The Lubrizol Corp.

Not all Industrial Gear oils are Formulated the Same

By Seth Crawley, Technology Manager | TLT CMF Plus November 2018

A next generation Industrial Gear oil with enhanced bearing and micropitting performance

© Can Stock Photo / maxuser

© Can Stock Photo / maxuser

Many of today’s industrial processes involve a gearbox as a critical element of a linear production line. This means that a single part failure in this gearbox can result in a number of costly scenarios, such as total shutdown of production, lost output or revenue, cancelled contracts and additional servicing costs. Furthermore, malfunctioning equipment can be a potential health and safety issue. In order to help prevent these scenarios from happening, a properly balanced industrial gear lubricant and a regular maintenance program are necessary to prevent the economic losses resulting from unplanned downtime.

It is common for industrial gear oil marketers to focus on delivering robust gear teeth protection. However, it is important to note that close to 49% of gearbox failures are due to bearing failures—consequently strong bearing protection must also be considered in the development of a robust industrial gear lubricant. Engineering trends are also influencing the possible conditions under which industrial gear systems can operate. These trends, and ultimately the conditions under which gearboxes operate, are also dictating the additional properties that effective industrial gear lubricants must possess.

For example, industrial gear systems are getting smaller, translating to smaller oil sumps with less lubricant to provide the essential system protection and cooling. Gear manufacturers are also using new gear surface finishing methods such as superfinishing and are focused on enabling higher loads for gear teeth and bearings, resulting in higher gearbox temperatures. This requires modern industrial gear oils to possess robust fatigue resistance, be balanced to provide reliable bearing protection and be capable of operating in many varied environments, where they must readily separate water, collapse foam and provide oxidative and thermal stability.

Industrial gear oil specifications have evolved over the years to include more stringent bench and mechanical testing to assess an oil’s ability to provide robust gear and bearing protection, perform satisfactorily under a variety of harsh conditions and be compatible with ancillary system componentry such as paints, seals and adhesives. Historically, specifications focused on corrosion, oxidation, EP tests such as FZG scuffing, and water tolerance. In the early 2000s, gearbox OEM specifications started to introduce FE-8 bearing, FVA-54 micropitting as well as system component compatibility tests. Continued evolution of specifications has led to more rigorous evaluations of industrial gear oils, such as micropitting tests under varied temperatures and bearing tests under even more extreme conditions like the Schaeffler Step 1-4 FE-8 bearing tests.

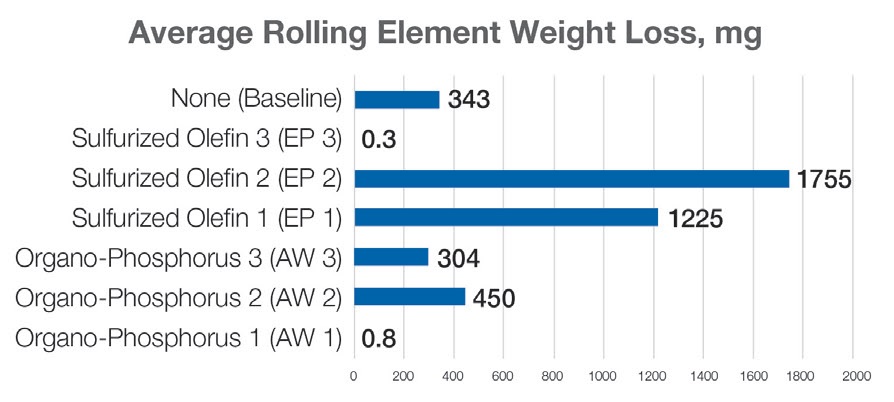

In order to formulate industrial gear oils capable of meeting these stringent requirements, formulators must consider a number of factors. Industrial gear oils are formulated using a variety of components, many of which are surface active and can potentially compete amongst themselves as they seek to bind to metal surfaces. Antiwear and extreme pressure additives often comprise the majority of industrial gear oil formulations and, to ensure proper bearing and gear protection, a proper balance must be struck between these components if all performance parameters are to be met. To demonstrate the importance of the requisite balance, a variety of sulfurized olefins and organophos antiwear were evaluated in the FE-8 bearing test as single components in base oil to get a better sense of their influence on bearing performance (

see Figure 1). The test oils were all run in ISO VG 68 for greater severity. The graph represents the MW

50 of the rolling element weight loss, or 50% of the bearings run will lose that much weight or less.

