The effect of adhesion on the frictional hysteresis loops at a rough interface

1,2M. Bazrafshan*, 2M.B. de Rooij, 2D.J. Schipper

1 Materials innovation institute (M2i), Elektronicaweg 25, 2628 XG, Delft, Netherlands

2 Laboratory for Surface Technology and Tribology, Department of Engineering Technology, University of Twente, P.O. box 217, 7500AE, Enschede, Netherlands

INTRODUCTION: Frictional hysteresis is the phenomenon in which mechanical contacts are subject to small (compared to contact area) oscillating tangential displacements. In the presence of adhesion at the interface, the contact repulsive force increases leading to a higher static friction force and pre-sliding displacement.

THEORY: In the pre-sliding regime, the stick and slip regions are defined based on the local values of shear stress ( ), and normal pressure (p)1,2:

), and normal pressure (p)1,2:

where  is the static coefficient of friction, and

is the static coefficient of friction, and the change in the slip distances between two consecutive steps of tangential loading in x and y directions.

the change in the slip distances between two consecutive steps of tangential loading in x and y directions.

A BEM model is implemented to find the pressure distribution over the contact domain and solve Eq. 1 for the shear stresses while the tangential force is varying. Adhesion increases the contact area and contact repulsive force .

.

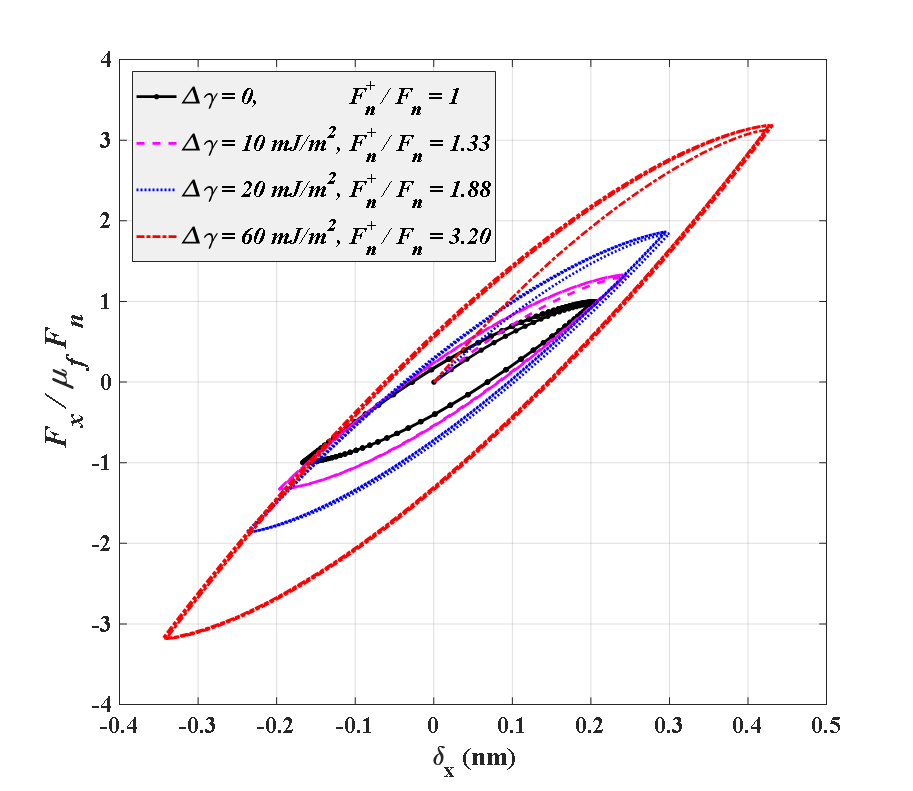

RESULTS: First, the adhesive frictional hysteresis loops at a smooth interface between a glass ball of radius R and a flat silicon wafer is simulated. The normal load,  , is 10mN and R is

, is 10mN and R is . The shear force,

. The shear force, , varies between

, varies between  and

and . The increase in the contact repulsive force due to adhesion results in a higher static friction force and pre-sliding displacement3,4 (Figure 1).

. The increase in the contact repulsive force due to adhesion results in a higher static friction force and pre-sliding displacement3,4 (Figure 1).

Figure 1 – The effect of adhesion on the frictional hysteresis loops of a smooth ball-on-flat configuration for different values of the work of adhesion,

