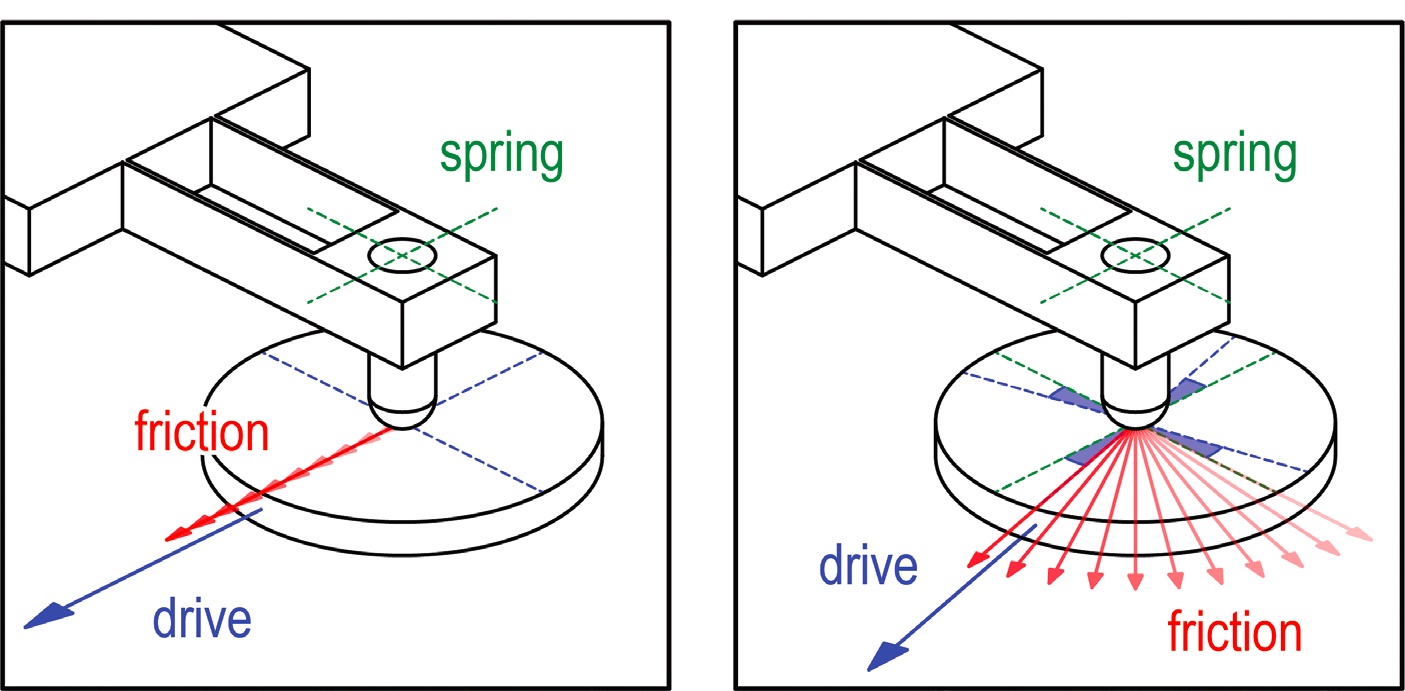

1 The key to solving this puzzle lies in the in-plane misalignment that can be recognized when a sliding system is viewed from above. It considers an inevitable non-zero angle between the “drive” direction and the “spring” direction (

see Figure 2).

conventional stiction and dynamic stiction

Figure 2. In conventional stiction (left), the magnitude of static friction changes. In dynamic stiction (right), the direction of kinetic friction changes. The blue angle is the in-plane misalignment.

TLT: How is it different from the conventional stiction?

Figure 2. In conventional stiction (left), the magnitude of static friction changes. In dynamic stiction (right), the direction of kinetic friction changes. The blue angle is the in-plane misalignment.

TLT: How is it different from the conventional stiction?