Figure 1. FE-8 Rolling element weight loss of single components

Figure 1. FE-8 Rolling element weight loss of single components

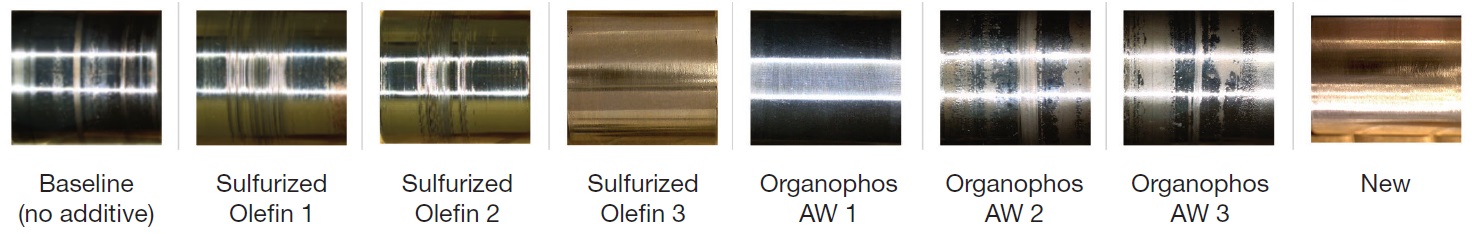

To start, a baseline was run with no additive, displaying some pitting and scuffing. It could be concluded that, when used as solitary components, sulfurized olefins are harmful to bearing performance with the exception of sulfurized olefin 3 (vegetable oil), but it is known that this offers insufficient scuffing protection for gears (

see Table 1).

Table 1. FE-8 parts for single components.

Table 1. FE-8 parts for single components.

In contrast, certain organophosphorus antiwear components can be highly beneficial to FE-8 performance especially organophosphorus AW 1, while others offer little or no protective capability. The key takeaway is that individual chemical components can register highly positive or highly negative responses in FE-8 testing.

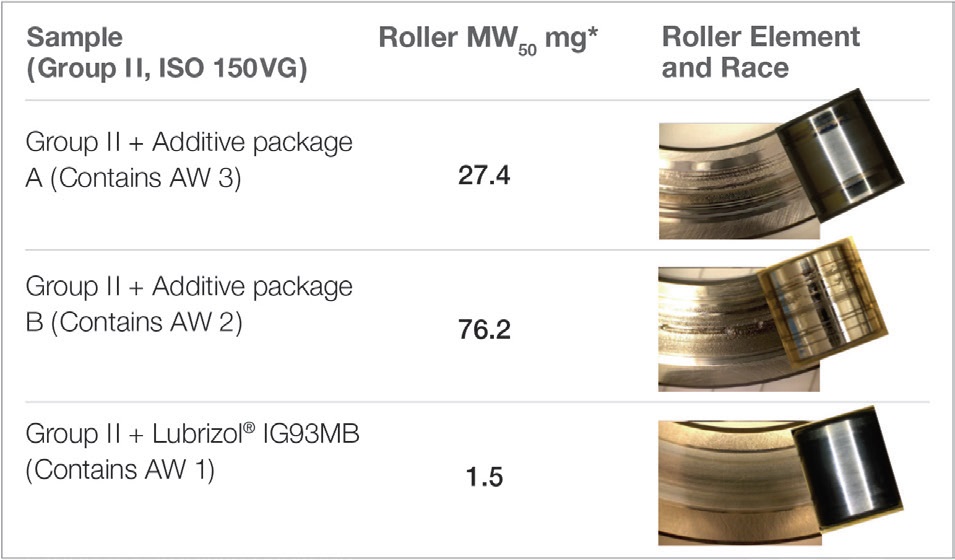

The next investigation conducted was to confirm if organophosphorus 1 (AW 1) could attenuate sulfurized olefin performance in the FE-8 bearing test in a fully formulated additive package while still delivering a proper balance with gear performance. To answer that question, complete additive packages in industrial gear oil formulations were evaluated in the FE-8 test after first confirming that they each delivered effective FZG gear scuffing protection, meaning FLS > 12 was obtained. In this case, three additive packages in a group II ISO VG 150 base oil, all containing the same componentry except for the organophosphorus antiwear component, were tested. Group II base oil was chosen because it offers a good chance for surface active chemistry forming an effective tribofilm on metal surfaces.