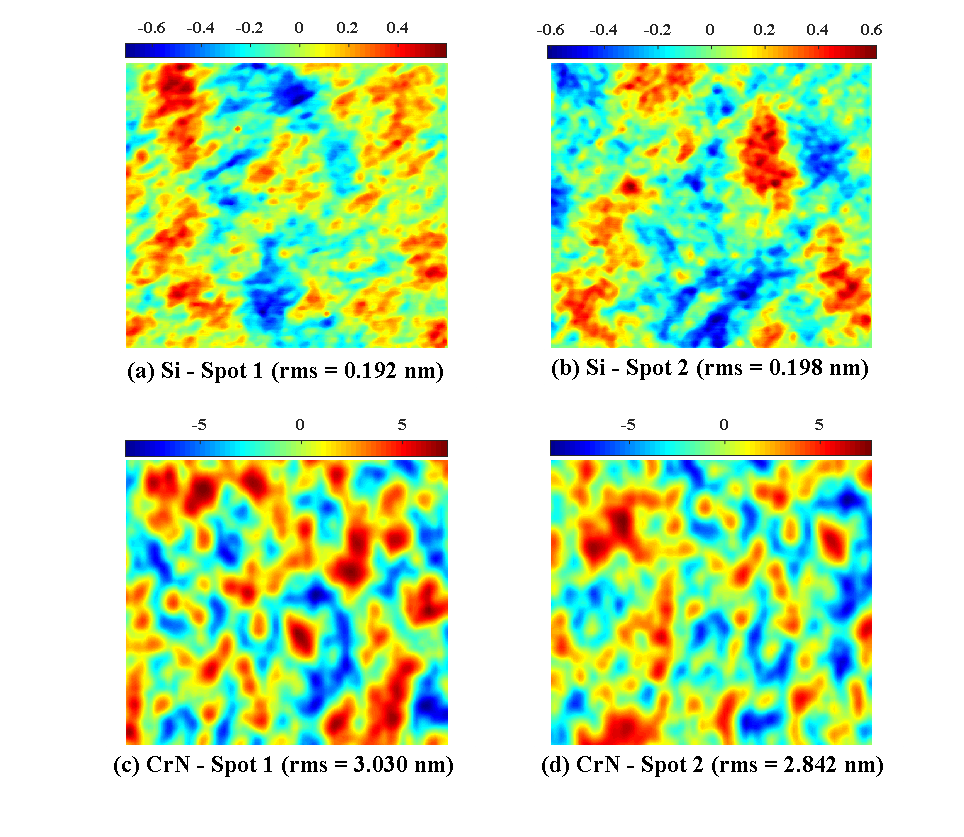

Second, the contact of a smooth glass ball of radius against a rough silicon wafer and a rough CrN coating is considered. The roughness of these two materials has been measured using an AFM in two different spots on each (Figure 2). The work of adhesion is set to

against a rough silicon wafer and a rough CrN coating is considered. The roughness of these two materials has been measured using an AFM in two different spots on each (Figure 2). The work of adhesion is set to  for both contacts.

for both contacts.

Figure 2 – The roughness heights (in nm) of a silicon wafer and a CrN coating at two different spots (scan size is 2 micron)

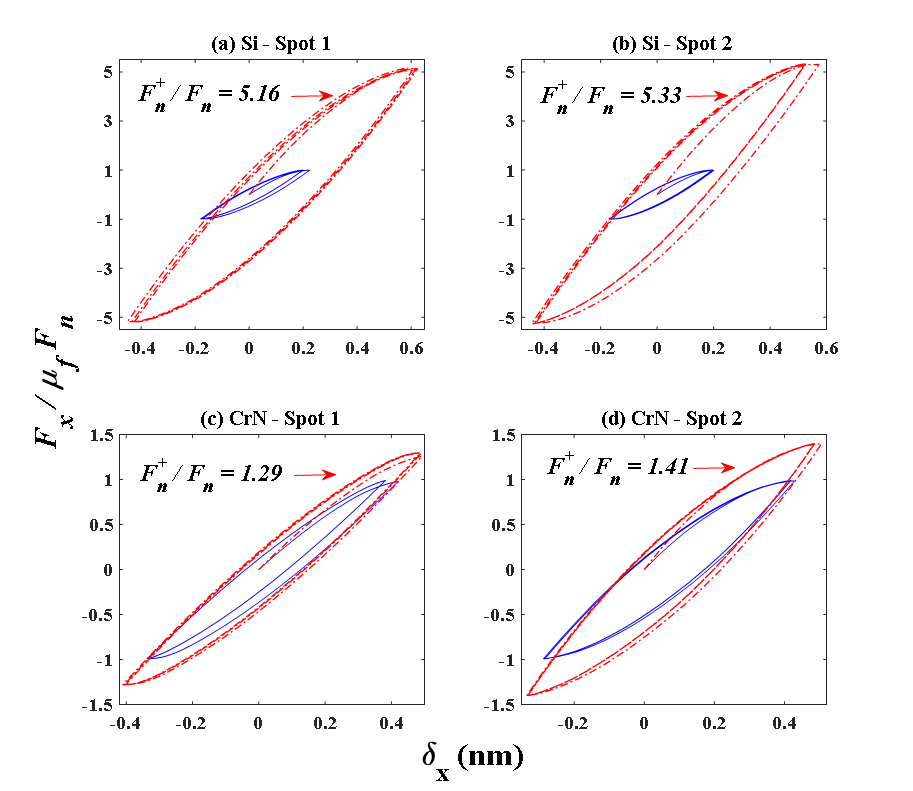

Figure 3 compares the frictional hysteresis loops for adhesive and non-adhesive contacts at the mentioned configuration. It can be observed that the roughness changes the adhesive force (and contact repulsive force) which results in a different hysteresis behavior compared to the non-adhesive contact.

Figure 3 – The effect of adhesion and roughness on the fretting contact at a rough interface (solid lines: non-adhesive contact, dashed lines: adhesive contact);

DISCUSSION: Adhesion enlarges the frictional hysteresis loop at a contact through increasing the contact repulsive force. This enlargement depends on the roughness characteristics of the interface.

REFERENCES: 1. Gallego, J Trib. (2007), 2. Wang, J Trib. (2010), 3. Bazrafshan, Trib. Int. (2017), 4. Bazrafshan, Trib. Int. (2018).