Nakano: In the conventional stiction, it is supposed to be static friction that produces a stick state. It has been believed that its magnitude changes, according to the external force. Meanwhile, in the different type of stiction, called dynamic stiction, it is kinetic friction that produces a stick state. It has been found that its direction changes, creating an apparent stick state that accompanies an extremely slow slip.

Please note that this friction vector rotation occurs autonomously as a purely mechanical response in sliding systems with in-plane misalignment. In dynamic stiction theory, discontinuous stick-to-slip transitions are described by continuous governing equations. Meaning, static friction might be an illusion made by the rotation of kinetic friction. I am trying to validate the theory by experiment.

TLT: It sounds counterintuitive but interesting. Do you think it works for tribotechnology?

Nakano: Yes. For example, it is expected to provide engineers various ideas to avoid stick-slip and achieve smooth motion of machines. For example, another collaborator, professor Chiharu Tadokoro of Saitama University, is dedicated to its applications.

2 This anti-vibration technique utilizes that the friction vector rotation provides virtual damping to tribosystems. Also, as our surroundings are full of static friction, we can find other various applications.

TLT: What other research are you working on?

Nakano: For the past five years, I had been involved in studies on concentrated polymer brushes in a national project led by professor Yoshinobu Tsujii of Kyoto University. Concentrated polymer brushes are unique materials that provide ultra-low friction under a wide range of operating conditions due to their low-adhesive properties and flexible structures. From fundamental sciences to application technologies, various studies have been carried out in cooperation with universities and companies in Japan. Although the project officially ended in March 2020, these studies are still being continued in the firm human network. One of the derivative projects is developing the virus inactivation coating technology, given the recent worldwide COVID-19 pandemic.

As a field exploring our lives, I am studying the pulsation and synchronization of cardiac cells with professor Mitsuru Akashi of Osaka University. As a matter of fact, just observing the cells is enough to inspire my curiosity because, although they are so tiny, they are certainly self-beating! The knowledge and technique of contact mechanics cultivated in tribology are helping me find beautiful order hidden in mysterious life phenomena.

3

Also, as a field exploring our deep psychology, I have studied tactile sensation for over a decade. It was my great pleasure that the December 2009 TLT introduced my cosmetics study in the Cutting Edge article. Since then, through collaborations with cosmetics companies, I have tried to describe emotional sensations using objective terms in tribology. For example, an interesting open question is: What is the silky feeling? We can feel it, but we cannot explain it. I believe it is a problem that should be solved by tribology.

TLT: I see. You must enjoy the diversity of tribology?

Nakano: Exactly. All thanks to my great collaborators with different perspectives. Also, thanks to this unique field: tribology.

TLT: Finally, what do you think about the future of tribology?

Nakano: I hope tribology will continue to be an attractive field. I believe the appeal of tribology, as an interdisciplinary field, lies in its flexibility and expansivity. I am sure that tribology should deepen as an independent field, but that does not mean building an exclusive wall surrounding it. It would be important to accept a white canvas in front of eyes and respect various perspectives.