Each formulation with varying organophosphorus antiwear was evaluated in the FE8 bearing test (as a reminder, AW 1 was the top performer in the FE-8 test as a single component).

As demonstrated in

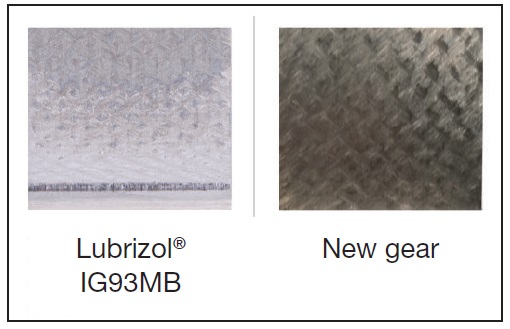

Table 2, a new product, Lubrizol® IG93MB, which contains organophosphorus AW1 is again the top performer in the FE-8 bearing test. However, additive package A, which is the formulation with AW 3, just barely meets the limits for the DIN51819-3 specification of 30mg roller bearing weight loss. While the numbers may not necessarily imply a clear difference between formulation A and Lubrizol IG93MB, the visual appearance of the parts help to reinforce that this is only one snapshot of additive A’s performance. In order to guarantee robust performance and broad base oil coverage, clearly Lubrizol IG93MB is the top performer.

Table 2. FE-8 performance of IGO candidates with different organophos AW.

Table 2. FE-8 performance of IGO candidates with different organophos AW.

Collectively, these results reinforce that a properly balanced industrial gear oil can deliver robust gearbox protection by ensuring both solid bearing performance and gear protection.

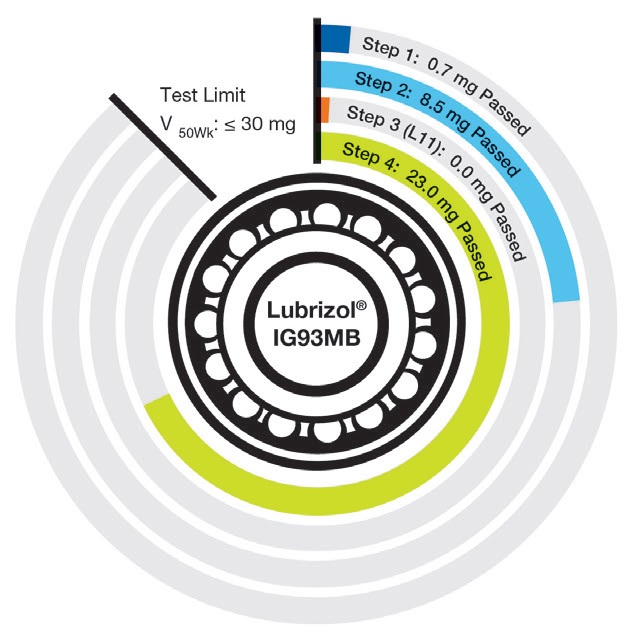

As mentioned earlier, step 1-4 FE8 bearing tests are now being used to assess bearing protection under a variety of speeds, loads, durations and with different bearing types. These tests were originally used in wind turbine specifications to assess bearing performance under a variety of conditions but are now being included in more mineral based industrial gearbox OEM specifications. Lubrizol IG93MB has been evaluated in a group I base oil under these Step 1-4 conditions and has demonstrated robust passing performance in all of these tests (

see Figure 2).

Figure 2. Step 1-4 FE8 bearing performance of Lubrizol IG93MB in group I base oil.

Figure 2. Step 1-4 FE8 bearing performance of Lubrizol IG93MB in group I base oil.

Previously, it was demonstrated that balancing extreme pressure and antiwear components is critical to provide effective bearing protection. However, balancing of all components in industrial gear oils is required for overall gearbox protection.

As stated above, industrial gear oil testing has evolved to include both FZG scuffing and FVA-54 micropitting evaluations. To demonstrate the superior gear protection of Lubrizol IG93MB under standard FZG scuffing conditions, rather than stopping the test at the standard FLS 12, our testing was extended to the mechanical limit of the equipment (FLS > 14).

Table 3 shows the exceptional scuffing protection which ensured only minimal damage even under these most extreme test conditions.

Table 3. Gear teeth from FZG.

Table 3. Gear teeth from FZG.

We have shown that strong FZG gear scuffing results do not guarantee robust bearing protection and that robust bearing protection does not guarantee gear scuffing performance. However, there is yet another parameter critical for modern industrial gearbox protection: micropitting resistance. This fatigue phenomenon is important because it can eventually lead to noise, vibration and sometimes macropitting with subsequent failure of the gear tooth. Furthermore, micropitting-related field issues are reported to be increasing, meaning that micropitting can also result in costly downtime for industrial processes. Again, there is a very delicate balance required to design a robust industrial gear oil able to deliver robust all-around performance.

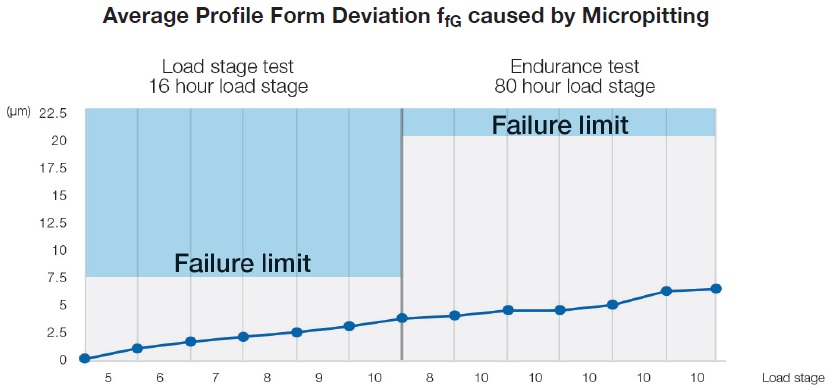

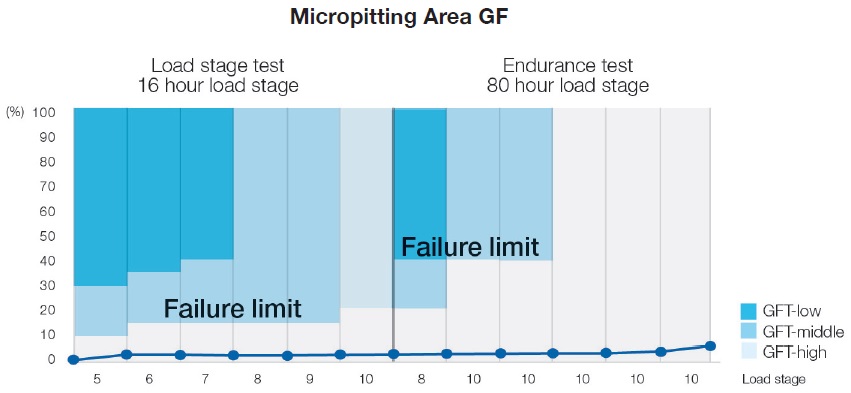

In order to assess Lubrizol IG93MB’s micropitting performance, a variety of group I formulations were evaluated in the FVA-54 micropitting test.

Figures 3 and 4 show two of the test parameters that the FVA-54 test assesses: gear profile deviation and percent micropitting of the gear tooth. Many of the industry and OEM specifications require industrial gear oils to have a FLS 10 high rating, which Lubrizol IG93MB comfortably (and repeatedly) meets because is it below the limits for each test parameter—see the areas highlighted in blue in

Figures 3 and 4.

Figure 3. Profile Deviation from Lubrizol IG93MB FVA-54.

Figure 3. Profile Deviation from Lubrizol IG93MB FVA-54.

Figure 4. Micropitting percentage of Lubrizol IG93MB in FVA-54.

Figure 4. Micropitting percentage of Lubrizol IG93MB in FVA-54.

In conclusion, since gearbox failures occur at the weakest point, it is important to deliver a consistent level of protection to all parts of the system including both gear teeth and bearings. Lubrizol continues to investigate how to consistently deliver the highest level of protection to all critical gearbox components and has developed additive technology which can enable the highest level of gearbox bearing performance. This technology has now been incorporated into our new product, Lubrizol IG93MB. And, through our extensive and rigorous testing protocols, we have demonstrated that Lubrizol IG93MB based formulations provide the right balance of best in class bearing performance, robust gear protection, along with superior micropitting resistance while offering compatibility with ancillary system componentry to ensure complete gearbox protection.