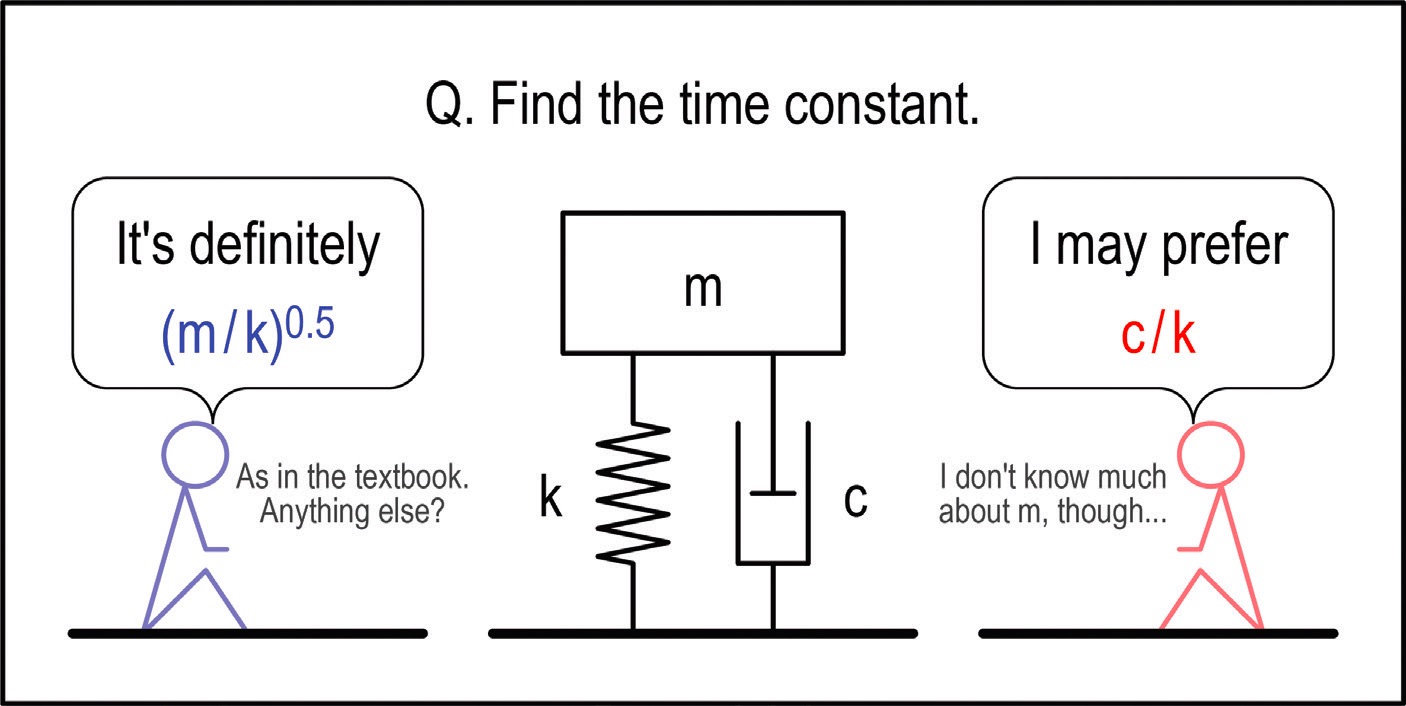

I have been an STLE member for more than 10 years and a JAST member for about 30 years. I am very pleased to know that, thanks to current JAST President and STLE Fellow Joichi Sugimura and others’ efforts, the official partnership between the two societies has been launched. I think what is important for the future of tribology is not competitions but fusions (

see Figure 3). I strongly hope that the culture of JAST in the Far East will be mixed with the culture of STLE, exploring new landscapes for tribology together.

Figure 3. A mechanical engineer (left) meets a materials engineer (right). To be sure, both answers are correct. This situation may be the beginning of a fusion.

REFERENCES

Figure 3. A mechanical engineer (left) meets a materials engineer (right). To be sure, both answers are correct. This situation may be the beginning of a fusion.

REFERENCES

1.

Nakano, K. and Popov, V. L. (2020), “Dynamic stiction without static friction: The role of friction vector rotation,”

Physical review. E, 102, 063001, click

here.

2.

Tadokoro, C., Aso, Y., Nagamine, T. and Nakano, K. (2021), “Anti-vibration and traction control of rotary sliding systems by orthogonal rotation providing transverse sliding,”

Tribology International,

159, 106992, click

here.

3.

Nakano, K., Nanri, N., Tsukamoto, Y. and Akashi, M. (2021), “Mechanical activities of self-beating cardiomyocyte aggregates under mechanical compression,”

Scientific Reports, in press, click

here.